CNC Threading – Know the Every Unknown

Precision part production in modern manufacturing is dominated by CNC threading. You can see it in everything from aerospace to everyday electronics. For this reason, understanding CNC threads totally helps you in making better design, material and tooling choices. In this article, you will uncover insights on the core concept, types, tools and methods used with the automated threading. In this post, you’ll discover what threads are, how they are created, and why computer controlled threading is the best way to go for unbeatable accuracy and efficiency. Prepare to uncover all the vital details you should know.

Table of Contents

ToggleWhat Is Threading in CNC Machining?

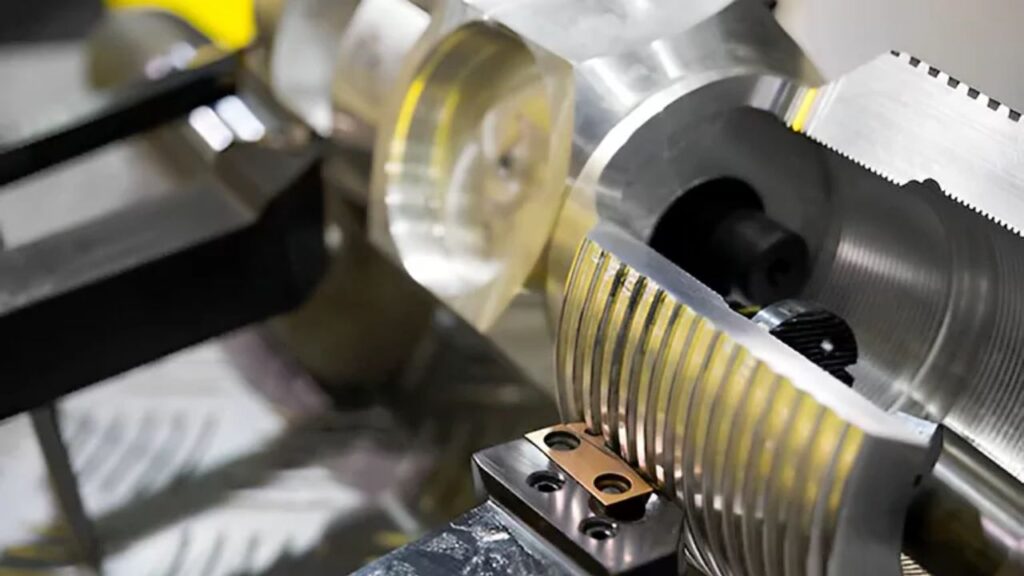

In CNC machining, threading refers to cutting helical grooves into a part’s surface to fit fasteners or help in motion control. You form precise threads using subtractive methods such as tapping, milling, or turning to remove material. Using a threading cutting machine, CNC threading becomes faster, more accurate and repeatable than manual methods across complex designs.

Anatomy of a Thread

Crest

The crest will be at the top of a thread. It is the highest point where two flanks meet. Good form crest makes better strength and fit.

Root

The thread groove has a bottom that the root sits at. To avoid stress concentrations which lead to failure, the root must be smooth.

Flank

The angled surfaces connecting the crest and root are known as flanks. Proper flank angles are used to control thread strength and load distribution.

Pitch

The distance from one thread crest to the next is pitch. To select that right pitch you have to match speed, load, and function.

Helix Angle

The thread spiral is the slope of the helix angle. This angle is adjusted based on the type of connection and the required performance.

Thread Direction

Threads are right (right hand) or left (left hand). Unless a specific application requires left-hand threading, you normally work with right-hand threads.

Single-Start vs. Multi-Start Threads

A single start thread has one continuous spiral and a multi start thread has two or more. For faster linear motion without sacrificing strength, you need to select multi-start.

Metric vs. Imperial Threads

Metric threads use millimeters and imperial threads use inches. To ensure proper assembly you must match the system to your design standards.

Types of Threads in CNC Machining

Classification by Thread Location

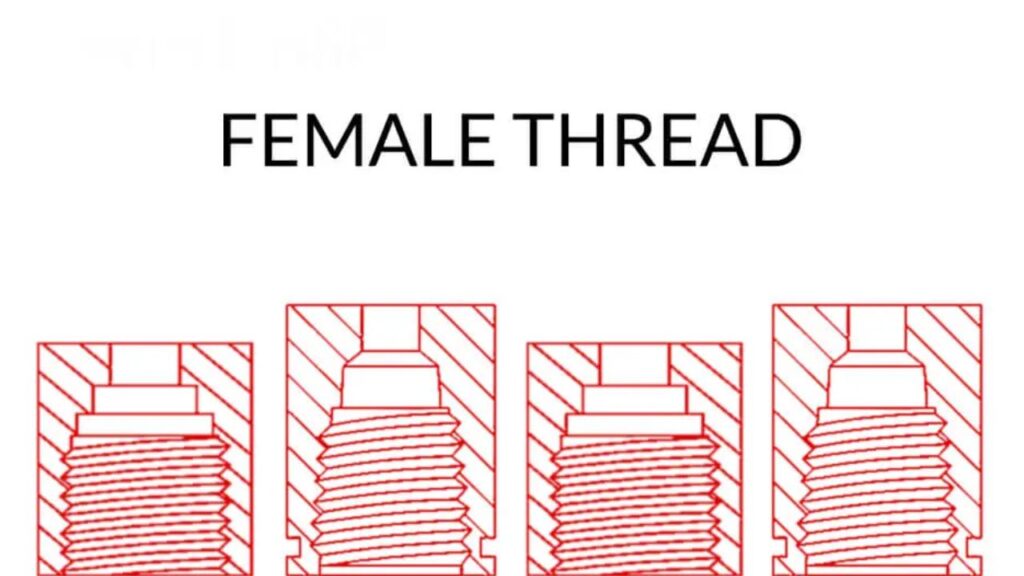

Internal Threads (female)

Oftentimes you are creating internal threads in a hole that you find in nuts, pipe fittings and machined parts. These threads are external and are used to hold external threaded parts securely. Usually, you use machine taps for CNC operations and hand taps for manual work to produce internal threads. Hand taps are flexible for simple setups, and machine taps get you precision and speed. In some cases, machining threads on a lathe is also applied for greater control and accuracy in critical parts. Always drill the correct pilot hole size before tapping, to get thread accuracy and strength.

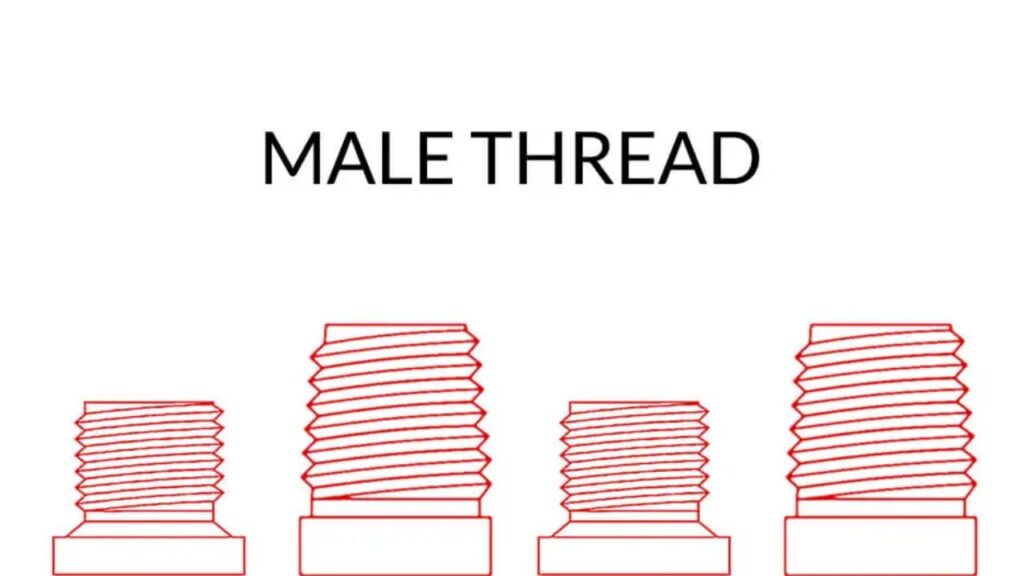

External Threads (male)

On the outside of parts like bolts, screws or shafts, the external threads are formed. Manual operations or CNC lathes are used to efficiently produce parts through dies. Lathe operations give you control over thread pitch, depth and profile, and dies help you quickly add threads to rods. For external machining threads on a lathe, the part should first be chamferred in order to obtain smoother starts and better fit against internal threads.

Classification by Standard/Thread Form

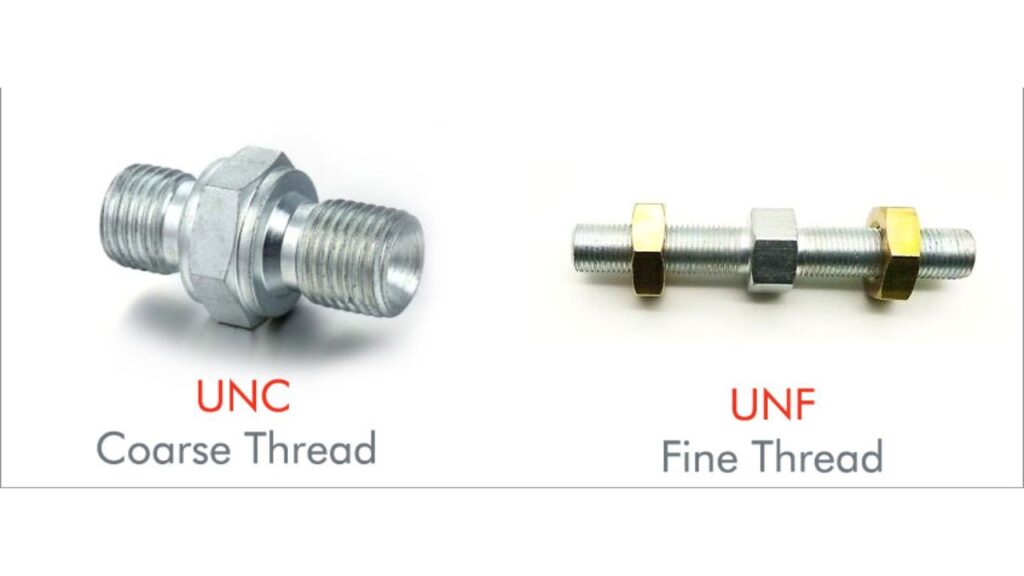

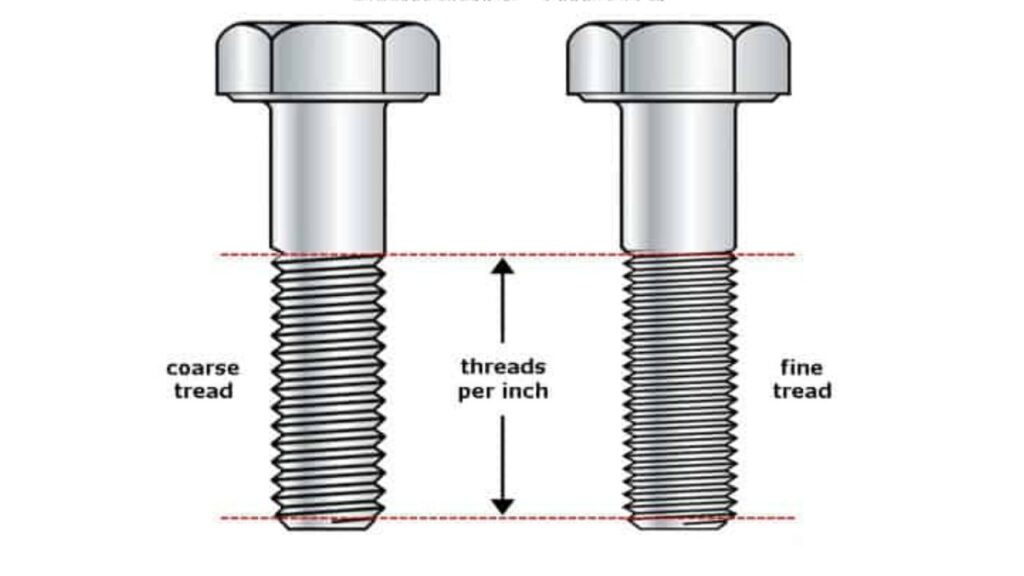

Unified Thread Standard (UNC, UNF)

North American industries are often populated with Unified Coarse (UNC) and Unified Fine (UNF) threads. UNC threads are tolerant to wear, easy to assemble, and are suitable for general construction. UNF threads, with their smaller pitch, provide better strength for shallow assemblies. Typical applications are in automotive and aerospace parts.

Metric Thread (Coarse/Fine)

If you work internationally, the metric threads are largely what you will be dealing with. Coarse metric threads are stronger and easier to assemble; good for general applications. Fine metric threads are better stress distributed and are better suited when precision and vibration resistance are required.

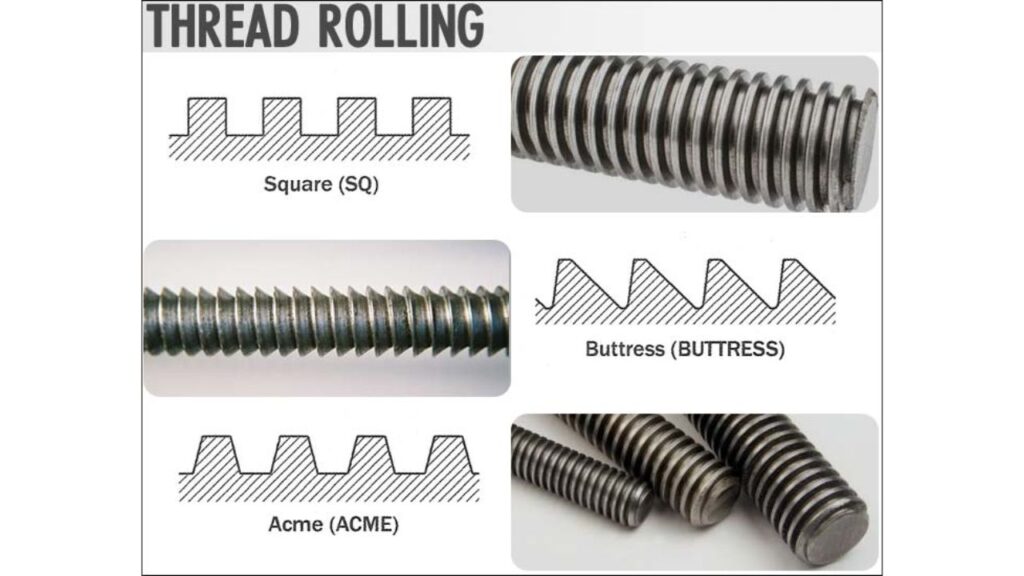

Acme Threads

If you are designning power screws and lead screws, you should choose Acme threads. Wide and strong profiles enable them to deal with heavy loads while minimizing wear, which they do well in machines such as lathes and vises.

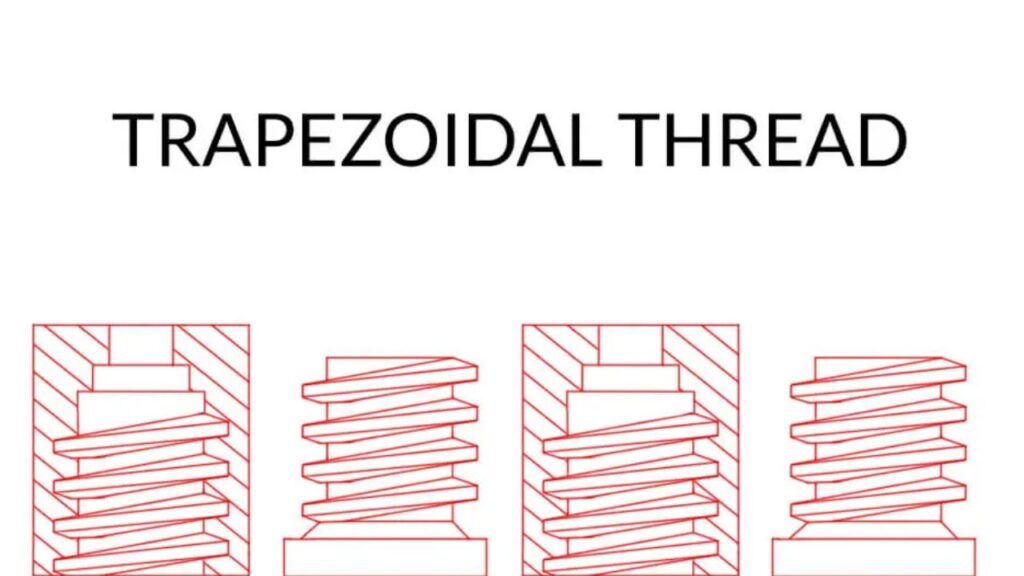

Trapezoidal Threads

Trapezoidal threads are similar to Acme, but with slightly different angle in European designs. They are used in applications requiring strong and smooth movement under load, such as jacks and actuators.

Buttress Threads

Buttress threads are recommended when you need threads capable of handling heavy axial loads on one direction. For applications such as oil field equipment or heavy presses, high force is pushing in one direction, and they’re ideal.

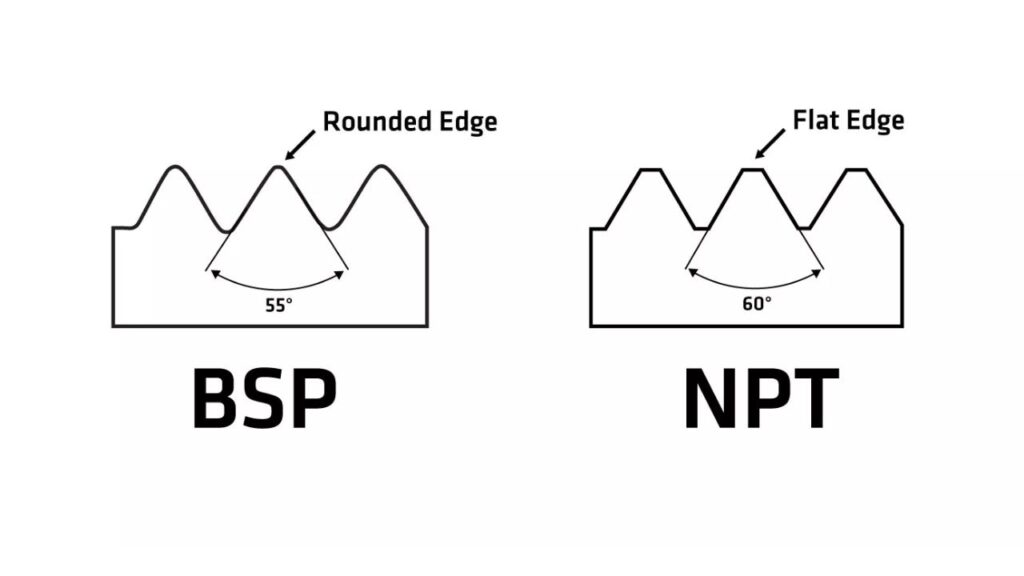

Pipe Threads (NPT, BSP)

If you’re machining pipe threads, you’ll see NPT (National Pipe Taper) or BSP (British Standard Pipe) threads. BSP threads sometimes use a gasket, and NPT threads seal tightly through a taper fit. They are both important for plumbing, hydraulic systems and gas lines.

Square Threads

Square threads give the greatest power transmission efficiency. They are meant to be used in jackscrews and valve stems where you need minimal friction and maximum load capacity. They are strong and harder to machine as a result of their symmetric design.

Classification by Thread Type

Single-start vs Multi-start Threads

Single start threads allow for one single continuous thread to wrap around the part. If you need tight, secure fastening, then they are common. On the other hand, multi start threads actually have 2 or more threads running concurrently. They’re good to use for faster assembly or a smoother motion, such as in a lead screw.

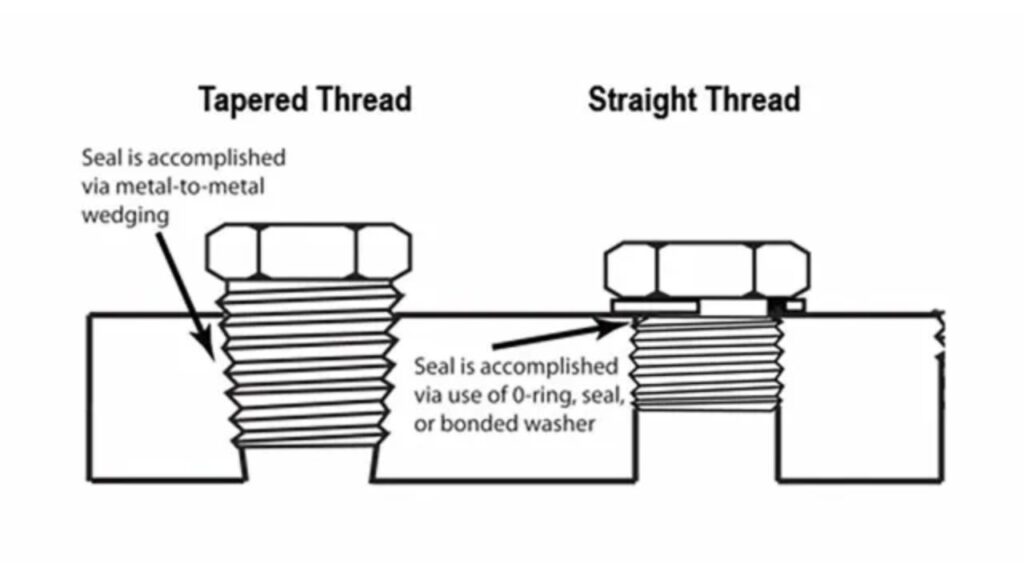

Tapered vs Straight Threads

The threads taper gradually to the end along their length, allowing you to get a tight, leak-proof fit, especially in piping. Straight threads have a constant diameter. If the thread itself is not sealed, you often choose these when sealing is done by an O ring or gasket.

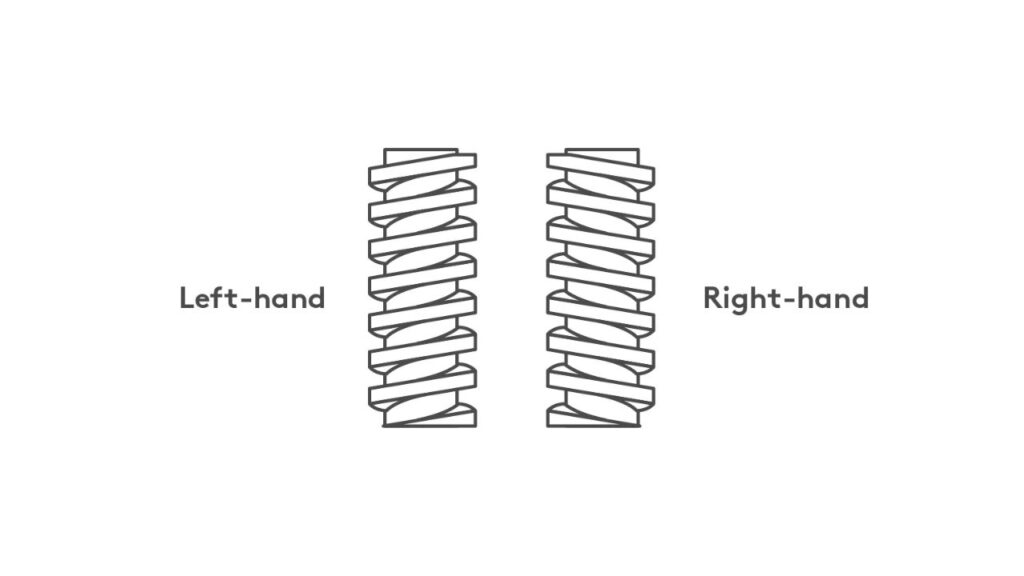

Right-hand vs Left-hand Threads

The standard in most applications are right-hand threads, which you tighten by turning them clockwise and which are turned counterclockwise to tighten. But you may also require left hand threads when motion or force could loosen the right hand thread. Ensure always to match thread direction to your assembly needs for safety and performance.

Common CNC Threading Methods

Tapping

Internal threads are commonly created through tapping. It works on the principle of putting a hole for pre-drilled, then using a tap to make threading cuts directly into the hole. Tapping can be done manually or by threading cutting machine for accuracy. For small jobs, manual tapping works; machine tapping, though, provides higher speed and accuracy. To know which you need, you have to have the right type of tap: spiral point, spiral flute, or forming tap, based on your material and hole depth. Taps can easily break in tough materials when proper feed rate and lubrication isn’t used.

Thread Milling

With thread milling, you have a flexible and efficient way of cutting internal and external threads. If you work with large diameter holes or exotic materials like titanium or Inconel, it is ideal. You can make use of a single thread mill across multiple sizes instead of one tool size per thread, thus saving you costs. And thread milling results in burr-free finishes and low tool pressure in thin walled parts.

Single-Point Thread Turning

By cutting threads on a lathe with a single point tool, single point thread turning lets you only do that. It is mostly used for external threads but can be applied on internal threads too. The G76 threading cycle makes this process faster and more precise on CNC lathes. This is a great method to use if you need custom or non standard threads. You need to pick the correct insert geometry to match the thread form and material. Using the G76 threading cycle also ensures accurate depth control and consistent thread quality. Single point turning offers you high precision but requires careful setup and programming.

Thread Grinding

Thread grinding is the method of choice when you need ultra precise threads on hardened materials. Depending on your production volume and thread profile, you grind either with a single rib or multi rib grinding wheel. Thread grinding is used for making thread gauges, lead screws and worm shafts, where accuracy is important.

Thread Rolling

used to push the material into shape. There are no chips to manage because you don’t remove material. In addition, you get stronger threads and a better surface finish. When you need high strength threads without post processing, it is a good choice.

How to Cut Threads Manually (For Understanding Basics)

Cutting Internal Threads

You’ll need a hand or machine tap, a twist drill, a countersink and a tap wrench. First, mark the spot carefully. Drill a hole a bit smaller than your tap size. Finish the hole with a countersink to help guide the tap. Insert the tap straight and slowly turn it, backing off after every few turns to clear chips. Don’t try to force the tap to avoid breakage. Cutting fluid must be used always for smoother threads and longer tool life.

Cutting External Threads

Get a round die, die stock, vise and cutting fluid. Begin by filing the rod’s end flat and then chamerring the tip. Set the rod up in a vise and secure it tightly. Put the die on the chamfered end and roll it evenly with pressure. Reduce friction and prevent galling with use of cutting fluid. Every few turns, you should back off to break chips. When cutting threads, you always want to have steady pressure to prevent misalignment and to ensure clean, consistent threads.

Thread Machining Best Practices

- Chamfer the ends of rods or holes before threading. This keeps the tool from getting damaged and prevents messy cuts. Using threaded inserts can also protect the base material during initial threading.

- Use cutting fluid consistently. It also helps in reducing tool wear, surface finish and heat dissipation.

- Minimize tool deflection and vibration. This also improves thread accuracy and extends tool life, especially when installing threaded inserts.

- Do not have excessive thread depth unless strictly necessary. Too deep will weaken the thread and also increase the risk of errors.

- If needed, eliminate thread reliefs or undercuts. It also makes it easier to assemble and lessens the stress on the threads.

- Ensure that the thread profile matches with the material type. There are different thread profiles necessary for certain materials to have strength and performance.

Threading Tools and Toolpaths in CNC

- Types of Thread Cutting Tools: Taps will cut internal threads, thread mills will be used for versatile threading, and single point cutters will be used for external threads in CNC threading. For added versatility or repairing damaged threads, a helicoil thread insert can also be used. Select tools which are suitable for the task.

- Toolpath Strategies: For precision for thread milling, helical toolpaths are used. Then, seek for continuous or step over strategies for a smooth result. This allows you to improve performance.

- CAM Programming Tips: It is important to select the right CAM tool when using it. Give accuracy by setting the correct pitch, lead, and depth of cut.

- Feed Rates, Depth of Cut: The feed rates are changed so that tools don’t wear out, and so that threads are of consistent small sizes. A correction in depth of cut per pass is assured by ensuring clean, precise threading.

- Coolant and Chip Evacuation: Coolant should always be used to reduce heat and increase the life of the tool. The chip evacuation is effective and prevents clogging and results in smooth threading and a high quality result.

Threading Parameters That Matter

- Thread pitch and lead selection: Choose the correct pitch and lead for your application. It also affects thread strength and performance, especially when performing helicoil thread repair on well worn components.

- Depth of cut per pass: Set the depth to keep the tool from getting worn out and to help form the thread smoothly. This is critical during helicoil thread repair to restore damaged threads accurately.

- Spindle speed recommendations: Optimize cutting efficiency and surface finish depending on the type of material and tool selected, selecting spindle speed.

- Toolpath and cycle time optimization: Maintain thread quality by fine tuning tool path and cycle times to decrease machining time.

- Thread tolerances (class fit): You try to find an appropriate thread class which will fit that and will perform as you expect.

- Tool material and coating: Carbide, HSS or TiN coated tools should be used for efficient threading, depending on material hardness and the required tool life.

Advantages of CNC Threading In Threading Machining

- High precision and repeatability: Computer control threading guarantees that every single thread is cut perfectly every time. You can have the certainty of consistent quality in every part for your product.

- Consistency across high-volume production: automated threading allows you to get uniform results in large batches. This is important for industries that need identical components in bulk.

- More rapid cycle times compared to manual threading: CNC machines provide better speed than manual threading. Increasing overall efficiency will include seeing shorter lead times.

- Capable of complex and custom threads: Computerized threading can cope with intricate designs. They can create customized solutions whether it’s tapered, multi start or non standard threads.

- Reduced human error and material waste: Automation minimizes mistakes. This reduces defects and waste, and saves you time and resources.

- Lower tool wear and longer tool life: It was optimized to reduce wear on CNC machines. This will save you on replacement costs as you will have longer lasting tools.

- Compatibility with a wide range of materials: It works with metals, plastics, and composites as well. It can be used for various applications with no limitation in the material.

- Multi-axis and hybrid threading capabilities: You can perform more advance threading machining tasks in a single setup with multi axis and hybrid threading. This expands your machining possibilities.

Challenges and Limitations

- Threading Thin-Walled Parts: Nevertheless, when working thin walled components, the threading process causes deformation. This is done by ensuring that there are the correct supports and tooling to reduce pressure on sensitive surfaces.

- Tool Breakage in Tough Materials: Harder materials can generate rapid tool wear or breakage. After that, the tool material should be picked as carbide and feed rates have to be optimized to avoid damaging the tools.

- Chip Control and Evacuation: It is important to manage chips for smooth threading. Too efficient clearance allows chips to concentrate in the tool or cause thread defects. It is the correct coolant and the correct chip removal system.

- Internal Threading in Deep Holes: When the hole is deep, it is a challenge to access the area. Specialized tools and precise control are required to get clean and accurate threads.

- High-Speed Threading: When threading is done at high speeds, synchronization is required. With that you have to keep feed rates and spindle speed in balance to avoid inaccuracy or tool failure.

Materials Used in CNC Threading

- Metals: Common metals used in Computer controlled threading are aluminum, steel, stainless steel, titanium and brass. Different cutting parameters and tools are needed for each metal. Titanium and stainless steel are tougher and require specialized tools and slower speeds, aluminum is soft and easier to cut.

- Plastics: ABS, PEEK, and Nylon are also usually threaded materials. Because plastics are softer than metals, however, they can be prone to heat. With the right tool and speed you’ll be able to prevent melting and get plenty of smooth threads.

- Composites: Like carbon fiber, Computerized threading in composites requires special attention. To prevent fiber pull out, you need to use carbide tools and adjust your cutting speeds.

- Material Choice: Your choice of material directly impacts tool selection, cutting speeds, and other process parameters. In more precise work, harder materials may require harder tools and slower cutting speeds.

Industries That Rely on CNC Threading

- Aerospace: Threaded components are critical parts of the fuselage, landing gear and turbine assemblies, and helicoil insert applications, accompanied by safety and reliability in flight.

- Automotive: Computer Numerical Control threading is based on precision and strength and is used in manufacturing engine blocks, transmission systems and brake components, and sometimes reinforced with a helicoil insert for added durability.

- Oil & Gas: Pressure fittings, valve housings, threaded drill pipes are critical to ensure system integrity under high pressure in this sector.

- Medical Device Manufacturing: Computer controlled Threading is also used in surgical implants, orthopedic screws, and dental hardware, due to the fact that it is necessary for fit and functionality for patient safety.

- Heavy Machinery & Construction: Hydraulic components and gear assemblies have to be threaded for the proper operation of large machinery and construction equipment.

- Electronics and Consumer Goods: For example, CNC threading produces small, but important, things like enclosure fasteners and mounting hardware that keep devices together.

Conclusion

Overall, CNC threading plays a key role in modern manufacturing through its capability of providing precision, efficiency and the repeatability across a wide range of industries. If you work with metals, plastics or composites, knowing the different types of threading, tools and methods of computer controlled threading, as well as CNC threads, will help you produce superior quality and performance. Despite these advantages, complications such as tool wear, chip control and threading thin walled parts, must be carefully managed. If mastered, these aspects will yield high quality threaded components in compliance with industry standards, facilitating flawless and reliable performance of your projects.