Optimized DFM Solutions for CNC Machined Parts

Reputable CNC Turning Service Supplier in China

- 21 years specialized CNC precision turned parts manufacturing experience.

- Fully equipped with 120+ professional CNC lathes, including 22 CNC automatic truss lathes, operated by a professional team of 125 people.

- Tolerances: Possible tolerances are: +/- 0.005mm minimum diameter, +/- 0.003mm minimum hole, +/- 0.005mm minimum wall thickness and surface finish as small as Ra 0.2 to 0.4 and Ra 0.8 to 1.6 micrometers.

- Certified to ISO9001 and ISO/TS16949 for uniform quality and reliability.

CNC Turning Company In China

CNC Swiss Masion is a top CNC turning company in China with a reputation for precision-engineered parts delivered on time and with accuracy. With high-end CNC turning technology and strict quality control system, the company can offer customized products to meet the needs of industries such as aerospace, automobile, medical, and electronics. With precision, efficiency, and cost-effectiveness at the forefront, every CNC Swiss Masion project meets international standards.

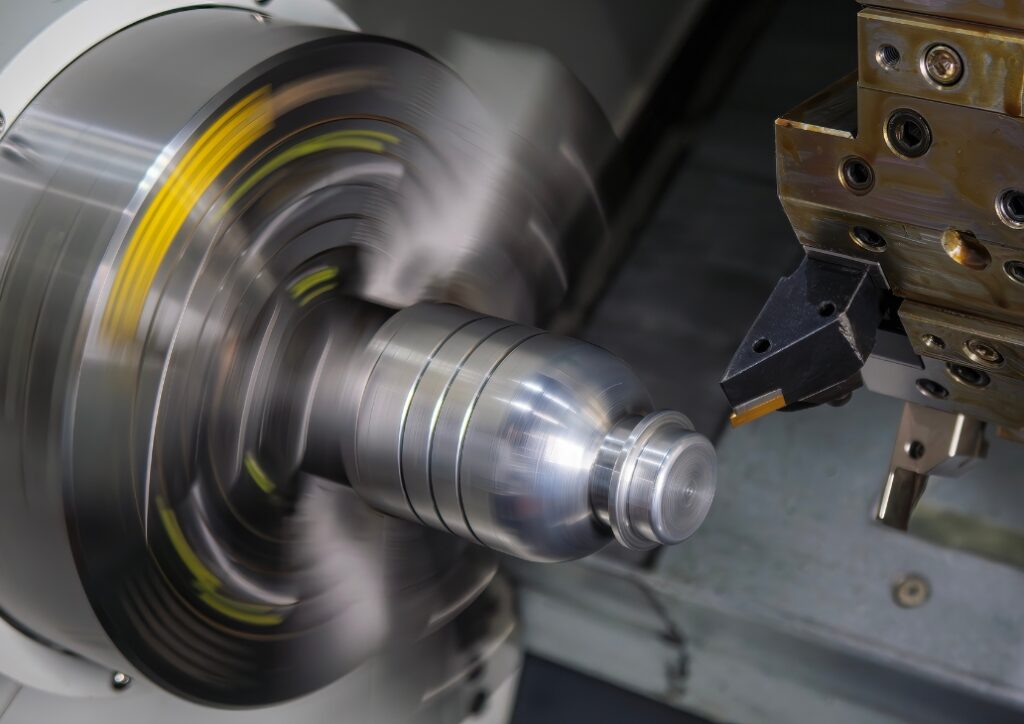

CNC Precision Turning Services

CNC Swiss Masion offers state-of-the-art CNC precision turning services for accuracy, efficiency, and complex part manufacturing. Multi-axis turrets which are designed to handle parts with complex geometries with ease. Micromachining of ultra-small parts, volume and customized machining. We also provide end-to-end DFM support including design optimisation, material guidance, prototyping and testing. With advanced technology and proven expertise, we guarantee precision-engineered results for various industries.

Materials

- Alloy

- Aluminum

- Brass

- Copper

- Bronze

- Stainless Steel

- High Temp and Special Alloy

- Titanium

- Steel

- Plastic

Machines

- CNC turning machine

- Automatic CNC lathe with truss

- CNC drilling machine

- Polishing machine

- External cylindrical grinding machine

- Surface grinding machine

- Centerless grinding machine

- Passivation equipment

- Ultrasonic cleaning equipment

Surface Finish

- Golden Plating

- zinc plating

- silver plating

- nickel plating

- Heat treatment

- Brass passivation

- Bead Blasting

- Polishing

- PVD coating

What is precision CNC turning machining?

Precision CNC turning machining utilizes computerized lathes for the machining of metal or plastic parts. You put the material in and a machine rotates it against a cutting tool. The process offers you high quality, repeatable and precise parts for many industries.

The Pros and Cons of precision turning

CNC precision turning is a manufacturing process that uses computer numerical control (CNC) lathes to produce highly accurate parts. Here are a few pros and cons which you will experience when working with CNC Turning:

Pros

- CNC machining offers high precision and repeatability for intricate parts.

- It produces efficiency improvement and scalable production volumes.

- Automation leads to lower labor demands and human errors.

- CNC systems can efficiently work on various types of materials.

- Consistent output means reliable quality and design retention

- Multiple operations can be merged in one set up.

Cons

- CNC machines involve a high cost of investment.

- Programming and configuration require a large amount of time and know-how.

- Difficulties in visibility and access are a barrier to real-time adaptation.

- Larger components can be limiting to the size of the machine.

- Material waste and wear of the cutting tools increase costs.

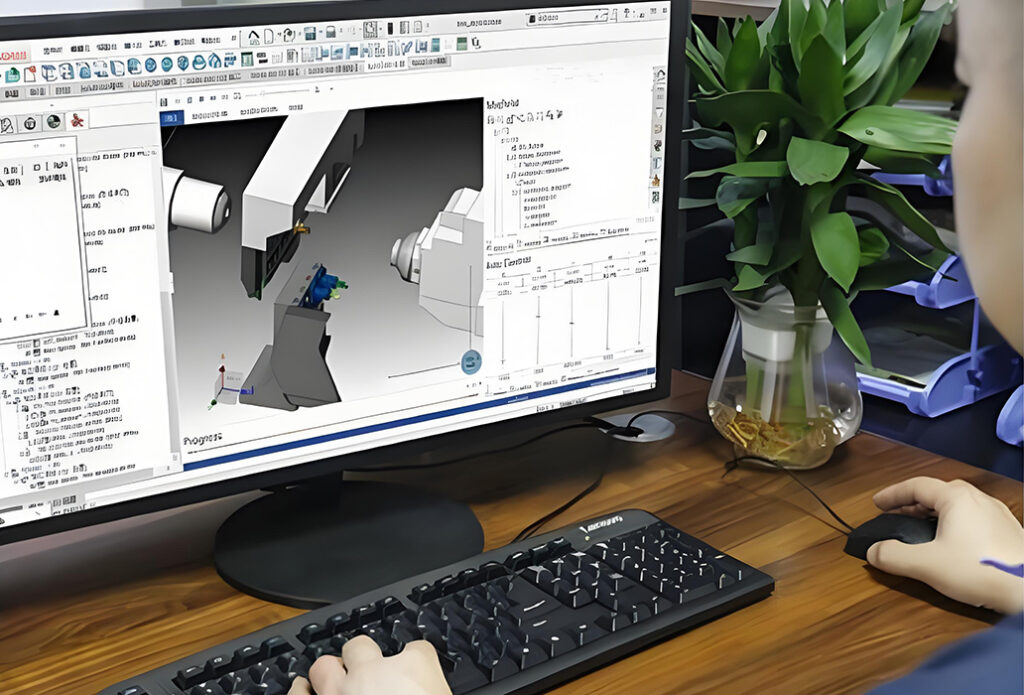

DFM for CNC precision turned parts

You guarantee manufacturability by using DFM principles at the earliest part of design. You save redesign costs by matching product geometry to CNC turning capabilities. You increase efficiency by choosing materials and tolerances that fit the machine limitations.

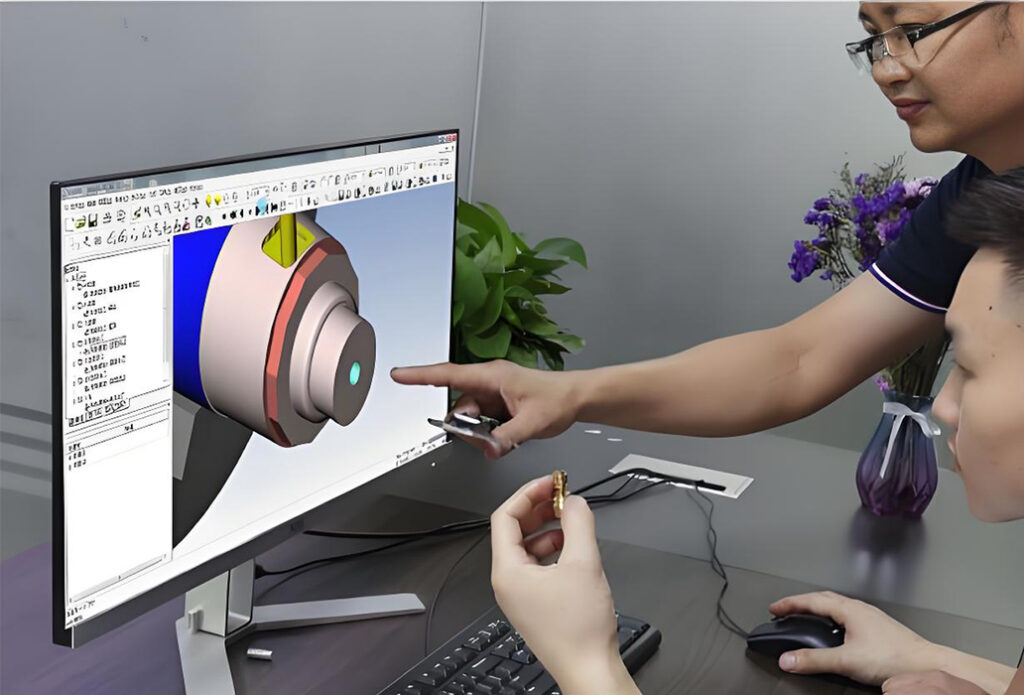

Product Design and Development

You work with engineers to validate design features before machining starts. You validate quality requirements to match functional requirements to production viability. You eliminate risks, reduce lead times, and obtain high precision part quality consistently.

Optimization of Part Geometry

You simplify complex geometries to lower machining time and tooling costs. You design with uniform wall thickness for stability and to reduce distortion. You add fillets and radii to lower stress and increase tool and part life.

Material Knowledge and Application

You test material characteristics such as strength, hardness, and machinability. You evaluate processing behavior for stability under manufacturing conditions. You match materials to end-use requirements for predictable performance in real-world applications.

Rational Tolerance Design

You use rational tolerance design to balance manufacturability, cost and performance. You establish tolerances that are consistent with functional requirements without over specifying accuracy. As a result, you minimize waste, improve quality and achieve consistent, reliable production results.

Tooling and Machining Process Optimization

Develop fixtures to correspond to material properties and part geometry. By selecting the appropriate tooling strategy, tool wear and vibration are minimized. Optimized tool and fixture design: You achieve greater accuracy, efficiency, and consistency.

Workholding and Clamping Strategy

Clamping systems that clamp the parts without deformation and guarantee accuracy by holding the parts in the same position throughout the machining process. With appropriate workholding design you increase safety, productivity and surface quality at each operation.

Surface Treatment and Post-Processing

You use coatings or treatments to increase durability and wear resistance while improving aesthetics, corrosion resistance and dimensional accuracy. This guarantees the functional, safety and industry-specific performances of all components.

Cost Control and Mass Production Optimization

You save money on reduced tool wear and material usage, improved workflow to reduce cycle times and boost efficiency. In this way, you get the maximum output while ensuring quality in high volume production runs.

Design for Assembly (DFA)

Part designs are designed for easier assembly (fewer steps), component interfaces are simplified to minimize the amount of assembly line errors that would result from part-to-part parting. This method reduces total costs while improving product reliability and assembly efficiency.

Why Choose Us for Precision Parts Turning

When it comes to precision parts turning, selecting the right partner can make all the difference between efficient and reliable production and subpar results. We integrate advanced systems, complete capabilities and stringent quality control to provide parts that are of the highest industry standard. That’s why we can count on clients from major companies like Huawei, Novel, Hysis, Tesla, Tuopu and Xusheng to entrust us with their projects.

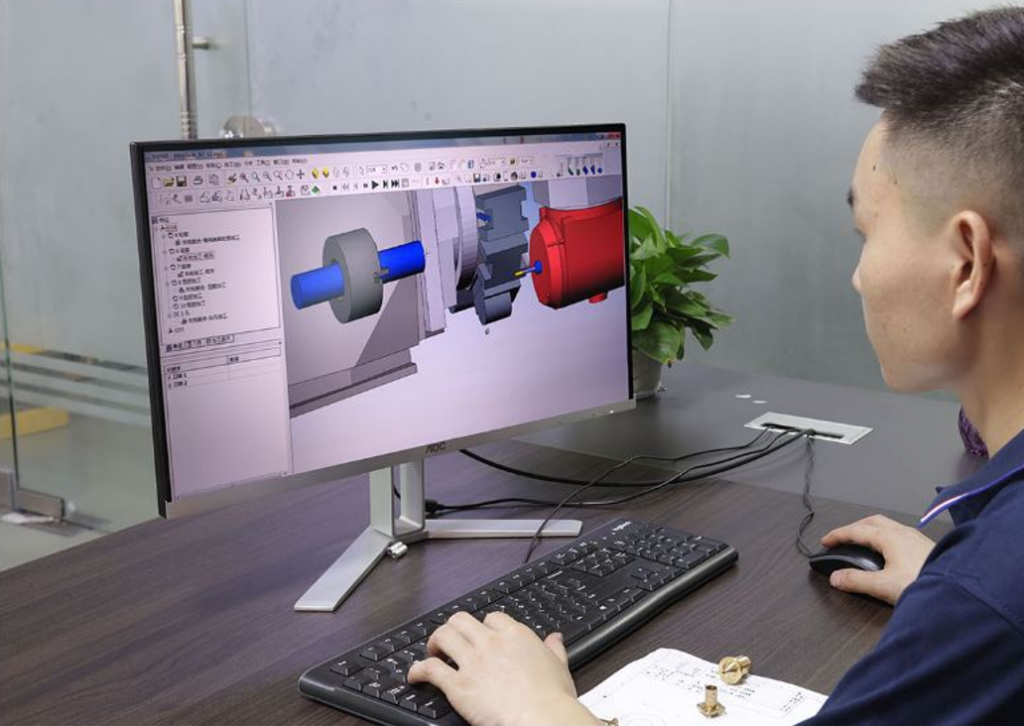

Intelligent Programming System: Our smart programming system optimizes machining toolpaths to increase production efficiency and reduce costs. By automating calculations, we ensure complex operations are consistent and lead times are minimized.

ERP Office Management System: With strong ERP office management software, we have full control over resources, scheduling, and workflows. This integrated system increases transparency and departmental efficiency.

MES Factory Management System: We use a MES factory management system to help us optimize the real-time monitoring of production. This means better product quality, speedier turnaround times, and less error on the shop floor.

Quality Management System with DFM Support: Quality is incorporated throughout the production cycle. Our in-house DFM (Design for Manufacturability) and design review ensure that each component is optimized for cost, accuracy, and performance before production starts.

Large Scale Project Capability: With the experience and resources of world-class companies, we are qualified to execute large projects with precision. Whether high-volume production or small-batch custom runs, we deliver every time.

Wide Variety of Materials and Diameters: We deal with alloys, aluminum, brass, copper, bronze, stainless steel, high temperature and special alloys, titanium, steels. Our machining capabilities accommodate components with an outer diameter of 1mm to 45mm, providing scalability for various applications.

Wide Processing Capabilities: Service: In addition to CNC turning and CNC milling, we can also perform secondary processes such as grinding, cleaning, surface finish and metal assembly. This end-to-end service minimizes outsourcing requirements and achieves consistent results.

Automatic CNC Truss Lathes for Advance Design: With advanced CNC lathes, we can reach the accuracy of 0.001mm, 0.002mm cylindricity, 0.002mm flatness, 0.002mm concentricity, 0.002mm symmetry, 0.002mm circular runout. These features make us a trusted partner for industries that need precision specifications.

Fully Automated Testing Devices: Our quality assurance is supported by fully automated testing systems. Every component is carefully inspected, ensuring that only quality products are delivered to you.

CNC precision turning Tolerance

- Diameter tolerance: ±0.001 mm

- Concentricity: 0.002 mm

- Surface roughness: 0.2 to 0.4 and Ra 0.8 to 1.6 micrometers.

- Length size tolerance: ±0.005 mm

- Angle accuracy: ±0.05°

- Thread machining accuracy: ±0.002 mm

- Positioning accuracy: ±0.005 mm

- Precision: 0.001 mm

- Cylindricity: 0.002 mm

- Flatness: 0.002 mm

- Symmetry: 0.002 mm

- Circular Runout: 0.002 mm

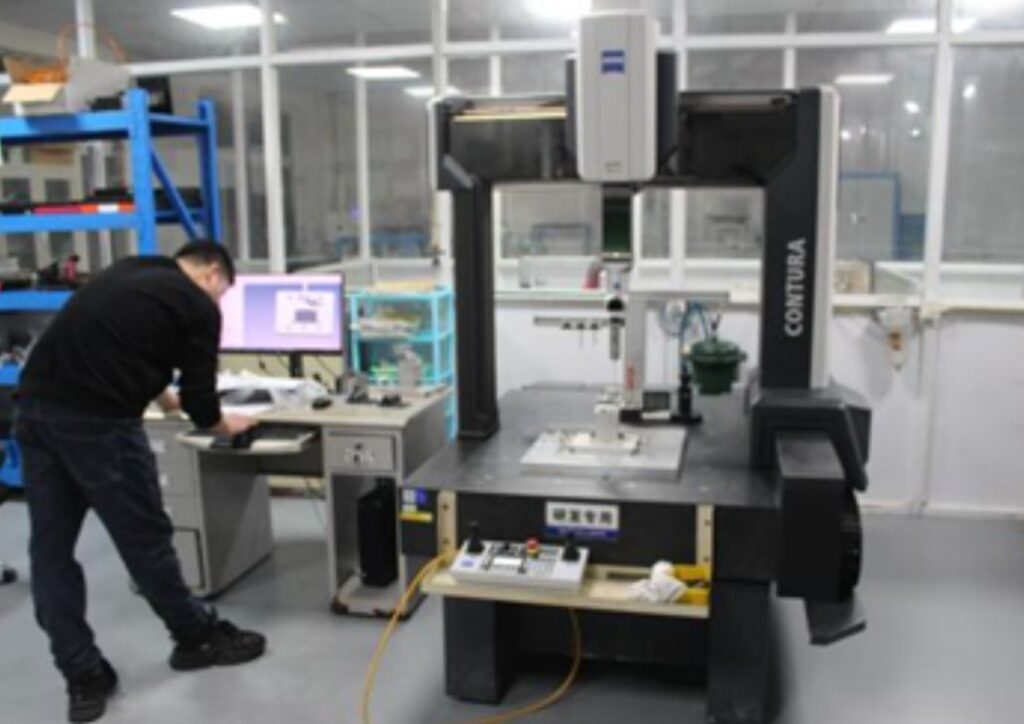

CNC Precision Turning Quality Control

CNC precision turning quality control is crucial to ensure accuracy, consistency, and reliability. By combining automation with rigorous inspection standards, we ensure that each component is of the highest possible quality for the industry.

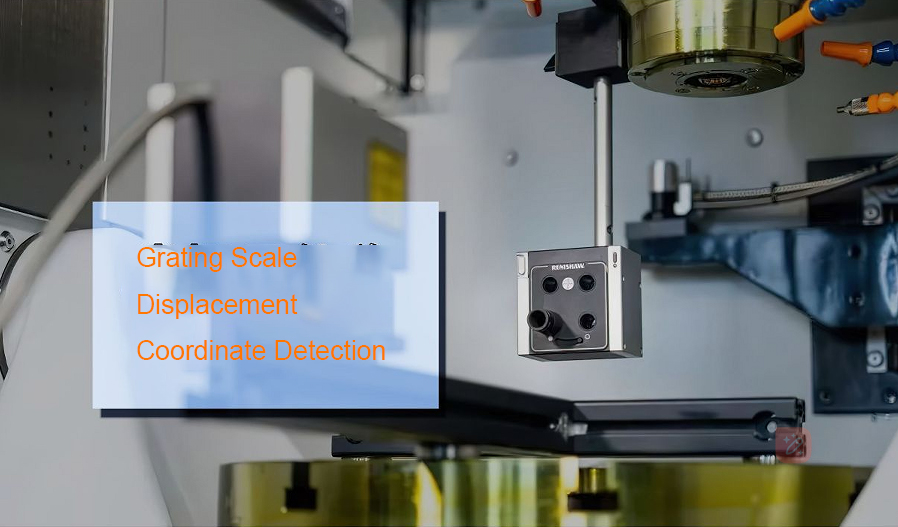

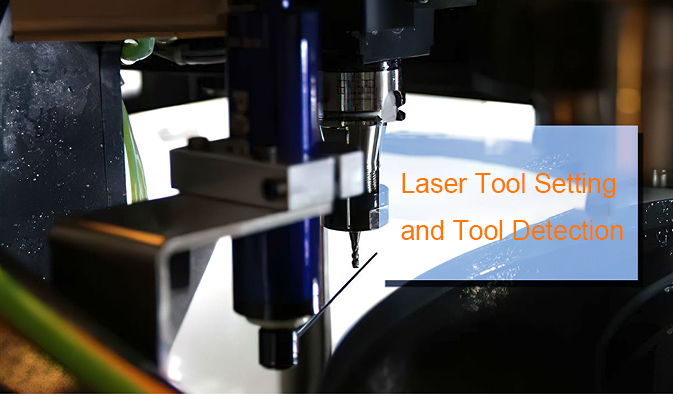

Complete 24 Hour Automatic Detection

Our quality control is running 24 hours a day with an automated detection. Machine tool coordinate setting and tool detection ensure the machining accuracy, and the automatic measurement of laser coordinate and grating scale in machine tool is detected in real time, to achieve the accuracy of positioning. This real-time monitoring assists in reducing errors and improving production efficiency.

Raw Material Feed Control

Quality begins with raw material. Each batch is checked prior to storage to ensure that it meets the requirements of REACH and RoHS. This system ensures defect prevention, environmental responsibility and provides a stable basis for reproducibility in production.

Finished Products Process Control

Everything is manufactured according to design specifications. Careful inspection at every stage; results documented and analysed. Detailed reports ensure accountability, validate compliance, and offer valuable insights for continuous improvement.

Product Traceability

A systematic traceability system is used to trace each phase of production from raw material intake to final delivery. This transparency helps to ensure the safety of the product, while also minimizing the risk of any potential issues.

Factory Quality Assurance

Control is maintained by random re-inspection and verification. Standard controls: A signature is required for confirmation of accountability. Prompt delivery on guaranteed quality and quantity is supported by comprehensive inspection reports attached to each delivery.

State of the Art Testing and Inspection Facilities

We have fully equipped laboratories for metrology, physical and chemical testing, product performance and life analysis. High performance equipment like vacuum direct reading spectrometer, X-ray flaw detector, CMM, hydrogen analyzer, contour measuring instrument, optical microscope, etc., is used to maintain the stability, precision, and reliability of all parts under production.

Our Certificates

At Masion, we are dedicated to delivering the finest in Automatic Bar Machining. With over 21 years of experience in custom Automatic Bar Machining and custom parts of high precision. It means we are committed to quality, industry standards and customer satisfaction through our certifications.

In fact, we have the ability to proudly boast key certifications that bear testament to our adherence to strict guidelines in different industries. This means that we are always up against the highest standards when it comes to Automatic Bar Machining.

- ISO 9001 Quality Management System

- ISO14001 Environmental Management System Certification

- Automotive Industry Quality Management System (IATF 16949)

- RoHS Restriction of Hazardous Substances (Available Upon Request)

- SGS Products Test – These tests are conducted to check the quality and if it matches industrial standards.

- Conformity to European standards: Solemn quality in Automatic Bar Machining.

Explore Our CNC Turning Services Gallery

CNC brass turning

Brass Component

Brass bush

CNC turning parts

Gripper guard wheel

Female House Coupling

CNC brass turning

CNC precision parts

Precision brass turned parts

Tri Clamp Hose Barb

CNC Precision Turned Parts Packaging

- The proper method of packing saves you money, reduces returns and ensures your customers receive their CNC turned parts in pristine condition. The correct type of packing is a function of size, weight and fragility of the parts. Here are some of the most trustworthy usually:

- Ziplock Bag Packing: Suitable for small parts, turned parts of lightweight and single pieces. The bags offer dust protection, moisture protection, and scratch protection. They also allow easy counting, identification and handling of parts during assembly or shipment, making the logistics operation more efficient.

- Bubble Bag Packing: Suitable for delicate, polished or high-precision parts where the bubble bag absorbs shocks during shipping. The bubbles in the air stop the parts from getting dents, scratches, or slight damages, so they can be used on delicate CNC turned pieces.

- Blister Packing: Ideal where there is a need for visibility and organisation. Each injection-molded turn piece remains securely in place yet remains clearly visible through the lucent blister material. This mode prevents confusion during distribution, and provides a professional presentation to customers.

- 5-Layer Corrugated Box Packing: ideal for bulk shipping of medium to heavy parts. The 5-layer structure is durable, stackable and shock-proof, so CNC parts can be transported long distances without distortion.

- Packing on a Pallet: Best for shipping high volume. Several cartons of turned parts may be stacked on a pallet and sealed with stretch film or strapping. This saves handling time, allows forklift movement, and improves overall supply chain efficiency.

- Wooden Box Packing: The most suitable choice for shipping CNC components that are heavy or large in size. Wooden boxes are impact, humidity and stacking pressure resistant and guarantee that the contents are delivered safely over long distances or abroad.

CNC Precision Turning Industries

- CNC turning services are widely used in industries that require high levels of precision, speed, and consistency. Advanced CNC technology: With advanced CNC technology, you can produce high-quality parts that meet stringent standards and complex requirements. This versatility makes CNC turning an invaluable process in a multitude of industries.

- Here are some of the biggest industries in which CNC turning has the most impact:

- Aerospace: You produce high-precision parts for aircraft and spacecraft instruments. you enforce rigorous adherence to safety and performance standards Your parts survive extreme temperatures and mechanical stress You aid the reliable and effective operation of Aerospace activities.

- Medical: You manufacture surgical instruments, implants, and diagnostic components with great precision. You have stringent hygiene and regulatory requirements Your components ensure reliability and safety for patients. You invest in the highest quality of healthcare solutions.

- Automotive: You manufacture engine, transmission and chassis components with high tolerance. You can optimize the parts for durability and performance under stress. Your components increase vehicle efficiency and safety. You help create smoother, safer, longer-lasting vehicles.

- Electronics: You’re a precision fabricator of connectors, enclosures and micro-components. You guarantee compatibility and electrical reliability Your parts are used in high-speed and miniaturized devices. You ensure efficient and durable electronic systems are obtained.

- Robotics and Automation: You are making gears, shafts, and joints for robotics. You optimise parts for accuracy and repeatability. Your parts provide smooth and reliable robot motion. You help make automation efficient and accurate.

- Telecommunications: You manufacture connectors, housings and signal components with tight tolerances. You improve the signal reliability and lower the transmission loss. Your parts maintain stable communication networks. You allow faster and more consistent telecommunication services

- Home Appliance: You produce precision parts for home appliances such as motors and valves. You guarantee durability, safety and smooth operation. Your parts increase appliance efficiency and life You help provide stable and high-performing home devices.

Checkout our Another Manufacturing Services

- Swiss Machining

- Custom Machining

- Micromachining

- Multi-spindle Machining

- Screw Machining

- Precision Machining

- CNC Mill/Turn

- Automatic Lathe Machining

FAQs

Can CNC precision turning be used to make custom shapes?

Yes, CNC precision turning can create complex shapes and custom designs with tolerances as small as +-0.0002mm. With the help of the latest Swiss lathe machines and multi-axis machines, you can adjust the dimensions and patterns according to the needs of different industries.

How quickly can CNC precision turned parts be made?

Turnaround times vary based on part complexity, batch size, and material but CNC turning is an automated process, which means faster production than manual methods. Advanced lathes and optimized toolpaths allow for maximum efficiency for quick delivery.

Can I mix materials in one CNC turning order?

Yes, it is possible to order parts of aluminium, titanium, stainless steel, brass or plastic in the same production run, customized to the requirements and specifications of your project.

How do you get CNC turned parts to fit in assemblies?

By designing and checking the parts for perfect fit in our DFM (Design for Manufacturing) using a tolerance of +-0.0002 mm we ensure that the parts will fit perfectly. Collaborative engineering ensures compatibility for your assembly needs.

Can I specify surface finishes in CNC precision turning?

Yes, you can choose finishes such as golden plating, polishing, bead blasting, or PVD coating to meet aesthetic and functional requirements while providing durability and corrosion resistance.

Can CNC precision turning be used for new industries?

Yes, due to its precision and versatility, CNC turning is perfectly suited for new industries such as robotics, green energy, and wearables and provides high-accuracy components for these new applications.