Precision Pogo Pins Provider in China

Specialized Pogo Pin Manufacturer for 21 Years

- Equipped with over 100 CNC turning machines, 75 Swiss CNC lathes, 50 automatic lathes, and a workforce of 125 professionals.

- Manufacturing tolerance maintained up to ±0.007 mm.

- Certified with ISO 9001 and ISO 16949 quality management systems.

Pogo Pin Supplier Experts in China

CNCSwissMasion is a prominent manufacturer of pogo pin based in China and has a state-of-the-art 5,000-square-meter plant. The company manufactures dustproof, waterproof, corrosion-resistant pogo pins to be used in automotive, medical, communications and industrial applications. All products are tested rigorously in electrical, mechanical, lifecycle and environmental tests to guarantee reliability. CNCSwissMasion provides solutions of superior quality worldwide with robust design skills and certified systems.

Pogo Pin Machining Service

We are CNCSwissMasion, offering precision pogo pin machining services that are designed to be reliable and perform well. Our products are manufactured using modern Swiss CNC technology, automatic lathes and multi-axis turn-mill centers, to produce high-tolerance products with premium alloys and stainless steels. In-house capabilities include material selection, close dimensional control and uniform surface finishes such as nickel, gold, silver, tin and palladium plating. Since prototyping to high-volume production, we have provided reliable quality, quick turnaround, and cost-effective solutions that are specific to your application with global manufacturing support around the globe.

Materials

- H59-1

- H58-1

- H62

- C3604

- C5191

- C5210

- C17200

- C17500

- Stainless steel m(303,304)

Machines

- Automatic CNC Lathe

- CNC turning machine

- Swiss CNC lathe

- CNC turn&mill machine

Surface Finish

- Nickle Plating

- Golden Plating

- Silver Plating

- Tin Plating

- Palladium Plating

What is a Pogo Pin?

A pogo pin is a spring-loaded electrical connector, which allows consistent and reliable contact. It is made up of three primary parts, a plunger, barrel, and internal spring which ensure stabilized connectivity during vibration or movement.

Pogo pin Manufacturing Process

Material Selection and Preparation

CNCSwissMasion begins with the selection of high quality raw material carefully based on the application requirements. The pin body is usually made of stainless steel or high grade brass to ensure that it is strong and corrosion resistance. Springs are made of phosphor bronze or stainless steel to ensure the same elasticity and contact tips or balls are made of stainless steel or tungsten to offer durability and consistent electrical contact.

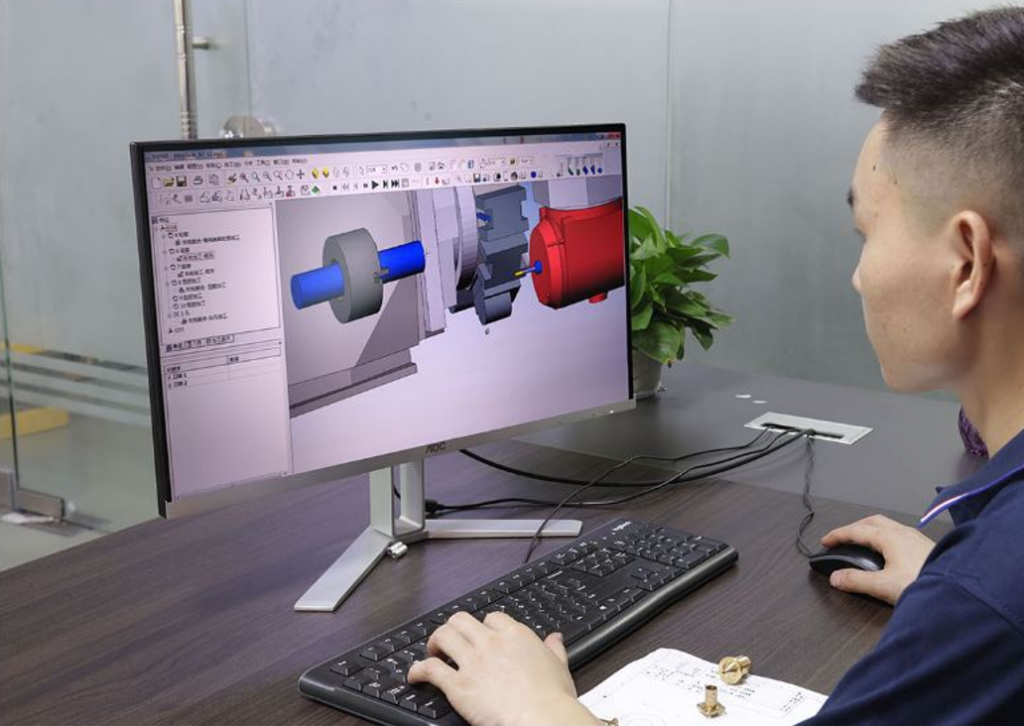

Precision CNC Turning of Pin Components

The pogo pin body, plunger, and sleeve are machined using very sophisticated CNC turning, Swiss CNC lathes, and automatic lathes. The machines are fed copper or metal rods and rotated to the specifications of the engineering drawings. The dimensions and tight tolerance are inspected during machining and all parts are deburred to run smoothly.

Dimensional and Visual Inspection

Once turned, the machined parts are checked to specification to ensure that they are of the correct size and tolerance. Microscopic inspection will be done to verify the quality of the surface, concentricity and finish and to verify that every part of the part is of the high quality standards of CNCSwissMasion.

Spring Manufacturing and Heat Treatment

A functional component that is critical is the spring. Precision coiling the wire to the necessary dimensions forms the springs which are then tempered and heat treated. This is done to achieve the right spring force, elasticity and fatigue resistance of long-term use to achieve reliable compression and rebound during repeated use.

Needle and Tube Arrangement

In pogo pin SMT patches, needle tubes are aligned in rows with automated systems. A column frame is filled with needle tubing, machine parameters are adjusted, and vibration is used so that every tube properly fills its respective hole. This measure provides uniform alignment and assembly preparation.

Spring Alignment and Placement

A correct amount of springs is added to a spring column plate. The spring plate and column frame are thoroughly rocked and brought into position so that each spring can fall into place. The correct positioning of springs is a condition of even contact force and consistent electrical operation.

Assembly of Pogo Pin Components

The spring is then inserted into the hollow pin body and the next step is to insert the plunger precisely. CNCSwissMasion provides controlled compression to ensure that the pogo pin is smooth as it extends and compresses without loss of force and jamming.

Contact Tip Attachment

The plunger end is firmly fixed to the contact tip or ball by press-fitting or other controlled means. This guarantees peak contact area, reduced resistance and increased wear resistance through repeated mating cycles.

Surface Finishing and Plating

Pogo pins can be finished in nickel, gold, silver, tin or palladium to improve conductivity, corrosion resistance and life. The entire plating procedures are very controlled to ensure uniformity in depth and bonding.

Comprehensive Testing and Quality Control

All pogo pins manufactured by CNCSwissMasion are rigorously tested, such as spring force test, electrical conductivity test, lifecycle durability test, and environmental test. Only those that have passed performance, reliability, and safety requirements are subjected to final packaging.

Pogo Pin Connector Advantages and Disadvantages

Advantages of Pogo Pins

- Long cycle life and high durability, thousands to millions of mating cycles with little performance degradation.

- Less wear and tear through spring-loaded wiping motion compared to traditional connectors which use friction.

- Low contact resistance, particularly with gold plating, which guarantees the efficient power transfer and signal integrity.

- Constant electrical behavior and predictable contact force, even when using high-frequency or power.

- Small and space-saving structure, suited to miniaturized and dense electronic assemblies.

- Strong shock and vibration durability, consistent contact in mobile, automotive and industrial applications.

- Blind-mating capability, which enables tolerance to misalignment and enhance user convenience.

- Inexpensive to use in the long term, simplifying assembly, minimizing the number of components and minimizing maintenance.

Disadvantages of Pogo Pins

- Cost per pin is larger than with less complex connector types.

- Proneness to dust and contamination when not sealed or maintained.

- Lateral forces, which may destroy the spring mechanism or shorten life.

- Possible wear on mating PCB pads particularly in high cycle applications where pad plating is not done properly.

- Small number of pins per connector housing, making very high-density designs more complex.

- Higher design complexity, whereby close consideration must be given to the choice of spring force, travel distance, materials, and surface plating to achieve the best performance.

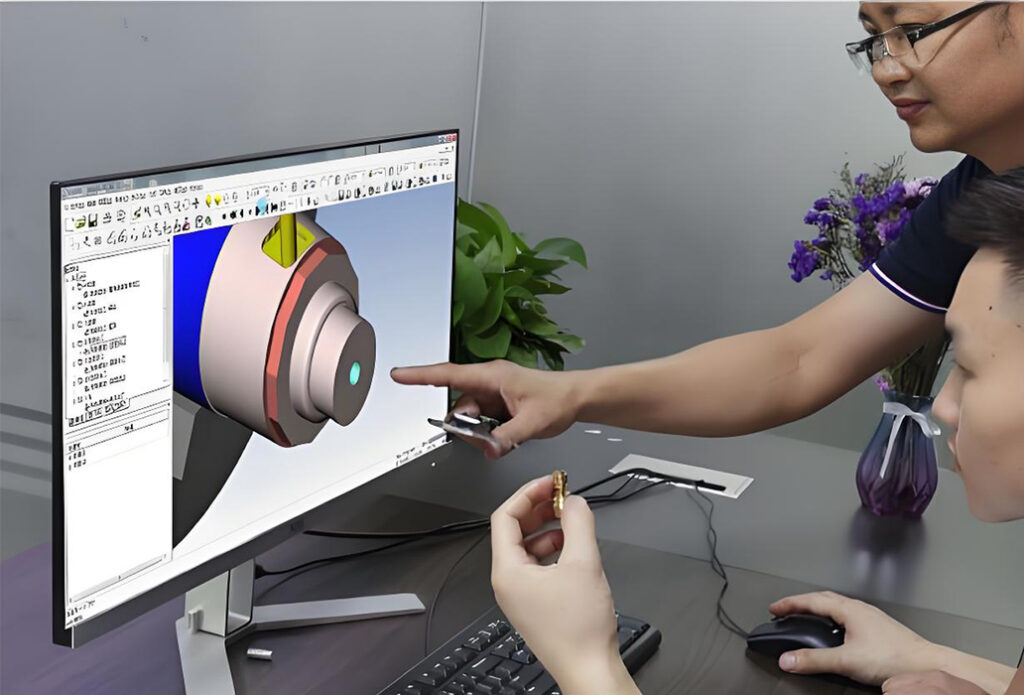

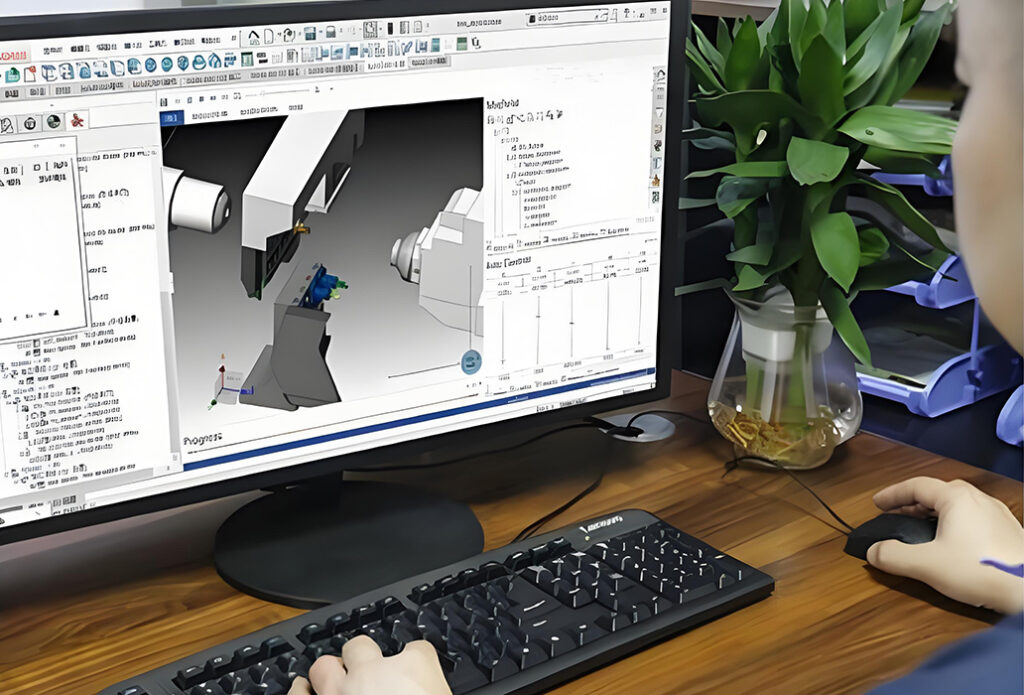

DFM For Custom Pogo Pin

CNCSwissMasion is one of the limited manufacturing partners that provides special Design for Manufacturing (DFM) services of custom pogo pins that are supported by extensive experience in CNC Swiss machining and multi-axis CNC turning and milling. You may be designing new pogo pin designs or struggling with existing ones but our staff can assist in streamlining designs to achieve the best performance, manufacturability, and cost effectiveness yet not affecting precision or reliability.

We provide a full line of DFM services of custom pogo pins, such as:

Pogo Pin Component Design:

We also aid in the design of high-precision pogo pins such as plungers, barrels, springs, and so on, which move without difficulty, with a constant contact force, and a long service life, yet are simple to manufacture.

Design Evaluation:

Our specialists analyze your pogo pin designs to ensure that they can be used in Swiss screw machining processes to minimize risks, rework, and delay in production.

Correct Material Selection:

Depending on electrical, mechanical and environmental needs, we advise you about the appropriate materials to use, either copper alloys or stainless steels, to make them durable, conductive and economical.

Cost Analysis:

Our cost analysis is specific and elaborated to recognize the potential of reducing cost of machining, plating and assembly without compromising on functionality.

Rapid prototyping capabilities:

We have fast prototyping capabilities in which pogo pin designs can be quickly validated and testing and refinement can be done before full-scale production.

Testing and Validation:

The design of each is verified by dimensional inspection and functional testing, to meet industry standards and application specific requirements.

CNCSwissMasion is equipped and has the experience to meet your requirements of custom pogo pin machining, precision pogo pin components and high volume pogo pin production. We are the preferred partner of OEMs and electronics manufacturers who want to see their pogo pin designs optimized in order to be manufactured efficiently, precisely, and at scale using Swiss machining.

Our Machines For Pogo Pins Connectors

Swiss CNC Lathe

Our Swiss CNC Lathes at CNCSwissMasion produce high precision and complex Pogo Pin at a high level of accuracy. You are able to attain close tolerances and high surface finishes. It has features such as synchronized slides, live tooling and automatic bar feeding. The advantages are low wastage, uniform quality of parts and high volume efficiency. You enjoy the advantage of having accurate dimensions on the smallest and most delicate parts, which is reliable in critical applications.

Auto CNC Lathe

We have Auto CNC Lathes that automate the process of turning to produce Pogo Pins quickly and with uniformity. You are able to deal with moderate to large volume orders easily. Its main characteristics are multi-axis control, automatic tool changers and programmable machining operations. The advantages include shorter cycle times, less labor needs, and batch-to-batch consistency. Your productivity is also enhanced, as is efficient use of materials, and capability to generate complex geometries reliably.

Cam Lathe

Cam Lathes of CNCSwissMasion are suitable in repetitive Pogo Pin designs that need mechanical accuracy. They include variable cutting speeds, cam-driven profiles, and repeatability. You enjoy low maintenance, high precision and low production costs. These lathes enable long production runs without the need to adjust them frequently. You produce quality, standardized components at very high rates and this is ideal in large volume, repeatable Pogo Pin production, but with high quality standards.

Why Choose CNCSwissMasion for Pogo Pin?

Getting the appropriate partner to manufacture Pogo Pin will determine success of your project. CNCSwissMasion is not a machine service, but a partner that strives to be precise, quality and efficient. Each production process guarantees performance, quality Pogo Pins. This is why CNCSwissMasion is so special.

Strong Quality Management

CNCSwissMasion ensures stringent quality assessment of each Pogo Pin. You will not have to deal with faulty or poor quality components. Auto checks and measurements ensure tight tolerances and performance consistency. Our quality operations ensure quality parts in use in aerospace, automotive and electronics.

Design and DFM Support

We offer Design for Manufacturability (DFM) services to streamline your Pogo Pin designs. You receive instructions regarding tolerances, choice of material and geometry. CNCSwissMasion makes parts functional, manufacturable, and cost-effective. Designs are done to the precise specifications and production is within the budget.

Capacity for Large and Complex Projects

CNCSwissMasion collaborates with such major firms as Tesla, Huawei, and Novel. You are able to make either small precision parts or massive assemblies with ease. We are capable of processing intricate geometries, bulk orders, and deadlines and do so with our modern equipment.

Wide Material Variety and Diameters

We provide a wide range of material choices such as:

- Brass, Copper, Aluminum, Bronze.

- Stainless steel, special alloys and high-temperature alloys.

Pogo pins of varying diameters, 1mm to 45mm, are easily made. You have the option of corrosion resistant, strong, or conductive materials.

Comprehensive Machining and Processing Services

- In addition to CNC Swiss machining, CNCSwissMasion offers:

- Grinding

- CNC milling and turning

- CNC mill & turn

- Cleaning and surface finishing

These combined services provide high-precision durable Pogo Pins that have a high-quality surface.

Modern Swiss Lathes for Precision

Our Swiss CNC Lathes make parts to a ±0.003mm to ±0.001mm tolerance. Even on small or complicated Pogo Pins, you get high precision. High quality is ensured using advanced tooling and monitoring and less time is wasted in production.

Automated Testing and Inspection

Pogo Pins are completely tested in size, surface finish and material. Components are to standard, so there are fewer defects and rework. Critical industries have traceable quality reports through automated inspections.

Pogo Pin Tolerance

The foundation of the Pogo Pin manufacturing is precision. We realize at CNCSwissMasion that performance in electronics, automotive or aerospace applications can be affected by the slightest deviation. This is why we have strict tolerances in all our Pogo Pin production.

Supported Tolerances

- Outer Diameter (OD): -0.003mm to -0.01mm based on pin size and material.

- Inner Diameter (ID) / Bore: ±0.005mm to ±0.015mm to fit the springs as accurately as possible.

- Heigth or length: -0.01mm to -0.03mm to provide appropriate connectors engagement.

- Travel or compression of spring: Tolerance of +/- 0.02mm to ensure required performance in electrical industry.

- Concentricity and Runout: Permissible tolerance of +/-0.005mm to ensure stability and contact.

Why Our Tolerances Matter

These tolerances will keep your Pogo Pins:

- Fits perfectly into PCBs, connectors, or assemblies.

- Provide continuous electrical contact.

- Unstable-Mechanical stability after repeated compression cycles.

Custom Tolerance Capabilities

We also endorse custom tolerances depending on your design specifications. Critical application requirements, such as high-frequency electronics, aerospace modules, or medical devices, can be specified. CNCSwissMasion optimizes parameters of tooling, inspection and machining, according to specifications.

CNCSwissMasion provides Pogo Pins that are accurate and reliable each time by utilizing modern Swiss CNC lathes, automated inspection, and skilled engineers.

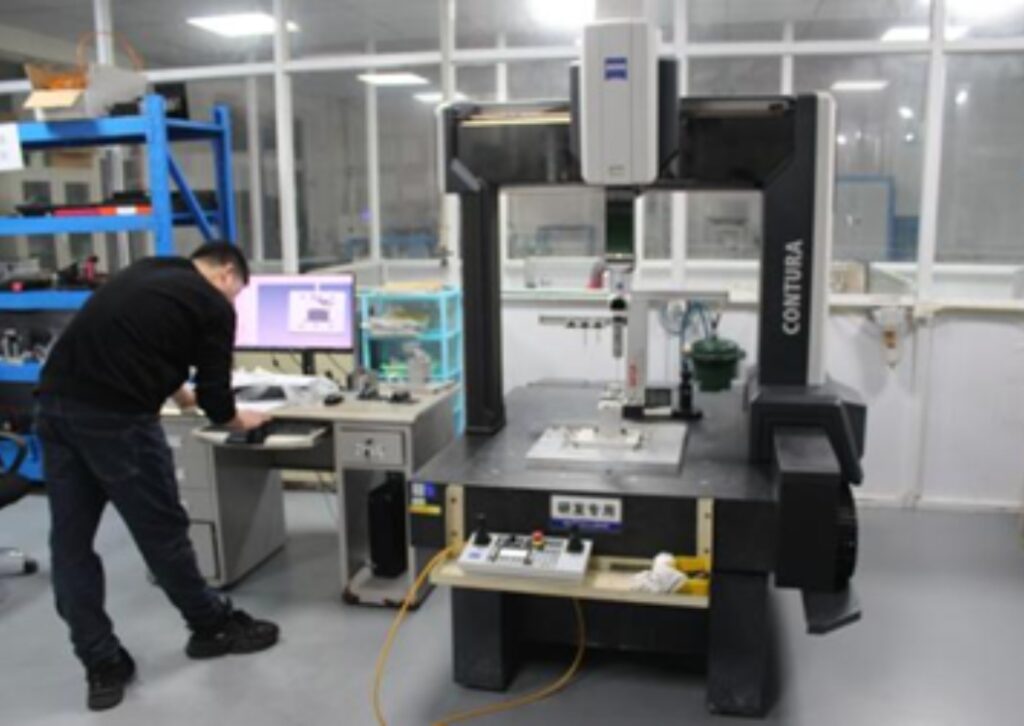

Pogo Pin Quality Control

Quality control is the foundation of all Pogo Pin manufactured at CNCSwissMasion. It must be very precise and reliable, particularly with electronics, aerospace, and automotive. We apply high-tech inspection methods and procedures to be sure that every Pogo Pin is of high specifications and industry standards. Our quality control process ensures that the dimensions and material integrity and functional performance are correct throughout each batch.

X-Ray Material Tester

Our X-Ray scanners scan the inside of the structure to ensure material integrity. You are able to identify voids, inclusions or structural anomalies. Its measurement accuracy is up to ±0.01 mm, which guarantees high-performance Pogo Pin internal accuracy.

Industrial Microscope

Industrial microscopes are used to analyze small objects such as tip geometry and plating. The smallest and complex Pogo Pin components can be inspected with the largest degree of accuracy and that is the tolerance of 0.002 mm.

Digital Projector

Part outlines and profiles are visualized on digital projectors. You can be assured that every part is exactly to your design specification with a high degree of precision of ±0.01 mm.

Optical Automatic Inspection Sorting Machine

This machine automates the process of sorting of Pogo Pins through the verification of dimensional and visual quality. It has a tolerance of 0.005 mm, which means that parts that are defective are detected and eliminated before assembly.

Flash Measuring Instrument

Flash measuring devices can be used to quickly inspect multiple pins with high accuracy. Tolerance accuracy: tolerance of accuracy is 0.005 mm which is quick to check and does not affect quality.

Roundness Tester

Roundness is essential to uniform compression of spring and electrical contact. We have roundness testers to an error of 0.001 mm, which ensures perfectly cylindrical pins to ensure reliability.

Mitutoyo Surface Roughness Tester

Surface finish influences friction, plating and electrical contact. The precision of our testers is at 0.0005 mm, which guarantees the smooth defect-free surfaces of our Pogo Pin to work optimally.

Hardness Tester

The hardness of material is confirmed to ensure the spring stability and integrity. This guarantees that Pogo Pins do not suffer deformation after repeated compression cycles.

Concentricity Tester

Concentricity testing provides a check of the alignment of the outer diameter, inner bore, and tip of the pin. Tolerance is 0.001 mm with a constant contact and mechanical stability.

Pin Gauges, Micrometers, and Calipers

Final dimensional checks are done using the following precision tools:

- Pin Gauges: ±0.002 mm for hole sizes

- Micrometers: OD, ID and length: 0.001 mm.

- Calipers: ±0.02 mm to make rapid dimensional checks.

Our Certificates

At Maison, we are dedicated to delivering the finest in CNC Swiss machining. With over 21 years of experience in custom Swiss machining and manufacturing of Swiss custom parts of high precision. It means we are committed to quality, industry standards and customer satisfaction through our certifications.

In fact, we have the ability to proudly boast key certifications that bear testament to our adherence to strict guidelines in different industries. This means that we are always up against the highest standards when it comes to CNC milling turning and small parts manufacturing.

- ISO 9001 Quality Management System

- ISO14001 Environmental Management System Certification

- Automotive Industry Quality Management System (IATF 16949)

- RoHS Restriction of Hazardous Substances (Available Upon Request)

- SGS Products Test – These tests are conducted to check the quality and if it matches industrial standards.

- Conformity to European standards: Solemn quality in CNC Swiss machining is CE marking.

Explore Types of Pogo Pins Gallery

Socket pogo pin

Pogo test pins

Locating pogo pin

High frequency pogo pin

High Current pogo pin

Directional pogo pin

Battery pogo pin

Switch pogo pin

Pogo Pin Applications

Electronics Testing and Production

Pogo pins are important in the use of bed-of-nails test fixtures in electronics production. They are used to test PCBs in connection, functionality and defects. The thousands of usage cycles are in your favor, and production testing becomes quicker, accurate, and cost-efficient. Pogo pins minimize downtimes and provide uniformity in high volume production.

Consumer Electronics

Pogo pin based devices such as docking stations, earbuds and smart watches are charged and provide data transfer. Their spring-loaded design makes them connect well even when there is a slight misalignment of the devices. This renders daily interactions between users smooth, dependable and sustainable.

Medical Devices

Pogo pins are safe, sterile, and reliable electric connections used in medical equipment. They are seen in diagnostic devices, wearable devices and hospital billing stations. They are perfect in critical healthcare applications due to their corrosion resistance, long life cycle, and easy to clean design.

Automobile and Electric Cars

In the modern vehicles, pogo pins are utilized in diagnostics, ECU programming, and sensor modules. They also promote EV charging systems. Pogo pins exhibit steady electrical contacts under vibration, shock and temperature changes, and guarantee quality operation in severe automotive conditions.

Industrial Automation and Robotics

In factories, pogo pins are also employed to give rapid-change instruments and sensor connections in robots. They automatically pass power and signals between components without wiring them. This reduces down time, increases production and eases maintenance in automated production.

Wearable Technology

Fitness devices, hearing aids and other wearable electronics also use pogo pins to charge or connect small modules. Their low size, spring loaded stability and reliability ensures that it is the best when handling small portable equipment where size and consistency count the most.

Aerospace and Defense

The use of aerospace-based Pogo pins as modular connections and testing points exists. Their high-strength materials and gold-plated contacts guarantee their durability under extreme temperatures, vibrations and under severe conditions. They are used in avionics and testers and defence modules where accuracy and reliability are not to be compromised.

FAQs

What are the main materials applied in the production of Pogo pins? What are the plating options?

Materials: Phosphor Bronze, Beryllium Copper, Brass, Stainless Steel and other specialty alloys.

Plating Options: Silver Plating, Palladium-Nickel Plating, Tin Plating, Gold Plating, Nickel Plating. Plating increases conductivity, corrosion properties, and life.

Do you make Pogo pins to our drawings or samples? How is the customization done and in what time frame?

Yes, we make Pogo Pins to your drawings or samples. Process:

- Accept and analyze drawing to ascertain practicability.

- Manufacture components and test in house.

- Send samples to your approval.

Timeline: 7-10 days (typically) depending on complexity. In case of changes, we discuss them prior to production.

Do you provide free samples? How long is the sample lead time?

Samples are of low cost. When you make an order, a portion of the sample price is charged off. The average lead time is 7-15 days depending on the complexity of samples.

What are your design optimization recommendations?

Yes, CNCSwissMasion provides design suggestions to enhance connector performance, manufacturability, and production efficiency.

What is your MOQ (Minimum Order Quantity)?

Sample orders may be any quantity. The standard MOQ in production is 50 pcs.

Does the quotation cover tooling (mold) costs? Who owns the tooling?

When necessary, tooling is quoted and with the unit price. Ownership: Tooling is owned by the client.

What are your payment terms?

We usually accept T/T (bank transfer) and PayPal.

What is your average lead time? How do you handle rush orders?

Time to lead is a factor of quantity: normal production is approximately 25 days. In case of rush orders, several machines will be used to accomplish production within 15-20 days.

How do you do quality control?

We work under the ISO9001 and ISO16949, and the complete QC system: IQC (Incoming), IPQC (In-process), and OQC (Final inspection).

Do you have CPK data, dimensional inspection, or material certifications?

Yes, CNCSwissMasion has the capability to provide CPK data, complete dimensional inspection data, and material certifications upon request.

What is the standard packaging?

Common choices are blister box, cardboard box, wooden box and pallets of larger parts. It also has anti-static and vacuum packaging.

How do returns or replacements work in case the products experience quality problems?

In case of serial quality concerns of parts, CNCSwissMasion will recast the components and deliver replacement parts without any additional cost.

How many years will you keep tooling and production files?

Tools and files are kept during the project lifetime. The stored production data is used to manage reorders.

Are you sure that you can maintain steady production capacity in the event that the market demand grows?

Yes. CNCSwissMasion buys more machines (when necessary) to ensure production stability.

What are Spring-Loaded Pins?

Spring-loaded pins are fine electrical connectors that have an internal spring to ensure repeatable, reliable contact.

What are Spring-Loaded Pins?

They squeeze when they are pressed into contact with a mating surface, ensuring constant contact with electricity in the face of mechanical motion.

What is the use of Spring-Loaded Pins?

They find applications in PCB testing, docking stations, sensors, charging connectors, medical devices and modular electronics.

How long is the longest stroke CNCSwissMasion pins?

We offer pins with a maximum stroke of up to 6 mm, which is spring-loaded, depending on size and design.

What should be the compression/travel range?

The optimal compression is recommended as 70-80% of total stroke to allow the best possible contact and avoid spring fatigue.

Are the pins closed or waterproof?

Yes, some CNCSwissMasion pins are waterproof and tight, and can be used in extreme locations.

Is it possible to have pins undergoing washdown procedures?

Yes, special corrosion-resistant and plated pins are able to endure washdown procedures.

What is the number of cycles that the pins are tested?

Normal testing guarantees a maximum of 100,000 mating cycles, depending on design and material.

What is the maximum rating of your pogo pins?

Our pins can handle up to 10A, based on size, material and plating.

Is it possible to mate pins and a pad on the opposite surface?

Yes, pins are made to mate with direct pads, making them reliable in connection.

Are the pins lubricated?

Pins are not usually lubricated, although lubrication may be added where needed because of certain applications.

Does it have pins on tape and reel?

Tape and reel Yes, standard pins can be used in automated assembly.

Should Tape and Reel pins have a Pick and Place Cap?

Yes, caps are suggested to avoid misalignment when automated placement is done.

Are 3D models available?

Yes, CNCSwissMasion offers 3D CAD models that can be incorporated in your design.

Are there other styles of plungers?

Yes, we provide various plungers, tips, and travel options to be adapted to custom designs.

Is it possible to customize Spring-Loaded Pins?

Yes, every pin can be configured to match project requirements in terms of dimensions, stroke, material, plating, and packaging.