Professional CNC Milling Services in China

Leading CNC Milling Component Manufacturer in China

As a trusted name in precision CNC milling machining. With decades of expertise, we ensure accuracy, consistency, and reliability in every component. Here is what differentiates us:

- 21 years of specialized CNC precision machining experience.

- Equipped with 33+ advanced 3-axis and 4-axis CNC machining centers, 13 state-of-the-art 5-axis machining centers, and a team of 125 professionals.

- Precision capabilities include tolerances of ±0.01mm minimum diameter, ±0.03mm minimum micro hole, ±0.02mm minimum wall thickness, and surface finish as small as Ra 0.2 to 0.4 and Ra 0.8 to 1.6 micrometers.

- Certified with ISO9001 and ISO16949 quality management systems.

CNC Milling Parts Experts In China

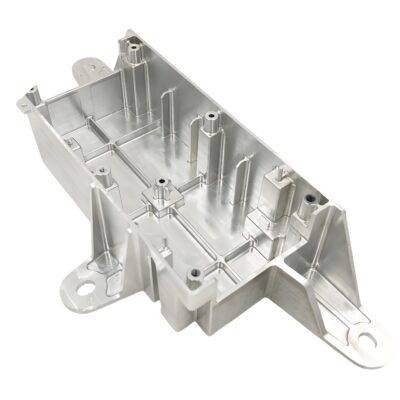

CNC Swiss Masion is one of the reliable CNC milling parts suppliers in China, and we provide precision solutions to your specific requirements. Having decades of experience and milling facilities, we guarantee high precision, stability, and finishes on all parts. Our skilled engineers and strict quality control systems guarantee reliable results for industries such as aerospace, automotive, electronics, and beyond. By selecting us, you will receive better performance, short lead time, and professional assistance to all your CNC milling projects.

CNC Milling Service

CNC milling services offer accurate and effective solutions to a broad variety of components and parts. You have the advantage of expert DFM (Design for Manufacturing) advice to streamline your project before machining starts, design through to final production. State-of-the-art CNC milling tools are accurate, consistent and versatile over complex geometries. Proficient engineers make sure that all components are within close tolerances and industry standards. Professional CNC milling will provide you with quality that is dependable, cost effective and the confidence to expand the business.

Materials

- Alloy

- Aluminum

- Brass

- Copper

- Bronze

- Stainless Steel

- High Temp and Special Alloy

- Titanium

- Steel

- Plastic

Machines

- CNC 3 axis machines

- CNC 4 axis machines

- CNC 5 axis machines(Gromax)

- CNC drilling machine

- Polishing machine

- External cylindrical grinding machine

- Surface grinding machine

- Centerless grinding machine

- Passivation equipment

Surface Finish

- Golden Plating

- Zinc plating

- Silver plating

- Nickel plating

- Heat treatment

- Brass passivation

- Bead Blasting

- Polishing

- PVD coating

What is CNC Milling Precision Machining?

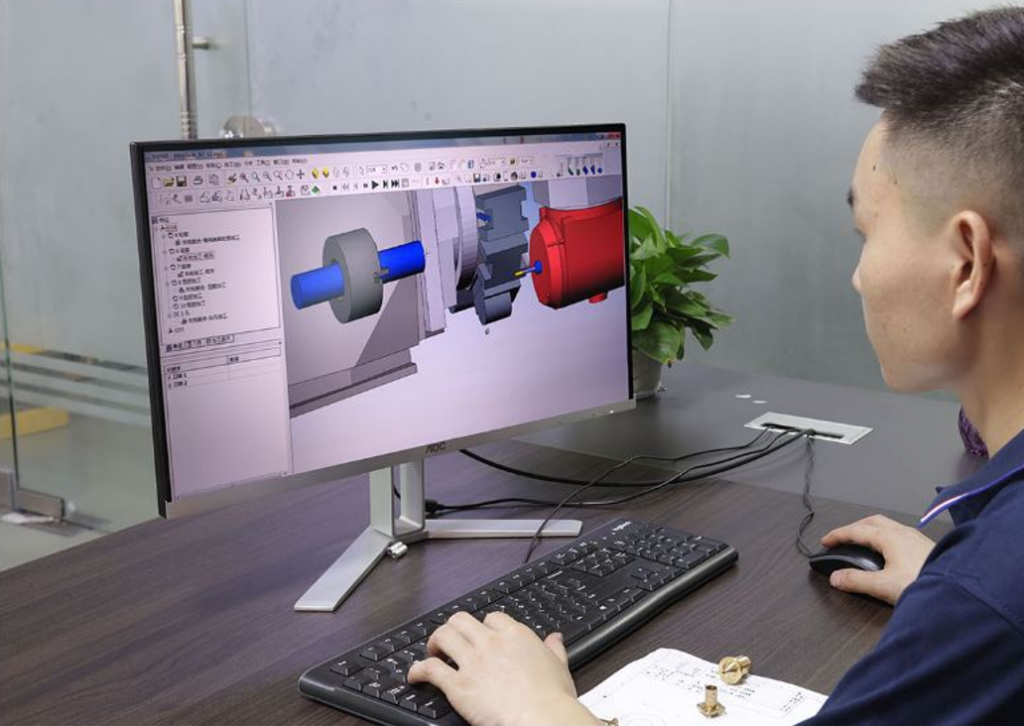

Precision machining CNC milling is a manufacturing technique that involves the use of computer-controlled milling machines to make highly precise and complicated components. It is the act of cutting material out of a solid work piece using rotating cutting tools with CAD/CAM software to ensure the highest accuracy. This is accomplished to very tight tolerances, typically in microns, and enables complex designs with repeatability. Precision machining CNC milling is used in most industries such as aerospace, automotive and medical to make components that require durability, reliability and high surface finishes.

The Pros and Cons of CNC Machining Milling

Pros

- High precision guarantees tight tolerance, complex parts that are precise.

- Efficiency will save a lot of time and labor costs.

- Versatility works with a variety of materials such as metals and plastics.

- Automation reduces human error and increases productivity.

- Repeatability delivers consistent results for large-scale production.

Cons

- High initial costs for equipment and software investment.

- Complexity involves high level programming and configuration skills.

- Maintenance demands regular upkeep and technical support.

- Waste of materials with subtractive manufacturing.

- The best performance requires skilled operators.

DFM For CNC Milling Components

Design for Manufacturability (DFM) is a critical factor in high accuracy, cost-efficiency, and reliability of CNC milling components. It incorporates product design, the choice of materials, the use of tools, and quality control into a simplified procedure.

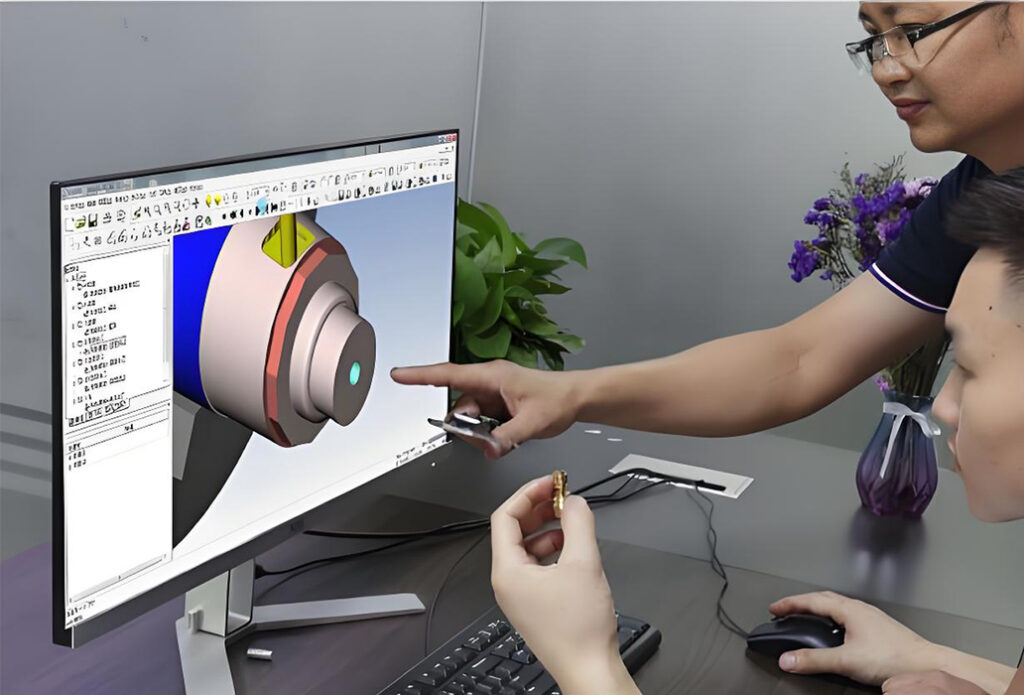

Product Design and Development

The company-client team meetings will be conducted jointly to make sure that the design attributes and product quality requirements are well established. Such a cooperative method reduces risks and synchronises functional expectations prior to the commencement of production.

Material Knowledge and Application

Proper examination of the properties of raw materials including composition, strength, and machinability will mean the most suitable one to the desired use. The use cases and functional requirements in the industry will ensure that the end-products are durable and perform well.

Tool Design and Application

It is necessary to choose and design the appropriate tools and fixtures depending on the material and structure. Effective tooling increases efficiency and precision in machining, minimizes tool wear and machine downtime.

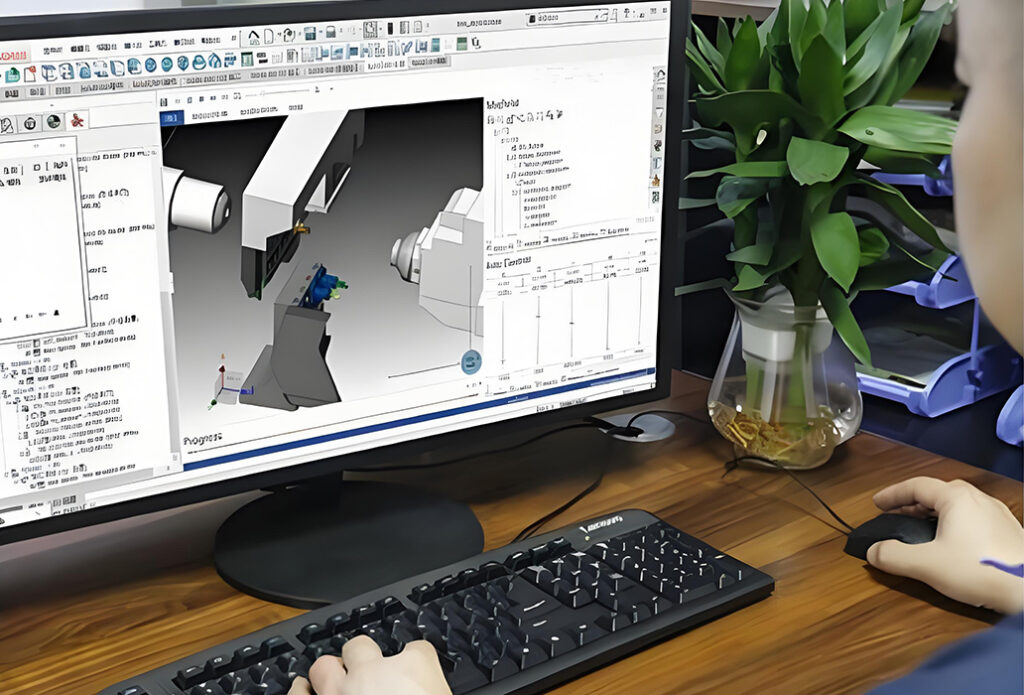

Programming Optimization and Processing

Precise machining strategies are enabled in advanced technical programming assisted by simulation and optimization. The inspection and tool adjustments are repeated so that accuracy is maintained in the production cycle.

Quality Control and Inspection

The quality assurance is provided by automated inspection and digital monitoring systems. These are used to minimize errors, enhance efficiency and parts are to be manufactured to high tolerance standards.

Solution Development and Cost Evaluation

Teams work together to assess the most appropriate technical solutions and optimize production and cost. This move will be used to maintain competitive prices without affecting the quality.

Technical Research and Advanced Training

The continued study of mechanical analysis, process improvement and cross-border exchange of technical knowledge promotes innovation. Ongoing training will keep the teams abreast of the latest technologies, thereby making them competitive in the long run in CNC milling.

Why Choose Us For CNC Milling Parts Manufacturing?

You desire reliability, precision and efficiency in all processes of production when choosing a partner to CNC milling parts manufacturing. We are the preferred vendor of companies in any industry because of our systems, capabilities, and experience. We use the latest programming equipment to produce the highest quality parts at controlled costs.

Intelligent Programming System: Intelligent programming system maximizes machining toolpaths, enhances production efficiency, and minimizes unnecessary costs. You have faster turnaround, less wastage, and more accuracy on any project.

ERP Office Management System: We have a powerful ERP office management system and as such, we handle information in totality. You enjoy better resource allocation, streamed workflows and better decision making across the entire production cycle.

MES Factory Management System: MES factory management system provides complete visibility of production. You are able to trace each stage, streamline processes and attain greater product quality with shorter lead times.

Quality Management System: There is no compromise of quality. Our quality management system is such that all processes are controlled, and all completed parts are of high international standards.

DFM and Design: You can trust our in-house engineering staff to provide Design for Manufacturing (DFM) assistance. This is to enhance manufacturability of parts, minimize errors, and maximize performance.

Large Projects: We have been working with such prominent companies as Huawei, Novel, Hysis, Tesla, Tuopu, and Xusheng. You may rely on us to do large scale, high volume projects that need consistency and reliability.

Diversity of Materials and Outer Diameter: CNC milling precision machining is used with a variety of metals such as aluminum, steel, brass, titanium, and a variety of plastics. It also has a broad variety of outer diameters with high precision, thus suitable in creating accurate, industry-specific components.

All-inclusive Processing Capabilities: You get more than CNC milling. We also offer our services to the secondary process like cleaning, grinding, and surface finishing to the exact specifications.

Fully Automatic Testing Equipment: We operate fully automated testing equipment to make sure that your parts are produced with precise tolerances and consistent, reliable results. This ensures uniformity and reassurance in all orders.

CNC Machining Tolerance

- Diameter Tolerance: ±0.01 mm

- Concentricity: 0.02 mm

- Surface Roughness: Ra 0.2 to 0.4 and Ra 0.8 to 1.6 micrometers.

- Length Size Tolerance: ±0.01 mm

- Angle Accuracy: Not specified (typically ±0.05° for CNC milling)

- Thread Machining Accuracy: ±0.01 mm

- Positioning Accuracy: ±0.01 mm

- Precision: ±0.001 mm

- Cylindricity: 0.02 mm

- Flatness: 0.02 mm

- Symmetry: 0.02 mm

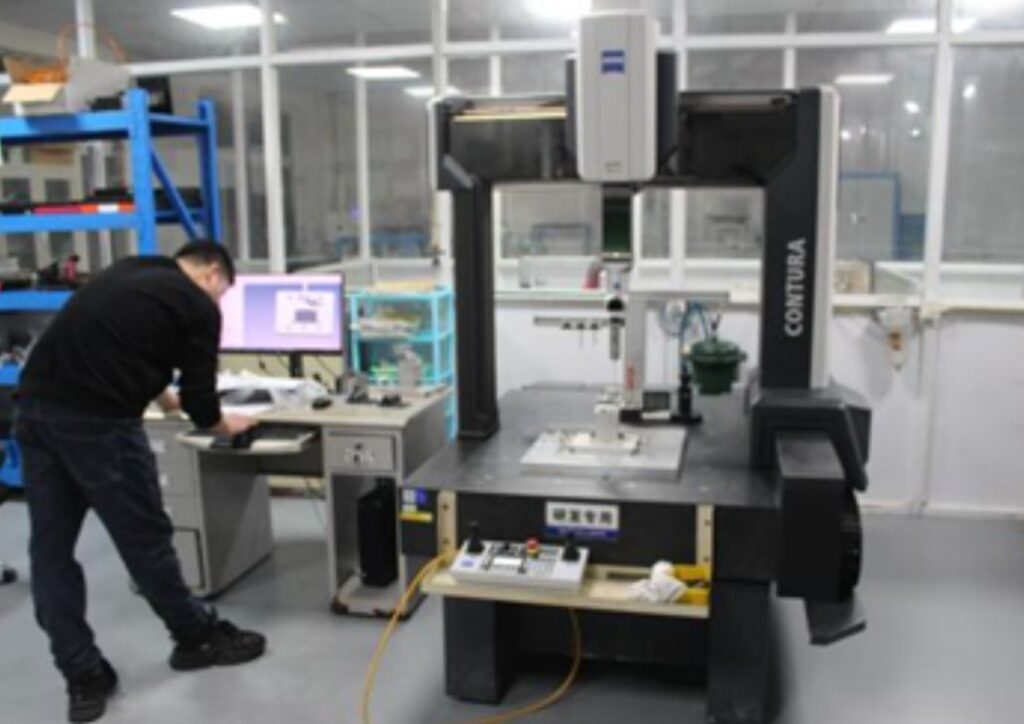

CNC Milling Machining Quality Control

The high-quality control systems are needed to ensure accuracy and uniformity of the CNC milling machining. CNC Swiss Masion ensure reliability and provide high-quality outcomes in all industries by combining automation, measurement technologies, and high inspection standards.

24-Hour Full Automatic Detection

Constant control is the important factor in the quality of products. The automated detection systems are 24/7 and detect any deviation in production. This minimizes human error, enhances consistency and even the slightest defects are detected in the early stages of the process.

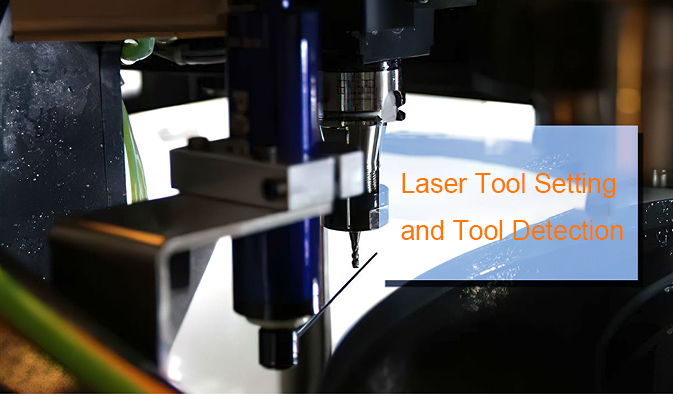

Laser Tool Setting and Tool Detection

Laser tool setting offers an accurate calibration prior to machining. It identifies tool wear, breakage and misalignment, and maintains cutting tools at optimal efficiency. This high detection enhances accuracy in machining and prolongs the life of the tools.

In-Machine Online Automatic Measurement

Part dimensions can be checked immediately by use of real time measurement within the machine. Production time is reduced and accuracy and repeatability are improved as the external measurement is removed. This provides tight tolerances of every component.

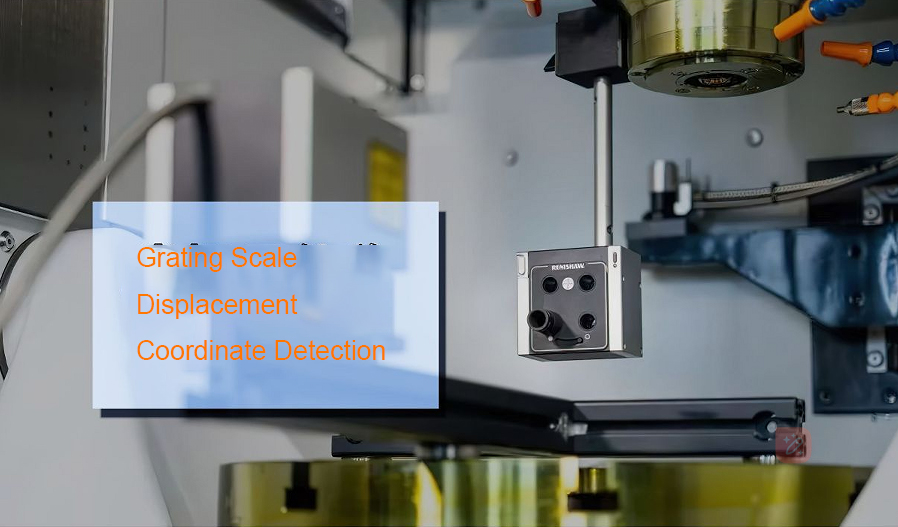

Grating Scale Displacement Coordinate Detection

Grating scale systems of high resolution monitor displacement and coordinate positioning at a very high level of accuracy. These systems will identify minute movements errors and the consistency in accuracy is maintained even in complex or multi axis milling.

Raw Material Feed Control

It requires a stable and safe system of raw materials supply. Materials that come in are checked very strictly prior to storage and these must meet the requirements of REACH and RoHS. This ensures high quality and safe inputs of machining processes.

Finished Product Process Control

Every product is produced on design specifications. Each stage is accompanied by comprehensive checks and detailed analysis reports, which guarantee consistency, accuracy and adherence to client requirements.

Product Traceability

The systematic traceability system documents the entire process of all products- starting with the intake of raw materials and delivery. This increases accountability and ensures reliability and safety of products.

Factory Quality Assurance

Random checks, verification of information and confirmation of signatures are used to check the quality of products before delivery. Delivery is accompanied by inspection reports that give evidence of quality and quantity assurance.

Advanced Testing and Inspection Facilities

The factory has metrology, physical and chemical laboratories, product performance and lifespan test centres. The equipment is state-of-the-art which guarantees unparalleled accuracy, stability and reliability in the quality control of CNC milling machining, including vacuum direct-reading spectrometers, X-ray flaw detectors, CMMs, hydrogen analyzers, contour measuring instruments and optical microscopes.

Our Certificates

At Masion, we are dedicated to delivering the finest in Automatic Bar Machining. With over 21 years of experience in custom Automatic Bar Machining and custom parts of high precision. It means we are committed to quality, industry standards and customer satisfaction through our certifications.

In fact, we have the ability to proudly boast key certifications that bear testament to our adherence to strict guidelines in different industries. This means that we are always up against the highest standards when it comes to Automatic Bar Machining.

- ISO 9001 Quality Management System

- ISO14001 Environmental Management System Certification

- Automotive Industry Quality Management System (IATF 16949)

- RoHS Restriction of Hazardous Substances (Available Upon Request)

- SGS Products Test – These tests are conducted to check the quality and if it matches industrial standards.

- Conformity to European standards: Solemn quality in Automatic Bar Machining.

Explore Our CNC Milling Services Gallery

3 axis cnc machining parts

5 axis cnc parts

CNC cooling plate

5 axis cnc machine parts

4 axis milling

4 axis machined parts

4 axis cnc

4 axis cnc machining

3 axis milled parts

3 axis cnc machining

CNC Milling Machining Industries

CNC milling machining is an important component in various industries because of its accuracy, speed, and capability to operate intricate shapes. It allows manufacturers to make extremely precise components at a steady quality and scale. CNC milling machining has been used as a foundation to high-level production in the aerospace sector as well as in consumer electronics.

Aerospace Industry

CNC milling provides high accuracy in the manufacture of aircraft engine components, turbine blades, landing gear components and structural components. Its capability to achieve close tolerances ensures safety and performance in high-performance aerospace conditions.

Automotive Industry

CNC milling provides efficiency and consistency in parts of engines and transmission housings, as well as custom car parts. Mass production is aided by the process and it ensures that the industry standards of durability and performance are met.

Medical Industry

Orthopedic implants, surgical equipment, dental machines, and medical devices are in need of extreme precision. Machining of biocompatible materials with CNC milling is safe, precise and meets healthcare standards.

Electronics Industry

Smartphones, computers, and consumer electronics miniaturized components, enclosures and connectors are produced by CNC milling. It is high-detailed and precise in micro-scale.

Defense Industry

Weapons systems, military vehicles, and radar equipment require reliable, high-strength components. CNC milling assists defense production with accuracy parts that can survive under severe conditions.

Energy Industry

CNC milling has been used to produce the correct and enduring components in oil and gas equipment such as wind turbine hubs and solar panel mounts among others, which are essential in long-term performance.

Checkout Our Another Manufacturing Services

- Swiss Machining

- Custom Machining

- Micromachining

- Multi-spindle Machining

- Screw Machining

- Precision Machining

- CNC Mill/Turn

- Automatic Lathe Machining

FAQs

What is the mechanism of CNC milling to guarantee consistent quality?

Quality is ensured by the use of high-level inspection, real-time measurements, automated detection, and such certification as ISO9001 and ISO16949. Each component is inspected to match the standards to be shipped.

What is 3 axis, 4 axis and 5 axis CNC milling?

- 3 axis machineries cut in X, Y, and Z directions.

- 4-axis provides rotation to machine more complicated shapes.

- 5-axis provides complete flexibility, allowing machining of complex components with greater accuracy in a single set-up.

What is the speed at which CNC milling projects can be delivered?

Lead times are based on complexity and volume. Simple components can be completed in a few days, and large or highly complicated projects in weeks. Many manufacturers are able to guarantee faster turnaround with advanced equipment.

Is CNC milling capable of dealing with custom designs?

Yes. CNC milling will suit custom parts, prototypes, and low-volume or high-volume production. Engineers have the ability to work directly off CAD drawings to produce parts to your design.

Is CNC milling economical?

Although the initial set up costs can be increased, CNC milling can minimize errors, wastes and provide repeatability. This renders it cost effective in both small and large production runs.

Why choose CNC milling services in China?

China has decades of experience, high-quality equipment, qualified engineers and reasonable prices. Most Chinese manufacturers are able to integrate high quality and efficiency thus becoming a good partner to international companies.