CNC Tapping – The Complete Beginners Guide

CNC tapping is the most dominating part of the CNC industry, which provides precise and efficient threading for various manufacturing applications. It is essential to understand Computer Controlled tapping to optimize production and have high quality threads. This article will tell you everything you need to know about the automated tapping process, the tools and the taps used, as well as rigid and floating tapping. You will also learn about issues and solutions and best practices. By the end of this article you will be ready to boost your Computerized tapping/C Tapping performance, resulting in more precision and productivity.

Table of Contents

ToggleWhat is CNC Tapping?

CNC tapping is a machining process that allows you to create internal threads inside pre drilled holes on CNC machines. The tapping operation is run automatically using computer numerical control, thus obtaining high accuracy and repeatability. Computerized tapping differs from manual tapping which, unlike automated tapping, requires the use of hand tools and an operator’s skill to guide the tap. You have access to key components such as taps, CNC control units, and pre drilled, chamfered holes. This setup enables you to produce more consistent, higher quality threads in less time. Modern CNC tapping centers often use advanced voron cnc tap systems.

Core Components in CNC Tapping

Taps: The Cutting Tools

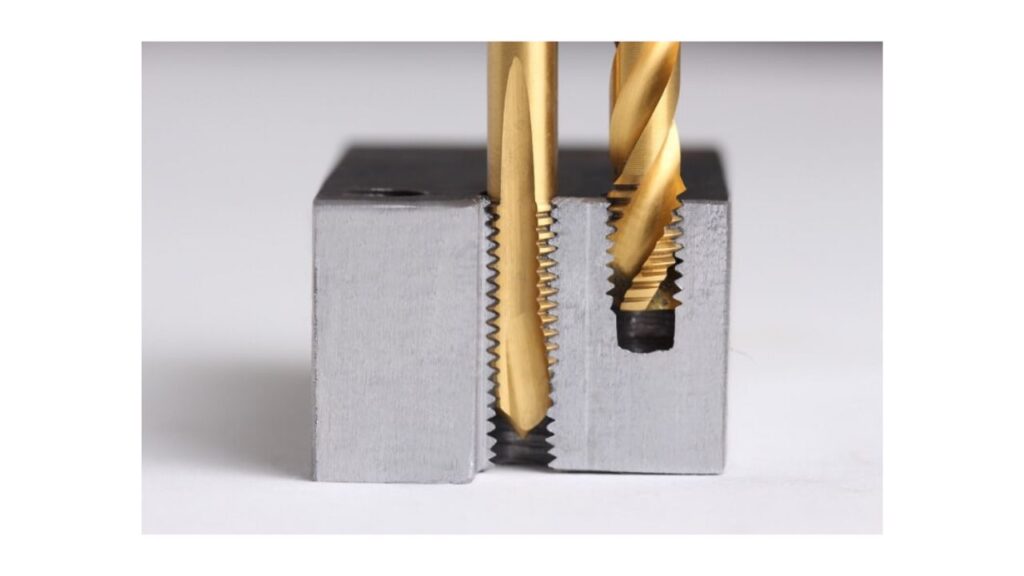

Taps are the cutting tools used as such in Machine Tapping to form internal threads into pre drilled holes. You’ll generally work with two kinds: cutting taps and forming taps. Cutting taps remove material by cutting to create threads and forming taps displace the material to shape a thread, leaving chips from the cutting process behind. Tapping collets help secure taps in CNC machines for precise rotation.

Knowing tap anatomy is helpful when choosing tools. These include the shank (that carries the tap), the flutes (that remove the chips), the cutting edge, and the thread lead (that starts the thread). Accuracy and finish quality of each part is important.

There is also the question of what tap materials you need to consider. HSS is fine for general use, but cobalt taps have greater heat resistance for tougher material. TiN (Titanium Nitride) and TiCN (Titanium Carbonitride) coatings reduce wear and increase tap life, especially while tapping machining hard or abrasive material.

CNC Machines for Tapping

Tapping is done on CNC mills, lathes and machining centers. Essential tapping features must be supported by each. Tap cycles such as G84 CNC code, spindle synchronization, and torque control should be looked for. They ensure exact thread depth and reduce the probability of tap breakage.

Workholding and Toolholding

Proper workholding is crucial. To do this, you need rigid setups to eliminate movement and ensure thread alignment. Always use the right tap holders: rigid for accuracy, floating for misalignment, and torque-control to avoid overloading the tap. Tapping heads provide additional stability for precision threading. Always ensure alignment and concentricity. This will help you get cleaner, more consistent threads every time.

How the CNC Tapping Process Works

Pre-Tapping Requirements

Before starting CNC tapping, your hole must be properly prepared. Pre-drilling is essential. The hole size needs to be chosen based on the tap and the desired resulting thread fit. Tight enough so that threads don’t form, but not too tight so that tools don’t break when you’re too loose. The quality of the hole surface also affects the precision of the thread and tool life.

By chamfering the hole, it helps the tap guide and help prevent thread deformation. Also, deburr the edges to avoid damaging the tap. Coolant not only reduces heat and friction, it also helps evacuate the chips from the cutting zone. Select oil based or synthetic fluids in accordance with the type of material and the type of tap and feeds and speeds for tapping.

Step-by-Step Tapping Process

Step 1. Select the Right Tap

Select the tap to suit your material, hole type and thread size. Spiral flute taps work well for blind holes. Thorough holes are tapped with spiral point taps. Tap matic systems help automate this selection for better accuracy and consistency. Make sure to always match the tap geometry to the application.

Step 2. Set Spindle Speed and Feedrate

Based on tap diameter, pitch and the material, determine spindle speed and feed. Otherwise, tool breakage can occur if spindle speed is not precisely the same as the feed rate. Cutting speed for tapping is critical to prevent breakage.

Step 3. Program the Tapping Cycle

The right G code exists — Gcode G84 is typically used for right hand threads. Parameters such as depth, speed, and feed rate should be set carefully. Confirm alignment and zero position.

Step 4. Run the Tapping Cycle

Execute the tapping operation. One continuous motion in which the tap enters, cuts the threads and retracts.

Step 5. Inspect the Thread

If needed, chamfer the edge, then inspect the finished thread for depth, alignment and finish.

Types of Taps Used in CNC Tapping

Spiral Point Taps (Gun Taps)

Through holes can be tapped with Spiral Point Taps (Gun Taps). The taps push chips forward and out of the hole and helps prevent clogging. They are efficient for high speed operations and suitable for rigid setup. Avoid them in blind holes as they can trap your chips.

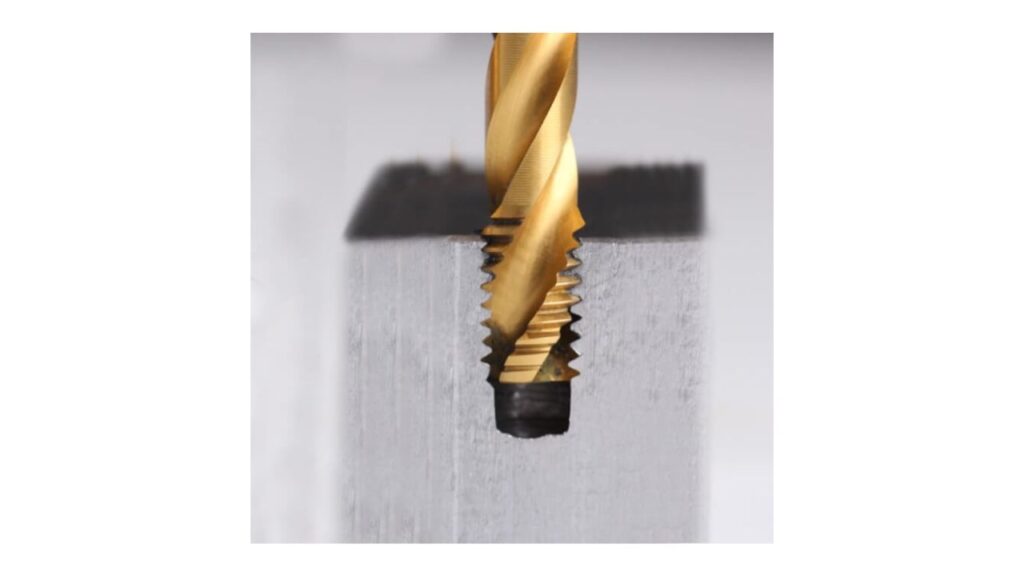

Spiral Flute Taps

Spiral Flute Taps are designed for blind hole cutting and softer materials such as aluminum. The spiral design of the chips pulls them back out of the hole, thereby reducing the chance of chip buildup. High chip removal efficiency is available with these taps, but proper alignment is necessary. Poor thread quality or tap damage can occur due to misalignment.

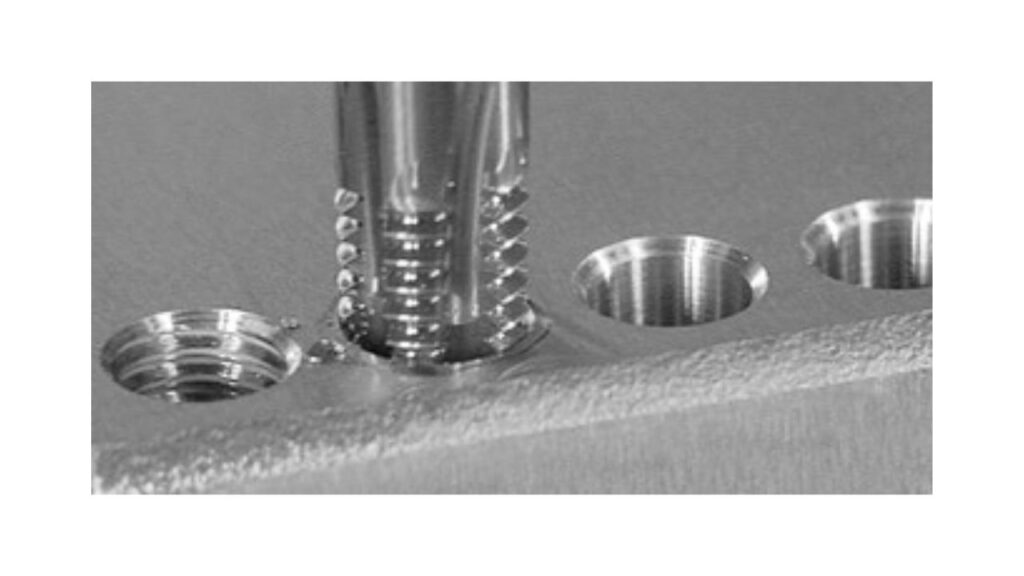

Form Taps (Roll Taps)

Roll Taps (Form Taps) do not cut material, they displace it to form threads. Since they produce no chips, in many chip sensitive environments like medical or electronic part machining. They are very good for ductile materials however, they are not suitable for hard or brittle metals. These are perfect if you want stronger threads and smoother finishes.

Plug, Bottoming and Taper Hand Taps (for hybrid/manual setups)

The usage of Bottoming, Plug and Taper Hand Taps are restricted to hybrid or manual setups. When tapping short threads or finishing near the hole bottom, you can still use them on CNC machines. They provide different thread depth so you have flexibility in tight spaces when working on a tap.

Types of CNC Tapping Operations

Through Hole Tapping

When tapping a hole that completely goes through the part, chip evacuation is much easier. The bottom has chips exiting, improving thread quality and decreasing breakage risk. For these operations spiral point or spiral flute taps will give you the best results.

Blind Hole Tapping

Removing chips for holes that stop inside the part are harder. To clear chips back through the entrance, they can clog or damage threads. Spiral flute taps are also good at pulling out chips. Peck tapping makes sense if you’re drilling deep blind holes. After short advances it retracts the tap, clearing chips and reducing stress.

Rigid Tapping

Rigid tapping links the spindle and feed rate. It lacks axial float so you get high precision and constant thread depth. But there’s more likely of tap breakage, in particular, if your setup is not perfectly aligned. It is used for softer materials and shallow holes.

Floating Tapping

The tap is moved slightly axially in this method to, in turn, aid in alignment with minor workpiece shifts. While more dangerous in misaligned setups, this is less precise than rigid tapping. Floating tapping offers more flexibility when you are working with deeper holes or with less rigid workpieces.

Synchronous / Self-Reversing Tapping

This high-speed method changes the direction of the tap at the bottom of the hole quickly. You won’t have to stop the spindle, speeding up the cycle time. This is ideal for mass producing through holes with minimal downtime.

Peck Tapping

Peck tapping chip clears better when you are tapping deep or blind holes. It moves in small increments and retracts to flush out chips. Although it requires additional time, it reduces breakage and gurantees clean threads.

Form Tapping

Form tapping does not cut, but instead displaces material in order to form the threads. The best application for this non-cutting method is in ductile materials such as aluminum or copper. Stronger threads, better finishes and longer tool life are the benefits. All you need to do is make sure your machine has enough torque and rigidity to take it on.

Programming CNC Tapping Cycles

Programming CNC Tapping Cycles

CNC tapping requires accurate programming for generation of thread quality and tool safety. Usually you use Gcode commands such as G84 for right hand tapping and G74 for left hand tapping. These cycles enable the tap to go back and forth with these cycles. In programming, you need to specify parameters, for example, spindle speed, feed rate, thread depth. The feed rate should always match the spindle speed; any mismatch can damage the tap or thread. Modern CNC tapping center systems automate these operations with exceptional accuracy and repeatability.

Live Tools on Lathes Tapping

Tapping on CNC turning centers is more than basic G code. You also need to coordinate the turret motion and spindle orientation. Live tools allow the part to be stationary while the spindle turns, making it the tool of choice for off center tapping. Using a taps head improves stability and ensures precise alignment during the operation. Before starting the cycle, you should also verify that the turret position aligns perfectly.

Error Prevention Strategies

Spindle override limits are set to avoid mistakes, to prevent unexpected speed changes. Set the feed rate to match thread pitch and spindle RPM precisely. Also, it makes sense to use torque monitoring or load sensors. These tools allow for early detection of problems, protect your tap, and maintain a constant thread quality.

Tapping Speed, Feed, and Lubrication

Speed and Feed Recommendations

This calculates the correct tapping speed: RPM = (Cutting Speed × 4) ÷ Tapping Diameter. After you have the RPM, find IPM (Inches per minute) by multiplying RPM with the thread pitch. These values always need to be adjusted according to your material type. Higher speeds are needed for softer materials and slower feeds for harder materials. Load, chip flow and thread quality are affected directly by tap diameter and thread pitch. With accurate data, breakage, and poor threads can be prevented.

Lubrication and Coolants

To cool the tap, flush out chips and reduce friction you require proper lubrication. For tough materials and deep holes oil-based lubricants are best. Coolants based in water provides good cooling but less lubrication. When working on a tap, ensure proper lubrication reaches the cutting edges for smooth operation. For aluminum tapping and clean environments, Minimum Quantity Lubrication (MQL) is an excellent method. Make sure you always use the same lubricant type as your material choice and tapping method. This leads to cleaner, more precise threads and an improvement in tool life.

Advantages and Disadvantages of CNC Tapping

Advantages

Precision and Consistency

Automated threading leads to highly precise threading. The automation keeps human error out, giving consistent results across multiple parts. But you can trust that the accuracy will be the same every time.

High Production Throughput

Computer-controlled tapping increases production speed. Automation reduces the manual labor, which makes production cycles faster. It enables you to scale up and optimize the workflow.

Reduced Operator Intervention

Machine-based thread cutting eliminates the need for constant operator supervision. The machine is set up and runs on its own after that, freeing up operators to focus on other things, speeding things up.

Better Quality Threads

Smooth threads with stronger content are achieved due to the automated control of speed and feed rates. The end result is better quality parts, which is essential for applications where the part precision is critical.

Improved Workplace Safety

Automated tapping machines require less direct interaction with the machines. This reduces the risk of operator injuries, making the working environment safer.

Disadvantages

High Initial Equipment Costs

Automated threading systems can be very expensive upfront. This may be a big investment for small shops, but it usually makes sense with time for its efficiency.

Programming Complexity

Specialized programming knowledge is needed to setup computerized tapping. Programming the machine correctly with CNC software can be time consuming and difficult if you are not familiar.

Tap Wear and Breakage Risk

Just as with any cutting tool, taps wear out. To prevent breakage that stops production and puffs up costs, you’ll need to monitor the condition of your taps regularly.

Limited Flexibility for Low-Volume or Customized Work

Automated thread cutting is the best way to go with mass production. For low volume or highly customized jobs where some level of manual intervention is required, it is less flexible.

Pre-Drilled Hole Requirement

Holes need to be pre drilled for machine-based threading. This is an additional step that can slow you down and takes another layer of preparation unless you’re mindful.

CNC Tapping vs Thread Milling

Automated threading rotates a tap into a pre-drilled hole to form threads. The thread milling, however, is done using a rotating cutter. Both methods are effective, and you’ll eventually choose the one that best serves your needs.

| Sr. No. | Feature | CNC Tapping | Thread Milling |

| 1 | Speed | Faster for through holes | Slower, but more flexible |

| 2 | Chip Control | Easy chip removal | Better chip control |

| 3 | Flexibility | Limited to pre-drilled holes | More flexible for complex parts |

| 4 | Cost | Lower cost for mass production | Higher cost per part |

When to Choose Tapping vs Thread Milling

Computerized tapping using a CNC tapping center is the way to go when you need to fast, cheaply, and in large quantities. If the part is complex, if the diameter is large, or if you need more precision in material, thread milling is the choice.

Tool Life and Part Geometry Considerations

For harder materials, thread milling is usually milder on the tool and can give longer life. automated tapping systems like voron cnc tap are faster but can wear taps at a rate faster, especially in tough metals. When making your choice, always consider the geometry of the part and the material.

Applications of CNC Tapping

Automotive Industry

Automated threading system is required for threading engine blocks, suspension parts and other critical automotive components. This allows you to get precise threads that guarantee secure part assembly and longevity in high stress environments.

Aerospace and Defense

Aerospace and defense applications rely on Computer Numerical Control tapping. This facilitates the creation of precision threads in such critical components as brackets and housings. Computerized tapping is the perfect solution for these components, given that they require high strength and accuracy.

Medical Devices

For medical devices, you have tight tolerance threaded holes for surgical tools and implants. These devices are safe and reliable in the most delicate procedure because this computer-controlled tapping makes them precise.

Consumer Electronics

Automated thread cutting is used for threading aluminum or plastic casings and camera mounts in consumer electronics. It ensures durable threads that can take regular use and tough conditions.

Industrial Equipment and Machinery

Computer-controlled thread cutting is used in threading parts for hydraulics, pneumatics, and machine frames. In industrial settings these components require strong and precise threads to function correctly.

Oil and Gas Components

However, automated thread machining is needed when creating threads in pipeline equipment and high pressure valve bodies. Such applications require strong threads that can withstand harsh environments and high pressure conditions.

Optics and Precision Engineering

Typically, computerized threading operations are used in optics for microthreading in telescopes, lasers, and precision mounts. It means tiny, spearlike threads hold complex optical components securely in place.

CNC Tapping Best Practices

Right Tap for Each Application

You need to choose the right tap. Taps are specific to different materials and types of holes. If you use the wrong tap you can get poor results, wear and even tap breakage. Match the tap type to your material and application.

Never Over Speed, Especially in Difficult Materials

Too fast a spindle speed can lead to tips wearing out quickly or to taps breaking in tough material. It is recommended to keep spindle speeds within recommended ranges to get best performance and tool life.

Regularly Inspect and Replace Worn Taps

Taps wear over time. Check that taps are free from signs of wear or damage. Replace worn taps to avoid poor thread quality or tap breakage during operation.

Ensure Proper Chip Evacuation

A smooth tapping process requires proper chip removal. Damaged chips or clogged chips can harm the tap or result in thread defects. You need to use enough coolant and you need to set the machine to remove the chips.

Use High-Quality Lubrication

Lubrication provides reduced friction, cools the tap, and also facilitates chip removal. It is important to use high quality lubricants which are suitable for your material to achieve smooth, consistent tapping results.

Always Test Tapping Program with Scrap Material

Run the tapping program on scrap material before running a full production batch. This allows the settings to be correct, minimizing errors and expensive mistakes.

CNC Tapping Troubleshooting Guide

Tap Breakage: Causes and Fixes

It can be due to excessive feed rates, improper spindle speeds, or poor chip removal. Adjust feed and speed settings and make sure there is enough lubrication to prevent breakage.

Poor Thread Finish: Reasons and Remedies

Worn taps, incorrect speeds, insufficient lubrication, or poor thread finish may lead to poor thread finish. Wear checking, adjusting speeds, and assuring the proper lubrication will give you smooth, precise threads.

Chip Clogging in Blind Holes

In deep or blind holes, chip clogging is common. In order to prevent this happen, use the proper tap, apply enough coolant, and consider peck tapping to facilitate chip evacuation.

Misalignment and Concentricity Errors

Misalignment leads to uneven threads. Proper workholding and tool alignment are ensured. Torque control holders can be used to maintain consistency.

Depth Control Issues

Threading issues can be caused by inconsistent tapping depth. Double check your machine’s depth control settings and make sure that the tap is on point to the depth of the hole.

Conclusion

In modern manufacturing, Computerized tapping is crucial in producing precision and consistent components. Learning how to tap correctly, which tools to use, and following best practice will help you get high quality results and have less downtime. Setting up properly, taking care of the tools, and good programming all help to increase productivity. Greater efficiency, longer tool life and better quality products are realized by optimizing tapping processes. Finally, mastering CNC tapping/C Tapping is essential toward the goal of enhancing the productivity and accuracy in your manufacturing operations, thereby allowing for improved thread quality at a cost effective performance.