CNC 5 Axis Machining. Types, Applications, Considerations and More

Modern industrial manufacturers use CNC 5-axis machines to efficiently produce complex parts with high levels of precision. Manufacturers and engineers rely on this knowledge to improve their production systems and deliver excellent results. This article examines all aspects of CNC 5 axis machining from different types to its applications and technical details. This guide will educate anyone new to CNC technology and experienced users about how to boost performance and make good choices during machining operations.

Table of Contents

ToggleWhat is 5-Axis CNC Machining?

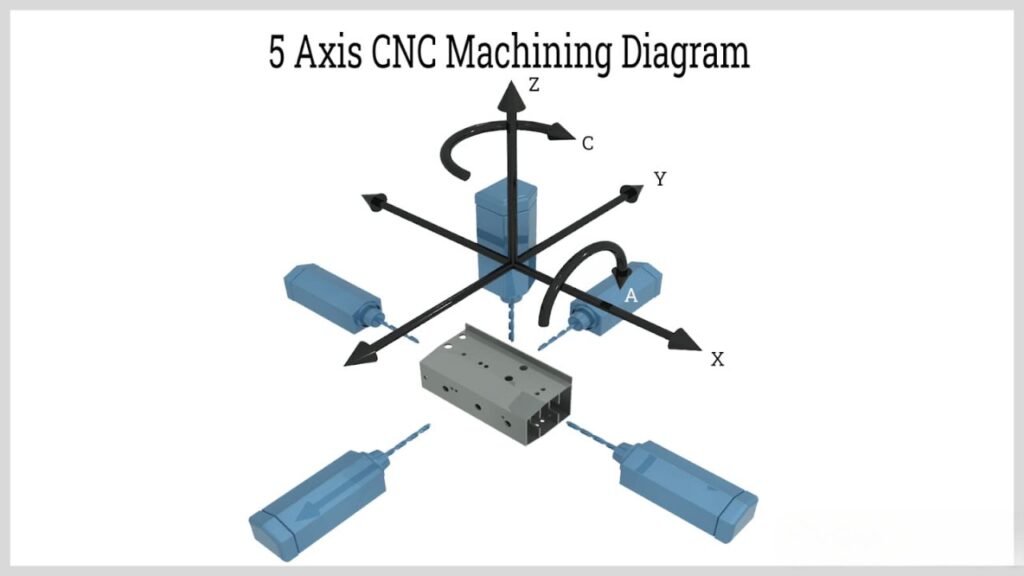

A 5 axis CNC machine system lets you produce complex parts precisely through tool movements along X, Y, Z, A, and B (or C) axes. With 5-axis CNC machining you achieve better results faster and cleaner. Advanced manufacturing needs 5-axis CNC machines which produce complex shapes quickly while providing exceptional precision. These machines assist aerospace, automotive, and medical industries through their precise technology.

| Sr. No. | Feature | 3-Axis Machining | 4-Axis Machining | 5-Axis Machining |

| 1 | Axes of Motion | X, Y, Z | X, Y, Z, A | X, Y, Z, A, B/C |

| 2 | Complexity | Simple | Moderate | High |

| 3 | Part Geometry | Basic | Complex | Highly Complex |

| 4 | Setup Time | Higher | Moderate | Lower |

| 5 | Surface Finish | Good | Better | Excellent |

| 6 | Tool Access | Limited | Improved | Enhanced |

| 7 | Applications | General Milling | Indexing, Rotary | Complex Parts |

Importance and Benefits of 5-Axis Machining

- Increased Precision and Efficiency: Simultaneous multi axis movement allows you to achieve tighter tolerance and faster production. It helps reduce errors and increases the overall accuracy.

- Capability to Produce Complex Geometries: Using undercuts and curved surfaces, you can easily create intricate parts without multiple setups.

- Reduction in Setup Time and Manual Intervention: You save time and are more consistent because you have fewer repositioning needs. This also reduces human errors.

- Enhanced Tool Life and Surface Finish: More optimum tool angles reduce wear and extend tool life. Another benefit is you also get a smoother surface finish with fewer post processing steps.

Construction and Components of a 5-Axis CNC Machine

A 5 axis CNC machine is a very specific type of very highly precise machining system that is used to do high precision machining. It will enable you to work more efficiently as well as optimize the performance. The machine is a precise cutting machine that consists of key structural, motion and control components that work together.

Main Components

- Machine Frame and Structure: It serves as a mechanical connector and offers stability against the vibration experienced from the machining process. It naturally provides the inherent rigidity to give it the consistent precision even with heavy loads.

- Rotary and Tilting Tables: They will give you additional axes through which to cut complex geometries. It allows access to tools with ease, allowing you to not reposition.

- Spindles and Tool Holders: The spindle holds and rotates the cutting tool at high speeds. The tool holder then holds the tool, stable and precise.

- Servo and Stepper Motor: Using them you can control the movement of the machine. Position and servo motors are high speed, dynamic motion motors, while stepper motors are controlled motors to specific positions.

- Linear Guides and Ball Screws: Mechanical parts that move smoothly in the X, Y, and Z axes are moved by linear guides. For machining accuracy, ball screw is good for accurate and backlash free movement.

Motion System and Kinematics

- Description of Linear and Rotary Axes: A 5 axis CNC machine is a machine which has three linear directions (X, Y, Z) and two axes of rotation (A, B or C). This type of movement permits complex part machining in a single setup.

- Kinematic Configurations: The three main types include.

- Trunnion (Table-Based) Design: The tool moves in linear directions while the table tilts and rotates. This is a good choice for machining heavy parts with high rigidity.

- Swivel Head Design: The table is fixed and the tool head rotates. Better tool reach is ideal for highly detailed machining.

- Hybrid Design: It combines both table and tool movement, providing maximum flexibility for generally applicable applications.

- Movement Coordination and Interpolation: All axis movements are synchronized by the CNC controller. Interpolation helps for smooth, accurate cutting, without tool deflection or resulting poor surface quality.

Electrical and Control Systems

- CNC Controllers and Programming Interfaces: G code instructions are processed by the CNC controller and turned into motion commands. It provides user friendly interfaces for both programming and monitoring machining operations.

- Power Supply and Signal Processing: To prevent the performance from being affected by voltage fluctuations, the machine requires a stable power supply. Signal processors help to maintain a smooth line of communication between components.

- Cooling and Lubrication Systems: They prevent overheating and reduce friction between the moving parts. Tool longevity and location accuracy are enhanced by proper cooling.

How 5-Axis CNC Machining Works

Understanding CNC Programming for 5-Axis Machining

- G-code and M-code: Movement is controlled by G code and auxiliary functions such as tool change and spindle operation are handled by M code. Knowing these codes enables you to develop efficient machining instructions.

- CAD/CAM Software: Using CAD software you design parts and then CAM software to generate toolpaths. It ensures smooth transition between the axes and thus increases accuracy.

- Toolpath Generation and Simulation: You simulate toolpaths before machining to make sure the toolpaths will work. This prevents collisions, optimizes cutting speed and improves efficiency.

Machining Operation

- Integrated Machining: The tool moves across all five axes at the same time. It is ideal for fabricating complex, curved surfaces such as turbine blades.

- Indexed Machining (3+2): As the tool cuts in three axes, the tool locks at a fixed angle. It works great for parts that need multiple precise angles.

- Tool Positioning and Material Removal: It provides advanced positioning so that you can work in hard to reach areas without moving the part.

Motion Capabilities and Axis Rotations

- Linear Motion: Has three X (left right), Y (front back), and Z (up down) axes of precise straight line movement.

- Rotational Movements: The tool or workpiece is rotated by A, B, or C axes for complex cuts.

- Real-World Applications: With extreme accuracy, you can machine aerospace turbine blades, medical implants, automotive engine components, and other high value, high precision parts.

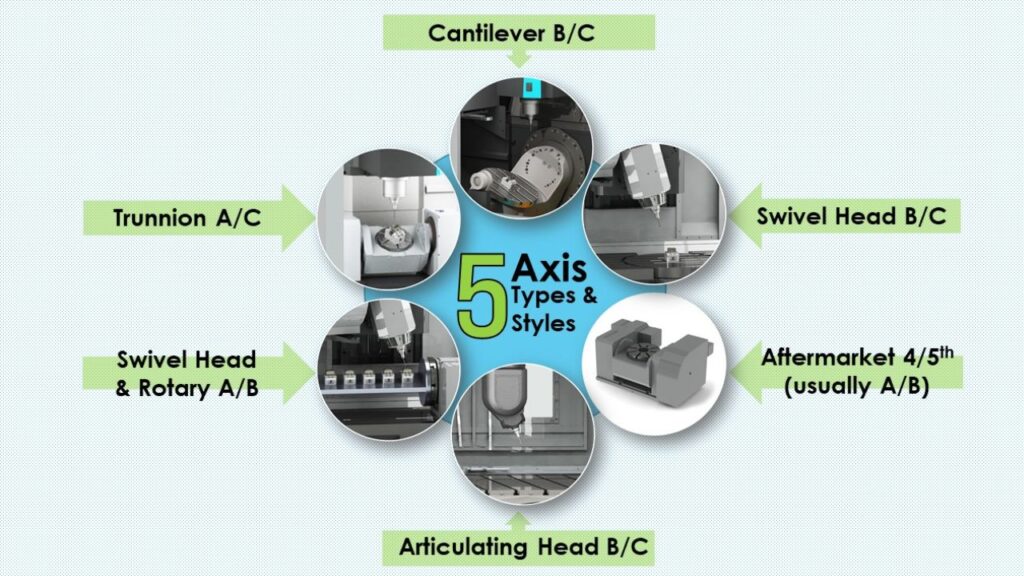

Types of 5-Axis CNC Machines

Trunnion (Table-Based) Machines

Multi axis movement in a Trunnion machine is achieved by rotating and tilting a table. The workpiece rotates to different angles while the cutting tool moves linearly. Its high rigidity is particularly suitable for heavy material removal. Trunnion machines are the ones to rely on for stable and accurate machining in demanding applications.

The best application for these machines is for large and heavy components demanding high cutting forces. Because aerospace structures and industrial equipment are large and heavy, they often require this type of machining. However, trunnion systems have reach limitations, particularly for deep, complex cuts.

Swivel Head Designs

Swivel head machines variation in their tool head’s position while holding the table in a relatively stationary fashion. It provides better reach and flexibility when machining complex shapes. It allows for tilting the cutting tool, which grants great access to undercuts, and is therefore excellent for intricate designs.

A swivel head machine is a great choice if you work with impellers, medical implants or other curved surfaces. The superior maneuverability means you can machine fine details without having to reposition as much. They are also more compact machines but may be less rigid than trunnion setups.

Hybrid Designs

Hybrid Machines are machines that combine trunnion and swivel head system capabilities. This versatility is provided by allowing both the table and tool head to rotate. It gives you the rigidity of a table based system, and the flexibility of a swivel head. Hybrid designs are most adaptable for complex machining needs due to this combination.

If your work involves parts that need both stability and extended reach, you should look into hybrid machines. Industries that require a wide range of machining operations like aerospace, automotive and precision manufacturing are just perfect for them. But their advanced motion control makes them more costly.

| Sr. No. | Feature | Trunnion (Table-Based) | Swivel Head | Hybrid Designs |

| 1 | Core Motion | Table tilts/rotates; tool moves linearly. | Tool head tilts/rotates; table may rotate. | Combines table and head rotation. |

| 2 | Key Strength | High rigidity for heavy cuts. | Excellent tool reach for complex shapes. | Versatile for diverse tasks. |

| 3 | Typical Use | Large, heavy parts; aerospace structures. | Intricate parts; impellers, medical implants. | Complex parts needing both stability and reach. |

| 4 | Main Benefit | Stable, accurate machining. | High flexibility, good for undercuts. | Enhanced versatility. |

| 5 | Primary application | Heavy structural components. | complex curved surfaces. | complex parts with varied machining needs. |

| 6 | Concise advantage | Stable and powerful. | Flexible and reach capable. | very versatile. |

| 7 | Concise disadvantage | Reach limitations. | less rigid. | high cost. |

Materials and Tooling in 5-Axis CNC Machining

Common Materials Used

With 5 axis CNC machining you can work with a majority of the materials. Commonly used metals include aluminum, titanium, and stainless steel because of their strength and durability. Titanium is strong, weighs little and is ideal for aerospace and medical applications due to its high strength to weight ratio. The corrosion resistance of stainless steel makes it ideal for industrial and medical parts. You can also machine plastics and composites which are useful for lightweight materials with good non conducting properties. Ceramics and brittle materials are used for high performance applications that require special tooling and technique to prevent cracking.

Cutting Tools and Tool Holders

To get precision and efficiency in 5 axis machining you need to have the right tools. Complex geometries are commonly machined with end mills, ball nose cutters, and tapered tools. That tool geometry significantly influences machining performance, such as chip removal, surface finish and tool life. Longer tools will increase deflection which will reduce accuracy. Tool wear should be closely monitored because worn out tools cause poor quality cuts and increased downtime. Constant performance requires regular inspection and timely replacement.

Cutting Parameters and Optimization

It is important to be able to optimize cutting parameters so that efficiency and precision are achieved. Selection of spindle speed, feed rate and depth of cut is dependent on material, tool type. For softer materials such as aluminum, high spindle speeds work well; however, lower spindle speeds can help prevent tool wear in harder materials like titanium. In addition, rigid setups and appropriate tool paths will enable you to minimize vibration and tool deflection. Real time optimization using software is used to optimize parameters, thereby reducing machining errors and increasing the efficiency. You can get away with high quality results, extending tool life, and saving on machining costs with the proper settings and tools.

Applications of 5-Axis CNC Machining

Aerospace Industry

In aerospace, precision is everything. With 5-axis CNC machining, turbine blades, airframe structures and other high performance components can be created. This helps you reduce part handling and improves structural integrity with fewer setups. Aircraft components are assured meeting strict safety and performance standards.

Automotive Industry

5 axis machining is utilized in the automotive industry for the manufacture of complex engine parts, transmission components, as well as chassis design. With the ability to machine lightweight and high strength materials, you are able to improve fuel efficiency and vehicle performance. You also improve the durability and reliability of critical parts with precise machining.

Medical Industry

Extreme accuracy and biocompatible materials are needed for medical implants and prosthetics. It allows you to manufacture intricate designs with smooth finish, no need for tedious manual adjustments. With 5 axis machining, patient specific implants fit perfectly providing comfort and functionality.

Energy Sector

But in the energy industry, you need materials around which work hard: turbines, compressors, heat exchangers all the same, and you can’t work with them 5 axis machining. It improves efficiency and longevity in power generation and oil and gas applications.

Tool and Die Making

High accuracy is necessary for precision molds and intricate die components. 5 axis machining allows you to cut a design with fewer parts, requiring less post processing and less manual labor. It quickens production and assures high quality molds to the industries like plastics, metals stamping, and injection molding.

Considerations When Choosing a 5-Axis CNC Machine

Machine Rigidity and Spindle Power

For precision and durability, you will need a rigid machine. Vibrations are minimized and surface finish and tool life are improved by a stable structure. The demand for spindle power is as important, particularly for heavy duty machining. More power lets you cut through messy materials like titanium and stainless steel quickly and easily. The combination of rigidity and power is a choice that leads to long term performance.

CNC Controller Capabilities

The speed, accuracy and overall efficiency of your machine are all affected by your machines’ controller. A high speed processor with look ahead tools paths the tool, reducing errors. It is compatible with CAD/CAM software to facilitate programming and reduce setup time. It provides powerful controller which helps you to maintain precision in complex geometries.

Workpiece Size and Machine Configuration

Think about what maximum parts you need to machine. Check that the table size and load capacity are adequate for your requirements. Stability for machining is greatly improved with proper clamping options. By choosing the right configuration, you avoid limitations in future projects.

Cost Analysis and ROI Considerations

A 5 axis CNC machine is a big expense. High initial cost with long term benefits of reduced setup times, faster production and higher precision. Calculate return on investment based on efficiency gains, labor savings, and material waste reduction. Maximizing profitability is selecting the right machine.

Quality Control and Inspection in 5-Axis CNC Machining

Tool Accuracy and Calibration

To maintain machining precision, you must repeat testing of tool positioning and motion often. Laser calibration detects deviations and accurate movement, and probing systems verify tool alignment. These methods enable you to reduce errors and optimize part quality.

Part Inspection Methods

With Coordinate Measuring Machines (CMM) you can measure parts extremely accurately with the use of touch probes. Non-contact inspection with optical and laser scanning techniques are available which capture fine details and complex geometries. These methods provide your machined components with exact specifications.

Process Monitoring and Error Prevention

The feedback and control is in real time, helping you detect and correct machining errors instantly. Reducing tool deflection and machine vibrations will result in better surface finish and longer tool life.

Conclusion

5-Axis CNC machining is going to revolutionize precision manufacturing more than ever by providing the utmost in precision, efficiency and versatility. This technology is suitable for aerospace, automotive, medical, or energy sectors, allowing you to produce complex geometries with minimal setup and superior surface quality. Multi axis machining continues to increase importance as industries require higher precision and faster production. For proper investment, the rigidity, spindle power, and control capabilities of the machine must be considered. By incorporating advanced machining tech and real time monitoring you can achieve maximum perfromance, reduce errors and continue to compete in an ever changing manufacturing environment.