What Is Heat Treatment? – The Complete Beginner’s Guide

The heat treatment is significant in changing the strength, hardness, and durability of metals. It assists you in strengthening material characteristics through precise heating and cooling. Regardless of whether you are using steel or any other alloy, the heat treatment process guarantees greater performance and durability. This guide will assist you to know what is heat treatment, the number of types of heat treatment process available and equipment such as a heat treatment furnace. You will also learn the important techniques, impacts, and best practices in a material science point of view.

Table of Contents

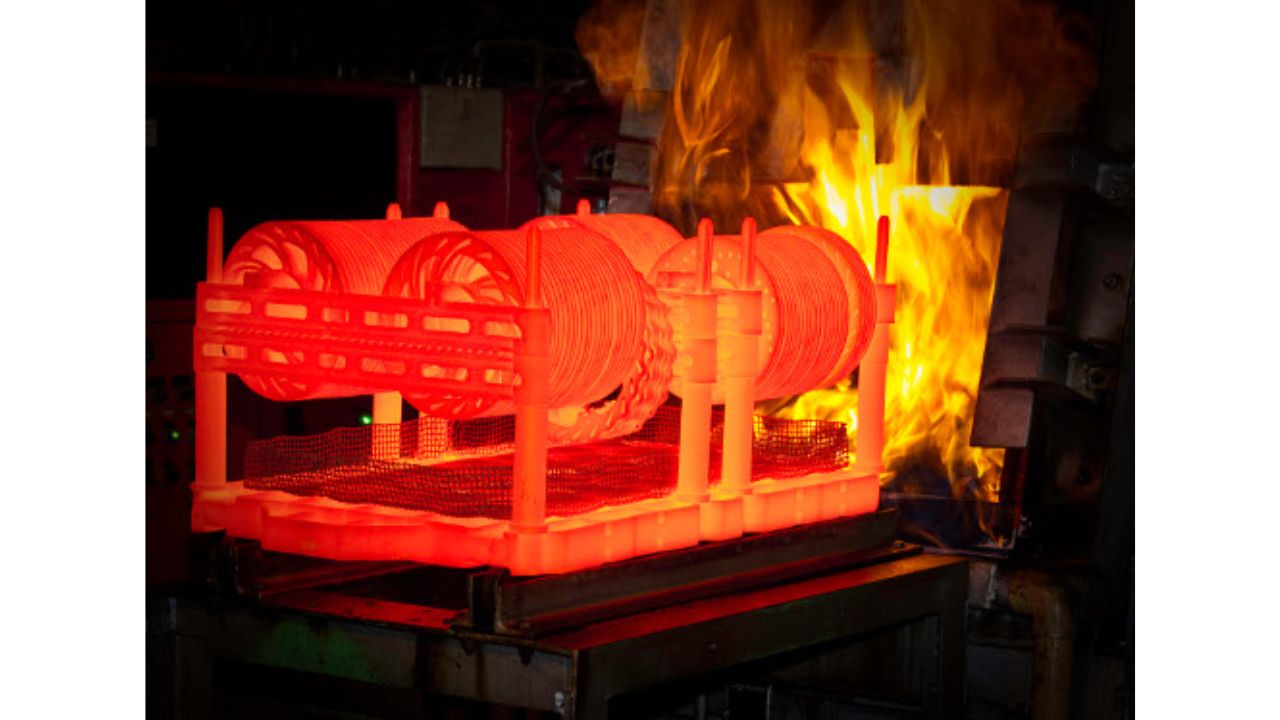

ToggleWhat Is Heat Treatment?

Heat treatment is a regulated process in which you cool and heat metals to modify their internal structure. It does not change the shape like mechanical processing or machining, but it changes microstructure. You employ it to enhance strength, hardness or ductility. The most heat-treated metal is steel because of its versatile characteristics. Nevertheless, you can also heat treat aluminum, copper and titanium to enhance their performance in different industrial applications.

Purpose of Heat Treatment

Increase Hardness and Strength

Heat treatment enables you to increase the hardness and strength of metals by a large margin. This is imperative when you require the use of parts that are resistant to wear like cutting tools or gears. The change in microstructure makes the material stronger and more able to sustain stress before deforming.

Improve Toughness

The toughness is the resistance of a material to absorb impact and not crack. By means such as tempering, it is possible to enhance the toughness of a metal. This implies that your parts could withstand quick jolt or strain without breaking down and is crucial in load bearing applications.

Eliminate Internal Stresses

Internal stresses tend to accumulate when metals are cast or machined. These have the ability to cause distortion or cracking. Heat treatment can assist you in expelling such stresses, enhancing the dimensional integrity of your components and minimizing deformation when the parts are in use.

Enhance Machinability

Heat treatment of a metal softens it and enables you to cut, shape, or drill it. This translates to shorter cycle times, reduced abrasion of the tools and improved surface finish particularly in mass volume production.

Enhance Corrosion and Wear Resistance

Heat treatment in this way enhances resistance to rust, chemical attack, and friction because of property changes on the surface. This assists you in prolonging the life of parts that are in harsh conditions or those that are subject to continuous movement like the valves or the shafts.

Structural Adjustment and Grain Refinement

The heat treatment enables you to perfect the grain size in the metal. The strength and ductility are enhanced by finer grains. This is structural control that provides you with improved performance in mechanical reliability and fatigue resistance.

How Many Types Of Heat Treatment Process?

Annealing

Annealing makes metal soft and more workable. You warm the metal to a certain degree and slowly cool it off in a furnace. This makes it less hard, enhances grain structure and makes it more ductile. It is applicable in cases where you need to recast or machine metal effectively.

Normalizing

Normalizing enhances uniformity of structure of grains. You warm up the metal to above its critical temperature and cool it in air. This enhances strength and hardness and preserves balanced ductility. It is the best when you require more durable elements but they cannot be too brittle.

Hardening

Hardening increases the hardness of the metal to a high level. You take it up to a critical temperature and rapidly cool it in water or oil. This clamps a hard microstructure. Apply it when you need high wear resistance of the surface.

Quenching

The cooling process after hardening is called quenching. You immerse the hot metal into a medium such as oil or water. This quench hardens the metal, and creates internal stresses that you have to deal with through tempering.

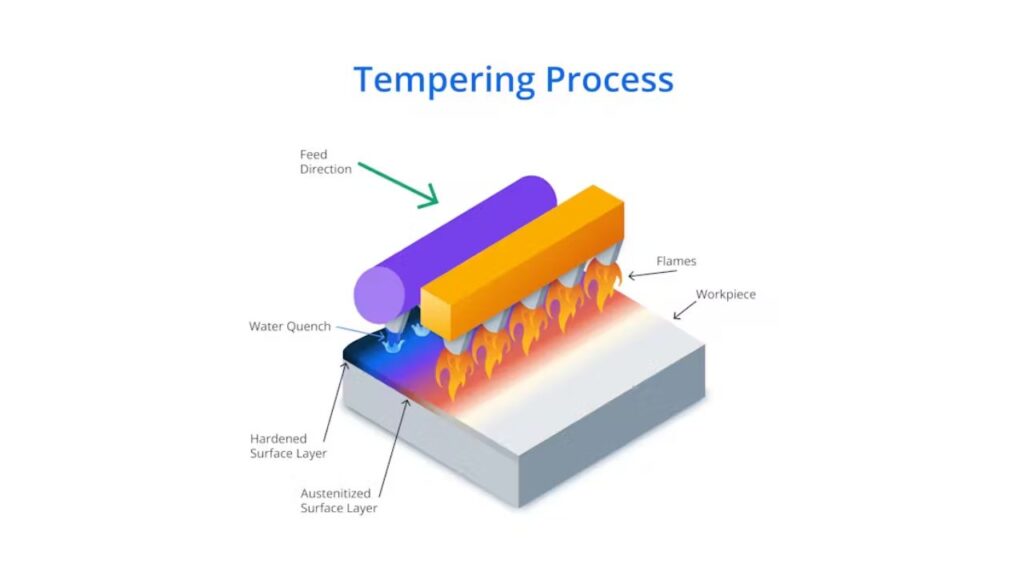

Tempering

Quenching is subsequently followed by tempering to lessen brittleness. You heat the solidified metal to a smaller temperature, and cool it down gradually. This resorts to ductility and increases toughness. Apply it when you require a tough but not so brittle component.

Case Hardening

Case hardening provides you with tough core and hard outer surface. You put the metal in a carbon rich atmosphere and heat it up and you quench it. This suits gears and parts that need wear resistance but would not compromise on toughness.

Carburizing

Carburizing is a process of adding carbon on the surface of the metal. You heat the metal in a carbon rich gas or solid to 850-950 degrees C and then quench it. The outer part becomes hard and the core soft. It is popular as transmission parts and bearing.

Nitriding

In nitriding, carbon is replaced with nitrogen. You raise the metal to 500-600 degrees C in an atmospheric load that is rich in nitrogen. Nitrogen enters into the surface and forms a hard layer. You can use it when high fatigue strength and wear resistance are required.

Cyaniding

The cyaniding is a low-cost rapid surface treatment. The metal is heated to 800 900 degrees C in a cyanide salt bath and quenched. This develops a hard surface layer rapidly. It works well with small items such as bolts and pins.

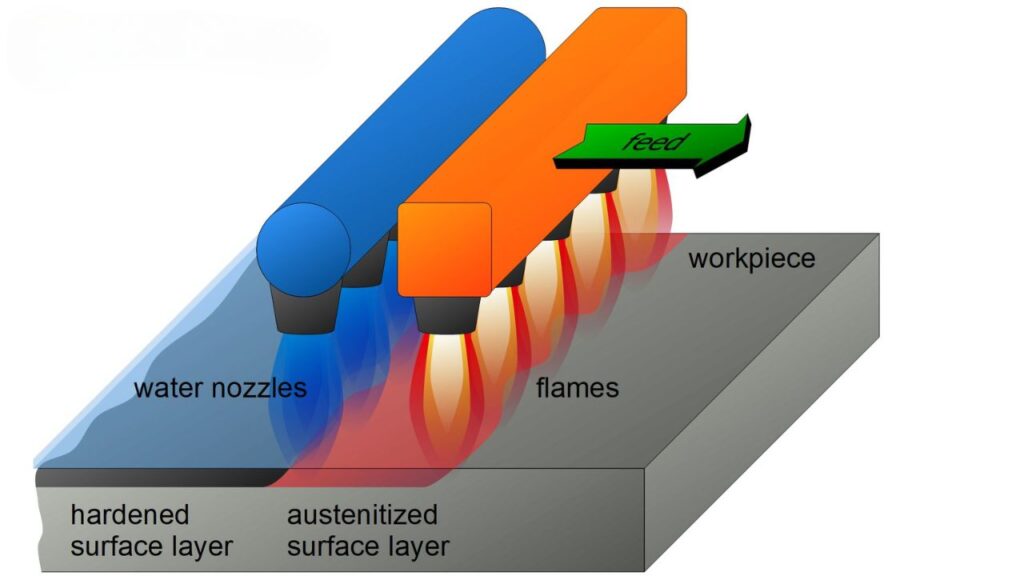

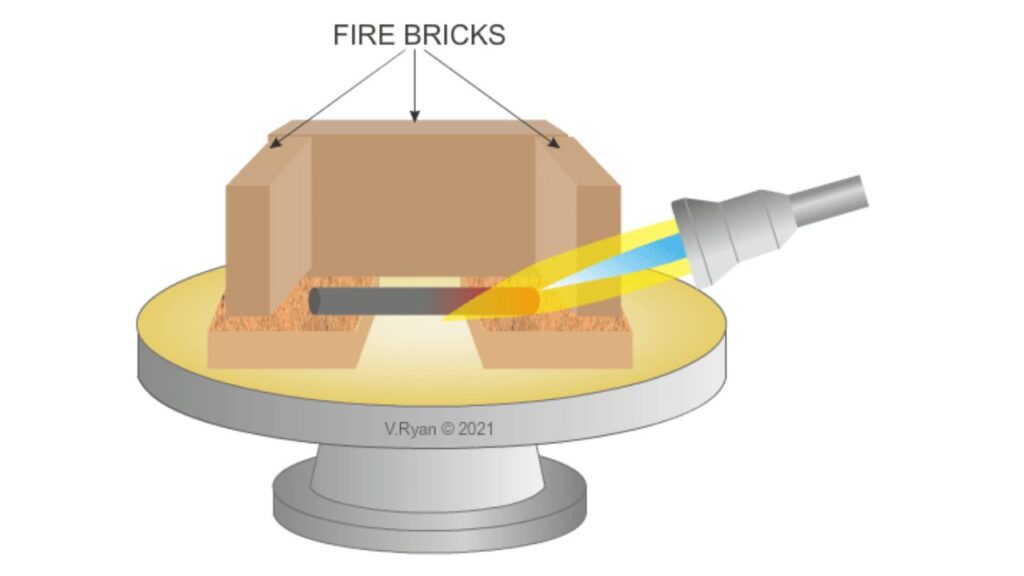

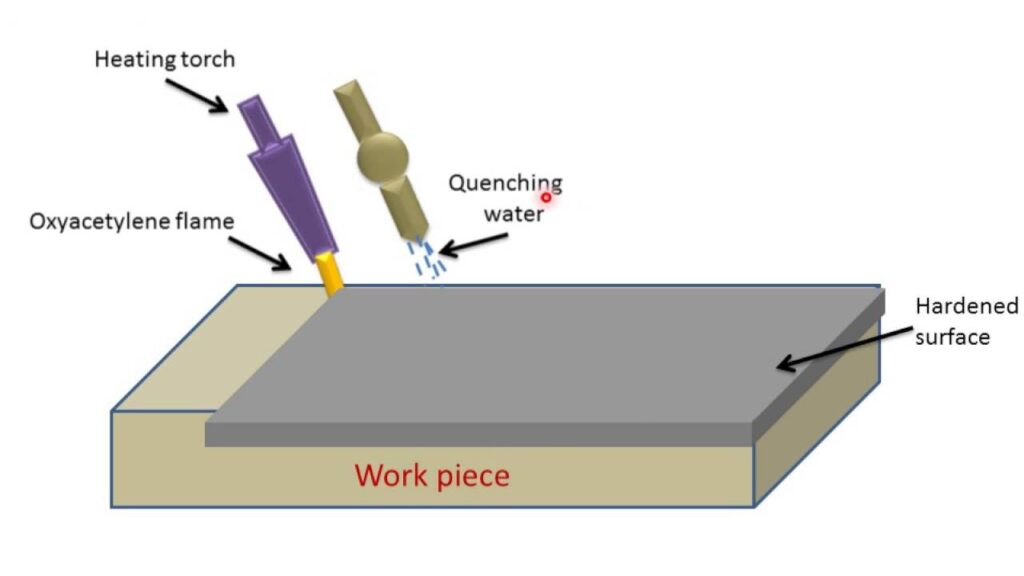

Flame Hardening

Flame hardening is done by applying a high temperature flame to the surface of a piece of metal. Then you put it out right away. The surface turns hard and the core remains as it is. It is excellent where extensive areas are required which only have to be hard on the surface.

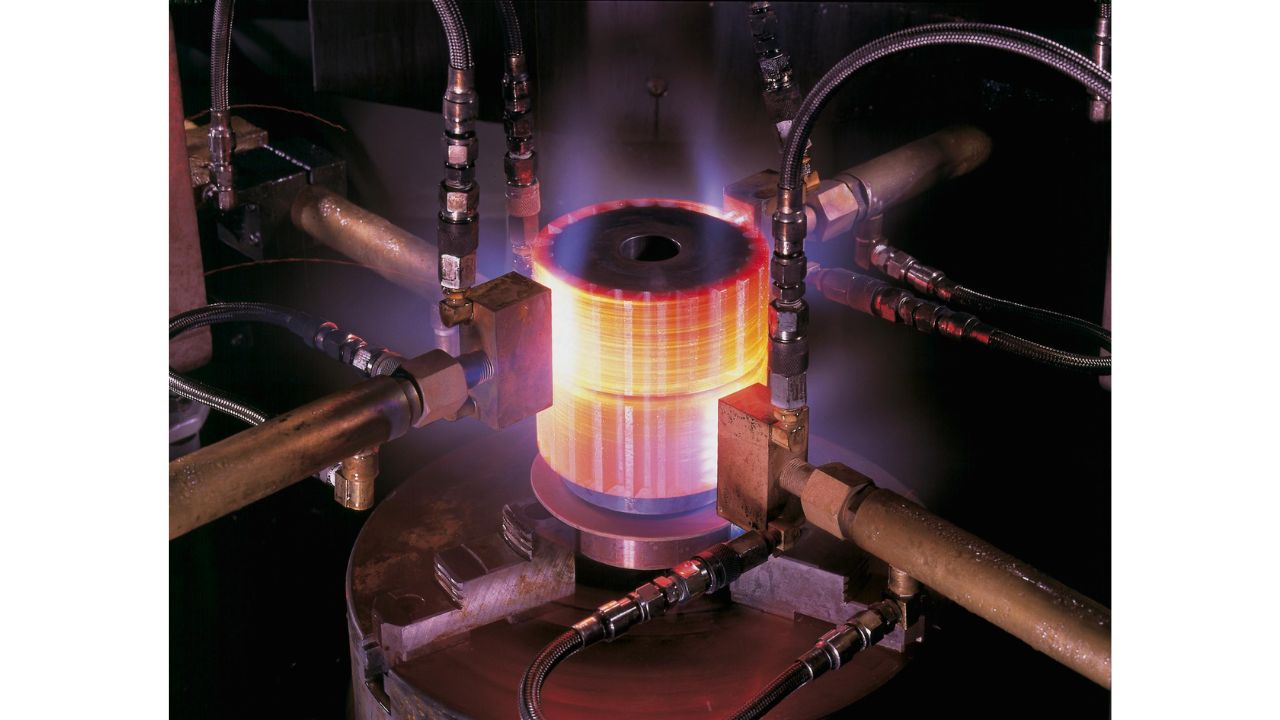

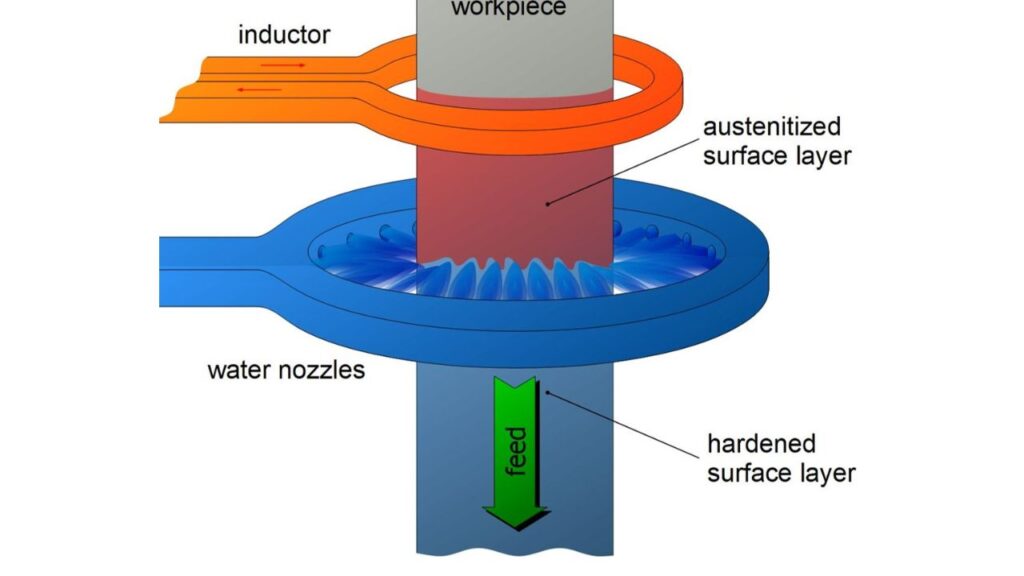

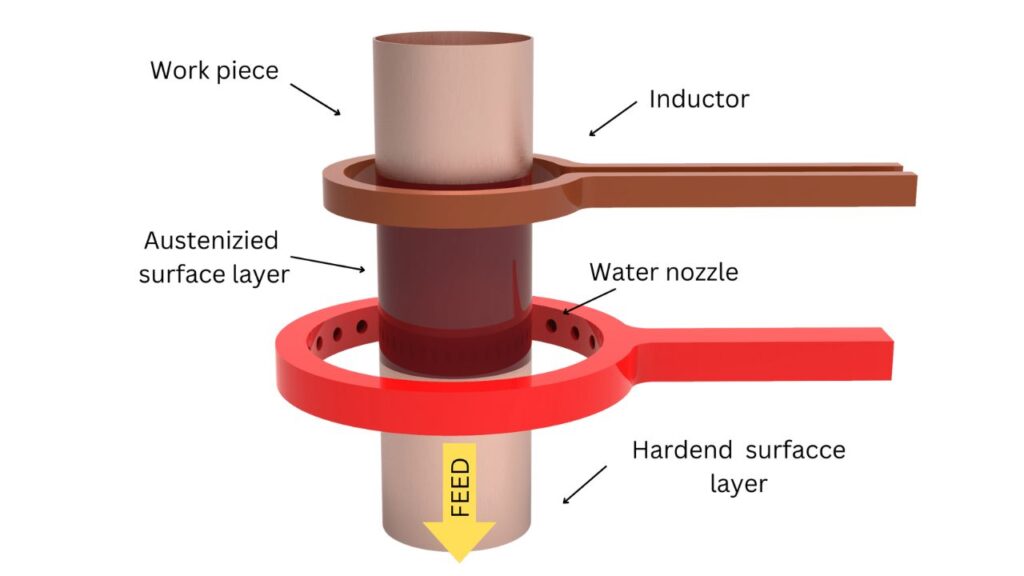

Induction Hardening

Induction hardening is a process in which electromagnetic induction heats metal surfaces quickly. You then quench metal. This makes the outer layer hard and the inside soft. It is best suited in shafts and gears that need to be highly wear resistant.

Spheroidizing

High-carbon steels are softened by spheroidizing. You overheat the metal to slightly below the critical temperature. The steel carbides are made round, or spheroidized, so that the steel is easier to machine and is less brittle.

Martempering

Martempering reduces distortion in quenching. You quench the metal in a medium slightly above the martensite start temperature and hold it, and then air-cool. This makes the part harder and diminishes cracking. It fits thin or complex components.

Austempering

Austempering strengthens and improves ductility. You plunge the metal in a salt bath and hold it until bainite is formed. Then you cool it by air. The outcome is a more powerful, impact-resistant part, which is applicable in high-stress usage.

Stress Relieving

Stress relieving minimizes residual stress caused by welding or machining. You heat the metal below transformation temperature, and cool it slowly. It is a process that prevents future distortion and cracking during use or any other further processing.

Cold Working

Cold working is not a heat treatment, however, it is essential. To make metal stronger, you strain harden it at room temperature by deforming. It increases its hardness and reduces its ductility. Apply it where dimensional accuracy and hardness are important.

Heating Methods in Heat Treatment

| Heating Method | Heat Source | Efficiency (%) | Heat Transfer Medium | Max Temperature (°C) | Application | Limitations |

| Conduction Heating | Direct contact | 70-90 | Solid objects | 1200 | Metals, glass | Requires physical contact |

| Convection Heating | Air, fluid | 50-70 | Gases, liquids | 350 | HVAC, ovens | Inefficient in vacuum |

| Radiation Heating | Electromagnetic waves | 80-95 | Vacuum, air | 3000 | Solar panels, heaters | Distance-dependent |

| Induction Heating | Electromagnetic field | 85-95 | Magnetic material | 3000 | Metal hardening, welding | Only for magnetic materials |

| Direct Resistance Heating | Electric current | 80-95 | Conductive materials | 2800 | Metal forming, glass manufacture | High energy costs |

| Infrared Heating | Infrared radiation | 85-90 | All types of materials | 3000 | Curing paints, drying | Requires line of sight |

| Microwave Heating | Microwave radiation | 60-75 | Dielectric materials | 300 | Cooking, sterilization | Not effective for metals |

Effects of Heat Treatment on Mechanical Properties

- Hardness improvement: You may strengthen the surface to be resistant to wear, particularly of tools and dies.

- Increase in strength: It enables you to enhance tensile strength and yield strength so that parts become more load-bearing.

- Ductility decrease: As the strength increases, there would be a slight decrease in ductility, so the material will not be as stretchable.

- Increase in toughness: Heat treatment enhances the capacity of the metal to take up energy before breaking.

- Elasticity change: You may change the amount that the material stretches and compresses, then goes back to its original form.

- Plasticity change: It assists you to manage load-induced permanent deformation which is vital in forming processes.

- Fatigue resistance: Treated metals are capable of resisting greater cyclic loading, which minimizes possibility of failure.

- Fracture toughness: You increase the ability to resist crack growth under stress.

- Wear and impact resistance: The process enhances resistant to wear and sudden force.

Alteration of Physical Properties Through Heat Treatment

- Color alteration: You will observe alteration of the surface color because of oxidation or scaling particularly during exposure to high temperatures.

- Alteration of magnetic property: Magnetic behavior of some materials such as iron can be reduced or eliminated by heating at high temperatures and cooling at a specific rate.

- Electrical and thermal conductivity: You can change the electrical or thermal conductivity of metals. An example being the annealing process which tends to heighten conductivity by decreasing internal stress.

- Density change: You can experience a variation in density, although it is very minute, as the spacing between atoms, and the distribution of phases, change during the treatment.

- Crystalline structure and dimensional stability: You will be able to refine grain structures and stabilize dimensions and minimize internal stresses which cause distortion.

- Reflectivity and surface appearance: The heat treatment can either produce a dull or bright surface. Reflectivity is a property of oxide layer formation.

- Specific heat capacity and lattice parameters: You will also get differences in the way metals absorb energy. Microstructural changes have been associated with these changes.

- Coefficient of Thermal Expansion (CTE): Changing the internal structure would affect the degree to which the material expands with heat which is important in applications involving high temperatures.

- Elastic modulus: variation The material may vary in its stiffness depending on grain refinement and residual stress relief.

- Corrosion resistance: Surface layers can be stabilized and impurities can be reduced to enhance a general resistance to rust and chemical attack.

Enhancement of Chemical Properties via Heat Treatment

| Criteria | Chemical Stability | Oxidation Resistance | Hydrogen Embrittlement Prevention | Sulfide Stress Cracking Resistance | Acid Resistance | Alkali Resistance | Crevice Corrosion Resistance |

| Heat Treatment Temperature Range | 500-800°C | 600-850°C | 650-900°C | 600-850°C | 500-700°C | 500-700°C | 550-800°C |

| Time Duration | 1-3 hrs | 2-4 hrs | 2-3 hrs | 2-4 hrs | 1-3 hrs | 1-3 hrs | 2-3 hrs |

| Atmosphere | Inert/Nitrogen | Air/Oxygen | Hydrogen-Free | Inert/Nitrogen | Acidic | Basic | Moist/Chloride-Rich |

| Alloy Types | All Alloys | Fe & Ni based | All Alloys | Fe & Ni based | Most Alloys | Most Alloys | Stainless Steel & Ni Alloys |

| Heating Method | Furnace | Furnace/Oven | Furnace | Furnace | Furnace | Furnace | Furnace/Oven |

| Cooling Method | Air/Water Quenching | Slow Cooling | Slow Cooling | Air/Water Quenching | Slow Cooling | Slow Cooling | Air/Water Quenching |

| Impact on Material | Enhances Stability | Reduces Oxidation | Prevents Embrittlement | Enhances Resistance | Increases Acid Resistance | Increases Alkali Resistance | Enhances Resistance |

Core Elements of Process Control in Heat Treatment

Temperature Control

You should ensure a high temperature and this varies depending on the material but is usually between 9000C -12000C. Proper monitoring with the use of thermocouples, pyrometers and digital sensors should be used. Microstructural flaws are avoided by uniform and stable heat. Brittleness or not-completely transformations may be caused by even small deviations in temperature.

Control of atmosphere (Heat Treatment Furnace)

Atmosphere in a furnace is a major factor in the quality of the surface. To prevent oxidation, decarburization, or undesired carburization you will frequently use nitrogen, hydrogen, or endothermic gases. It is important to mention vacuum and inert gas furnaces in the case of sensitive metals. Surface and consistency is maintained by monitoring the oxygen levels and dew point.

Regulation of Cooling Rate

It is vital to control the cooling speed in order to adjust metal properties. Depending on the required results, you will decide on fast quenching and slow annealing. The cooling techniques are fans, quenching tanks or air curtains. The correct rate assists in refinement of grain structure and in creation of balanced hardness and ductility.

Quenching Media Management

Depending on the type and size of alloy, you will select the media such as water, oil, air, polymer or salt bath. When cooling or warping, it is crucial to stir. Ensure that the media is maintained clean and cool by being frequently filtered and maintained. This will make you evade expensive defects.

Heat Distribution

To have equal treatment, make sure you have a furnace layout, which enables equal heating. The spacing and load placements are important as much as multi-zone systems or PID controllers. Failure to distribute heat uniformly means that you expose the workpiece to the risk of inconsistency in the mechanical properties.

Equipment Calibration

This requires regular calibration of furnaces, sensors, and controllers to prevent process drifts. Meet such industry standards as AMS 2750 and CQI-9. To guarantee consistency in each run, resort to the use of certified tools and traceable procedures. Improper calibration results in inaccurate information and wastage of the material.

Pressure Control at Furnace

The pressure has a direct influence on such processes as nitriding or carburizing in vacuum or gas furnaces. To keep it in the right levels, you will need the pressure sensors and leak detectors. Pressure instability changes diffusion depth or surface hardness to any degree, and therefore stability of output depends on stability of pressure.

Process Sequencing

The perfect sequence of the heat treatment process is preheating, soaking, quenching, and tempering. One wrong step, you may be exposed to thermal shock or improper phase changes. It should be done with timers or automation to maintain the sequence. Structural and performance problems are avoided by following the correct order.

Automation Integration

Implementation of PLCs or SCADA increases your accuracy and performance. Automation assists you to control batch recipes, alarms as well as safety interlocks. It reduces the human error factor and makes results reproducible. This will also enhance safety since you will be exposed to less high temperatures and chemicals.

DAS Data Acquisition Systems

You will have to monitor such data as temperature, time, pressure, and the composition of gases. An effective DAS facilitates traceability, analysis and quality checks. With the MES or ERP system integration you can better manage the production. Data records provide you with ideas to streamline operations and achieve norms.

Material Considerations in Heat Treatment Material Science

Material Composition

You have to measure the carbon content because it directly influences the amount a material could be made hard. You can fine tune strength, corrosion resistance and thermal behavior by alloying with elements such as chromium, nickel, molybdenum and vanadium. Avoid contaminants like sulfur, phosphorus and oxygen; their presence in minor quantities may cause problems with heat treatment control and result in defects.

Material Structure

Heat treatment results are influenced greatly by grain size. You are expected to know how it changes when heating and cooling. Consider phase diagrams to monitor changes in structure. The microstructure can be analyzed with tools such as SEM and metallography and the effectiveness of treatment can be checked.

Thickness and Shape of material

The transmission of heat occurs in a different way in thick and thin materials. You have to change the rate of heating and cooling to ensure uniformity. Non-standard shapes or dimensions require close control over the process to prevent internal tension or non-homogeneous hardening. The process should always be matched to the geometry of the part.

Material Surface Condition

Heat transfer will be impaired by rust, scale or surface coatings, and results will be influenced. The surface should be cleaned and treated by such techniques as pickling or blasting. Free of contamination, a clean surface would allow the movement of the heat to flow smoothly and avoid undesired reactions throughout processing.

Material Properties

Prior to treatment, examine characteristics such as ductility, toughness, and residual stress. These affect the way the material reacts to heat. The progress can be measured by hardness in the use of tools such as Rockwell or Vickers to ensure that the required change of the desired mechanical property has been achieved.

Enhancing Heat Treatment Efficiency

Process Optimization

Select the appropriate heat treatment process to your material and objective. Regulate heating rates, soak times and cooling curves. To evade trial and error, utilize process modeling.

Energy Saving

Install efficient furnaces that consume less energy and high-quality inspections. Use exhaust heat and maximize thermal mass. This assists you to reduce CO 2 emissions and reduce the energy bills.

Reduction of Waste

Handle water and quenching media safely. Recycle scrap metals as much as you can. Remain in compliance with environmental regulations and cut down on disposal expenditures.

Automation Integration

Install robotics to load and unload more safely and quickly. Put in automatic doors and conveyors. This saves on labor and guarantees quality that can be repeated.

High-tech Heat Treatment Machines

Use induction heaters to save time and heat selectively. Choose hybrid systems to be flexible. Get accurate temperature control using smart modules.

Heat Treatment Lean Manufacturing

Stop wasting time and time wastage. Minimize set up time through effective batch planning. Use JIT scheduling to achieve production objectives.

Quality Improvement

Track the process live to detect the defects. Increase consistency and decrease rework. Match your work to the ISO, ASTM, or NADCAP standards.

Cycle Time Reduction

Apply quick-heating components and improved quenching arrangements. Batches should be preloaded to minimize wait time. Maintain quality at the same level as reducing process times.

Material Use

Utilize more of your raw material by not over processing. Cut out quality-non improving steps. This assists you in reducing the cost of materials.

Continuous Improvement & Predictive Maintenance

Use Six Sigma or Kaizen techniques to identify waste. Plan maintenance on the basis of data to prevent breakdowns. Make your system operate without unexpected failures.

Operational & Cost Efficiency

Monitor energy, quality, and uptime using dashboards. Automate where it is cost effective. Check the long-term equipment costs prior to upgrading.

Skill Training

Metallurgical and software training of train operators. Give certifications to increase team knowledge. This enables you to remain quality despite technological changes.

Safety Improvement

Provide your crew with appropriate PPE. Conduct regular risk assessment. Put emergency shutdowns and ventilation in high-temp areas.

Reduction of Carbon Footprint

Utilize vacuum furnaces, hybrid or solar powered furnaces. Minimize energy consumption cycle by cycle. Target sustainability certifications as a sign of your greenness.

Troubleshooting in Heat Treatment Processes

Distortion Correction

Warping may be observed because of uneven heating or rapid cooling. Repair with staged cooling and corrective heating.

Prevention of Cracking

High thermal gradients, or rapid quenching, are frequent sources of cracks. Before processing, adjust quenching speed and alloy geometry.

Overheating Solution

When the metal is overheated, the grain grows, and the metal becomes weak. Watch maximum heat to maintain ductility and strength.

Decarburization Prevention

Hardness is lost by losing surface carbon. Control the furnace atmosphere and apply protective coatings to decrease carbon loss.

Hardness Problems

Inconsistent hardness is caused by lack of time control or temperature control. Retest and re-temper to achieve mechanical specs.

Scaling Solution

Scale is formed on the surface by oxidation. Employ good furnace atmospheres and clean treated surfaces.

Non-uniform Heating

The lack of uniform temperatures causes variable properties. Use thermal mapping and multi-zone control to achieve improved uniformity.

Defects of Materials

Failures can be caused by inclusions or voids. Check materials prior to treatment and employ certified stock where practicable.

Residual Stress Control

Cracking is due to uncontrolled stress. Subcritical anneal and ramp rates during heating and cooling.

Quenching Problems

Bad agitation or unclean quench media induces flaws. Ensure media is clean and load shape and material quenching is adjusted.

Time & Temperature Control Failures

Human mistakes or time misalignment decrease the accuracy of the process. Automate cycles and check all settings prior to each run.

Mismanagement of Atmosphere

Surface quality is impacted by oxygen spikes or gas mix problems. Monitor gas and use alarm or reserve gas.

Failure of equipment

Heat control is affected by malfunctioning sensors or relays. Have regular maintenance and records of calibration.

Surface Contamination

Results are interfered with by dirt or oil. Before heating, clean and handle clean materials with appropriate procedures.

Conclusion

Knowledge of what is heat treatment puts you in a clear advantage of enhancing metal performance in industries. The heat treatment process enables you to manage hardness, strength, ductility, and corrosion resistant by maintaining precise temperatures and using special heat treatment facilities such as heat treatment furnaces. Being aware of the number of different heat treatment process types available enables you to choose the most appropriate one according to the application. This guide provides important facts and suggestions based on material science, which applies to metal heat treatment and high temperature heat treatment. Through heat treatment temperature and equipment mastering, you get enhanced durability, efficiency, and long-term reliability of each component.

FAQs

Can you subject all metals to metal heat treatment?

Metals do not all react in the same way to heat treatment. Heat treating of most ferrous metals such as steel and cast iron is possible. Nonetheless, certain non-ferrous metals, including some aluminum or copper alloys, can experience small structural changes. The composition of the metal needs to be known prior to heat.

How does heat treatment affect grain structure?

In metals, the grain size and pattern are altered by heat treatment. Grains can be refined by methods such as annealing or normalizing. This enhances strength, toughness and ductility. Heating and cooling under control can keep you away from undesired grain growth or weak spots.

What is stress relieving in heat treatment?

Stress relieving is a heat treatment that assists you in eliminating internal stresses induced by machining, welding or forming. With the metal below its critical temperature, you can increase dimensional stability and decrease the chances that it will crack or distort by slowly cooling it.

What does heat treatment do to steel?

Steel has its mechanical properties changed by heat treatment. Depending on the process, you can either harden and strengthen it and make it more wear resistant or ductilize and make it tougher. It is also useful in enabling you to manage residual stresses and improve overall performance to various applications.

How much heat treatment costs?

The price varies with the type of metal to be used, the heat treatment procedure, the size of the parts and the quantity of the batch. You can expect to pay about 0.10 to 2.00 dollars per pound on average. High temperature or custom heat treatment processes involving sophisticated heat treatment equipment can also be costly. Compare at all times on the basis of treatment goals.