Bar Feeding – A Comprehensive Guide

Bar feeding is an important part of machining, delivering continuous and efficient material supply. Knowing how to work with CNC, its components, and types will enable you to optimize CNC operations. This guide aims at explaining these systems, their advantages, set up, and troubleshooting. You’ll find out how to pick, install and maintain a bar feeder to work best. This guide offers practical knowledge to improve your machining process regardless if you are new to CNC operations or looking for more advanced information. Now let’s have a look at everything you have to know about these systems in CNC machining.

Table of Contents

ToggleUnderstanding Bar Feeding in CNC Machining

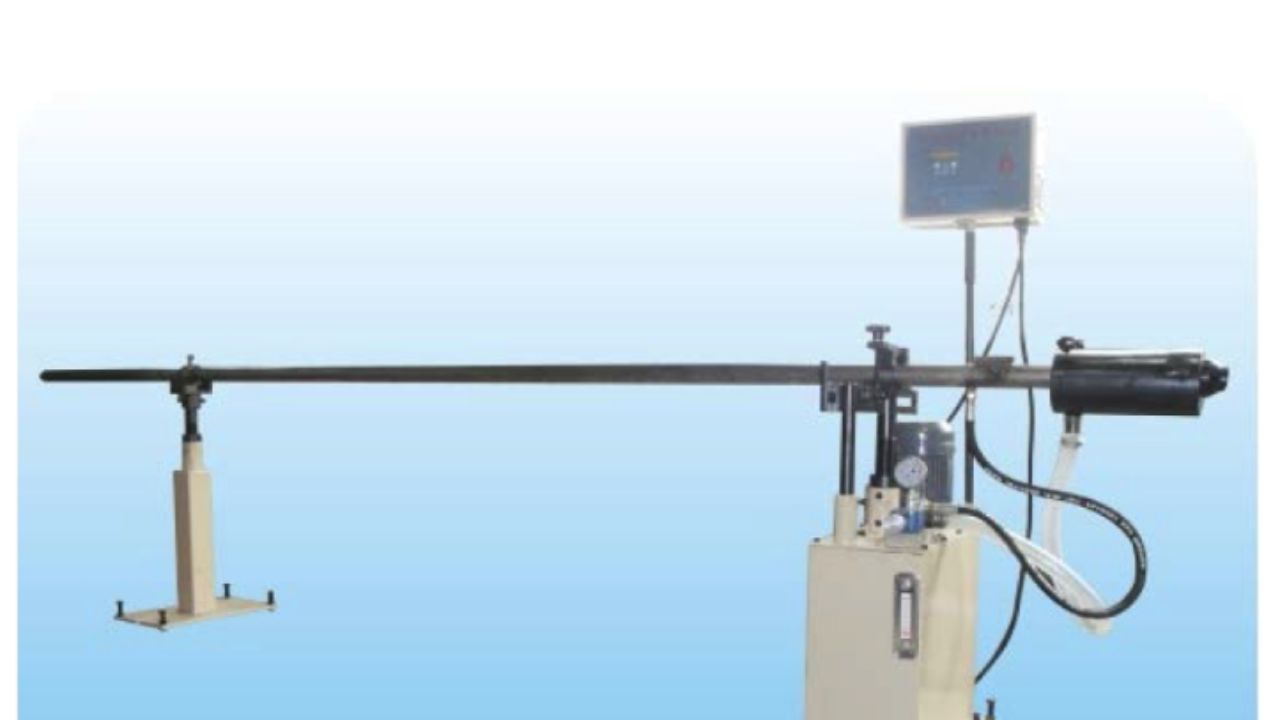

A bar feeder is a device that feeds an automatic supply of metal bars to CNC lathes and Swiss type machines, thereby bypassing manual loading. It feeds or pushes bars into the spindle for continuous machining. Smooth operation requires you to place confidence in some components, such as the magazine, guide channels, and pusher mechanism. Just like data precision in bar chart feeder cattle systems, proper alignment of bars contribute to higher accuracy and efficiency.

Types of Bar Feeders

| Sr. No. | Type of Bar Feeder | Working Principle | Key Advantages | Typical Applications |

| 1 | Magazine | Mechanical push/grip from a storage magazine. | High capacity, continuous feeding. | High-volume, identical parts. |

| 2 | Hydrodynamic | Fluid support reduces friction/vibration. | Smooth operation, high precision. | Precision machining, long/slender parts. |

| 3 | Hydro-Hybrid | Fluid + mechanical for balanced control. | Precision and speed combined. | Variable sizes, demanding conditions. |

| 4 | Pneumatic | Air pressure for bar movement. | Simple, cost-effective, light bars. | Small diameters, light machining. |

| 5 | Servo-Driven | Electronic control for precise movement. | High speed, automation, accuracy. | High-speed, complex parts. |

Magazine Bar Feeders

In a magazine bar feeder, bars from a storage magazine are fed into machining using a mechanical push or grip mechanism, much like a feed mill bar and grill supplies ingredients steadily for continuous operation. It provides a steady supply of material, making it a good choice for repeated use. This feeder has high capacity to minimise downtime and maximise efficiency. It can be relied on for high volume production of identical parts with minimal manual involvement. Suitable for automotive and aerospace manufacturing applications where consistency and speed are crucial.

Hydrodynamic Bar Feeders

Fluid is used to support the bar by hydrodynamic feeders, such as bar ale chicken feed and C bar D feed, which eventually reduces friction and vibration. It also makes it easier and more precise in machining. A hydrodynamic feeder is an ideal choice if your process involves long or slender bars. It does not allow bending or instability, and thus is best for fine machining, such as medical or aerospace component making.

Hydrodynamic Hybrid Bar Feeders

It combines the fluid support with mechanical components to balance speed and precision. The hybrid system improves control by adapting to different bar sizes and machining conditions. This is a great option if you need accuracy and efficiency in your operation. This is particularly useful for industries in which machining conditions change, for instance, in custom metal fabrication, or even when coordinating events at places like The Feed Store Grill and Bar.

Pneumatic Bar Feeders

Air pressure is used to feed bars into position using pneumatic bar feeders. Simple, lightweight and economical, they are well suited to small diameter bars and support operations like three bars feed & tack. If you are looking for a light machining solution on a budget, pneumatic bar feeders fit right in. While this does not offer the same level of control as servo operated feeders, it is best for less demanding requirements.

Servo-Driven Bar Feeders

Electronic controls in Haas bar feeders are used to move the bar precisely. High speed, automation, and synchronization with CNC machines are the advantages they offer. A servo-driven feeder is the best choice if your operation demands precision and efficiency. Industries, such as electronics and medical device manufacturing, that rely on complex, high-speed machining use these feeders.

Advantages of Using Bar Feeders in CNC Machining

- Increased Efficiency: A bar feeder reduces manual loading and downtime. Continuous supply of material ensures that your CNC machine runs without frequent stops. It enhances workflow and general machining efficiency.

- Higher Production Rates: Machining cycle is uninterrupted with bar feeding. This means that production speed increases, so that you can cope with rising demands without compromising on quality.

- Reduced Waste: Bar feeders reduce scrap by getting as much material as possible from each piece of steel. It provides precise cuts and less of the rejected parts so you save on costs and manage your resources better.

- Enhanced Precision & Stability: A bar feeder makes machining more accurate by minimizing vibration and deflection. Consistent results also means that errors are reduced, and high quality standards are maintained.

- Cost Reduction: You will reduce labor and material costs over time. By removing the need for manual intervention and minimizing the operator’s time spent working on the machine, automated bar feeding increases machine output while decreasing the number of operators needed.

- Operator Safety: This is where a bar feeder comes in because you are reducing direct handling of metal bars. It reduces workplace injuries and makes it a safer place for CNC machine operators.

Key Factors to Consider When Choosing a Bar Feeder

- Machine Compatibility: Check if the bar feeder is suitable for your CNC lathe. Make sure spindle bore size, interface compatibility, and software integration is all fine.

- Bar Diameter Range: If you are using bar sizes, make sure the feeder is made to support that bar size. This is not something new, you can easily work with different materials and you don’t have to change it very often.

- Loading Capacity & Automation Level: You can select manual or automatic loading. Automatic feeders are used in high volume production, while manual feeders can be used in low batch machining.

- Material Type & Surface Finish: Consider how you handle, steel, aluminum, brass etc. and different feeders exist to handle delicate materials without scratching and deforming them.

- Floor Space & Installation Requirements: Evaluate available workspace. Compact feeders are available for small scale systems, whilst large scale systems require dedicated area for stability and accessibility.

Bar Feeder Setup and Calibration

Installation Process

The correct installation of a bar feeder is vital for a smooth CNC machining. It must be aligned and configured properly in order to achieve seamless material flow. Find out how to set up an optimal setup.

Proper Alignment with CNC Lathe

Put the bar feeder at the right relative height to the lathe spindle. It prevents unnecessary strain on the material. Also, the bar feeder should be aligned axially with the spindle bore. Deflection can occur due to misalignment which can result in feeding issues and machining errors. Both horizontal and vertical alignment is verified to allow smooth bar movement through the feeder and into the spindle.

Electrical and Pneumatic Connections

Next connect the bar feeder to the CNC lathe’s control system. This is to ensure feeding cycles are in sync with machining operations. Ensure that both the power supply and voltage are set up and compatible to avoid electrical failures. If you have pneumatic components, set up the connections; but this applies to any system you have. There is potential for incorrect pressure settings to disrupt the feeding process. Finally, run the feeder to test the emergency stop mechanisms to ensure that they are safe.

Spindle Liners and Guide Channels Setup

Spindle liners are used to keep the bar stable as it moves through the feeder. Select the proper liner for bar diameter to eliminate vibration and misalignment. Install guide channels to guide the bar into the lathe spindle smoothly. Adjust clearance if necessary and check for clearance. It reduces friction to help reduce feed consistency and prevent jamming.

Testing Initial Bar Feeding Operation

Run a dry test on sample bars from the feed mill bar and grill before full operation. Check out the feeding cycle to look out for obstructions. Minor mechanical adjustments if you see any irregular movements, or stoppages. It helps to ensure proper functionality before actually producing the product, so that the time is not wasted and expensive errors aren’t made. Correct installation of your bar feeder will improve CNC machining efficiency and precision.

Calibration and Adjustments for Bar Feeders

Smooth operation, exact feeding and no waste is achieved by bar feeder calibration. Good machine adjustments increase life, decrease downtime and increase precision. Do the following in order to optimize performance.

Feed Length and Bar Advance Rate Configuration

Set the bar advance parameters based on your CNC program. Feed length is set according to the depth of the cutting tool and the machining cycle. Ensure the bar advance rate is constant; otherwise, alignment or delays will occur.

Tension adjustment for various bar diameters.

Make the pressure settings for clamps or collets to hold the bars in place. Feed interruptions or material deformation should be avoided to excessive tension. Maintain flexibility of material handling options by evaluating bar diameters.

Verifying Accuracy and Stability

Run trial cycles to verify exact bar positioning and feed consistency. You may inspect to verify that bar slippage or excessive pull force affecting machining accuracy is not present. These can be adjusted in real time according to first observations.

Fine-Tuning for Optimal Performance

Monitor bar straightness to prevent bar ale feed issues. Adjust guide bushings and dampeners to reduce vibration. Make sure heat buildup and material expansion can be prevented with sufficient coolant flow.

Final Operational Testing and Verification

Run tests in production conditions. Check bar feeder and CNC lathe synchronization. For future reference and troubleshooting, document settings.

Common Challenges and Troubleshooting in Bar Feeding

Bar Jamming Issues

It occurs due to improper bar straightness, debris buildup, or the wrong feeder settings. This can be avoided by using good quality, straight bars and keeping the feeder clean. This reduces friction and keeps the movement smooth.

Vibration and Deflection

Precision and surface finish are also affected by excessive vibration. This is usually caused by unsupported bar ends, spindle speeds not being optimized, or inconsistent feed—sometimes visualized in a bar chart feeder cattle analysis. Stabilizing the bar using spindle liners and dampeners, minimizes deflection and improves accuracy.

Misalignment with CNC Lathe

Feed interruptions occur caused by misalignment between the bar feeder and spindle. It is important that you have proper height positioning and axial alignment. Check feeder’s connection to lathe regularly to prevent inconsistencies in feeding.

Feed Rate & Length Inconsistencies

Bar advancement is inconsistent and this affects machining accuracy. Inspect the feeder advance mechanism in order to diagnose issues. In the CNC control system, feed parameters are adjusted to optimize movement, so that overfeeding and underfeeding will be avoided.

Material Slippage During Feeding

If there is not enough clamping pressure or bad grip, bars may slip. Stability is enhanced by adjusting the clamping mechanisms and proper bar support. Unexpected feed failures are prevented through regularly inspecting bar holders.

Bar Feeder Maintenance & Best Practices

Routine Maintenance Tasks

- Clean and Lubricate: Clean dust, chips and debris on a daily basis. Lubrication to moving parts when they are scheduled by the manufacturer can reduce friction and wear, especially on the three bars feed & tack system.

- Check Alignment and Roller Guides: Also, make sure to inspect the CNC lathe alignment with the feeder to avoid misfeeds. It should have no obstructions and roller guides pass smoothly.

- Inspect Electrical and Pneumatic Systems: Look for loose connections, frayed wires or air lines that leak. Make sure you sensors and actuators work properly.

- Monitor Wear and Replace Parts: Check for bushings, rollers, or guide channels that are worn. Maintain the system stable and precise by replacing damaged components.

Best Practices for Long-Term Performance

- Using high quality bars will reduce machine component wear. Excessive friction caused by low quality materials will damage your tools and feeders prematurely.

- Furnish automatic feeders with firmware and software updates. The regular updates bring the performance up, fix bugs and make the software compatible with CNC systems.

- Follow a preventative maintenance schedule. Routine inspections, lubrication and part replacement will help you avoid costly breakdowns, and smooth operation.

- Provide training for handling and troubleshooting. Staff trained well will be able to detect problems early, set the settings properly, and operate efficiently.

Industry Applications of Bar Feeders

Automotive Industry

High-volume precision machining in the automotive sector depends on Haas bar feeders. They ensure production of engine parts, shafts and transmission parts with constant quality by automating material feeding. This reduces downtime, and thereby, leads to faster cycle times, lower operational costs, and higher quality.

Aerospace & Defense

Aerospace and defense require precision. The machining of high strength alloys used in aircraft components, landing gear and defense hardware can be done with bar feeders. It reduces material waste while delivering stable and vibration free cutting that helps in part accuracy.

Medical Device Manufacturing

Medical device manufacturing of surgical tools, implants, micro-components is performed using bar feeders. They are capable of small diameter machining and machined small diameter parts to meet tight industry regulations.

General Engineering & Metalworking

Bar feeders are used in general engineering and metalworking to increase efficiency. Automated feeding reduces manual handling, speeds up production time, and keeps quality consistent whether you are machining brackets, fasteners, custom parts, etc.

Electronics Industry

Electronic components require precision. Small delicate metal parts such as circuit board connectors and microprocessors can be produced with high accuracy and minimum error on bar feeders.

Oil & Gas Sector

In oil and gas, durability matters. Bar feeders help with machining robust pipeline fittings, drilling tools and valve components. Increased production efficiency is achieved by the smooth feeding of tough materials such as stainless steel and titanium.

Conclusion

CNC machining benefits from bar feeding since it ensures continuous supply of material, reduces downtime, and improves efficiency. Like the seamless service at The Feed Store Grill and Bar, knowing about the various bar feeder types, setup, calibration, and maintenance ensures operations to run optimally. Jamming and misalignment are prevented by proper alignment, feed rate adjustments, and troubleshooting. Regular maintenance extends equipment life and keeps them performing smoothly. You must learn proper feeding techniques so that you can get precise machining, lower costs, and better workflow in manufacturing.