CNC Steel Machining 101 – The Complete Beginner’s Guide

Steel CNC machining is an essential part of the contemporary manufacturing industry with its unrivaled strength, durability, and precision. Steel is not easily machined compared to other materials; therefore, knowing its CNC process is essential in meeting the optimum results. Designing automotive parts or industrial components, no matter what you are doing, knowing the behavior of steel under CNC operations will save you time, tools, and cost. This guide will take you through all you need: the fundamentals and procedures, tools, finishes, types of steel and their uses, and insider secrets on how to be successful.

Table of Contents

ToggleCNC Steel Machining – Revealing Facts

Computer numerical control, enables you to program accurate movements of cut, drill, and shape. Steel is the right material in this process due to its strength, heat resistance and durability. Steel historically fuelled the industrialization and CNC introduced other-worldly precision to the equation. By selecting steel as your CNC, you have the advantage of tough steel, recyclable steel, and cost-effective steel and ideal in high-performance components of automobile, aerospace, and industrial uses.

Step-by-Step Process

The production of steel by CNC machining is done in a methodical, controlled procedure to provide precise and repeatable components. This is how it works in steps:

- Computer-Aided Design (CAD): First, you build a 3D digital representation with the help of Computer-Aided Design (CAD) software. This model determines the shape, size and characteristics of your steel part.

- CAM Programming: Then, you enter your design into a program that translates it into instructions that the machine can read (Computer-Aided Manufacturing programming). The software will create the toolpaths, feed rates, and spindle speeds of your CNC machine.

- Machine Setup: You will fit the right cutting tools, choose the proper workholding devices and home the coordinates of the machine. The correct installation provides accuracy in the machining process.

- Machining Execution: The CNC machine now does the job. It acts on the instructions you have programmed it to cut, mill, drill, tap, or grind the steel to the shape you want. This phase requires proper selection of tools, and the use of coolants to avoid wearing of tools, and heat damage.

- Inspection and Finishing: Lastly, you inspect the part with calipers, micrometers, or CMMs to check the tolerances. Depending on your finishing requirements, you can use deburring, polishing, or coatings.

Core Components of CNC System

In order to operate a profitable CNC steel machining operation, you must be aware of what it is comprised of. All the components are important in maintaining accuracy, speed, and reproducibility. This is what you ought to know:

- Controller: This is the brain of the CNC. It decodes your programmed instructions and controls the movements of the machine with utmost accuracy.

- Machine Tools: They are lathes, mills, grinders, routers. You pick the appropriate tool depending on the task you are undertaking, turning, milling or drilling steel.

- Work holding Devices: These are fixtures that keep your piece of steel in place, such as vises, chucks, and clamps. They keep things stationary and in line when machining.

- Software (CAD/CAM): You design the part using CAD and then use CAM to prepare a design in such a way that a machine can read it. This program will fill the gap between your idea and the machine doing it.

What Are the Key Operations in CNC Steel Machining?

Cutting Processes

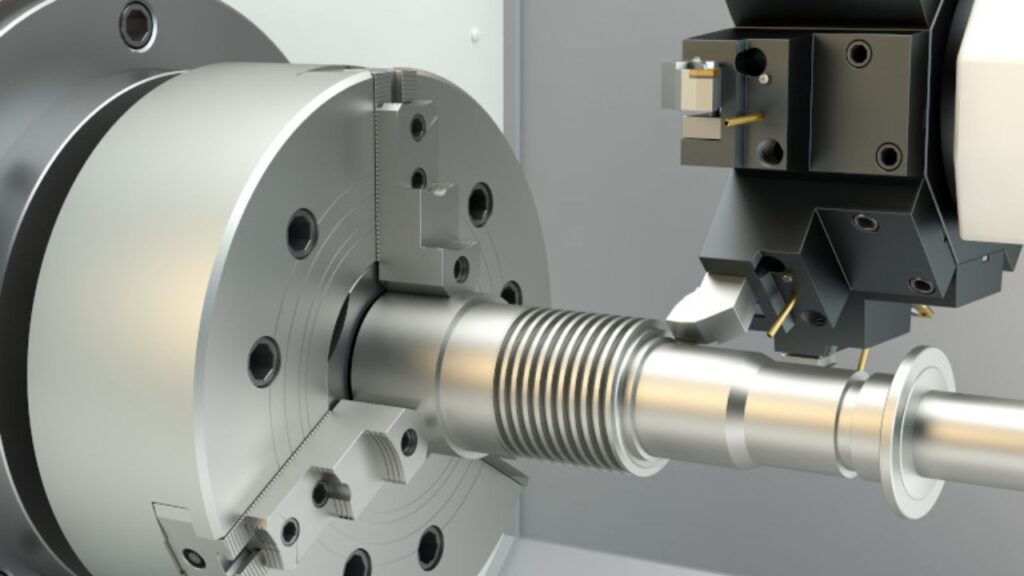

Turning

Turning enables you to form cylindrical steel parts such as shafts and spindles. The workpiece is rotated and the cutting tool removes the material. It is perfect when fine tolerances must be used on diameters and smooth finishes. You will depend on a turn to furnish parts that require roundness, straightness, and delicate surface finishes.

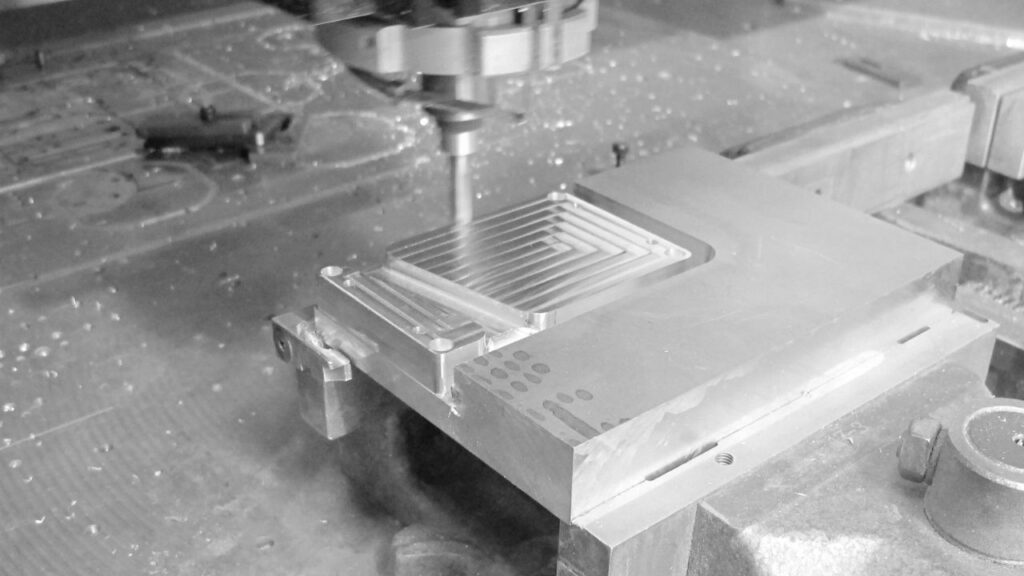

Milling

Your operation of choice when you need to cut slots, pockets, and intricate surface contours is milling. The rotating tool travels over the steel surface, and you can make very precise geometries. It is also applicable in machining flat or inclined surfaces and even 3D contours using multi-axis configurations.

Drilling

Utilize drilling where you require to produce holes with regard to bolts, fasteners, or passage of fluids. You will see it to be quick and precise and of absolute necessity in nearly all designs of steel components. You are able to make deep, aligned holes with structural integrity, with proper tooling.

Tapping

Tapping produces internal steel holes that are threaded. It would be necessary when you are putting things together by screws or bolts. Tapping done properly provides vibration-free joints that are secure. It is also possible to combine tapping and drilling in one setup so as to save time and enhance efficiency.

Grinding

When your need is high accuracy and mirror finishes, then grinding is the best. It is perfect to finish machined parts after rough machining, particularly when the quality of the surface is significant. The grinding process also assists you to get tight dimensional tolerances which other processes might not be able to achieve.

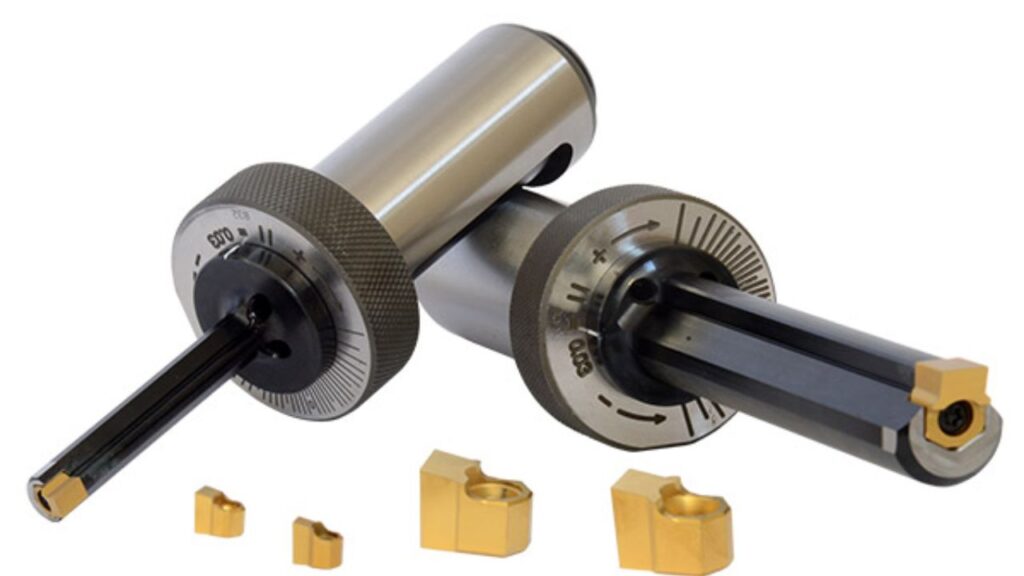

Boring

Boring expands pre-drilled holes to an exact diameter. Apply here when you require an ideal internal fit of shafts or bearings. It comes in handy in areas where high concentricity and smooth internal surfaces are crucial.

Broaching

Broaching assists in the cutting of keyways, splines and other intricate internal contours. It works very well on large production lots. Detailed internal profiles can be obtained in one pass with little secondary operations.

EDM

Hardened steel is excellent in Electrical Discharge Machining (EDM). You are able to create elaborate dies and molding features that are inaccessible to conventional tools. It operates through removal of material by electrical sparks and so is ideal on fine details and sharp internal corners.

Laser Cutting

Laser cutting provides you with a very crisp pattern or engraved marks. It is ideal to fit sheet steel and thin profiles. The fact that the process is non-contact minimizes tool wear and allows you to cut delicate features at a high speed.

Waterjet Cutting

Waterjet is perfect in case you deal with thick plates. It does not distort heat and keeps the original properties of steel. You can apply it to multilayer or composite steel components in which thermal processes can lead to the degradation of materials.

Forming Processes

Bending

Bending may be used to produce brackets, frames, or enclosures. It consists of the use of force to form steel sheets on a straight axis. To get clean, accurate angles, you will find yourself relying on press brakes or V-dies.

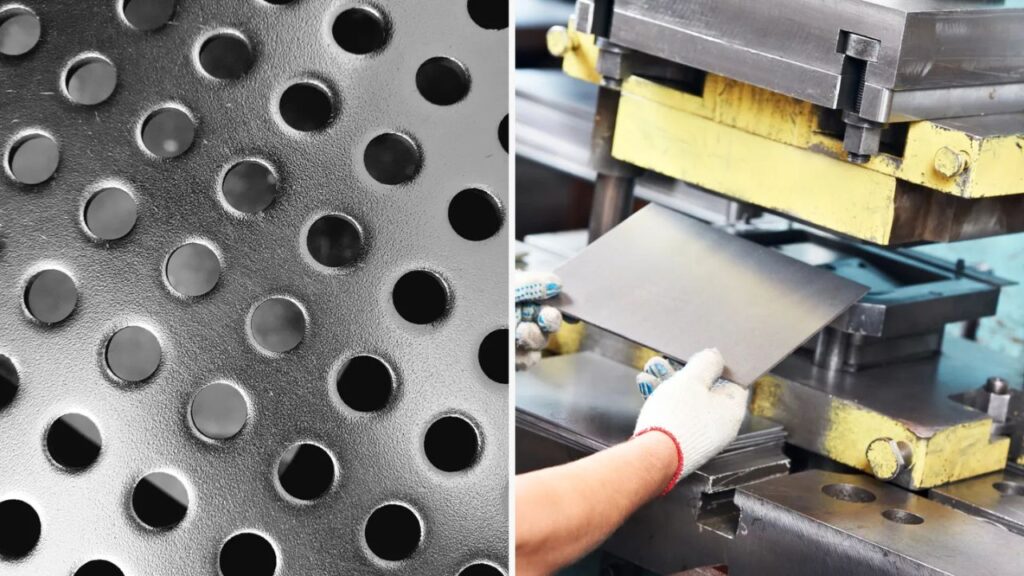

Stamping

When you are making huge numbers of the same part, stamping is your tool of choice. It is a high-speed, high-precision metal press that presses steel into dies in large quantities. Stamping is very automated thus cost effective when it comes to mass production.

Rolling

Rolling assists you in shaping flat sheets or profiles of steel. You will end up with thinner material that is uniform, which is ideal in structure. It also enhances grain structure and mechanical properties in a compressed manner.

Forging

Select forging when it is strength that counts. It pressurizes steel under extreme pressure, which makes it more durable and wear resistant. The most widespread application of forged parts is in the aerospace, automotive, and heavy machinery industries.

Extrusion

Extrusion should be used to produce long, even products such as tubes. It pushes hot steel through a shaped die to have a uniform cross-section. You will also enjoy reduced wastage and high dimensional accuracy.

Deep Drawing

Deep drawing produces hollow sections of seamless walls. It is perfect in containers, cylinders and metal housings with high integrity. The material flow will require a high level of control to avoid wrinkles or tear.

What Are the Types of Surface Finishes in Steel CNC Machining?

Surface finishes in steel CNC machining are vital in enhancing both the appearance, functionality, and durability. The selection of the proper finish is determined by the purpose of your part, where it is used, and the performance requirements. These are the key types that you should take into consideration:

- As-Machined Finish: This is the surface that is left on the CNC machine. You can see tool marks, but that is good when appearance is not key and tolerances are more important.

- Bead Blasted: This provides you with a smooth matte appearance because it uses fine glass beads to eliminate sharp edges and flaws. It is effective in non-reflective components that have a similar look.

- Anodizing (Type II and III): Steel does not have the ability to anodize in the same way that aluminum does, but certain alloys of steel, with certain treatment, can carry this finish. It provides corrosion protection and decorative surface- primarily on treated surfaces.

- Powder Coating: Powder coating is the best option when you need a colorful protective finish. It has great scratch, chemical and weatherability.

- Electroplating: It is the process that uses a metal coating such as zinc or nickel. It increases resistance to corrosion and it may make your steel component look polished and professional.

Admissible Feed Rate and Speed for Steel

Moderate input speeds and feed rates are required to cut as much as possible and minimize the heat build-up. Among them is the turning speeds of about 100-200 SFM with a feed rate of 0.01-0.2 mm/rev. Other parameters are proposed as:

| Process | Speed (SFM) | Feed Rate (mm/rev) |

| Turning | 100-200 | 0.01-0.2 |

| Cutting Off | 150 SFM | 0.06 mm/rev (for 1.4″ hole) |

| Drilling | 120 SFM | 0.04-0.08 mm/rev (for 1.7″ hole) |

| Reaming | -100 SFM | 0.06-0.13 mm/rev (for 1.7″ hole) |

| Tapping | Based on thread and diameter |

Admissible Steel Chemical and Mechanical Characteristics

You should know the chemical composition and mechanical properties of steel. Here’s the accurate data:

| Category | Property | Value |

| Chemical Composition | Chromium (Cr) | 16.0-18.0% |

| Nickel (Ni) | 10.0-14.0% | |

| Manganese (Mn) | ≤ 2.0% | |

| Silicon (Si) | ≤ 1.0% | |

| Carbon (C) | ≤ 0.08% | |

| Phosphorus (P) | ≤ 0.045% | |

| Sulfur (S) | ≤ 0.03% | |

| Mechanical Properties | Iron (Fe) | Balance (~66-74%) |

| Tensile Strength | 515-690 MPa (75-100 ksi) | |

| Yield Strength | 205-240 MPa (30-35 ksi) | |

| Elongation | 40% (in 2″) | |

| Hardness | 92 HB (Brinell) | |

| Density | 8.0 g/cm³ | |

| Thermal Conductivity | 16.2 W/m·K at 25°C |

What Tools Are Required in CNC Steel Machining?

In machining steel, it is important to have the right tools in place. All the tools have a particular role in terms of precision, durability, and safety in CNC operations.

Cutting Tools

You will require good quality end mills, drills, taps, dies, reamers, boring tools and inserts. These devices use different processes to form the steel which include milling, drilling, threading and finishing. Steel is hard and therefore you need to select carbide or coated tools to minimize wear and increase tool life.

Tool Holders

Ensure the cutting tools are secured with collets, chucks, or end mill holders. These materials are stable at high-speed machining. The right holders will allow you to reduce vibration and increase precision.

Workholding Equipment

Steel components have to be fastened tightly. You can hold the workpiece using vises, fixture plates, clamps and chucks. Tight tolerances and improved surface quality are achieved when your workpiece remains stable.

Inspection and Measurement Tools

You will need calipers, micrometers, gauges, and coordinate measuring machines (CMMs) to be accurate. These assist in checking that every cut suits your design requirements.

Support Equipment

You must also have good CNC controllers and CAD/CAM software. The tools are not overheated by coolant systems. Chip conveyors sweep away trash and spindle speeders and deburring tools improve efficiency and finish.

What Types and Grades of Steel Are Used in CNC Machining?

Stainless Steel

The 304 and 316 stainless steels will be your most common stainless steels when resistance to corrosion is a factor, perhaps in food-grade and marine environments. 410 and 430 are dependable in wear resistance and aesthetic finishes. 17-4 PH is ideal in aerospace parts, and is strong. Duplex steel is good when you require strength and corrosion resistance.

Alloy Steel

4130, 4140 and 4340 alloy steels are good alternatives when your project requires high strength and fatigue resistant. Their hardness in asking mechanical parts will be of benefit to you.

Carbon Steel

To make it easy to machine, 1018 offers a fantastic all-purpose alternative. Want to be stronger? Use 1020 or 1045 as a structural part or shaft. These are cheap steels that are easy to weld. They are also very easily available to prototype or mass produce.

Tool Steel

When making molds or dies, use D2, A2, or O1. These steels are wear resistant and also withstand pressure. They are ideal in demanding precision applications which require dimensional stability. You will enjoy their work even during severe machining stress.

High-Speed Steel (HSS)

M2 and T1 will come in handy when you need to make cutting tools that work at high speeds. These steels are hard even when exposed to high temperatures. They are excellent when you require robustness in constant or violent cutting cycles.

Structural/Specialty Steel

A36 and A572 are economical and versatile in construction work or infrastructure work. They are very weldable and formable. They are a safe bet when it comes to frames, beams and heavy duty support systems.

How to Select the Right Steel for Your CNC Project?

Selecting the correct steel to use in your CNC project directly influences performance, cost, and the amount of time it takes to produce. This is the way to make an intelligent choice:

- Outline performance requirements: Firstly, determine the needed strength, fatigue resistance, and corrosion protection. To illustrate, stainless or alloy steel would be preferable in case the part is under continuous stress or moisture.

- Inspect machinability: Not all steels are the same in terms of ease of cutting. You will need a combination of speed of machining and final accuracy. Steel such as low-carbon 1018 is simpler to machine, whereas tool steel can be more difficult to machine and may need slower speeds and special tools.

- Think about environmental exposure: Will your component be in a hot environment, subjected to chemicals, or in a wet environment? In such cases use stainless steel grades like 316 which are corrosion resistant.

- Post-processing planning: Plan your post-processing treatment. If the design needs heat treatment or coating, use a steel that can be heat-treated or coated.

- Match tolerances: High-precision applications require steels that have dimensional stability. Such steels as 4140 or 17-4 PH are preferable.

- Keep it lean: High-end steels are expensive and also perform. Ensure what you choose is functional and not extravagant.

Key Use Cases

When you use steel and CNC technology, you open the world of possibilities. This is where you will find it in use:

- Automotive: You can machine gearboxes, crankshafts, and axles to close tolerances. The components have to withstand stresses, which is why the strength and accuracy of the machining of steel come into play.

- Aerospace: You will use CNC steel machining in landing gear, turbine casings, and other structural components that are essential. The best quality steel parts are required in terms of safety and performance.

- Medical: CNC machining is used to produce surgical tools, implants, and device housings. Patient-safe components require clean cuts and high precision.

- Defense: When you are designing weapon systems or armored vehicle components, you can count on the CNC-machined steel to perform under extreme conditions.

- Industrial Machinery: Steel is wear resistant and is used in bearings, dies, and custom fixtures. You will save costs through downtime and prolong the life of equipment.

- Energy Sector: Steel products such as drilling heads, wind turbine shafts, and electrical contacts make power generation and transmission efficient.

- Consumer Products: CNC steel machining adds durability to kitchen appliances, electronic components, and long-lasting sports equipment.

- Construction: You will be able to create robust fasteners, support brackets and made to last custom structural components.

- Tool and Die Making: High quality production lines require precision molds and punches made of tool steel.

- Semiconductor Industry: CNC steel machining will allow you to work on thermal management components and EMI shields in high-performance electronics.

What Advantages Does Steel CNC Machining Offer?

Steel CNC machining introduces an effective set of strength, accuracy, and efficiency. This is why it ought to be your high-performance manufacturing solution:

Dimensional precision could not be matched

CNC machines provide you with close tolerances even down to microns. That makes sure that all the steel pieces you make fit into their areas of application in an optimal fashion.

Flexibility in design of complex and custom component

It is easy to generate intricate shapes, large hollowings, and small and subtle details. This agility enables you to prototype, iterate and scale designs effectively.

Reproducibility and volume-to-volume consistency

Whether you want to produce five parts or five thousand, CNC machining offers a uniform outcome. Every component is of the same specification, every time.

Better mechanical strength and durability

Steel is very strong in tensile and when machined in the right way, it maintains its structural integrity. You have stress, heat and pressure parts that are longer lasting.

Engineered surface finish

CNC steel machining provides smooth and un-distorted surfaces. There is a wide range of finishing technology, which simplifies additional polishing or treatment.

Reduced waste particularly during subtractive manufacturing

By having accurate toolpaths and material control, you minimize scrap. That saves you a buck and contributes to the sustainable manufacturing process.

Automation: Operates 24 hours a day

CNC machines are capable of running continuously with little supervision. This increases production without the increase in labor costs.

Mid to high volume cost savings

The setup cost can be high but the long-term savings are realized as the production increases. You are able to get lower per-unit pricing and quicker turnaround times.

What Are the Common Challenges in Steel CNC Machining?

Wear of tool caused by hardness of material

The high hardness of steel causes rapid wear of cutting tools. You will have to be more frequent in replacing tools that will add to your operational expenses and shutdown time.

Difficult CAM programming and setup time

It may be a time-consuming process to create efficient toolpaths with steel. You will have to consider cutting forces, cooling, and tool engagement which makes the CAM programming more intricate than during working with softer materials.

Equipment heavy investment

Machines that operate on steel need stronger frames, spindles and coolers. This implies that you will require a larger initial investment than when dealing with aluminum or plastic setups.

The shortage of experienced machinists

Machining of steel is not a first-comer. You will require skilled machinists who are familiar with the feed rates, speeds and the management of the tool life without sacrificing the quality of the parts.

Thermal warping in long-distance runs

Thermal expansion may also occur due to heat accumulating in steel parts, resulting in warped or internally stressed parts. This should be avoided by keeping an eye on temperatures and employing coolant efficiently.

Post-processing treatments impose an addition cost/time

Steel can be heat-treated, coated or deburred. They add some time and expense to your production process so make plans accordingly.

Potential dimensional distortion

The dimensional changes may be caused by residual stresses in steel, particularly following machining or heat treatment. To keep it accurate, you will have to be very careful about inspection and adjustment.

Considerations Factors for Right Service Selection

These are the things you should search:

Experience with Steel Grades:

Ensure that the supplier deals with a range of steel alloys, such as 304 stainless, 4140 alloy, and D2 tool steel. This will make them know the behavior of each grade under machining.

Industry Experience:

A service that is conversant with your industry e.g. aerospace, automotive or medical will be better placed in terms of meeting your technical and design requirements.

Ask Questions about Certifications:

Seek ISO 9001, AS9100, or ITAR certification. These demonstrate that the shop has stringent quality and traceability processes.

Assess the Production Capacity:

You require a partner with the capability to manufacture small prototypes as well as the large production runs without sacrificing speed and quality.

Learn About Their Tech Stack:

More flexibility to complex or tight-tolerance parts is available with the use of services utilizing 5-axis CNC, Swiss turning, EDM, and laser cutting.

Verifying Turnaround Time and Reliability:

The lead times ought to be quick, stable, and communicated. Time is money you cannot afford to lose.

Surface Finishing Capabilities:

Providers that have in-house bead blasting, coating or electroplating will save you having to work with several vendors.

Evaluate Customer Support:

Find proactive engineering groups that walk you through design adjustments or tolerance issues or selection of materials.

Think Sustainability:

Responsible manufacturing service providers are committed to waste and eco-friendly services, and they are long-term valuable.

Recommended:

CNC Swiss Masion provides fast prototyping, 0.01 mm tolerance and a broad material choice. Best suited to high precision, custom steel machining requirements.

Conclusion

CNC steel machining is at the heart of precision manufacturing and offers strength, accuracy, and repeatability in any industry. Whether aerospace or automotive, it is versatile enough to support complex, mission-critical components. The knowledge of properties of steel, machining types, and, finishing procedures will help you make sound design and production decisions. The choice of the CNC service will guarantee the best results and service efficiency. With the development of technology, which includes AI, automation, and eco-friendly processes, you will have more opportunities to advance innovation with the use of CNC steel machining.

FAQs

Which Is the Most Common Steel in CNC Machining?

304 stainless steel is the most common steel used in CNC machining. It provides a fantastic combination of toughness, corrosion resistance and low price. You will find it in other industries such as automotive, medical, and consumer products since it can be used in different environments. It is also food-safe, readily available, and as such a popular choice among CNC designs.

Which is the easiest steel to machine on CNC?

When you want the best machinability, 1018 carbon steel is the one to go. It machines well, has close tolerances, and does not take tools out rapidly. This is why it is frequently applied to prototypes and cost-effective uses. It will be useful to you in its dependability in simple designs and small production.

Which Steel is Most difficult to CNC?

D2 tool steel is one of the most difficult materials to machine. It is so hard and wear resistant that specialized tooling is needed. By working with D2, be ready to have slower speeds and sophisticated machining strategies.