Titanium Machining 101 – The Ultimate Beginner’s Guide

Titanium machining is crucial in the machining of aerospace, medical, marine, and automotive parts. Due to its strength, light weight and resistance to corrosion, titanium is a leading option, however, it is difficult to machine. This is why it is important to know how it behaves. It prevents tool wear and overheating, as well as bad finishes. This guide takes you through all the most important areas, including alloy, cutting tools, machining techniques and cooling strategies, so you can machine titanium with greater success, fewer mistakes and greater productivity.

Table of Contents

ToggleUnderstanding Titanium and Its Machining Relevance

Titanium is an ultra-performance metal that boasts strength-to-weight, resistance to corrosion and heat. It is also lighter than copper and approximately half the density of stainless steel. It is particularly useful where durability and biocompatibility are of importance such as in aerospace, medical, or marine applications. Titanium is more difficult to machine than aluminum or steel, because it retains heat and work hardens easily. However, when you deal with heat and select the appropriate equipment, you can take advantage of its unsurpassed strength and durability.

Challenges of Machining Titanium

Inherent Difficulties

When machining titanium, there are multiple built-in obstacles that may affect efficiency and the life of the tool. The knowledge of those difficulties will allow you to plan more properly and prevent expensive mistakes.

- Low thermal conductivity: Titanium retains heat at the point of cutting. Your tools will thus wear out sooner unless you employ high-pressure coolant and heat-resistant coating.

- Chemical reactivity: Titanium reacts with cutting tools during heating. It leads to chip welding and galling, particularly when you have a dull or uncoated tool.

- Work hardening: When your tool is in contact with your workpiece too long, the surface becomes hard. Then you will have a problem with stiffer incisions and quicker tool failure.

- Elasticity: Titanium has a low Young modulus, so it is easily bendable. It may cause chatter, deflection, and bad surface finish when your setup is not rigid.

- Stringy chips: Chips do not cut well and stick to tools. You should make sure there is appropriate chip evacuation or the tool and part will be damaged.

Impact on Machining

- Titanium will make you encounter a rapid wear of tools during machining because of the excessive heat concentration in the cutting area.

- Without temperature control, your tools will wear out more quickly and add to expenses and idle time.

- Accurate coolant techniques that employ high pressure or cryogenic cooling to cool a chip and expel chips are required.

- Absent a stiff arrangement, you run the risk of vibration and deflection, which will destroy surface finish and accuracy.

- Lack of proper planning will cause dimensional inaccuracies that you cannot afford in critical applications.

Titanium Alloys and Their Machinability

Commercially Pure Titanium (Grades 1–4)

These grades are unalloyed titanium and tend to be machined easier than their alloyed counterparts.

- Grade 1: It is the softest and the most ductile grade. It will be easiest to machine, particularly when the strength is not the primary concern.

- Grade 2: This is also referred to as the workhorse grade, which is balanced in terms of machinability, strength, and corrosion resistance.

- Grade 3: Provides medium strength. It is applicable to components that require higher strength than Grade 2 but are not very complex.

- Grade 4: The most powerful of the commercially pure type. It is not as easy to cut as the others, but with the right tools and parameters, you can still accomplish it.

Alloyed Titanium Grades

Titanium mixed with other metals such as aluminum, vanadium and molybdenum become stronger. However, there is a trade-off to that strength, which is, you will find it harder to machine.

- Grade 5 (Ti-6Al-4V): It is the most widely used titanium alloy. It is very powerful and resistant to heat, yet hard to machine. You will require sharp tools, high-pressure coolant, and parameters control.

- Ti-5-5-5-3: Provides even more strength and toughness. It is commonly found in aerospace and is extremely demanding to machine. You can anticipate more wear on tools and more time on machines.

- Ti-407: A more formable and softer alloy than Grade 5. It can be machine more easily and is a good alternative where formability is a consideration.

- Grades 7 & 11: These contain traces of palladium which enhances corrosion resistance greatly. They are normally applied under chemical processing as well as in marine conditions. That will require changes in the choice of tools.

- Grade 12: This is well known to be weldable and capable of withstanding high temperatures. This would be helpful in hot-forming processes, yet not impossible to machine.

- Grade 23 (Ti-6Al-4V ELI): A low-interstitial variant of Grade 5. It is more biocompatible and is applied primarily in medical implants. Machinability is like Grade 5 but a bit simpler because of fewer impurities.

Machinability Variations

Pure Titanium Vs Titanium Alloys

If you need easier machining, go with pure titanium such as Grade 1 or 2. They do not cause as much wear on your tools as they are less hard and do not contain tough alloying elements. But in case your application requires a higher level of strength or resistance, you must replace your application to alloys- and that means that you will need to make some set-up changes.

Effects of Alloying Elements

The alloying of aluminum (Al), vanadium (V), or molybdenum (Mo) strengthens titanium and makes it more resistant to temperature. However, it also complicates machining. These factors lower thermal conductivity, lead to chip welding and higher tool load. You need top of the line carbide tools, coatings such as TiAlN, and optimized cutting speeds.

Tool and Parameter Considerations

Use trusty sharp tools with the right coating when machining Grade 5 or any other tough alloy. Minimise your radial engagement, maintain a regular feed rate and employ high pressure coolant. On softer grades, you may ease the parameters a little, but still, have good chip control to avoid galling or poor finishes.

Tools for Titanium Machining

The Tools You Will Need

Begin with carbide sharp tools. They are resistant to wear, and they perform satisfactorily at high temperatures. When you are dealing with coated carbide tools, then choose PVD or TiAlN coating, they enhance heat resistance. High-Speed Steel (HSS) tools can be used as an acceptable alternative to more demanding or smaller jobs. They decrease the accumulation of heat during small-diameter machining.

Apply high-end toolholders such as hydraulic chucks or anti-pullout holders in situations where the tool needs to be stable under high torque. Also, round inserts and variable helix geometry tools were also considered to mitigate chatter and to keep the cutting balanced.

Tool Coatings Matter

Your operation can either be made or broken by tool coatings. TiAlN coatings create a shielding layer of alumina which protects the tool against heat and friction. In case that you require yet more hardness, TiCN coatings are more resistant to abrasion and last longer under severe conditions.

The Importance of Sharpness

Never use dull tools. Blunt edges produce heat and gall. The use of sharp tools reduces cutting forces, enhances surface finish, and increases tool life. Sharpen them on a regular basis to maintain performance.

High-Feed Mills

To rough, the large-radius edges of high-feed mills allow you to take a lot of material at once. They produce thinner chips, reduce temperatures and enhance productivity.

Select the Appropriate Inserts

Choose powerful insert shapes with solid corners and second relief angles. Round or toroidal inserts spread the force evenly, minimise chatter of the tool, and make you more effective at machining titanium.

Machining Parameters for Titanium

Operating with titanium, it is important to choose the correct parameters in order to obtain precision, reduce wear, and achieve a longer tool life. You should find a compromise between efficiency and thermal management. Use a cutting speed of 40-150 m/min, but lower the range on hard alloys and increase it on softer alloys. Set the feed per tooth 0.03-0.15 mm. This aids you in the removal of material effectively without overloading the tool

Optimize Radial and Axial Interface

Radial engagement should be less than 70%. This limits contact area, limiting the amount of heat produced and preventing the tools breaking. It also aids cooling fluid to the cutting area enhancing chip removal. Modify the axial depth of cut according to the grade of titanium and rigidity of tools. Shallow cuts are more suited to high-strength alloys, whereas deeper cuts are suited to the softer grades with stable setups.

High-Pressure Coolant Use Should be Wise

Coolant pressure is important Use pressure systems of 70-100 bar. This high-pressure stream evacuates chips rapidly and avoids recutting and welding of chips. You also minimize heat at the cutting edge, and that increases tool life by a considerable margin. Moreover, you can speed up feed rates without fear of heating damage. By adhering to these parameters, you will get smoother finishes and more consistent results.

Stages of Titanium Machining Process – Step by Step

Workholding and Material Selection

The first step is to select the appropriate grade of titanium to suit your application. An example is Grade 5 for aerospace or Grade 23 medical implants. After the workpiece is chosen, fix it in rigid fixturing. This action will prevent vibration, deflection, and surface error in cutting.

Tool Selection and Coating

Carbide: TiAlN or TiCN coated tools. Such coatings aid in resistance to heat and wear. Select the right tool based on the titanium alloy and the complexity of the job. Tools should be sharp at all times to reduce the cutting force.

Roughing

Start with roughing to get rid of bulk. Apply steady tool cuts such as trochoidal or plunge milling. Maintain radial engagement to a minimum and use high-pressure coolant. The arrangement will assist you to control the accumulation of heat and increase the life of the tools.

Semi-Finishing

Now strive to improve the tolerances. Slow down the speeds and feed rates. Keep the chip load low to prevent surface damage.

Finishing

High precision now uses sharp tools and light cuts. Emphasis on the quality of surfaces and accuracy of dimensions. You wish to have the end product of precise specification.

Post-Machining Processes

Lastly, do deburring and polishing. Conduct non-destructive testing and inspection on critical components to check quality and quality assurance.

Machining Techniques for Titanium

Conventional Techniques

Turning

Apply low torque/high RPM. Keep the feed rates constant to prevent heating. Use PVD or TiAlN coated tools to resist wear and galling. You must also have rigid setups to minimize vibration and have dimensional accuracy.

Milling

The most suitable option is climb milling. Radial engagement should be kept low and tools should have more flutes to spread the heat more evenly. This reduces chatter and increases surface finish. Never vary the cutting paths in order to prevent work hardening.

Drilling

Use TiAlN coated drills. High-pressure coolant and peck drilling should be used always to flush chips and prevent chip welding. To avoid deflection and burr formation, pay attention to the tool alignment.

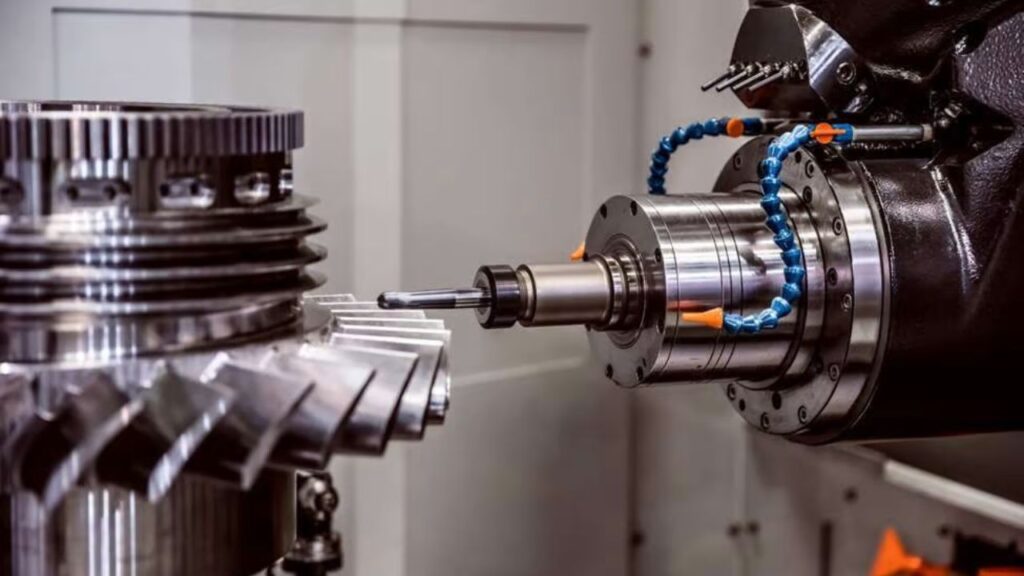

CNC Turning and Milling

Precision cuts of titanium: CNC milling and turning. With sophisticated software you are in control of the process. Tune speeds and feeds to titanium characteristics. This process will achieve high accuracy on complex parts.

CNC Swiss Machining

Consider CNC Swiss machining of small, detailed parts made of titanium. You feed a stock of bar through a sliding headstock Use it to achieve close tolerances with little waste. This process is appropriate to you when it is high-volume production.

Sawing

Select abrasive or carbide tipped blades. Keep feed rates moderate and use generous amounts of lubrication to prevent tooth wear and overheating. Be careful to ensure that the workpiece is held in a manner that prevents distortion when cutting.

Advanced Techniques

High-Speed Machining (HSM)

High speeds with shallow radial depths. You will also have increased feed rates and less heat. Lightweight tool holders should be used to minimize inertia and improve the response at high speeds.

Plunge Milling

Machine deep cavities by engaging axially. This reduces radial force and tool wear, particularly in hard titanium alloys. It also enhances chip removal in deep pockets or narrow pockets.

Electrical Discharge Machining (EDM)

EDM does not require cutting forces so it is most suitable to complicated shapes. Apply it when tight tolerances are required on complex geometries. It can be of particular use on features that are hard to access using conventional tools.

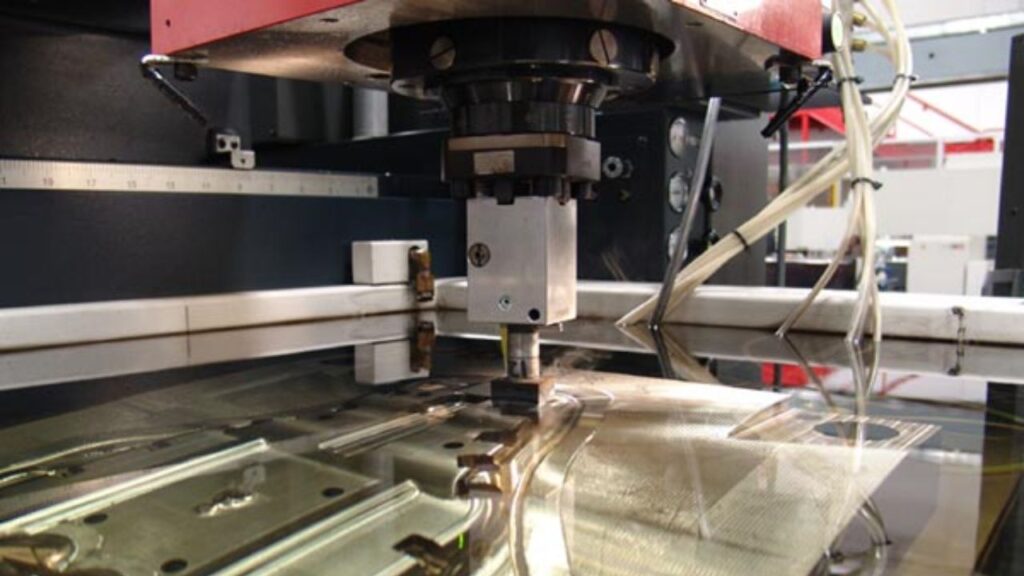

Waterjet Cutting

This thermally-neutral procedure does not include heat-affected areas. It can be used to cut titanium with little distortion of materials. It can also be used on thick areas where other techniques are difficult.

CNC Automatic Lathe Machining

Use CNC machine automated lathe to perform repetitive titanium operations. You fix it to manufacturing in a steady way. Use special tools to work with the strength of titanium. Count on it to produce at high and consistent quality.

Finishing Techniques

Grinding

Use cBN wheels and make controlled passes. You will also get tight tolerances and finishes on critical pieces. Heat should be always controlled during the grinding to prevent surface burns.

Polishing/Buffing

Decrease surface roughness and enhance fatigue strength. This is particularly applicable to medical or aerospace parts. Corrosion resistance is also improved after polishing by smoothing micro-crevices.

Deburring

You may use abrasive brushes or tumbling or thermal. These clear edges and make the part safe and dependable. Select the correct deburring procedure to maintain part geometry.

Sandblasting

Produce a uniform matte finish. Simply watch out when selecting media so as not to contaminate the surface of titanium. Keep surface integrity with fine, inert media.

Additive and Hybrid Techniques

Laser-Assisted Machining (LAM)

Laser preheat titanium locally. This makes the material softer and allows you to cut more easily, with less chatter and less tool wear. It can also provide increased cutting speeds at lower mechanical stress.

DMLS/EBM Additive Manufacturing

This can be applied to create complex shapes in layers. CNC finishing will be required after to make dimensional specs. It suits well to low-volume, high-complexity parts that include internal channels.

Hybrid Machining

Additive manufacturing + CNC. This will assist in making near-net shapes accurately, saving time and material. It also saves wastage because it avoids much of the excess stock out.

Admissible Feed Rate and Speed for Titanium

You can optimize your titanium machining process using the following feed rate and speed parameters. Tune the various input speeds and feed rates maximizing the cutting efficiency and minimizing the heat. The recommended settings are provided in the table below.

| Process | Speed (SFM) | Feed Rate (mm/rev) |

| Turning | 50-100 | 0.10-0.20 |

| Cutting Off | 50-75 | 0.05-0.10 (for 1.5″ dia hole) |

| Drilling | 40-60 | 0.04-0.08 (for 1.5″ dia hole) |

| Reaming | 30-50 | 0.03-0.06 (for 1.5″ dia hole) |

| Tapping | -100 | Based on thread and diameter |

Admissible Titanium Chemical and Mechanical Characteristics

| Category | Property | Value |

| Chemical Composition | Chromium (Cr) | 0.0-0.1% |

| Nickel (Ni) | 0.0-0.05% | |

| Manganese (Mn) | ≤ 0.5% | |

| Silicon (Si) | ≤ 0.1% | |

| Carbon (C) | ≤ 0.08% | |

| Phosphorus (P) | ≤ 0.04% | |

| Sulfur (S) | ≤ 0.03% | |

| Mechanical Properties | Iron (Fe) | Balance (0.5%-1%) |

| Tensile Strength | 895 MPa (130 ksi) | |

| Yield Strength | 825 MPa (120 ksi) | |

| Elongation | 10% (in 2″) | |

| Hardness | 36 HRC | |

| Density | 4.43 g/cm³ | |

| Thermal Conductivity | 6.7 W/m·K at 25°C |

Tool Path Strategies

Climb Milling

The cutter rotates with the feed when you apply climb milling. This forms thick to thin chips, which minimize friction and heat generation. You end up with superior chip evacuation and a finer finish. Milling climb also assists you in prolonging tool life through reduced wear and vibration.

Trochoidal Milling

In trochoidal milling, tool paths are curved so that tool load is maintained. This will lower the concentration of heat and inhibit work hardening. You will be able to feed faster without harming the material or the tool. It works perfectly when machining hard titanium alloys.

Constant Engagement Tool Paths

As you continue to work on it, your cutter will have a consistent arc of contact with the workpiece. This helps to avoid overloading, minimises chatter and spreads tool wear uniformly. You will increase the machining efficiency and achieve a better surface integrity during the process.

Coolant and Lubrication Techniques

During the machining of titanium, efficient coolant and lubrication methods are necessary. You have to manage heat, safeguard your tools, and make clean and precise cuts. This is what you ought to take into consideration:

- Flood Coolant Systems: These should be used to cool down fast, remove chips, and avoid overheating of tools.

- High-Pressure Coolant (HPC): Point pressurized jets at the cutting zone. You will minimize galling, enhance chip removal, and keep temperatures down.

- Cryogenic Cooling: Use liquid nitrogen or CO 2 to achieve extreme cooling. It is perfect when you are dealing with hard titanium alloys.

- Minimum Quantity Lubrication (MQL): This environmentally friendly mist is suitable when making light finishing passes. But do not use it to rough, or to cut deep.

- Best Practices: The combination of HPC and cryogenic cooling will give you the best results. These are processes that prolong tool life and improve chip control.

Emerging Techniques in Titanium Machining

The latest methods in titanium machining provide you with new opportunities to enhance precision, surface and tool life. These techniques minimize stress and heat accumulation that throws a major challenge in traditional machining.

- Cryogenic Machining: Sub-zero coolants, such as liquid nitrogen, are used to reduce cutting temperatures by a large degree. This minimizes wear of the tools and prolongs tool life, particularly in hard titanium alloys.

- Ultrasonic Machining: The vibration of the tools at a high frequency assists in cutting with fewer forces. It is perfect when you require to machine finer or thin features without ruining the part.

- Plasma Arc Cutting: This process involves the use of high-velocity ionized gas in cutting titanium in a clean way. It is possible to form parts with minimal deformation or strain.

- Chemical Milling (Etching): You use controlled chemical to dissolve titanium. It is ideal when you require complex contours and zero mechanical contact or wear of the tool.

Applications of Machined Titanium Parts

Titanium machined components play vital functions in several high-performance sectors. Due to the strength-to-weight ratio, corrosion resistance, and heat tolerance of titanium, you will discover it in systems where durability and precision are not optional. And this is where you can watch it in action:

- Aerospace: Titanium is machined to make components of jet engines, airframes, landing gears, and structural fasteners. It is strong to high temperatures and stress and is lightweight.

- Military: Titanium components drive missile systems, armor plating, and the structures of submarines. It is strong and corrosion resistant in both combat and marine conditions, to your advantage.

- Marine: Propellers, ballast tanks, and hull reinforcements are made of titanium. It is also strong against saltwater; hence can be used over a long period at sea.

- Medical: You can trust titanium on implants, pacemakers and prosthetics. It is biocompatible, which means that it will be incorporated safely into the human body.

- Sports Equipment: You want performance and lightness? Bicycle frames, golf clubs, and tennis rackets made of titanium do so.

- Automotive: Titanium is used in precision parts such as engine valves, brake parts and the exhaust system to increase performance and durability.

- Industrial: Titanium is resistant to severe reactions in chemical processing. You will also find it in heat exchangers and reactors.

- Power Generation: Titanium is used in turbine blades and the structure of power generation due to its stability at high pressures and temperatures.

Cost Considerations

Machining titanium is an expensive endeavor that can cost a pretty penny very easily. This is what you must observe:

Cost Drivers

- Raw Material- Titanium alloys: Titanium alloys have been priced at 20-50 dollars per pound. The extraction and refinement complexity makes this a high priced commodity.

- Machining Rates: You can expect prices to be between 50 and 300 dollars an hour, depending on the complexity of the part, your precision requirements, and the abilities of a shop.

- Tool Wear and Cycle Times: Titanium is tough and causes tool wear to be faster as well as slows down the speed, lengthening the overall production cycle and making it more expensive.

Cost Cutting Hints

- Maximize Cutting Strategies: Apply the correct speeds, feeds, and tool paths to avoid heating and prolong tool durability.

- Work with High-Efficiency Tools: Invest in coated carbide tools and high-tech holders. They enhance productivity and minimize scrap.

- Set Up Plan: Reduce the number of tool changes and part handling to save time.

- Chip Control: Clear chip evacuation ensures no damage and less rework.

Achieving Optimal Surface Finishes

Optimum surface finishes in titanium machining are both functional and aesthetic. You should adhere to specific strategies and use post-machining processes properly to achieve the best outcomes.

Surface Perfection Strategies:

- Apply sharp tools that minimize resistance to the cut and prevent ripping of the surface.

- Be sure to maintain your setup stable to avoid vibration and chatter.

- Use high-pressure coolant (HPC) to control heat and to flush chips.

- Adjust cutting parameters to optimize feeding, depth and speed.

- Use light finish cuts to smooth out the surface without causing stress.

Post-Machining processes that you should utilize:

- Polishing: Increases aesthetics and fatigue resistance, particularly on medical/aerospace parts.

- Grinding: Assists you in attaining close tolerances and smooth, dimensionally perfect finishes.

- Deburring: Cleans sharp edges and burr, which is safe and improves assembly accuracy.

- Anodizing: Anodizing increases corrosion resistance, and permits color coding where critical.

Design Tips for Titanium Machining

You must consider stability, accessibility and heat control when designing parts to be machined out of titanium. Vibration, wear on tools and part failure can be escalated by poor design. The following tips will prevent these problems and enhance the performance of the machining.

- No thin walls: Thin areas will deflect and chatter. Thicker and stiff features will provide you with improved stability and surface finish.

- Make sure there are clear chip evacuation routes: Titanium creates long, stringy chips. Failure to allocate sufficient space to allow chips to escape poses the risk of damaging the tool and overheating.

- Add chamfers: Internal sharp corners are stress risers. Load is more evenly distributed by the chamfers and the possibility of cracking or failure is minimised.

- Stable workholding design: You must always ensure that you design your work in such a way the part is held securely. Vibration and dimensional errors are caused by poor fixturing.

- Reduce tool overhang: the more the tool protrudes, the more it will deflect. Reduce overhang to maximize accuracy and minimize wear of tools.

Latest Advancements in Titanium Machining

The only option to remain a leader in titanium machining is to implement the latest changes, which enhance efficiency and minimize expenditures. Now, you can access the latest technologies that render titanium easier to handle than before. And this is what you can investigate:

- TiAlN and Nano-Coated Tools: The coatings increase thermal resistance and decrease wear. You have a longer tool life and a cleaner cut.

- Advanced Toolpaths: Dynamic and trochoid milling minimizes heat accumulation. You ensure that you have the same cutting loads and you avoid overloading your tools.

- Cryogenic Machining: Liquid nitrogen is used to cool the liquid that reduces the temperatures greatly. You are able to push feed rates without wearing out your tools.

- Ultrasonic Machining: In this method, high frequency vibrations are used to minimize cutting forces. It is perfect when you are doing something fragile or detailed.

- High-Torque CNC Machines: These have additional rigidity and power. You will detect less chatter and improved dimensional precision of hard titanium alloys.

Conclusion

Machining titanium requires precision, patience and a right strategy. Its durability and ability to resist both heat and corrosion as well as its strength make it perfect in critical industries but it is also hard to cut. You can eliminate the challenges such as tool wear and heat accumulation by choosing the appropriate alloys, tools, and cooling techniques. Working with Grade 2 or Ti-6Al-4V, it pays to know how titanium will behave so that finishes are smooth, tool life is increased, and results are positive. Keep up with the latest technologies, be on top of the trends in machining, and you will both improve performance and productivity.

Frequently Asked Questions

Is titanium harder to machine than aluminum?

Yes, Titanium is considerably more difficult to machine than aluminum, as it does not dissipate the heat generated at the cutting zone very well, it becomes work-hardened rather easily and has the tendency to wear out the tools rapidly. You will need special tools, reduced cutting speeds and high pressure coolant systems to cope with heat and precision.

Is Titanium More Difficult To Machine than Inconel?

Both are hard, but in different ways. Titanium is difficult to heat treat because of its low thermal conductivity and Inconel needs to be cut with abrasion and extreme toughness resistant tools. Your machining process will have to vary depending on the alloy and application.