What is a Helical Gear?

A helical gear has a cylindrical shape featuring angled teeth. The teeth slice at an angle of helix to the gear axis. Helical gears mesh gradually, unlike spur gears with straight teeth. Such level involvement ensures convenience power transfer and negligible shock loads. They relay motion and torque effectively between parallel or crossed shafts. They are popular in applications involving high-speed and heavy load by engineers. Helical gears increase torque while lowering rotational speed between shafts. Their design of teeth enhances contact ratio and makes the distribution of the load to be more uniform. The feature minimizes the noise, vibration, and wear in operation.

Leading and Trusted Helical Gears Manufacturer

With over 21 years of expertise in helical gear manufacturing, CNCSwissMasion delivers precision gear solutions worldwide. Our CNC turning and gear hobbing machines are over 100 to ensure production that is consistent and scalable. Our 125 experienced technicians produce gears with narrow tolerances to within 0.004 mm. We comply with DIN Grade 5 standards of smooth and reliable transmission. The quality is reliable and repeatable in our ISO 9001 and IATF 16949-certified plant. As experienced helical gear manufacturers, we support demanding industrial applications globally. We also stand recognized as a reliable helical gear manufacturer in China. Our customers include automotive, robotics, medical, and industrial business with prototyping to high-volume orders.

Materials

- Carburising steel. (20CrMnTi,20CrMo,18Cr2Ni4WA,17CrNiMo6)

- Carbon steel.(35CrMo 45#,40Cr,42CrMo)

- Nitriding steel.(38CrMoAlA, 31CrMoV9)

- Cast iron.(HT250,QT600-3)

- Powder metallurgy.(Fe-Cu-C)(FC-0208)Fe-Ni-C(FN-0205)

- Brass

- Copper

- Bronze(ZCuSn10P1,ZCuAl10Fe3)

- Stainless steel(316L,304,2Cr13 / 3Cr13,0Cr18Ni9)

- Aluminium(AISi10Mg,AiMgSi)

- PEEK

- Phenol-Formaldehyde

- POM

- PC

- PA66

Machines

- CNC Lathe

- CNC Machine

- Polishing machine

- External cylindrical grinding machine

- Surface grinding machine

- Centerless grinding machine

- Broaching machine

- Slotting machine

- Gear Hobbing machine

Surface Finish

- CNC lathe

- CNC machine

- Polishing machine

- External cylindrical grinding machine

- Surface grinding machine

- Centerless grinding machine

- Broaching machine

- Slotting machine

- Gear hobbing Machine

Types of Helical Gear Sets

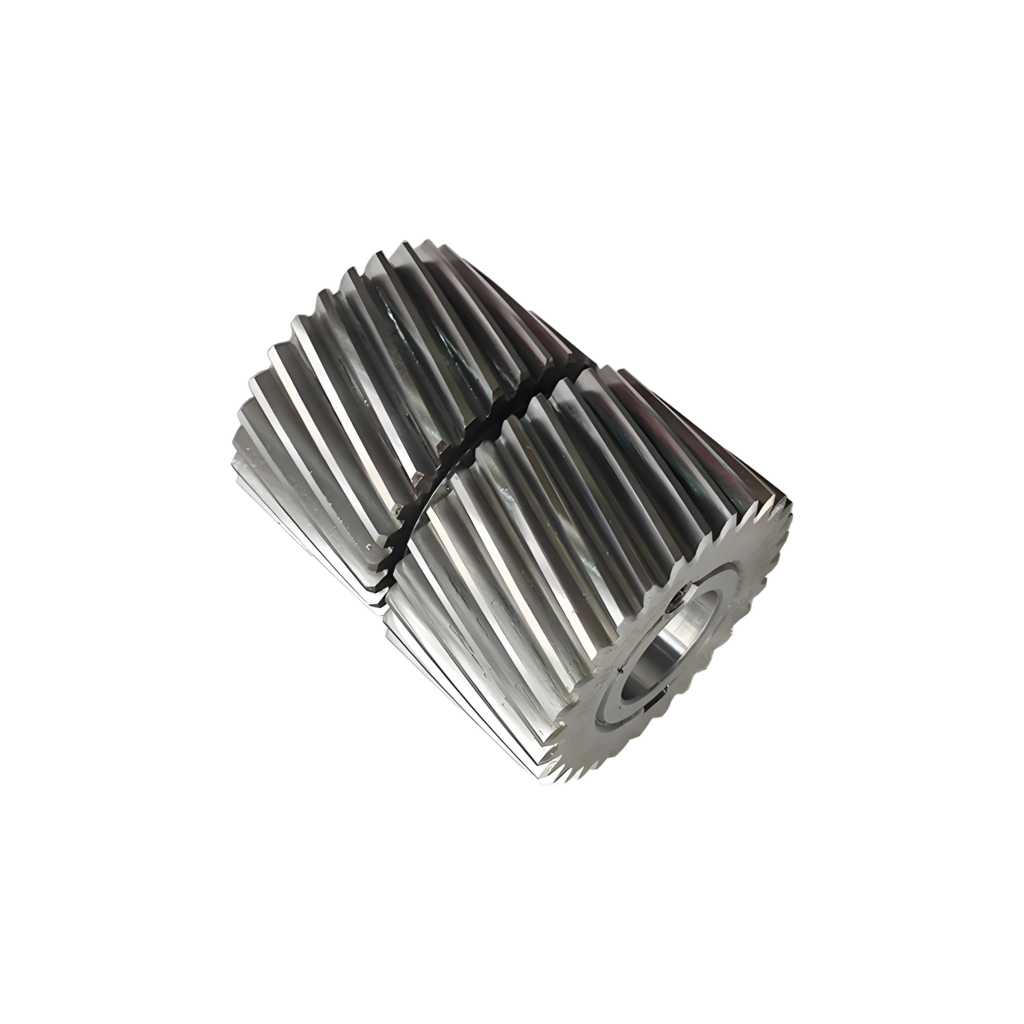

Double Helical Gear

Double helical gears use two opposing sets of angled teeth on one gear body. Such a layout eliminates the axial thrust and safeguards bearings against additional loads. It provides the high torque transmission and smooth and quiet functioning. The design enhances the load distribution and minimizes vibration during heavy load cycles. These gears occur frequently in turbines, compressors, marine drives, and big industrial machines.

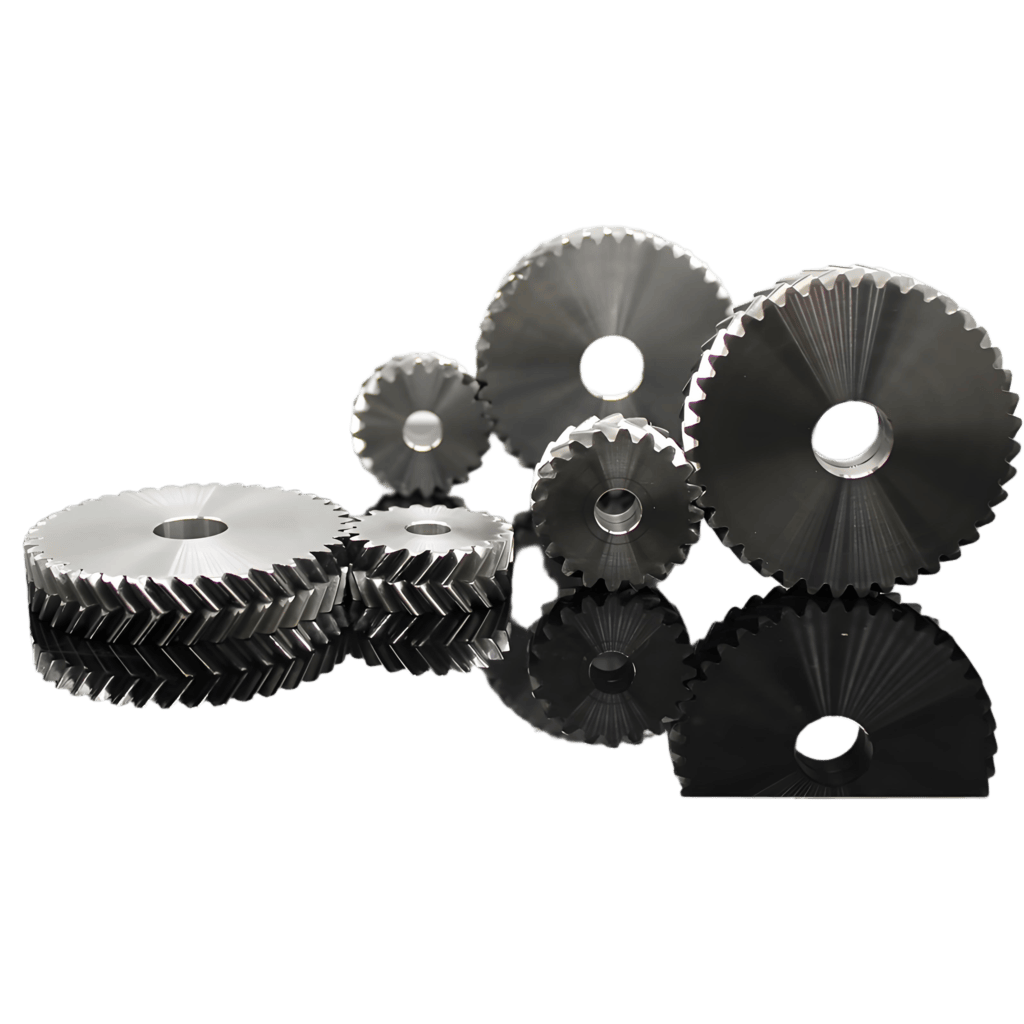

Herringbone Gear

The herringbone gears have mirrored teeth that create a unique V-shaped design on the gear surface. This structure is balanced in its axial forces and eliminates side thrust on shafts. It provides low vibration and noise with smooth transmission of torque. Several teeth work simultaneously, enhancing rigidity and accuracy. They are used in ship propulsion systems, steel mills, engines, and high-speed power equipment.

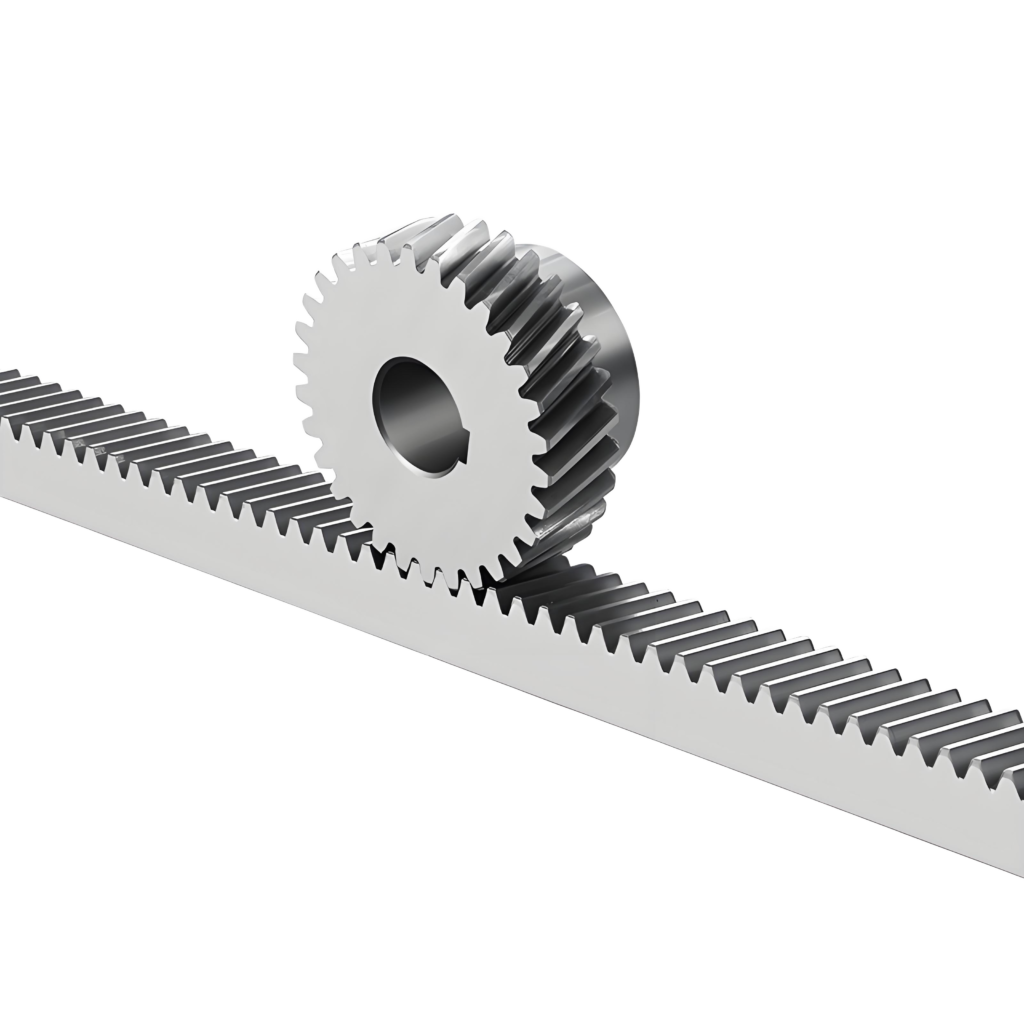

Helical Gear Rack and Pinion

Helical rack and pinion systems transform rotary motion to accurate linear motion. The angeled shapes teeths ensure slower interaction and smooth passage. This design minimizes backlash and increases positioning accuracy. It helps to carry heavier loads than straight rack systems. It is commonly found in CNC machines, automation lines, robotics and automotive steering systems.

Screw Gear

Screw gears work on parallel and non-intersecting shafts. They relay motion by sliding contact between helical teeth. The result of this interaction is smooth and noisy operation at moderate speeds. Efficiency is also low because of continuous sliding action. Screw gears are appropriate in small machinery, light torque motors and in machined assemblies.

Helical Worm Gear

Helical worm gears combine a threaded worm with a matching worm wheel. This design provides a high speed reduction and high torque multiplication. The system has a tendency to give a self-locking effect as a safety measure. It operates quietly and with shock loads. The most common applications are conveyors, elevators, gates, crushers, and material handling equipment.

Helical Bevel Gear

Bevel helical gears transmit power between shafts set at right angles. Their spiral teeth guarantee progressive involvement as well as smooth rotation. This design has a high torque and shock absorption. It is more efficient than the conventional worm gear systems. Bevel helical gears serve mining, steel processing, automotive assembly, and heavy industrial machinery.

Helical Gear Manufacturing Process at CNCSwissMasion

At CNCSwissMasion, helical gears begin with careful material selection based on application demands. We cast, forge, extrude or powder metallurgy gear blanks to create a balance between strength, cost and production volume. CNC helical gear machining corrects fine geometry of gear teeth after blank preparation. Hobbing serves as the primary process for external helical gear cutting, while shaping creates internal or complex profiles. Broaching is used to facilitate high-volume manufacturing of small precision gears and milling is used to facilitate prototyping and custom designs. Heat treatment is done to enhance hardness, wear resistance, and fatigue strength. Final grinding and inspection ensure tight tolerances, smooth finishes, and reliable helical gear performance.

What are Helical Gears Used For? – Key Industries

Helical gears suit fast-paced industries where speed, precision, and reliability matter most. Their curved teeth bite slowly, which causes less vibration in the fast working process. This design reduces wear in high rotational speeds. Machines can operate on sustained duty cycles. Manufacturers choose helical gears to maintain performance under demanding production schedules globally today.

Fast-Paced Industries

Helical gears improve pump performance by creating smoother, more consistent fluid discharge. The overlapping of teeth reduces the pulsation of the flow during operation. This enables more capacity designs using fewer large teeth. Pumps produce constant pressure output. Engineers favor helical gears when uniform flow, efficiency, and reduced noise remain critical for industrial systems.

Pumps with Helical Gears

Industrial chemistry relies on helical gears to control speeds in critical equipment. These gears slow down turbine and compressor speeds securely. They match machinery to motors and generators. Adequate lubrication will help avoid overheating and wear. The cooling system is designed with care, so that it provides stable, efficient and continuous chemical processing of facilities across the globe.

Industrial Chemistry

Automotive manufacturers widely use helical gears for reliable power transmission systems. Staggered tooth interaction minimizes noise in vehicle drives. During operation, more teeth share the load. This enhances high torque usage durability. In the contemporary high-performance automotive applications, transmissions have the advantage of smoother shifts, better comfort, and extended service life.

Automotive Industry

Production industries depend on helical gears for continuous, high-load machinery operation. Angled teeth can work the twisting and spinning forces. These gears allow high rotational speeds without vibration. Machines operate longer without interruptions. Manufacturers select helical gears for reliable output, efficiency, and stable production environments across demanding global industries.

Production Industry

Advantages and Disadvantages Of Helical Gears

Advantages

- Helical gears operate quietly and smoothly, reducing vibration and shock during machine operation.

- They allow transfer of power between non parallel shafts when needed.

- Angled teeth- These apply the axial forces and are best applied when the requirement is to run at high velocity or constantly.

- Helical gears can handle higher torque due to balanced and well-designed teeth for heavy machinery.

- Spiral tooth orientation creates greater load bearing capacity that is more robust in comparison to comparable spur gears.

- They include elastic joints of shafts that allow machines to be changed to parallel or perpendicular positions.

- Helical gears and gearboxes are strong, durable, and suitable for demanding high-load applications.

- Automotive industries use helical gears to transmit force between shafts at right or parallel angles.

Disadvantages

- The angle of the helix generates axial force that must be supported by bearings.

- Sliding is an activity that produces more heat, and thus, it is very important to have good lubrication that is going to last long.

- Efficiency also is somewhat lower than comparable spur gears due to sliding and friction during engagement.

- Power loss is higher in helical gear trains compared to spur gear trains under similar conditions.

- Complexity requirements and precision requirements ensure that manufacturing and designing cost are higher as compared to spur gears.

Selecting the Right Helical Gear System

Load Capacity

The load capacity defines the amount of torque that the gear system can withstand. You have to evaluate both dynamic and static loads. Take into account peak load conditions and constant operating torque. The large torque values require more powerful materials and efficient gear design. Applying gears of a smaller size than needed may lead to early wear and time out.

Speed Ratio

Speed ratio is an influence on the rotational output of input. Right ratio guarantees required speed and torque in driven parts. Helical gears offer smooth transmission even at high ratios. You should keep in mind such application-related considerations as efficiency and backlash tolerance. An incorrect ratio of speed may cause vibration and noise or parts failure.

Material and Hardness

The material of gears influences their strength, wear resistance and longevity. Steel alloys are the most common but surface treatments make alloys more durable. Hardness guarantees that the teeth of the gears will not deform under pressure. Take into account operational conditions, temperature and exposure to corrosion. Quality material choice ensures less maintenance and enhances the reliability of the system as a whole.

Alignment and Mounting

Helical gears require precise alignment to prevent uneven load distribution. You have to check shaft positioning and housing tolerances. Misalignment enhances noise, vibration and wear on the teeth surfaces. Proper mounting also minimizes the backlash and enhances the effectiveness of transmission. Snugness in fit extends gear life and minimizes downtime.

Lubrication Requirements

A proper lubrication avoids friction, overheating and excessive wear. The type of oil and lubrication system is something that you need to choose. Look at speed, load and environmental factors during lubricant selections. Correct lubrication also lowers maintenance time and cost of operation. The failure to consider this aspect may result in the failure of gear, and costly repairs.

Custom Helical Gears - Why CNCSwissMasion is the right choice?

Technology and Equipment

We manufacture high precision machining with CNC machine tools, gear hobbing machines, gear grinding machines and gear honing machines. Various machining procedures such as gear hobbing, shaping, shaving, grinding, honing and powder metallurgy all address a wide range of industrial requirements. Hardness is enhanced through optimized heat treatment techniques like carburizing, quenching, nitriding, and induction hardening to achieve a reliable performance of hardness at HRC 58-62 and wear resistance.

Extensive Gear Product Line

We provide a complete range of gears, including spur gears, helical gears, bevel gears, worm gears, planetary gears, and racks. We have 20CrMnTi, 42CrMo, 45# steel, stainless steel, copper alloys, nylon and POM to meet a wide range of working conditions. Non-standard gear designs are assisted with customized services, modules 0.3 to 20, and diameters up to 2000mm, so that gears can be made to meet accurate industrial demands at a considerable cost.

Tough Quality Control System

Quality is maintained by complete process testing of raw materials to final products as a part of spectral analysis, hardness test, CMM test, and verification of gear meshing. The products comply with ISO 9001 and IATF 16949 requirements of a consistent quality. The design of the tooth profile has been optimized to ensure transmission noise of 65dB or less and that the gear life exceeds 100,000 hours of service, ensuring consistent performance, low maintenance and lifespan in the most demanding industrial environments.

Effective Supply and Cost Benefits

Our production system guarantees a quick response time, where regular gears will be shipped in 7-15 days, and urgent orders will be fulfilled, as necessary. Production at large quantities in our own factory gives bulk orders a cost reduction of 15-30 percent. We are also offering stable international delivery via partners such as DHL and FedEx. These strengths guarantee customers who need quality gears on time, affordability, and worldwide availability.

Ample Application Knowledge

We are a supplier of automotive, industrial machines, new energy and robotics with precision gears to meet different requirements. The automotive uses involve transmission and differential gears that are of industry standard. Industrial machinery gears include reducers, pumps, valves and machine tools. The new applications of the energy are wind turbine gearboxes and power tool gears, and robotics applications are harmonic reducers and servo motor gears. This experience guarantees high quality gears which are optimized to all industry needs effectively.

Explore Our Range of Products

What is a Helical Gear - FAQs

Are helical gears directional?

Yes, helical gears are directional due to the angled teeth. Tooth helix provides axial thrust on the shaft. Left-hand and right-hand helical gears rotate in specific directions and must mesh with opposite-handed gears. Poor orientation may lead to the creation of noise, vibration, or wear and tear. Machinery Proper alignment guarantees smooth transmission of torque, and good life of gears.

How are helical gears different than spur gears?

Helical gears have angled teeth, whereas spur gears have straight teeth parallel to the axis. Helical gears transmit torque more smoothly and quietly due to gradual tooth engagement. They are able to support larger loads and have better speeds. Spur gears are less complex, less expensive to make and can be used in lower load conditions. Helical gears require axial thrust management, unlike spur gears, which produce no thrust.

What is the gear inspection process? Is there a complete quality control system?

Our quality control system is ISO9001 and we have a gear inspection process. This inspection begins with the incoming material and blanks and checks the composition and major dimensions by OES spectroscopic analysis, calipers, and a coordinate measuring machine. Inspections in machining processes verify the blank dimensions and tempering hardness. Finishing checks after machining measure tooth profile, helix error, involute curve, pitch error, cumulative error and surface roughness. Surface hardness and deformation are checked during heat treatment. End checks are performed to measure tooth contact spots to achieve 80 percent meshing.

What are the testing methods and equipment for key gear parameters (such as tooth profile, tooth direction, and hardness)?

We apply gear testing tools to measure tooth profile, helix angle and tooth direction. Micrometers are precise in measuring the distances between spans. Ra are measured using surface roughness testers. HRC is checked using hardness testers. Gear concentricity is tested by runout testers. Coordinate measuring machines (CMM) have been used to measure the pitch of gears, sizes, and alignment accurately. This integration provides uniform, quality performance of gears when needed.

Do you support customized gear production? What is the lead time from drawing to sample?

Yes, we are in favor of tailored equipment manufacturing. You submit your drawings to engineering. We offer sample prices, delivery time, and bulk production lead times. Provided that custom cutting tools are not needed, samples are usually prepared within 10 days. Samples usually require 20-25 days when special gear cutting tools are required. This guarantees the delivery in an efficient manner and at high standards of precision.

What is the gear precision grade?

The present equipment has a DIN grade 5 accuracy in gears. Additional equipment can be added to achieve greater precision requirements. This enables us to produce gears with tighter aerospace, robotics or medical tolerances. Precision control provides low backlash, precision in transmission of torque and enhances operational reliability in harsh machinery conditions.

What information is needed for a quotation?

In order to give a correct quotation, you need to give drawing of gears, quantity, material and precision grade required. Provide surface treatment, type of gear, module, and diameter. The greater the information you provide, the quicker we can calculate costs and times of delivery. This guarantees clear pricing and accurate prototypes as well as bulk production planning.

What industries do your main clients come from?

Our primary customers are in the automotive, robotics, wind power, aerospace, machine tools, and medical equipment market. Every industry requires accurate, long lasting, and high quality gear. We develop gears which address varying loads, speed and environmental needs. The experience in different industries guarantees that our solutions are optimal in performance, durability, and safety in operation.

Can helical gears be used at any angle?

Helical gears can transmit motion at various angles, but the shaft alignment must match the helix orientation. Parallel and crossed helical gear arrangements are possible, each requiring precise mounting to prevent excessive axial thrust. The correct installation allows easy power flow, less vibration, and wear. This misalignment may cause noise, loss of efficiency or damage of gears.

How do helical gears work?

Helical gears transmit power through angled teeth that gradually engage with mating gear teeth. Such slow interaction minimizes noise and shock loads. The angled teeth provide an axial thrust, which has to be handled with bearings. Helical gears convert rotational motion efficiently while maintaining high torque transmission. They are used in high speed and high load applications that need smooth running and extended service life.

How much end play for helical gears?

End play in helical gears depends on gear type, shaft alignment, and bearing arrangement. It is usually regulated to very precise limits to enable thermal expansion and minimize stress of bearings. When there is excessive end play, it will result in vibration, noise, and uneven contact of teeth. Adequate axial clearance is provided by proper design and installation to allow smooth operation and a long life of gears.