Aluminum Anodizing – Everything You Need to Know

With its durability, corrosion resistance and sleek finish, aluminum anodizing dominates modern surface treatments. If you are working with aluminum or designing parts, you definitely need to know how the anodizing process really works. Anodizing is a process implemented to prevent corrosion of aluminum and some other metals. In this guide, you will learn every detail, from the science behind anodizing, its types, step by step process and its advantages. In this article, you’ll see what makes each method different, how to pick the one that’s right for you and what to expect at every stage. Let’s dive right in and uncover facts.

Table of Contents

ToggleHistory and Evolution of Anodizing

Anodizing started in 1923 as a means of protecting seaplane parts from corrosion. You can see how electrolytes and techniques have evolved over the years to make both function and appearance better. Sulfuric acid anodizing, introduced by Gowen and O’Brien, was a key breakthrough and set a new industry standard. Today, you have access to the latest technology that provides a more precise, vibrant and smoother finish for engineering, architecture and product design.

The Science Behind Anodizing

Anodizing is a method that uses an electrolytic cell to perform a controlled oxidation process. The circuit is completed by a cathode which is often lead or stainless steel and aluminum serves as the anode. Oxygen ions bond with the aluminum surface when you apply electric current through the electrolyte. It forms a stable, protective oxide layer. Aluminum is especially well suited because it naturally forms a good oxide barrier.

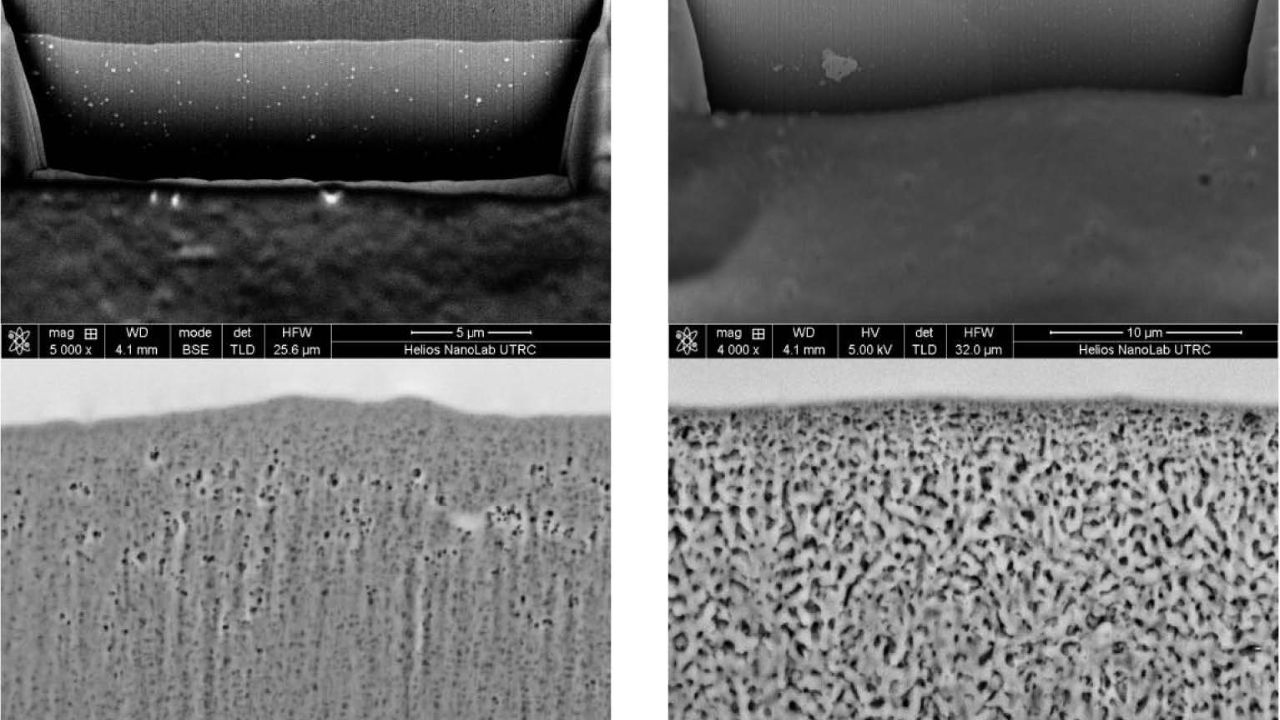

The Aluminum Oxide Layer Formation

There are two parts to this oxide layer: the thin barrier layer and the thicker, porous layer. It can be adjusted for thickness according to the application needs: thinner for decorative uses and thicker for heavy duty protection. The created aluminum oxide is extremely hard and corrosion resistant, with a Mohs hardness up to 9. It increases durability and longevity.

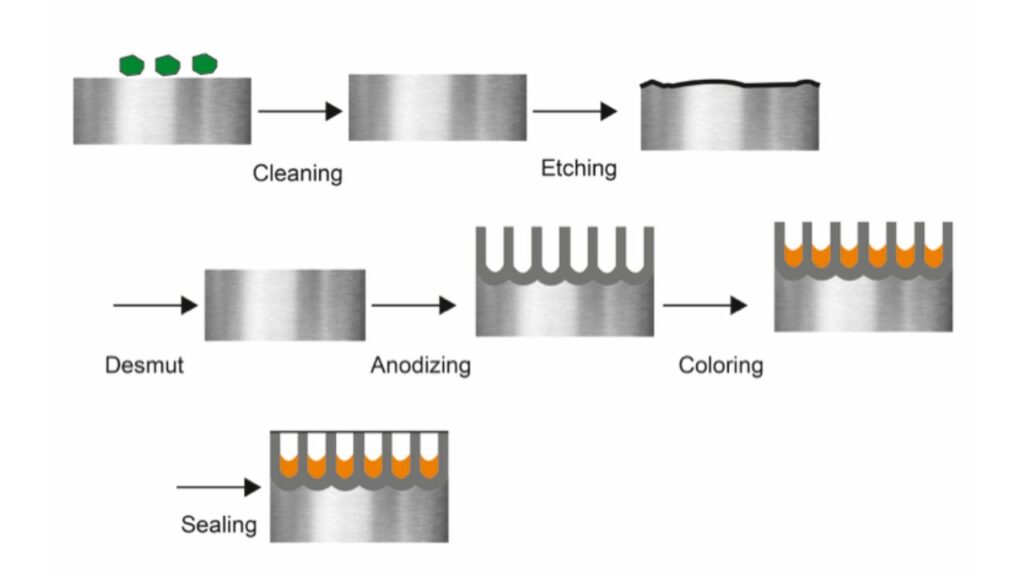

Detailed Anodizing Process

Cleaning

You must clean the aluminum thoroughly before anodizing. Oils, grease, dust and machining residue all interfere with proper coating formation. Either alkaline cleaners that destroy the organic matter or acidic cleaners that dissolve the oxidation and inorganic contaminants. Consistent, high quality finished can be achieved through proper cleaning.

Pre-Treatment

After cleaning, you go to pre treatment to level the surface. The goal of this step is to have the aluminum finish uniform before anodizing. You can decide to brighten or etch, depending on what look you want. A shiny appearance is achieved via brightening, whereas a matte surface is achieved through etching. Both assist in preparing the metal for superior oxide layer formation.

Brightening

Surface reflectivity is enhanced by brightening. To remove minor imperfections and put a polish on the surface, you apply a chemical mix, usually nitric and phosphoric acids. This step is a must if you are going for a decorative or high gloss finish. Moreover, it can also help in achieving uniform light reflection in the product.

Etching

Etching is the way to go if you are looking for a satin or matte look. In this step, we’ll remove a thin layer off the aluminum by using sodium hydroxide. It evens out the surface and gets rid of small defects. The final look is also enhanced through etching as it softens up the sharp edges and diffuses the light reflection.

Anodizing

The core process, electrochemical anodizing, is what comes next. To do this, you submerge the aluminum in an acid electrolyte bath of sulfuric, phosphoric or chromic acid. You apply an electric current to the aluminum surface which then converts it into a durable oxide layer. You can control current density, temperature and timing to tailor the thickness and performance of the coating.

Colouring (Optional)

If you have color as part of your goal, you can do it after anodizing. You can elect dyeing for an extensive range of colors or electrocolouring for metallic shades. Deeper, more UV resistant tones require metal salts and current: electrocolouring. It is faster and more versatile, but may fade more quickly with sun exposure.

Sealing

Your final step is sealing which locks everything in. It closes the pores of the oxide, improving corrosion resistance and color fastness. It can be sealed with hot deionized water, cold nickel fluoride or a hybrid at mid temperature. Sealing also improves durability, reduces staining and generally keeps your finish looking good longer.

Types of Anodizing Aluminum Process

Type I – Chromic Acid Anodizing

The electrolyte in this method is chromic acid. It is great when you need tight tolerance because it forms a very thin coating. It is nonconductive and highly corrosion resistant finish. It’s best for aerospace and aviation components where precision counts. But if you do use this method, you will have to deal with toxic waste in a safe way because of environmental considerations.

Type II – Sulfuric Acid Anodizing

The most common option is type II anodizing. It employs sulfuric acid and makes a coating 0.1 to 1 mil thick. The coating can be dyed for a decorative finish and has moderate hardness. It is used in architecture, electronics and cookware. However, it’s not as durable as Type III anodizing, so consider that for high stress applications.

Type III – Hard Anodizing

Anodizing hard is a heavy duty process. Cold sulfuric acid and high current are used to produce coatings greater than 1 mil. With this method, you get great wear and corrosion resistance. Friction can be reduced by adding PTFE. For military, aerospace or automotive parts that need durability, you’ll want this. It just changes dimensions and costs more to apply.

Thin film sulfuric anodizing

In this variation, a very thin layer is produced using diluted sulfuric acid. It’s great if you want a dyeable, flexible coating. It is good for low wear parts and decorative pieces because it tolerates surface stress well. It does not offer much for corrosion protection though, so don’t rely on it.

Clear Anodizing

The sulfuric acid for clear anodizing is followed by a hot water seal. The coating is transparent and you can mix dye if you want. For things like frames, railings and trims, it’s great. Also, understand that the final look is dependent on the aluminum alloy and the thickness layer. Therefore, you will have to test for visual consistency.

Phosphoric Acid Anodizing (PAA)

The process involves the formation of a thin porous coating with phosphoric acid. It offers good adhesion and performs well in resisting humidity. You will frequently use it to prime or bond a surface. However, if you need corrosion resistance, this method alone won’t do the trick.

Boric-Sulfuric Acid Anodizing

Boric sulfuric anodizing is an eco friendlier option. It is made of a blend of boric and sulfuric acids that make a thin, precise coating. You’ll achieve excellent adhesive compatibility and tight tolerance. Aerospace and aviation often use it. Keep in mind that it’s not too common and may be more expensive for you to acquire.

Bright Dip Anodizing

Dip anodizing uses a blend of sulfuric and phosphoric acid and is bright. It provides a glossy and reflective finish which stands out. It can be dyed too, making it good for decorative hardware and consumer products. Now, keep in mind that not all aluminum alloys will respond well to this treatment. Depending on your situation, you may need to test samples before you go into production.

Properties and Benefits of Anodized Aluminum

Mechanical Benefits

You get a surface hardness of about 9 on the Mohs scale from anodized aluminum. As a result, you receive exceptional protection against dents and deformation. It also resists wear and abrasion, making it suitable for use with high traffic or moving parts. It will last longer under mechanical stress.

Chemical Benefits

Anodizing aluminum will dramatically increase its corrosion resistance. Working in marine, industrial or outdoor environments makes this especially useful. Also, the aluminum oxide layer is stable in extreme temperatures and harsh chemicals. Even in challenging conditions, you get reliability.

Functional Benefits

Electrical insulation is offered by anodized aluminum which prevents short circuits in sensitive equipment. Additionally, the material resists high temperatures, so it works well near engines or heat sources. And the surface allows better paint and adhesive bonding, resulting in cleaner, more lasting finishes.

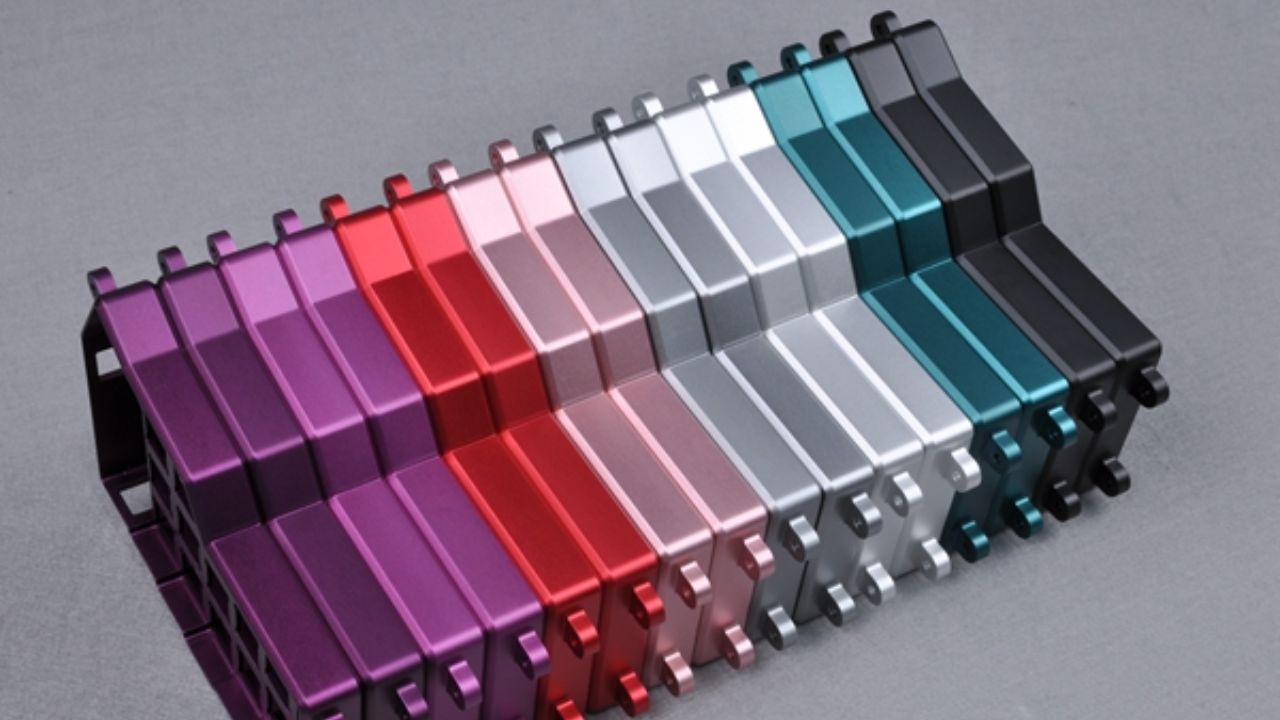

Aesthetic Benefits

Anodizing keeps color locked in for the years to come, with no fade or aging from the sun. It also gives a consistent metallic luster that won’t peel or flake. You get beauty and performance with a clean, uniform appearance that lasts.

Coloring Methods after Anodizing Aluminum

Dip Coloring

In dip coloring, the anodized aluminum is placed into a dye solution. During anodizing, the porous oxide layer is filled with the dye. You pay relatively little for a broad spectrum of vibrant colors. This method, however, is UV sensitive, meaning it will fade the colors in direct sunlight over time.

Integral Coloring

Integral coloring is anodizing plus coloring in one step. The color is formed naturally during the electrochemical process. It is highly durable and designed for parts worn out. You’re limited to bronze, gray and black shades. This method is also more expensive due to specialized equipment and tighter control.

Two-Step Electrolytic Coloring

This technique colors the anodized layer with the aid of metallic salts and an electric current. It makes rich, UV resistant finishes in the colors of bronze, black and gray. You get more aesthetic control over it than dip dyes and more durability. It is widely used in architectural and industrial products.

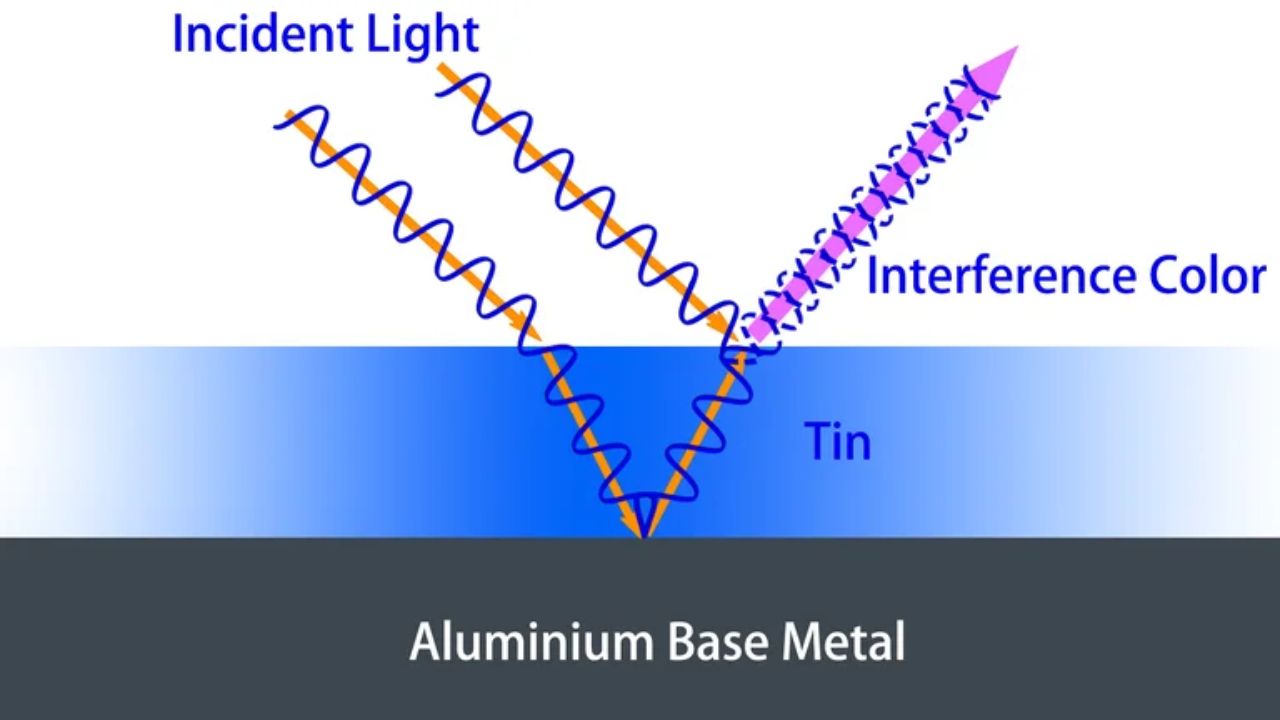

Interference Coloring

The pore structure is changed to reflect specific wavelengths of light through interference coloring. It allows you bold optical colors like red, blue, green and yellow. It’s visually stunning, but it’s more complex and not used as often because it requires tighter processes.

Surface Finishing Options

The gloss, matte or satin finish is suitable for your visual goals. Use etching for matte effect and polishing for glossy effect. This step determines how light reflects off your part and how it feels to the touch.

Sealing Techniques in Detail

Hot Sealing

Boiling deionized water or steam is used for hot sealing which hydrates the oxide layer. It makes the pores swell and close. This makes the strongest, most durable seal and is best for harsh environments. But it uses more energy and takes longer. If you’re all about maximum protection, this is your best option.

Cold Sealing

Nickel fluoride solutions are employed for cold sealing to chemically close the pores. It is a much faster and energy efficient technique. However, strict process control is required to prevent defect formation such as smut. Cold sealing is great if you need high throughput with decent sealing quality, just make sure you keep tight controls.

Mid-Temperature Sealing

This method combines the best of hot and cold sealing. Speed and quality are balanced through the use of moderate heat and chemical additives. It is widely used in commercial anodizers because of its reliability and efficiency. This hybrid approach is a good option if you want something that is cost effective and has good durability.

Anodizing vs. Powder Coating

Electrochemical oxidation of aluminum through anodizing produces a durable layer of aluminum oxide on the surface of the aluminum. On the other hand, powder coating involves applying a polyester based powder onto the surface and then curing under heat. Anodizing integrates into the metal, powder coating forms a layer on top.

Durability and Longevity

Anodizing is a better choice if you need a finish that can take extreme environments. Without peeling, it resists UV rays and salt and wear. Over time, powder coating can chip or fade, especially in outdoor and high impact applications.

Comparison of Aesthetic Finish

Anodizing provides a sleek, metallic sheen that will bring out the natural aluminum look. While powder coating has more of a color range, it looks more like a paint job. Choose according to whether you want natural metallic tones or more bold solid colours.

Maintenance and Recoating

Anodized surfaces require little upkeep and are rarely needed to recoat. Powder coated finishes are more delicate and require more upkeep and may need reapplication after damage. Anodizing will save you more in the long run, especially for industrial and high use applications.

Cost of Aluminum Anodizing

Aluminum anodizing varies from $0.10 to $0.50 per square inch. The finish, anodizing type and overall production needs determine the final price. The cost of anodizing aluminum depends on the following factors.

Anodizing Type

There are different anodizing types and they have different costs. Decorative anodizing is cheaper than hard anodizing because it requires less energy and less time.

Part Complexity

You’ll pay more if your parts have tight angles, internal cavities or detailed surfaces. Masking is careful and setup takes longer for complex shapes.

Colouring & Sealing

The cost rises for adding color or to seal the anodized surface. Each step of the process adds steps and materials: dyeing, electrolytic coloring, sealing.

The Thickness & Standards.

If you need a thick coating or you have to meet a standard like MIL-A-8625, the cost increases. More resources are always needed for precision and durability.

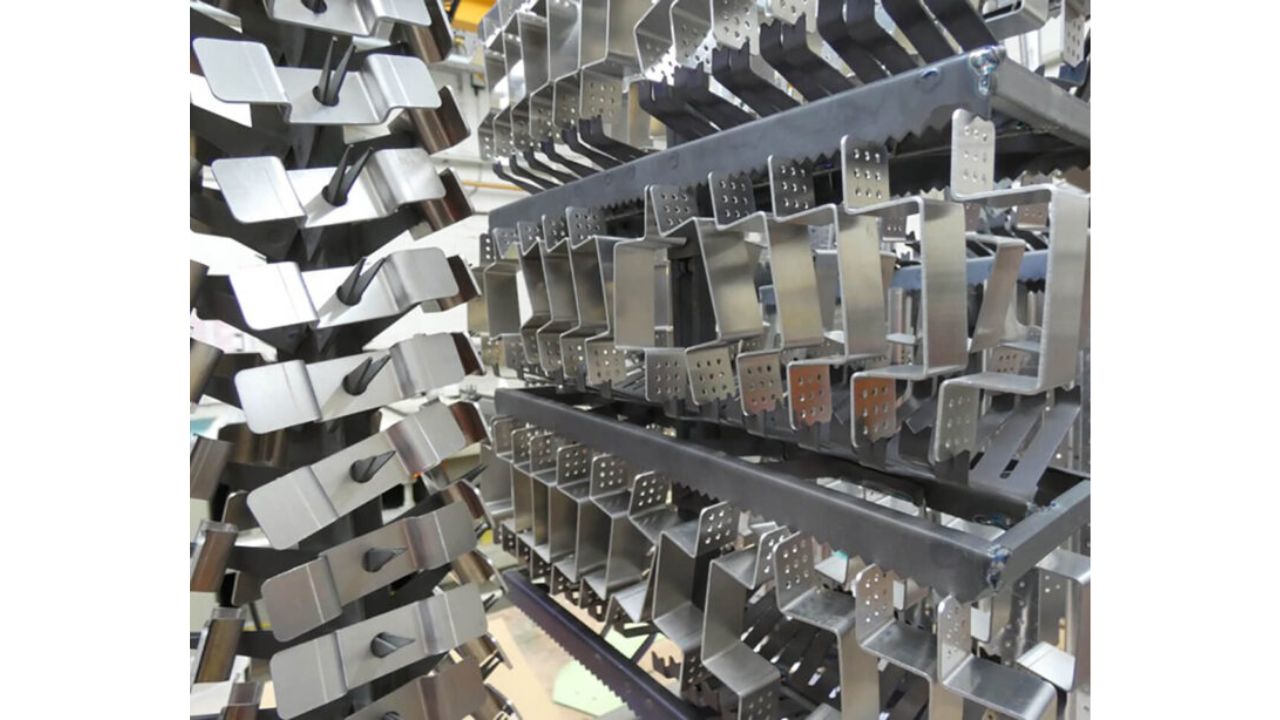

Batch Size

Higher volumes mean you’ll save more. Setup and labor can add significant costs per unit for small batches or one off pieces.

What Materials Can Be Anodized?

Commonly Anodized Metals

Aluminum

Aluminum is used in almost every anodizing application. It creates a strong corrosion resistant oxide layer. It can be used in architecture, electronics and consumer products.

Magnesium

Magnesium anodizing is used in aerospace or automotive industries to improve corrosion resistance and adhesion. Lightweight structural parts are ideal.

Titanium

Titanium can be anodized to form a stable, colorful oxide. Due to its strength and biocompatibility, it is widely used in medical implants and jewelry.

Zirconium

Anodizing zirconium increases the hardness of the surface and chemical stability. It is commonly used in chemical processing equipment.

Niobium

Bright, vibrant finishes are offered by niobium. This material provides excellent color control if you make jewelry or decorative parts.

Plastics and Composites

Some anodizing is possible with conductive plastics, but it is rare. Advanced electronics will use them for flexibility and design versatility.

Industrial Applications of Anodized Aluminum

Aerospace

In aerospace, anodized aluminum provides you with lightweight and highly durable parts. This improves friction control and fatigue resistance, both of which are critical for safety and performance in flight.

Architecture and Construction

Anodized aluminum is found in building facades, cladding and roofing. The structures are both attractive and resilient and it offers long term UV stability and excellent weatherproofing.

Consumer Electronics

Smartphones, laptops and accessories use anodized aluminum manufactured by the same companies. It adds a sleek metallic look to your device and protects it from scratches and everyday wear.

Automotive and Transport

In the auto industry, brake calipers, trims and interior panels are anodized parts. These components are salt, heat and corrosion resistant, especially in tough driving conditions.

Medical and Food Equipment

Anodized aluminum delivers when hygiene matters. You can get surfaces that are corrosion resistant, biocompatible and easy to clean — all of which are ideal for surgical tools or food processing equipment.

Quality Standards and Certification

- It should be known that according to the ISO and MIL-A standards, aluminum anodizing quality has strict guidelines. These standards guarantee your parts are built to industry standards for durability and performance.

- Using thickness testing, you can confirm that the anodized layer is within specified limits, important for protective and wear resistance. Techniques such as eddy current or micrometer measurements can be used.

- Porosity, adhesion and sealing must be inspected. You want the coating to be uniform, well bonded and sealed to prevent corrosion and maintain finish quality.

- Quality control helps your batches stay consistent during large scale production. You should expect regular inspections and process monitoring to catch defects early and cut waste.

Limitations and Considerations

- In order to anodize, you need electrical contact points and therefore cannot easily anodize complete surfaces. This restricts your prepping and masking of parts.

- Anodizing is more expensive and takes longer than simpler surface treatments such as painting or powder coating.

- Anodizing coverage is so complex that even simple geometries present challenges, so plan designs accordingly.

- Anodizing results depend on the alloy composition. If you want to anodize, you should confirm that your aluminum grade is suitable.

Choosing the Right Anodizing Type

- Choosing requires thinking about the application, environment, budget and the aesthetic wanted. Each of these factors contributes to which anodizing method suits best.

- By using a flowchart or decision matrix, you can simplify your choice and avoid expensive mistakes.

- Close collaboration with anodizing service providers. They can impart technical details and make processes to fit your needs.

Conclusion

Anodizing aluminum is a powerful way to increase the durability, corrosion resistance and appearance of aluminum. Knowing the different types, processes and benefits allows you to choose the right anodizing method for your requirements. Anodizing can provide long lasting, low maintenance surfaces from decorative finishes to heavy duty protection in a vast array of industries. Whether you are in aerospace, architecture or developing everyday products, this guide will teach you the basics you need to make informed decisions and get the best aluminum anodizing results.