Alloy Machining 101 Guide – Everything You Need to Know

Alloy machining is the art of shaping engineered metals, which are combinations of elements whose properties are improved, with engineered tools and processes. It is essential in such industries as aerospace, automotive, and medical where performance, durability, and accuracy are not negotiable. However, due to different hardness, thermal conductivity, and work-hardening properties, alloys are difficult to machine without experience. This tutorial fixes that by defining categories, processes, tools, and challenges and best practices so that you can effectively work any alloy. Continue reading to learn alloy machining and improve manufacturing outputs today.

Table of Contents

ToggleCommon Alloy Categories

Ferrous Alloys

You deal with alloys with iron as the chief component. Stainless steel is resistant to corrosion and durable. Carbon steel is strong and machineable in low-carbon grades. Tool steel provides cutting and forming hardness. When the strength and the wear resistance are vital, you select ferrous alloys.

Non-Ferrous Alloys

You employ alloys that do not have a considerable amount of iron in them due to certain benefits. Aluminum alloys are easily machinable and light in weight. Titanium alloys have the advantage of strength-to-weight and corrosion resistance. Copper alloys are excellent in electrical and thermal conductivity. Nickel alloys can work under extreme levels of heat and stress. The two types require different machining approaches to yield optimum output.

Properties of Alloys Relevant to Machining

You need to know the core properties of the alloys when machining them. All of these properties influence cutting performance, tool life and surface quality.

- Hardness: Hardness is a measure of resistance to deformation. Greater hardness requires tougher tools. Soft alloys are easily cut, but have a tendency to burr. Hard alloys are wear resistant yet their cutting speed must be lower.

- Toughness: Toughness is the characteristic of absorbing energy without breakage. Strong alloys are not easily cracked. When tooling is not rigid, they may chatter.

- Ductility: Ductility enables alloys to be drawn out of shape without fracturing. High ductility is good in forming but may result in long chips. The issue of chip control is critical in ductile materials.

- Thermal Conductivity: Thermal conductivity governs the heat during machining. High conductivity alloys such as aluminum dissipate heat quickly. The heat is entrapped close to the tool by low conductivity alloys such as titanium.

- Corrosion Resistance: Corrosion resistant alloys such as stainless steel are alloys that do not lose their surface quality. Chromium or nickel is frequently included in these alloys. They can work-harden in cutting.

- Wear Resistance: Wear resistant alloys prolong service life of parts. They are not easily abraded but wear the tool more. In this case, the performance of tools is enhanced by specialized coatings.

- Composition Effects on Machinability: Composition of alloys alters machinability. There is increased hardness with high carbon content. It also diminishes speed of cutting potential. Machine speed is quicker with low-carbon steels.

- Thermal Expansion Coefficient: This is a property that influences dimensional stability. Enormous expansion leads to changes in size of parts when hot. You should set tolerances accordingly.

- Work Hardening Tendency: Certain alloys become harder as they are cut. A typical example is the austenitic stainless steel. Sharp tools and correct feeds are needed to prevent problems.

Comparison Table: Machining Different Types of Alloys

| Alloy Type | Mechanical Properties | Physical Properties | Machinability | Common Machining Techniques | Challenges | Applications |

| Carbon Steel | High strength, moderate ductility, hardness varies (100-400 HB) | Density: ~7.8 g/cm³, moderate thermal conductivity (~50 W/m·K) | Good; easier to machine at lower carbon content | Turning, milling, drilling, grinding | Tool wear with high-carbon grades, chip control | Automotive parts, machinery, tools |

| Stainless Steel | High strength, good corrosion resistance, hardness (150-300 HB) | Density: ~7.9 g/cm³, low thermal conductivity (~15-30 W/m·K) | Moderate; work hardening common | Turning, milling, drilling, EDM | Work hardening, heat buildup, sticky chips | Medical devices, aerospace, kitchenware |

| Aluminum Alloys | Low strength, high ductility, low hardness (30-100 HB) | Density: ~2.7 g/cm³, high thermal conductivity (~150-200 W/m·K) | Excellent; soft and easy to cut | High-speed milling, turning, drilling | Chip control, burr formation | Aerospace, automotive, electronics |

| Titanium Alloys | High strength-to-weight ratio, moderate hardness (250-350 HB) | Density: ~4.5 g/cm³, low thermal conductivity (~7-20 W/m·K) | Poor; high strength and low conductivity | Turning, milling, cryogenic machining, EDM | High tool wear, heat buildup, work hardening | Aerospace, medical implants, turbines |

| Nickel-Based Superalloys (e.g., Inconel) | Exceptional strength, high hardness (300-450 HB), creep resistance | Density: ~8.2 g/cm³, very low thermal conductivity (~10-15 W/m·K) | Very poor; difficult to machine | EDM, grinding, cryogenic machining | Extreme tool wear, heat generation, surface integrity | Gas turbines, aerospace, nuclear reactors |

| Copper Alloys | Moderate strength, high ductility, low hardness (50-150 HB) | Density: ~8.9 g/cm³, high thermal conductivity (~300-400 W/m·K) | Good; soft but can be gummy | Turning, milling, drilling | Burr formation, tool sticking | Electrical components, heat exchangers |

| Magnesium Alloys | Low strength, high ductility, very low hardness (40-80 HB) | Density: ~1.8 g/cm³, moderate thermal conductivity (~50-100 W/m·K) | Excellent; very easy to machine | High-speed milling, turning | Flammability, chip ignition risk | Automotive, aerospace, electronics |

Tools and Materials for Alloy Machining

Cutting Tool Materials

High-speed steel (HSS) is suitable with softer metals such as aluminium or copper, and is strong, easily re-sharpened, and economical on short runs. Carbide tools are appropriate with steel, titanium, and harder alloys and have higher speeds and edge life, and coated carbide tools are resistant to wear and heat. Ceramic tools are used with high-temperature alloys such as Inconel, allowing high speeds, but not good at interrupted cuts. Polycrystalline diamond (PCD) is used on ultra-hard non-ferrous alloys and cubic boron nitride (CBN) on hardened steels and superalloys. Both are excellent in wear protection and precision at high-volume production.

Tool Coatings

Titanium Nitride (TiN) can be used to improve the wear resistance of general machining. It minimizes the friction and stops the material sticking to the tool. TiN is suitable on stainless steel, aluminum alloys and steel. Titanium Aluminum Nitride (TiAlN) is used with high temperatures and harder alloys. It creates its own protective layer of oxide that keeps it hard at high temperatures. DLC decreases the friction of non-ferrous alloys such as copper and aluminum. Do not apply DLC on ferrous metals because heat can destroy it.

Tool Geometry

The rake angle can be varied to manipulate chip flow and minimize cutting forces. Soft alloys are suited by positive angles, hard metals by negative angles. Prevention of rubbing and enhanced edge strength occurs through clearance angle. Better surface finish and precision is achieved through proper selection. Chip formation and chip surface quality are influenced by edge radius. Soft metals are more suited to sharp edges, hard alloys to honed. Proper radius increases tool life and keeps dimensions.

Coolants and Lubricants

Cutting zone is cooled with water-based fluids and flushes away chips. Higher cutting performance on harder alloys is achieved by using oil-based lubricants. Dry machining is applicable in high temperature metals. MQL and biodegradable coolants minimise waste and conserve energy. The two approaches enhance safety in the workplace and promote sustainable machining. Appropriate selection of coolants improves the surface finish and minimizes tool wear.

Conventional Machining Techniques

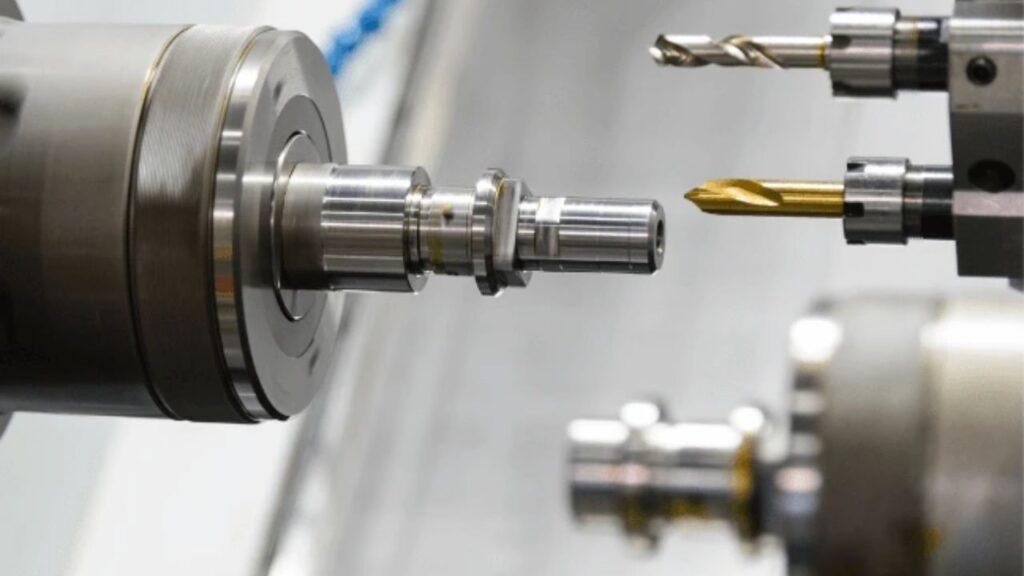

Turning

In turning, the workpiece is rotated and the cutting tool takes away the material. You frequently employ carbide inserts when you want strength and heat resistance. Turning is applicable to machinable alloys like steel, aluminum. Feed rates must be kept constant to avoid tool chatter. Sharp tools should be used to minimize stainless steel work hardening. Regulate cutting speed to achieve the balance between tool life and surface finish.

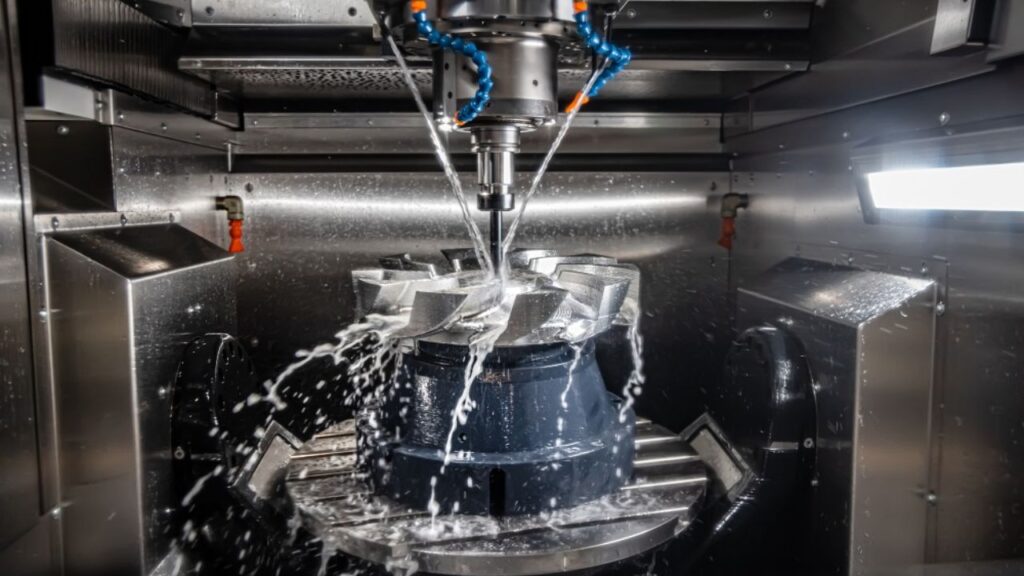

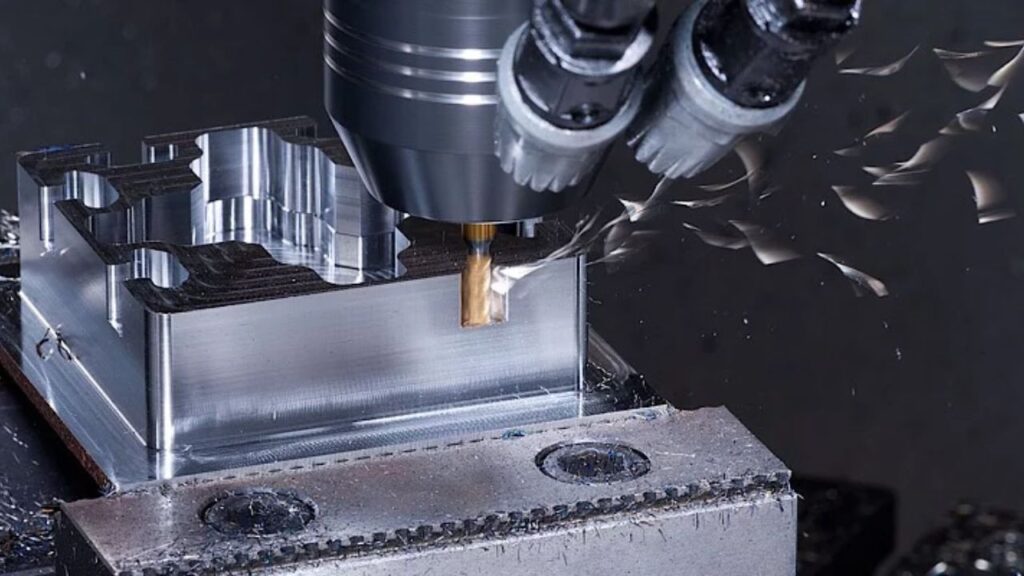

Milling

The rotating cutter is called the milling cutter and is used to cut away material on a stationary piece of stock. The face milling forms flat surfaces and end milling forms edges and slots. Low hardness makes aluminum alloys suitable to be milled at a high speed. To minimize tool wear, slow down in tougher alloys. When possible, secure work rigorously in order to avoid vibration. Temperature and accuracy were achieved by use of coolant.

Drilling

Drilling produces circular holes with the help of twist drills or special bits. Slower speeds and increased feed rates are required in hard alloys such as titanium. Choose cobalt or carbide drills to use because they are strong and resistant to heat. Clear chips in deep holes with peck drilling. Continue coolant circulation to avoid overheat and bit damage. Maintain drill bits sharp in order to maintain quality holes.

Grinding

Grinding involves the use of abrasive wheels to give surface a fine finish. Superalloys and tool steel frequently need grinding following the machining. Select the right type of abrasive to the hardness of the alloy. Regulate the speed of the control wheel to avoid burning the surface. Cool by using coolant to ease off heat and enhance finish. Periodically dress the wheel to keep cutting efficiency.

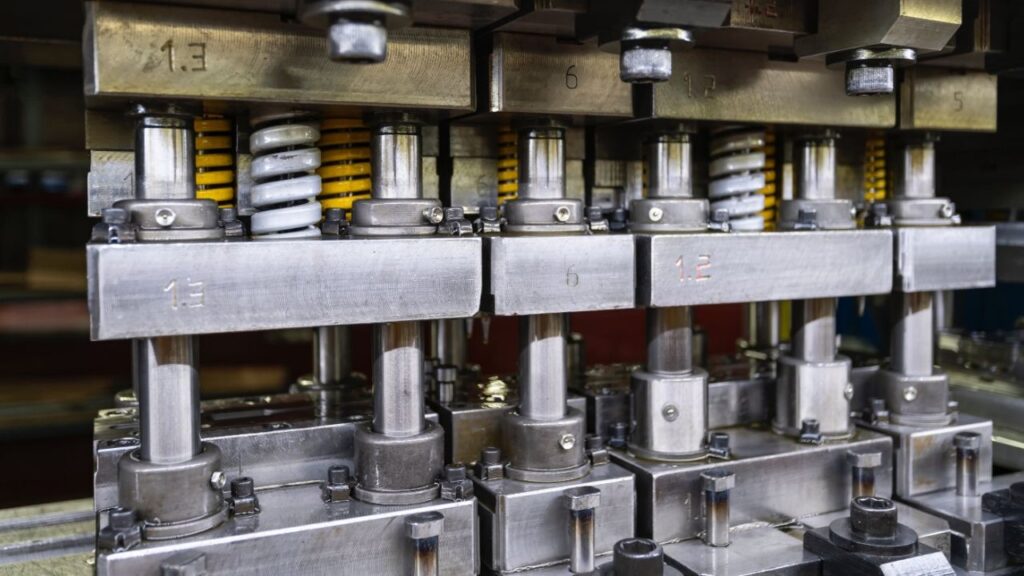

Stamping

Stamping is a process of forming metal sheets with high-pressure dies. You press the material against a punch and die to shape accurate parts in a short time. Depending on complexity, you can use progressive, transfer, or single-stage stamping. Stamping provides you with repeatability and accuracy in high-volume production. You should observe good die maintenance to prevent defects as well as tool life.

Non-Conventional Machining Techniques

Electrical Discharge Machining (EDM)

Machine titanium and Inconel using EDM. It removes material by electrical sparks, without the physical contact of a tool. You are able to achieve complicated profiles and close tolerances. Part integrity is preserved by small heat-affected zones.

Laser Cutting

Laser cut with thin alloy sheets that require precision. A laser is used to melt or vaporize material by means of laser energy. You may draw intricate patterns fast and cleanly. It is effective on stainless steel, aluminum and titanium.

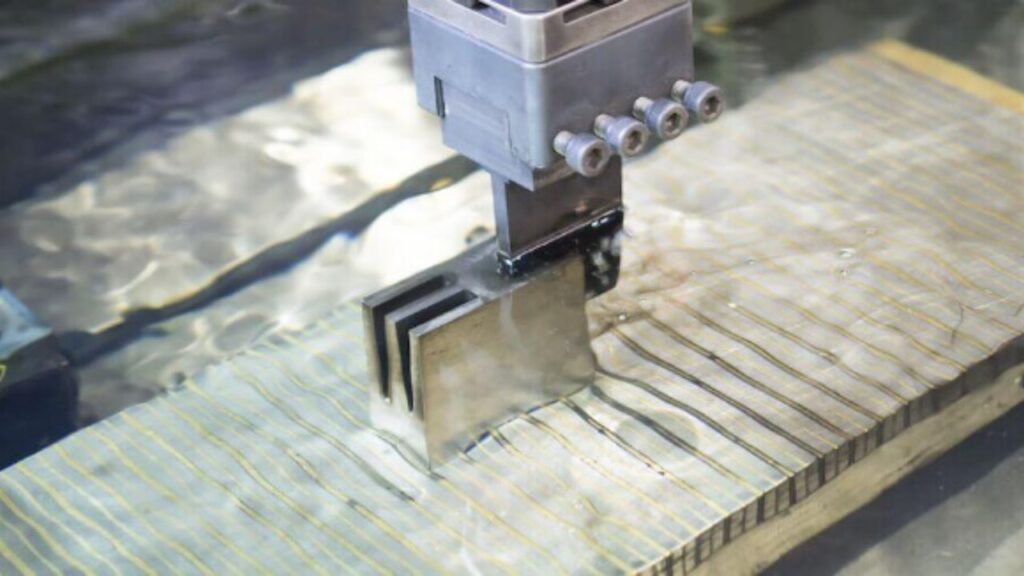

Waterjet Cutting

Waterjet cutting should be applied to heat-sensitive alloys such as aluminum and copper. Abrasive water cutting is done under high pressures and without heat distortion. You are able to process thick materials in good edge quality. During the cut structural integrity is maintained.

Ultrasonic Machining

Brittle or hard alloys should be machined using ultrasonic machining. Material is removed efficiently by high-frequency vibrations with abrasive slurry. Cavities and holes you can produce in detail. The technique provides low tool wear and fine finishes.

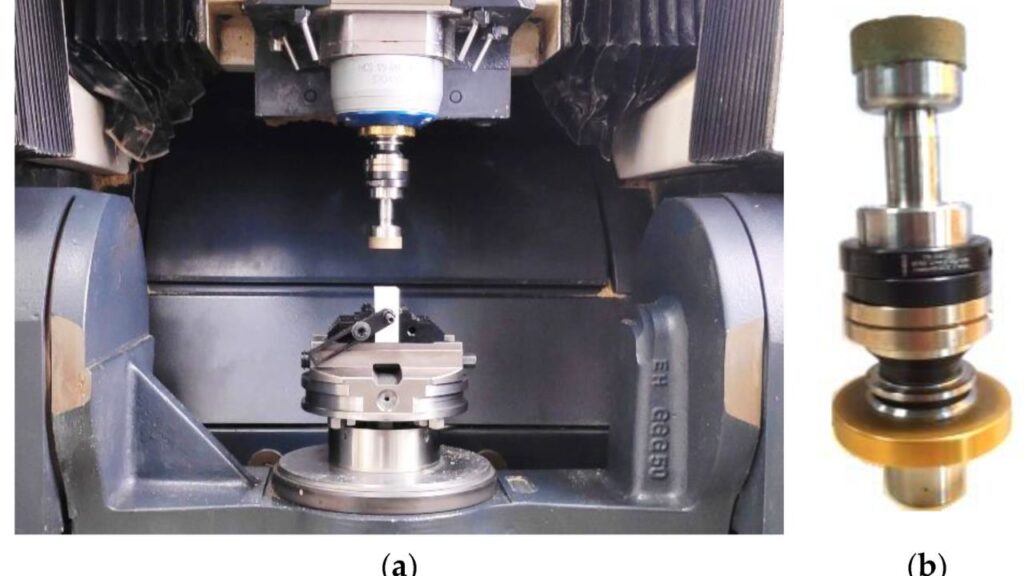

CNC Swiss Machining

CNC Swiss machining is specialized in small and complex production with close tolerances. The workpiece is rotated and several tools are used at the same time as much as possible. The guide bushing helps hold the material near to the cutting area with minimal deflection and vibration. Complex features can be machined in a single setup and the cycle time is shortened. This process is perfect when you want precision parts of a medical machine, aerospace or electronics.

Automatic Lathe Machining

Automatic machining on lathes allows you to make large numbers of turned parts without close attention. You insert bar stock into the machine which automatically turns, drills, and threads. Once set up, you can make endless production with little operator intervention. The automated tooling enhances efficiency and downtimes. You are supposed to measure the wear of the tool to ensure that the accuracy is maintained in long production runs.

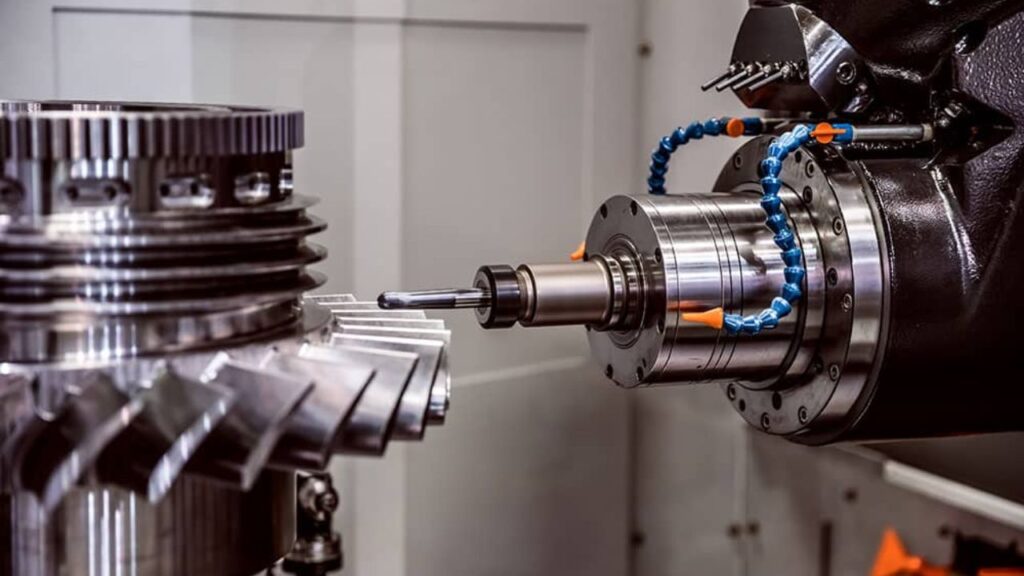

CNC Turn and Mill

CNC turn and mill machines are lathe turning and milling machines integrated into a single machine. A part can be turned around on a lathe, then milled using cutters to produce slots, flats or more complex shapes. This integration controls handling time and enhances accuracy of dimension. It makes it possible to do parts in fewer setups and increase productivity. The versatility enables you to work on both basic and multi-axis jobs.

High-Speed Machining (HSM)

High-speed machining employs increased spindle speed and feed rates to reduce machining time and increase productivity. You cut more per pass and keep accuracy and fine surface finish. The problems are high rate of wear on the tools, heat generation and vibrations. These can be controlled by ensuring that the machines are rigid and also by ensuring that proper cooling is provided. HSM is really suited to aluminum alloys, specialized stainless steels, and ductile metals. Use coated tools and adjust the speeds, feeds to get the best results.

Cryogenic Machining

The cryogenic machining involves instant cooling of the cutting zone using liquid nitrogen or CO 2. This dissipates heat, eliminates thermal expansion and maintains dimensions. It works very well on titanium and nickel-based superalloys and lowers friction and increases tool life. At increased cutting speeds, you obtain smoother finishes. Aerospace uses are turbine blades and other high tolerance critical parts. It also minimizes the requirements of post-processing.

Cost of Machining

Cost Factor Overview

There are three principal machining costs to you, namely, material, tooling, and labor. The cost of the materials is subject to the price and the stability of the alloy. Tooling and labor encompass the purchase, maintenance, installation and wages of skilled operators.

Alloy Type Effect

The type of alloy alters the time and complexity of machining. Stainless steel makes tools wear out quicker, and the cutting rates decrease. Aluminum can be cut at higher speeds, whereas titanium has to be cut at lower speeds and with special cooling.

Wear and Replacement of Tools

Tool life is greatly diminished by hard alloys. Regular worn-outs enhance expenses and outages. Life and efficiency can be enhanced by the use of coated or advanced tools.

Complexity and Setup Time of Machining

Complicated components require more programming, fixtures and adjustments. The precision work has several test cuts prior to production. The greater the number of steps, the more labor and machine time.

Economies of Scale

Increasing the volume of output decreases unit cost. Tooling and setting up expenses are distributed between more quantities. This renders large-volume runs cheaper and more predictable.

Cost Mitigation

The cutting parameters should be optimized to save time and waste. Automation decreases the work and promotes repetition. Preventive maintenance eliminates production shutdowns that are costly.

Challenges and Solutions in Alloy Machining

- Work Hardening: You encounter work hardening when machining alloy such as stainless steel or titanium. The surface of the material gets harder and cutting becomes more difficult. Apply reduced cutting speeds and max feed rates. Ensure that tools are sharp at all times so as to have a smooth cut.

- Thermal Management: Titanium and Inconel are low-conductivity alloys, which experience heat buildup. Too much heat decreases the life and precision of tools. Use cryogenic cooling or high-pressure coolant. Optimize the tool paths to reduce the concentration of heat.

- Tool Wear: Hard materials such as superalloys and tool steel produce an excessive wear on tools. This is less productive and more expensive. Employ superior materials such as CBN or PCD. Use protective layers and optimize the cutting parameters. Rotate monitors to schedule early tool replenishments.

- Chatter and Vibration: Chatter and vibration are the results of machine instability and bad setups. These damage the surface finish and accuracy. Apply damping systems and stiff arrangements. Adjust the speeds of spindles to minimize vibrations. Fix the workpiece so that it does not move.

- Environmental and Safety Issues: Safety and sustainability are affected by the use of coolant waste, dust, and excessive energy consumption. Identify environmental friendly coolants and dust collection systems. Use machines that have less effect on the environment. Train employees about safe practices in handling and disposal.

Applications of Alloy Machining

Aerospace Industry

You utilize alloy machining to make turbine blades, landing equipment, and structural components. Titanium/Inconel/aluminum prevail, as their strengths have a good balance to weight ratio. You have to achieve close tolerances on safety-critical performance. Tool wear and heat buildup are always a problem.

Automotive Industry

You make machine engine blocks, pistons and gears of steel, aluminum and magnesium. Such alloys enable you to save weight without compromising strength. Compact structures enhance fuel economy and reduce emissions. Accuracy guarantees an excellent fit and operation of parts.

Medical Industry

You can make orthopedic implants and surgical instruments using titanium, stainless steel and cobalt-chromium. It must be biocompatible to prevent rejection within the body. You also provide good surface finish under hygienic and safety reasons. Constantcy sustains patient confidence and device dependability.

Energy Sector

Your products are machine made nickel superalloys and stainless steel wind turbine hubs and nuclear reactor parts. These are corrosion and high heat resistant alloys. Reliability of machining accuracy is required in extreme conditions. The durability over long periods avoids expensive down times and failures.

Emerging Applications

You carry out hybrid production by combining additive manufacturing and machining. This enhances economical use of materials and flexibility in design. You print alloy parts to be completed to performance. New opportunities are created in bespoke production due to hybrid techniques.

Best Practices for Alloy Machining

- Pre-Machining Preparation: Before machining the alloy, you will need to test it and characterise it. This makes you familiar with hardness, ductility and thermal properties. Choose cutting tools and cutting parameters appropriate to the machinability of the alloy. Proper preparation minimizes the wear of the tools and eliminates expensive mistakes.

- In-Process Monitoring: Monitor the temperature, vibration, and tool wear during cutting using sensors. The monitoring in real time will enable you to identify the issues at an early stage. Compensate damage instantly by adjusting feeds, speeds or coolant flow.

- Post-Machining Inspection: Examine the surface finish via profilometer to measure roughness. Use CMM to check dimensional accuracy to achieve the tolerance. Verification involves checking the industry-standard by parts.

- Training and Skill Development: Train and acquire skills to work with complex alloys. Keep abreast of contemporary machining processes and techniques. Study micro-machining of small, precise alloy parts of electronic devices.

Conclusion

You have to match the tools, the techniques, and the parameters to any material in alloy machining. Proper selection enhances efficiency, precision, and quality of the surface. Never overlook alloy hardness, thermal qualities and machinability. Maximize the use of speeds, feeds, and coolants. Check tool wear so as to preserve accuracy. Keep abreast with new machining technology and processes. Change with the changing requirements of alloys in industries. This way, you will have quality, safety, and readiness in any project.