Deep Hole Drilling – Know the Every Unknown

Deep hole drilling is prevalent in numerous precision-intensive industries such as aerospace and medical. Its high accuracy, depth control and repeatability makes it preferable in critical components. That is why, it is necessary to have an idea how it works and what role it plays in the contemporary world. In this article, you will have an insight into all the aspects of drilling that can be imagined. You will be acquainted with its methods, instruments, advantages, prevalence, and standards. This guide provides all the information you need whether you are starting or are looking to hone your skills for fast and accurate drilling using deep hole drilling machines.

Table of Contents

ToggleConcept of Deep Hole Drilling

Deep hole drilling is the process of making holes with a diameter to depth ratio of 10:1 or more. You’ll need this method when accuracy, detail, and the ability to replicate matter the most. It is currently applied extensively in aerospace, automotive, oil and gas, medical and defense sectors. You will be dealing with such materials as metals, stainless steel and super alloys most of the time. These materials require special equipment and methods. For those applications which require high level of precision and repeatability especially in critical and thin-walled components, deep hole drills offer the ideal solution.

Why Deep Hole Drilling Matters in Modern Industries?

Automotive Applications

Sometimes, this process is applied when working with crankshafts, fuel injectors, and hydraulic cylinders to ensure high precision. These adaptations are drilled using deep hole boring in a deep and well-aligned manner, which subsequently helps in improving the performance and durability of the engines.

Defense and Aerospace

This specialized drilling process is employed to fabricate components such as turbine blades and landing gears in aerospace industry. Each of these components requires very high accuracy and reproduce ability. In defense, gundrill techniques are used for manufacturing gun barrels, which need to be straight and of tight tolerances.

Medical Device Manufacturing

In the medical sector, there are tight tolerance levels that need to be met. Hole drilling is used to drill precise passages in surgical instruments and other implantable gadgets. It is especially beneficial when producing items such as catheters or equipment for diagnosis where no room is left for errors.

Gas and Oil Exploration

When it comes to oil extraction, the best approach is deep hole drilling and deep drilling, since you will be creating boreholes that must withstand high pressure and tough materials. That is why the industry employs customized tooling and drill shafts capable of handling the harsh conditions of drilling.

Main Perks of Deep Hole Drilling

Improved Surface Finish

Deep hole methods produce a smoother internal finish than traditional twist drilling. Using deep hole drills along with high-pressure coolants helps fight friction and remove chips quickly. This produces clean bores, fewer surface defects, and less post-processing. That’s ideal where surface quality really matters.

Precision and Accuracy

With an automated system, this precision-boring method provides exceptional precision. When making high tolerance parts you use strict ratios of depth to diameter. In aerospace and medical industries, even small errors can be life changing and this accuracy is essential. Having the right setup gives you repeatable results and consistent quality each time.

Enhanced Tool Life

The tools which are used for this type of drilling, including your hole machine, are built to last. Optimized cutting and coolant flow means you experience less tool wear. This increases the tool’s life span, and thus lowers cost of replacing the tools. This, in turn, saves you downtime and your production line is up and running.

Reduced Cycle Time

Faster operations without sacrificing precision are made possible by deep hole drilling. Better chip removal and steady coolant flow mean you drill more efficiently. That means you save on machining time and increase throughput. It also allows you to take an edge in time sensitive production.

Consistent Quality Output

Precise alignment and real time monitoring of hole quality is ensured. Every part must meet very specific tolerances in order to mitigate the chance of defects. You create a reliable workflow that kept consistency from start to end. This means less errors, and more customer confidence.

Common Techniques in Deep Hole Drilling

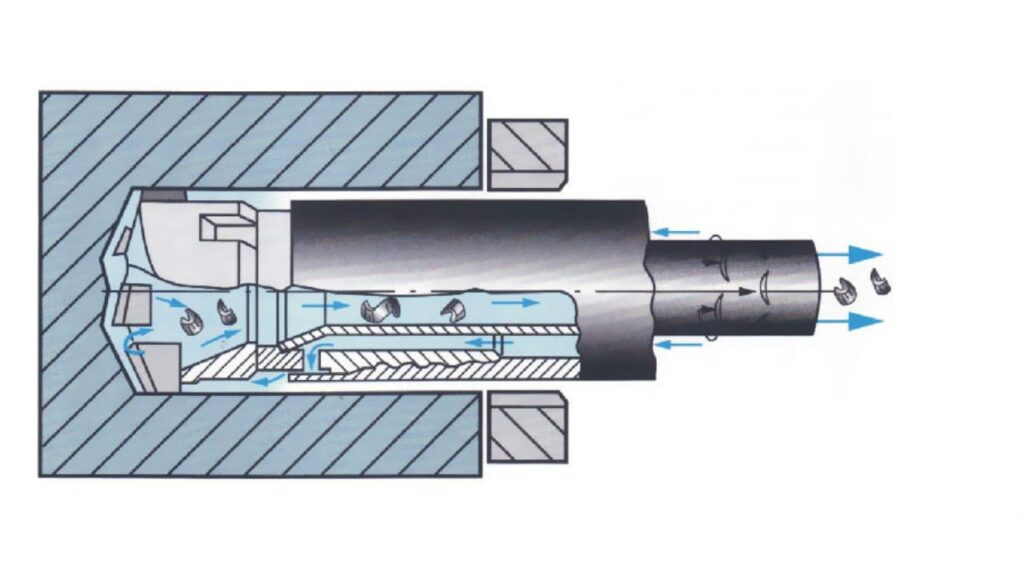

Gun Drilling

Gun drill is a special process for drilling very straight, deep, and very precise holes. It is a long, straight drill bit with built in cooling holes for coolant that continually lubricates the bit. This keeps the chips out of the hole and thus protects against damage. This is a technique that can be used to drill in different materials, including metals and alloys. It guarantees high accuracy and is applied in aerospace, automotive, and medical industries.

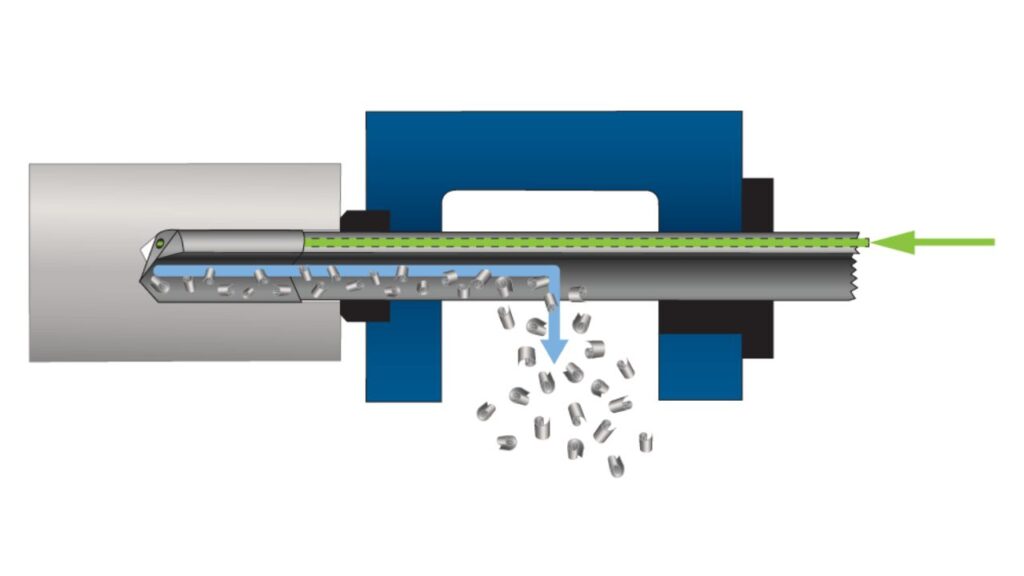

BTA Drilling

For larger diameter, deep holes, BTA (Boring and Trepanning Association) drilling suits the purpose. It employs a deep hole drilling machine with a cutting head that cuts away material and an internal coolant system that flushes chips at the same time. Drilling deep large holes with minimum distortion of BTA is excellent. It’s the popular choice where high-volume production is required such as aerospace and oil exploration. The system is the most efficient system if the system can handle the hard materials and it is also efficient.

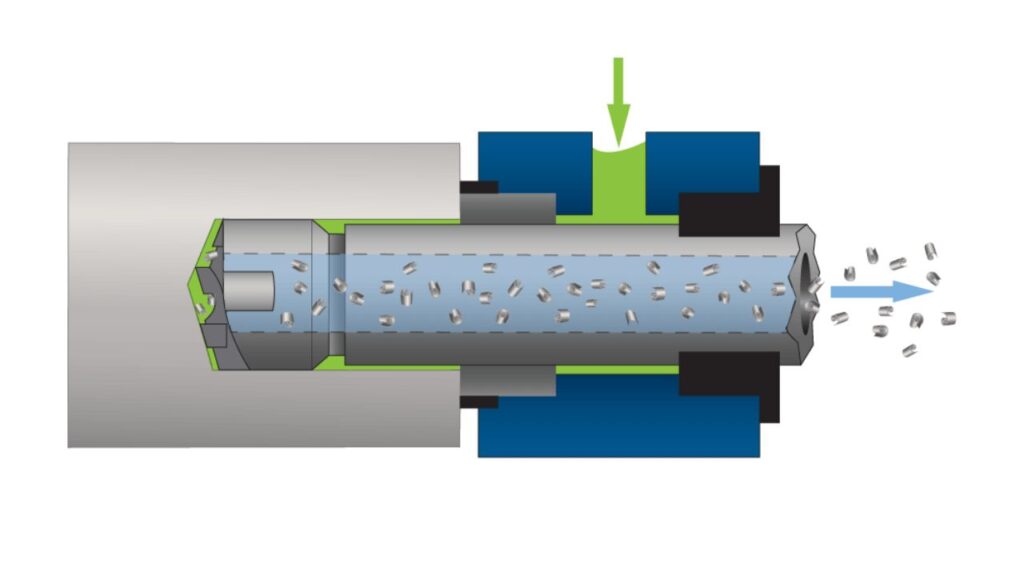

Ejector Drilling

Ejector drilling is a chip removal and cooling double tube system. The drill bit is carried on the inner tube, and the outer tube gives the chips the boot. This is a great technique to use when boring at an oblique angle into deep holes or when there are discontinuous parts. It is very effective in keeping the surfaces clean and smooth and prevents the overheating while drilling.

Comparing Techniques

Strengths of each drilling technique. Small, precise holes are best drilled using Gun drilling, while BTA is best suited to large diameters. Oblique angles are an area where ejector drilling outshines. It depends on the specific requirements of the project to choose the right one.

Considerations for Tools and Equipment in Deep Hole Drilling

Choosing the Right Drill Bit

Accuracy in this specialized boring process depends highly upon choosing the right drill bit. Second, you’ll have to select a bit that fits your material and the depth that you want to cut. A full-face crown drill bit is popular because they have a longer life span and consistent results. They distribute the load evenly, therefore reducing wear and tear during the drilling process and as well extending the life of the tool. You can get max length of the hole 1m the hole:10mm and the smallest hole 0.05mm: with length 1mm.

The Role of Coolants

Deep hole drilling relies heavily on the high-pressure coolant systems of a deep hole drilling machine. Coolants cool and lubricate the drill bit to keep the temperature at the right level. This prevents overheating, which will damage tool and material. Also, coolants aid in chip evacuation, preventing chip buildup, which could interfere with the hole finish.

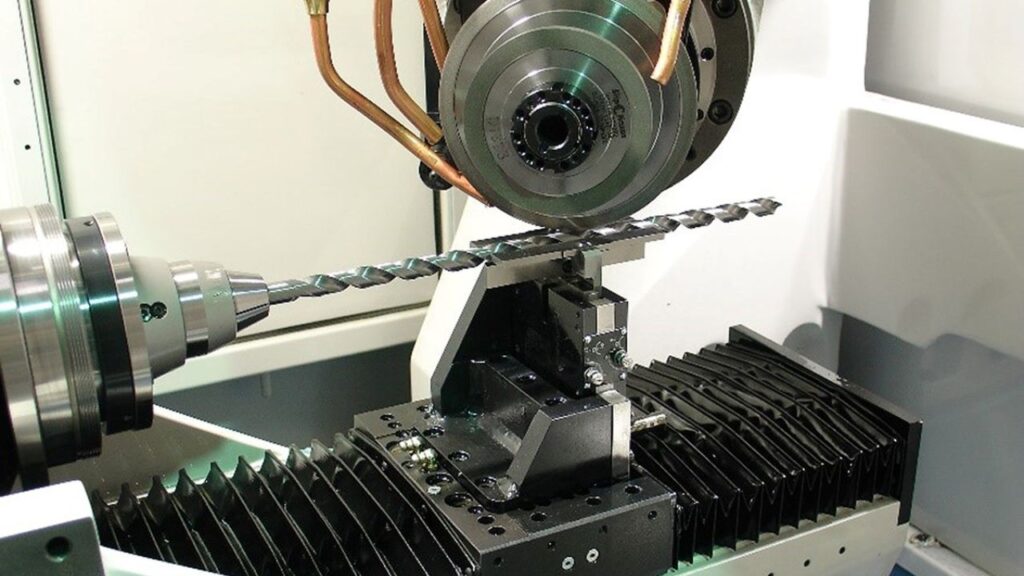

Modern Drilling Equipment

Modern CNC systems have revolutionized this accuracy-focused drilling method. These hole drilling machine systems are controlled with computers and provide unparalleled precision and efficiency. You can set exact drilling parameters, and you get consistent results. With advanced CNC systems, you can monitor and adjust on the fly to optimize the drilling for improved performance and provide higher accuracy across a variety of applications.

Challenges in Deep Hole Drilling and How to Overcome Them

Misalignment and Drill Bit Incompatibility

The most common causes for deep hole drilling inaccuracies are misalignment and misuse of incompatible drill bits. Crooked holes and poor quality can occur when the drill bit or hole machine is not properly aligned with the workpiece. The solution is simple: Before ever starting the process, you should always check your alignment. Additionally, you should choose the right drill bit that will suit your project’s needs and be appropriate for the material and the depth you want to drill.

Workpiece Stability and Deflection

Deflection of hole can occur during deep hole boring due to improper work piece positioning and affect accuracy of the hole. When there are no good chucking points on the workpiece, it can move when drilling and wind up offset by that amount. This can be avoided by using special fixturing or custom fixtures that hold the workpiece in place for the entire drilling process. It will help in minimizing vibrations and giving a consistent result.

Material-Specific Challenges

Different materials pose unique challenges. Drilling into soft materials can deform the material, while drilling into hard materials will cause excessive tool wear. For handling these, choose deep hole drills speciality made for particular materials. Slow down the feed rates for softer materials to prevent deformation. If the material is harder, feed rates can be reduced and drill bits can be coated with wear resistant materials to prolong tool life.

Deep Hole Drilling Applications and Case Studies

Aerospace

Precision parts like turbine blades and landing gear wouldn’t be possible without deep hole drilling. The accuracy requirements for the performance of these components are extreme. A case study in aerospace describes how gun drilling techniques ensure defect free, deep holes for fuel systems. This helps to ensure that parts work as intended without failure when under pressure.

Automotive

This specialized deep drilling process is used for fuel injectors and hydraulic cylinders holes in automotive manufacturing. They are small holes, but they are very important for controlling the fuel flow and fluid pressure. For example, precision deep-boring techniques are used to provide precise drilling of injector holes in order to increase engine performance and efficiency.

Medical

Precision is a must for medical devices and they rely on deep hole drilling. Imperatives are high tolerance requirements for implants and surgical tools for patient safety. Using a hole drilling machine ensures drilling holes for catheters or diagnostic instruments with accuracy. In order for these tools to work, they must fit within strict dimensional limits, which requires deep, clean holes.

Oil & Gas

In the oil and gas industry, high-depth drilling operations are essential for creating long-lasting boreholes. Oil extraction and petroleum logging instruments use custom drill shaft tools. Specialized tools that can operate in demanding environments where pressures and materials are harsh, these specialize tools will go through extreme pressures and hostile materials to ensure that they work efficiently.

Best Practices for Effective Deep Hole Drilling

Pre-Drilling Preparation

When you start, make sure to begin with the right materials, tools, and cooling systems. It is very important to chose the right drill bit depending on the material type. Make sure you have the right coolant system so that it doesn’t overheat and cut smoothly. Fixturing and alignment is crucial—slight misalignments can lead to inaccuracies. Check the workpiece setup to avoid errors that will cause the depth to diameter ratio.

Monitoring and Maintaining Consistency

Precision must be maintained throughout the drilling process and automated systems are necessary to do this. The systems help to adjust the parameters in real time to maintain consistent drilling quality. You have to watch the process and adjust. Continuously monitoring the drilling machine will help you make sure that the machine is working at the optimum level so that there are no variations in the hole dimensions or surface finish that can cause problems with your work.

Post-Drilling Inspection and Quality Control

Check the hole accuracy and surface quality after drilling. Check the depth and diameter with specialized inspection tools, such as bore gauges or micrometers. Use quality control measures to check that the hole has the required tolerances. Post drilling inspection ensures that your work is clean and defect free and meets the highest standards.

Innovations in Deep Hole Drilling Technology

Advancements in Equipment

This advanced drilling technique is evolving thanks to new technologies in CNC deep hole drilling machines and automation. It makes speed and precision better, for more consistent results. Automation also helps to mitigate human error and make use of high volume production. These innovations allow you to attain tighter tolerances and a faster turnaround time.

Innovative Materials and Tools

The innovation in this specialized drilling process is coming from new drill bits, coatings and coolants. They aid you in working with tougher materials and increase tool life. Advance coatings reduce wear and heat buildup, for example. Better coolants keep temperatures at bay, allowing both speed and surface finish to improve. They are pushing the boundaries and enabling better results and more versatile drilling form.

Conclusion

In modern manufacturing, deep hole drilling is an important task, especially, when the accuracy, precision and quality of operations are of a great importance. Using an advanced hole drilling machine, it can deliver superior surface finishes, prolong tool life and provide repeatable results, making it indispensable. With further advancement in technology, you will see more innovations of equipment, materials, and techniques. With these developments, this high-precision drilling process will continue to increase its speed, efficiency, and versatility, and will remain an important tool in precision manufacturing. By understanding these advancements you will remain one step ahead in optimizing your drilling process.