Chamfering and Deburring: Everything You Need to Know

In precision manufacturing, chamfering and deburring have a dominant role. The quality, safety and performance of finished parts are directly impacted by these processes. That’s why you need to know how they work, when to use them and what works best. This guide will outline the basic concepts, tools, and hurdles related to chamfering and deburring. You’ll also learn how to integrate them into your workflow. By the end of this, you’ll know exactly what technique to use based on what you need.

Table of Contents

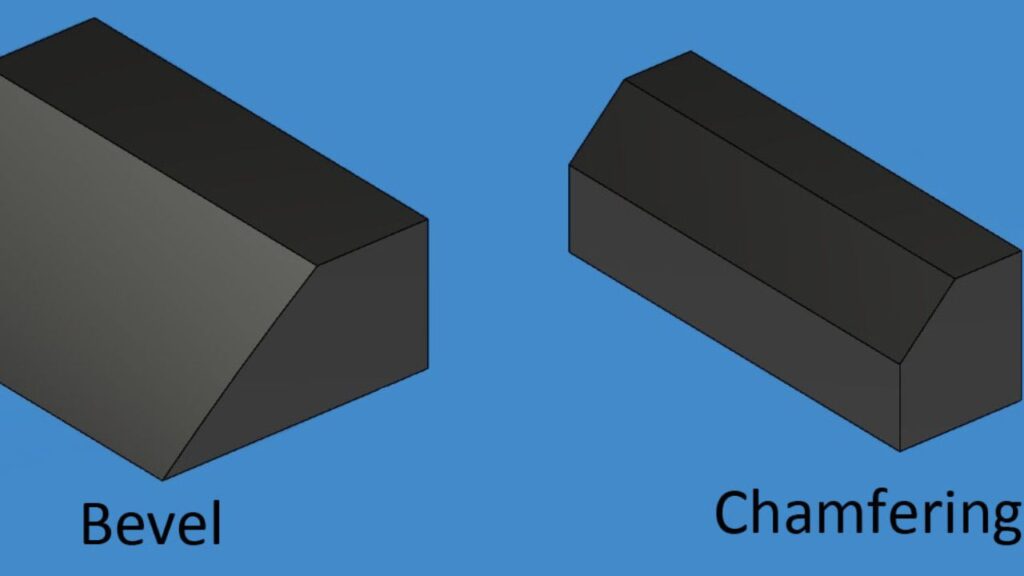

ToggleWhat Is Chamfering?

Chamfering is the term given to cutting a sloped edge, usually at 45°, on holes, edges or corners. It is used to remove sharp edges and for a smooth, angular finish. It makes things safer and helps parts fit together better. Whereas beveling applies to larger surfaces and is less precise, chamfering is more precise. Also, the countersinking doesn’t produce a conical hole entry.

What Is Deburring?

Deburring refers to the removal of little, sharp projections or burrs that often come up during machining. You do this to avoid injury, achieve a better fit, and ensure product strength. Such burrs as rollover, breakout, or Poisson types can penetrate surface finish and performance. If you ignore them, you risk poor assembly and even mechanical failure. It deburrs your parts to quality, safety, and durability standards.

Importance in Manufacturing Processes

Improving component safety

Machining sharp edges left during machining can cut or injure a person handling the part. Chamfering and deburring parts eliminates the hazards. This makes your components more safe for technicians, assemblers, and end users.

Improving assembly fit and precision

Sometimes, burrs and uneven edges can interfere with parts fitting together. They also require that you remove them properly so you ensure tighter fits and more accurate assemblies. This directly increases performance and reduces rework.

Increasing aesthetic quality

Smooth edges also clean up how your parts look. If you care about presentation, and especially if you are working in consumer or medical products, deburring makes a real difference. You make a better impression on your clients.

Reducing mechanical failures

Burrs weaken parts over time due to acting as stress risers. Deburring is just plainly removing them, and you can reduce premature failure just by doing that. It strengthens structural integrity.

Ensuring standards compliance

Burr free, chamfered edges are often required following ISO, ASME and similar standards. Meeting these guidelines will improve trust and reduce the risk of expensive non compliance issues.

Product life extension and reliability

Correct deburr and chamfering help parts last longer. Reduced stress points and better fit mean less wear and fewer breakdowns over time.

Methods of Chamfering

Manual Chamfering

For small scale jobs or jobs where precision isn’t important, your go to method is manual chamfering. You will use files, scrapers, or handheld deburring tools. This method is good because it gives you control and flexibility, especially for prototypes or custom parts. This is time consuming and not suitable for consistent, large scale production.

Machine Chamfering

Machine chamfering can be fast and repetitive for high volume work. Most of the time you will be using CNC milling or turning machines with chamfering tools. Angles are controlled automatically by these machines with you hitting exact specs every time. This method is the most reliable if you deal with mass production or tight tolerances.

Grinding and Abrasive Chamfering

Abrasive chamfering is highly effective when you’re working with hard metals and you require fine-edge control. It involves smoothing and creating precise bevels by using grinding wheels or abrasive belts. It finishes well, especially on tough materials like stainless steel or titanium.

Laser or Waterjet Chamfering

Laser or waterjet chamfering is used when your parts are delicate or heat sensitive. By eliminating the mechanical stress, these non contact methods provide high precision. They are ideal for use on fragile composites, plastics or thin metal sheets. In addition, they leave minimal burrs, making post processing unnecessary.

Methods of Deburring

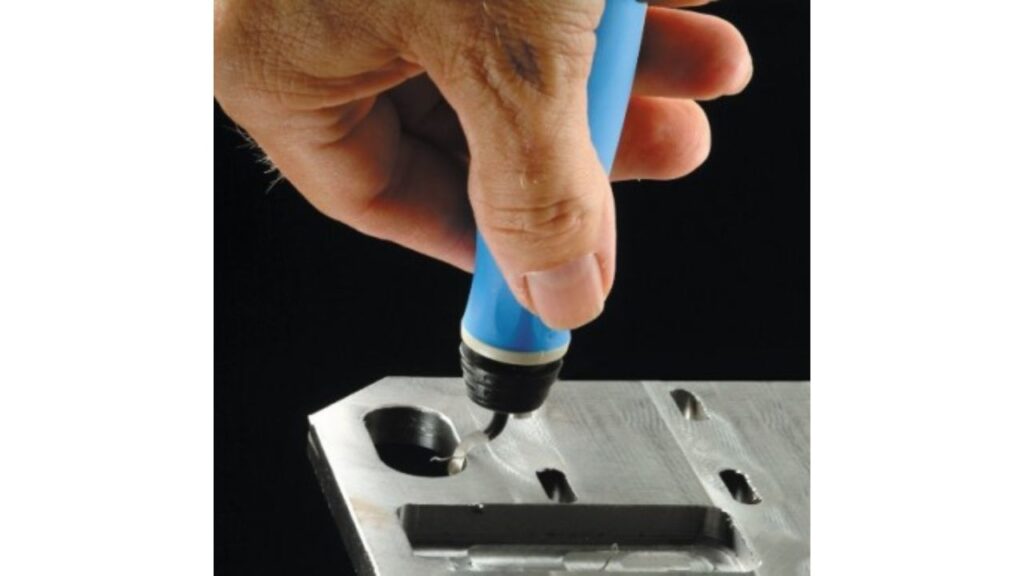

Manual Deburring

Manual deburring is a good idea if you are working with prototypes or small production runs. You’ll also use hand tools such as files, brushes and blades to remove burrs from the edges and surfaces. It is labor intensive but you have total control over each part. It will be priced out when precision is required for small quantities. Still, for repeatable results, you need skilled hands and careful inspection.

Mechanical Deburring

Mechanical deburring enables you to scale up for larger batches, retaining efficiency. It includes tumbling, vibratory finishing, and spindle mounted tools. The parts are placed into machines that agitate or rotate the parts with abrasive media. Repeated contact wears the burrs down. It does well for metal parts, has good uniform results across medium to high volume production. This is an excellent choice if you want to cut down on manual labor.

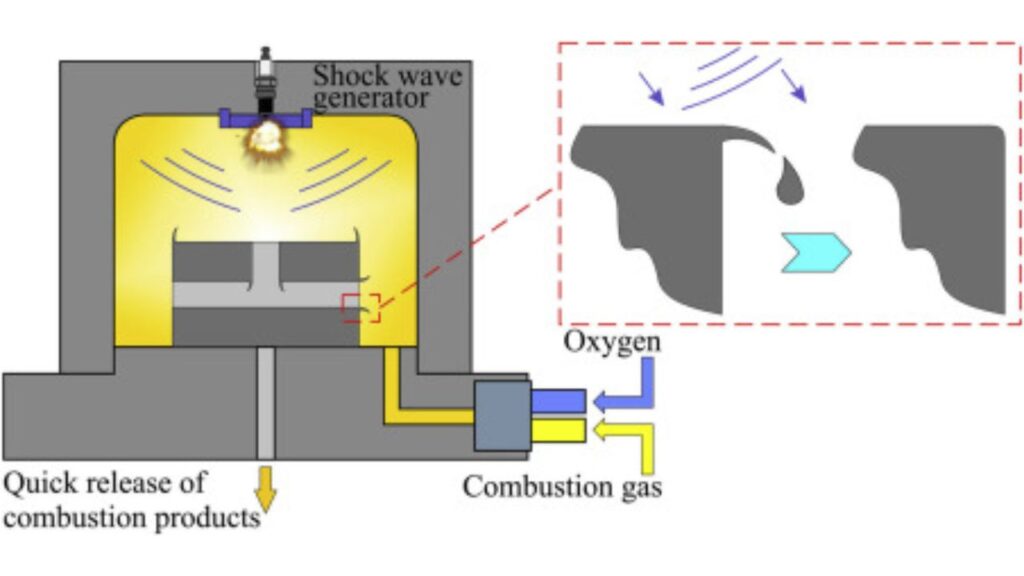

Thermal Energy Method (TEM)

TEM produces fast and clean results when you have to deal with internal burrs or complex shapes. In this method, burrs are burned off through a carefully controlled combustion reaction inside of a pressurized chamber. In seconds you get high precision. This type of 3D printing is ideal for very high volume parts with intricate features. This is the method to use if your goal is speed and repeatability, especially for internal burrs.

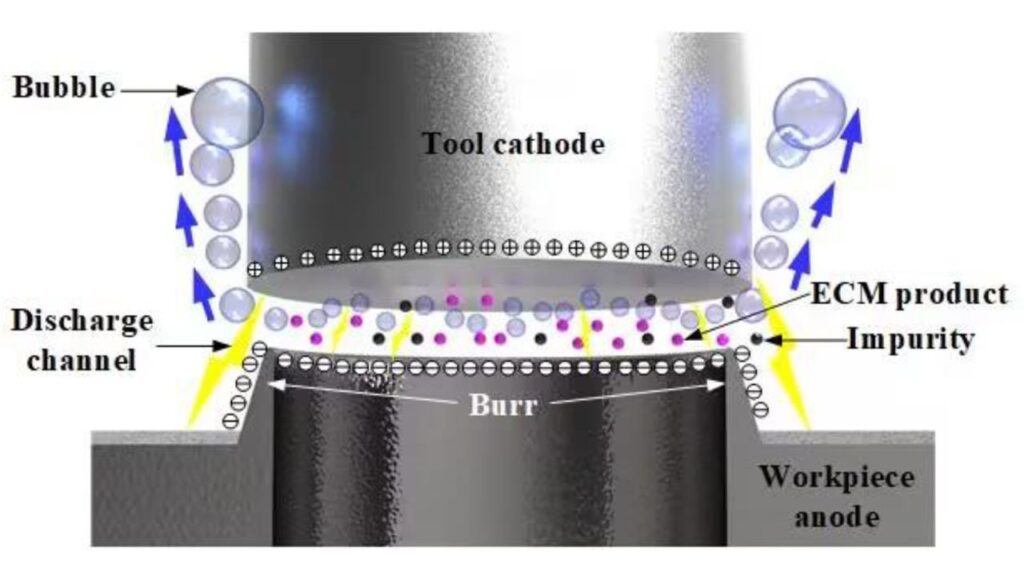

Electrochemical Deburring (ECD)

Electrolysis to remove burrs without applying mechanical force is the working principle of ECD. It is extremely effective for delicate or hard to reach areas. This process lets you avoid deformation if you’re working with tight tolerances or fragile parts. You will also have clean edges with little or no manual cleanup. In complex geometries, ECD is perfect when accuracy matters most.

Cryogenic Deburring

This is a good method for soft materials such as plastics or rubbers. You then cool the parts with liquid nitrogen and make burrs brittle. You then blast the surface with media to break off the frozen burrs. For handling sensitive parts which can deform under heat or pressure, cryogenic deburring is perfect to achieve clean results without damage.

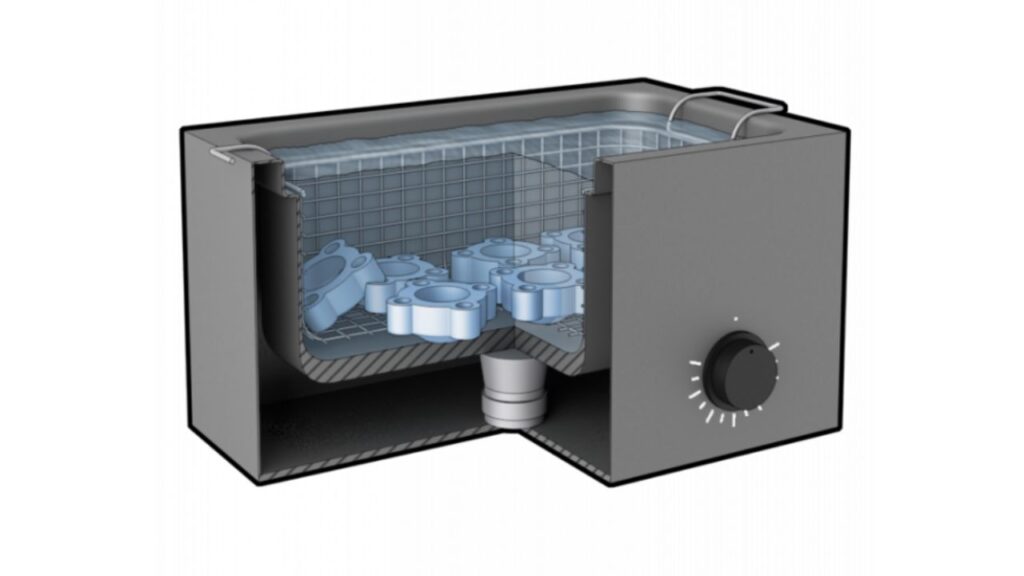

Ultrasonic Deburring

Ultrasonic deburring provides you with exceptional control for micro-sized burrs or intricate components. With ultrasonic waves, you immerse the part into a liquid medium. These waves then produce cavitation bubbles that gently dislodge burrs. If you manufacture precision parts in the medical or electronics fields, this is a technique that provides you with excellent edge quality with no physical contact.

Chamfering and Deburring Tools and Equipment

Manual Tools

For prototypes and low volume production, manual tools are a great choice. Deburring knives, countersinks and scrapers can be used by hand to remove burrs or to create simple chamfers. These tools have full control and are affordable for small jobs. Manual tools are very efficient if you’re working with soft metals or plastics.

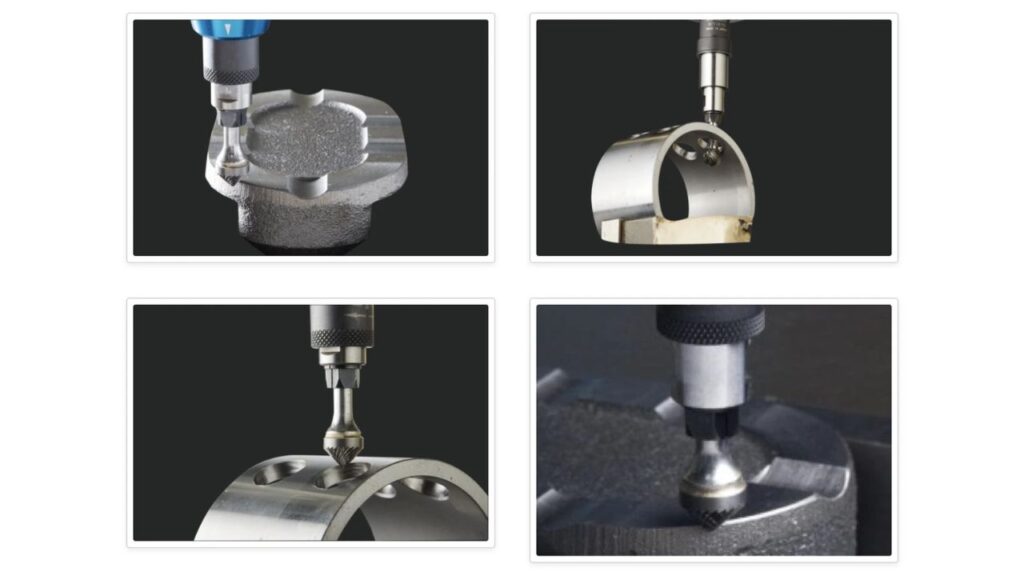

Machine Attachments

In order to get faster and more consistent results, affix chamfering or deburring tools to your machining equipment. During CNC operations, chamfer mills, end mills, or rotary burrs can be used. These tools enable edge finishing automation within your machining cycle. This means it won’t need to be moved to a secondary station, cutting down on time and handling errors.

Specialty Machines

Dedicated machines are great when you’re running complex or high volume projects for precision and speed. Automated edge detection on CNC chamfering tools allows you to maintain consistency on parts with varying geometries. Inline processing can also be done through deburring stations integrated in CNC centers. This setup will help you keep the workflow smooth and minimize downtime.

Automation and Robotics

If you’re looking to scale your production it’s a good idea to use automated systems. Robotic arms with vision systems are able to sense edges and adapt to different part shapes without preprogrammable fixtures. Large batches with strict tolerances are ideal for these systems. Automated cells are also used for non stop production. These systems run round the clock generating repeatable high quality results with minimal human intervention.

Materials and Geometry Considerations

Material-Specific Approaches

Different materials require you to adapt your chamfering and deburring techniques. For hard metals such as titanium and stainless steel tools must be durable and will have to run at slower feed rates to prevent tool wear. For soft metals like aluminium and brass, you need to keep pressure under control to stop over cutting. If you are working on plastics or composites, focus on not having heat build up and not having stress fractures. Use sharp tools and lighter passes, and easily deforming materials.

Part Geometry

Specialized methods are needed for complex geometries. Thin walls will bend under pressure, so you need to use minimal pressure and sharp cutters. It is difficult to access tight radii and small holes, and usually requires micro deburring tools or precision abrasive methods. Internal holes are especially tricky. Options such as electrochemical or thermal deburring are useful since you can’t easily reach them. For external surfaces, manual or mechanical methods are usually adequate.

Tolerance and Surface Finish Requirements

Precision matters. You need to control chamfer size extremely carefully to meet engineering specs. Too much material removed can also cause dimensional errors. You need to get a clean finish without damaging the surface for burr removal. Always inspect for consistent results. By following this guidelines you will get precision and high part performance along with quality standards.

Integration into Manufacturing Workflow

Inline Deburring in Automated Setups

Inline deburring in automated setups is often the best choice for large scale manufacturing. With this method, robotic systems or specially built machines are used to remove burrs and make chamfers as the parts are produced. Integrating this process into your automated systems allows you to boost precision and minimize manual labor, producing the same quality on large batches.

CAD/CAM Programming

Chamfering toolpath integration is critical for the optimization of the machining process. With CAD/CAM programming, you can actually plan the exact tool paths you need for economical chamfering. These programs contain simulation features to predict burr formation and to guide in the selection of the best deburring method before the physical machining begins. As a result, there are less errors and less rework.

Quality Assurance

Quality assurance is of vital importance for chamfering and deburring. For accuracy, you can check with visual, tactile and CMM (Coordinate Measuring Machine) inspections. Measuring chamfer angles and burr heights helps to make sure that the process is meeting your exact specifications and that there are no defects or safety issues in the final product.

Common Challenges and How to Address Them

Inconsistent Chamfer Sizes

Tool wear or incorrect toolpaths generally results in inconsistent chamfer sizes. Finally as the tools wear down, they become less precise and thus less effective in producing a quality chamfer. For this, you should monitor tools regularly and use automatic compensation. These methods online compensate for tool wear in real time, making results produceable on the shop floor.

Incomplete Burr Removal

Removal of burrs can be a very difficult process, especially with complicated geometries or incorrect procedures. Burrs that are not properly removed can affect the part’s functionality and safety. Hybrid techniques or a multi step deburring process can help. These methods apply mechanical and thermal burr removal methods and effectively remove burrs on all surfaces even in hard to reach areas.

Over-Deburring or Chamfering

If there is over deburring or chamfering, it can cause dimensional inaccuracies or weakened parts. Excess material is removed and part integrity compromised. To avoid this you have to use precise tolerances and control processes. By implementing tighter controls, you don’t over do the deburring or chamfering of the part, and you protect the part’s strength and accuracy.

Tool Wear and Breakage

Common phenomena in machining hard materials are tool wear and breakage. These are issues mainly caused due to wrong feeds and speeds. This is avoided by choosing the right tool materials, such as carbide or PCD, which are more durabl

Best Practices for Effective Chamfering and Deburring

- Select a suitable method for the geometry and material. Different material calls for a different approach to get the best results. Think of hardness and part shape.

- The process is inspected early and often. Checks help catch issues early, saving money on what would be otherwise costly mistakes and rework.

- When possible, integrate into CNC routines. Chamfering and deburring can be automated using CNC machines, increasing precision as well as efficiency, especially for large scale production.

- Coolants and cutting fluids should be used properly to reduce heat and prevent tool wear. It also gives improved surface finish and prolongs tool life.

- Regularly maintain tools and keep an eye on tool wear. Poorly made tools can cause inconsistencies with the chamfer or burr removal to the point of dull or damage.

- Train operators on visual and tactile inspection techniques. Automated systems can miss all of this, so skilled operators can notice subtle things that the automated systems might not.

Industry Applications

- Aerospace: Deburring turbine blades and chamfering bolt holes will reduce friction and prevent damage during flight.

- Automotive: Deburring sharp edges improves performance and safety through prevention of wear and improved assembly fit in transmission components, gears, and brake parts.

- Medical Devices: High precision deburring for implants and surgical tools provides smooth surfaces for lower risk of infection and better patient outcomes.

- Electronics: Chamfering edges and cleaning connectors in PCBs makes a smooth connection and prevents short circuits thus ensuring product reliability.

- Oil & Gas: Deburring of pipe ends and valve fittings is necessary to ensure a seal and prevent mechanical failures in harsh environments.

Conclusion

In modern manufacturing, chamfering and deburring are essential to achieve precision, safety and performance. While these processes are not the last finishing touches, they are important in the overall quality of your parts. When choosing methods, factors such as production scale, material, and part complexity may be important. Machine based methods are best for high volume production whereas manual techniques are best for smaller runs. Don’t forget that deburring and chamfering directly affect to the durability and functionality of your product, so never forget them during the manufacturing process.