Auto Buffing Machine – The Complete Beginner’s Guide in 2026

Auto buffing machines are important in contemporary production since they produce quality surface finishes in a cost-effective manner. The polishing process is critical in automobile, aerospace, jewelry, and metalworking sectors to improve durability, appearance and performance of components. It is important to know all the aspects of these machines in order to choose correct type, to optimize processes and to attain consistent results. The article is a complete guide to start beginners and understand the types of auto polish machines, the principles of their work, materials, polishing, and the maintenance tips to provide the readers with a clear and practical picture of the application to the profession.

Table of Contents

ToggleTypes of Auto Buffing (Polishing) Machines

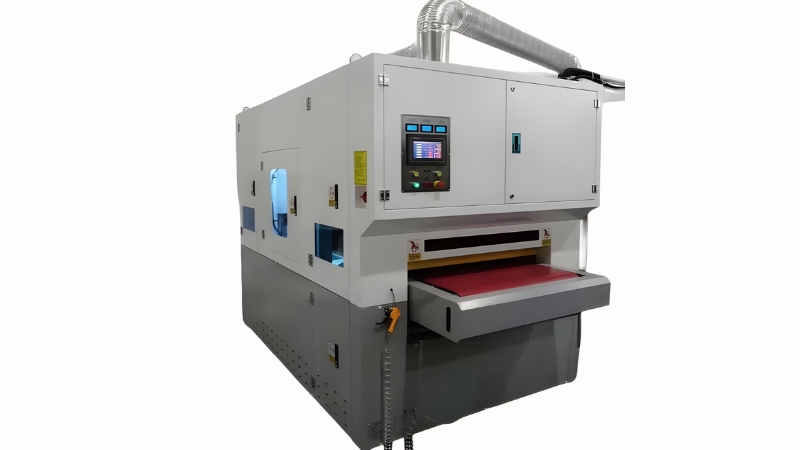

GRID Type Dry High-Speed Buffing (Polishing) Machine

GRID type dry high-speed buffing machines are machines that use high-speed rotating wheels or brushes. They are effective in polishing metals and plastics giving smooth finishes. These automatic metal polishing machines can be used on sheets, on rods, or on flat surfaces. They are very fast and therefore quick to process. They can however generate heat and are not as effective in areas that are irregular or delicate.

Hanging Type Dry High-Speed Buffing (Polishing) Machine

Hanging type machines have hooks or carriers to grip small parts or complex shaped parts. Lightweight objects can always be polished at a high speed. They are designed in such a way that they do not damage during rotation. They are capable of handling delicate geometries in comparison to standard GRID machines. You obtain a fine finish with little or no hand work.

Dry Type Rotary Finishing Machine

Dry rotary finishing machine is one of the best auto buffing machines having a rotary drum or tub that contains the parts and abrasives. Metals and plastics can be processed effectively. Constant rotation means even removal of material. They are more rapid than hand polishing and minimize the fatigue of operators. It can be used as a deburring, edge rounding, and pre-finishing industrial component.

Tunnel Vibratory Finishing Line

Vibratory finishing lines involve controlled vibration to transfer parts in media with the use of tunnel vibratory lines. Wet or dry finishing can be used according to the needs. This line is appropriate to massive production with regular outcomes. Vibratory action is used to remove burrs, smooth surfaces and enhance texture. It is very effective in small and medium sized parts.

Fully Automatic Finishing, Cleaning, Drying Line

The magnetic force finishing is a method of polishing parts using magnetic abrasives. You are able to have smooth and detailed finishing. It works best with small high precision components. The process saves on manual work and enhances uniformity. The automatic magnetic force machine polishing has a limited capacity though and it is not suited to big parts or high volume operations.

Fully Automatic Magnetic Force Finishing Machine

The magnetic force finishing is a method of polishing parts using magnetic abrasives. You are able to have smooth and detailed finishing. It works best with small high precision components. The process saves on manual work and enhances uniformity. It has a limited capacity though and it is not suited to big parts or high volume operations.

Flow Polishing Machine

Flow polishing machines produce an uninterrupted flow of polishing media and abrasives. Part mass production can be fed in a controlled flow. This guarantees uniform surface finish of components. They are effective with plastics and metals. The process reduces operator intervention, cycle time, and creates homogenous and high-quality polished surfaces effectively.

Centrifugal Finishing Machine

Centrifugal finishing machines rotate at high speeds to provide centrifugal force on the parts and abrasive media. You are able to feed small parts at high speed with good finishing. The force enhances efficiency in polishing as opposed to vibratory machines. They shorten cycle time and provide smooth and uniform surfaces. Nonetheless, bigger or non-uniformly shaped segments might not be comfortable.

3-D Vibrator Finishing Machine

Multi-directional vibration is used in 3-D vibrator machines to access every part surface. Complex geometries or delicate components can be polished without being damaged. Horizontal and vertical movement make the finish uniform. In industrial finishing, you are able to obtain greater accuracy, shorter cycle times, and more difficult shapes with improved handling using industrial metal polishing machines.

Rotary Polishing Machine

Rotary polishing machines have spinning wheels, drum or belt to remove material. You are able to obtain mirror-like finishes on metals, plastics or composite. They can be used in small to medium parts. The design enables the uniform application of pressure. These machines have the benefits of reducing labor, enhancing quality, and increasing productivity in the industrial polishing processes compared to manual polishing.

Working Principle of Buffing Machines

Buffing machines operate by applying a mixture of rotational or vibratory movement and abrasive action to the surfaces to be smoothed. They can be worked in either dry or wet polishing, depending on the material and finish required. When the workpiece comes into contact with the rotating buff, abrasives and polishing tools or compounds are used to remove minute surface defects, deburr edges, and gloss. Polishing compounds are important in the attainment of a consistent shine and reduction of scratches. Today, buffing machines are frequently automated, so it is possible to maintain the same amount of pressure, speed, and surface quality on many parts efficiently.

Materials Suitable for machine polishing

Automotive buffing machine materials have diverse industrial and consumer applications. You can work on metals like:

- Stainless steel

- Aluminum

- Copper

- Zinc alloy

- Titanium

- Brass

- Iron

Plastics, synthetic materials and composite materials are also effective when buffing is used to provide smooth polished surfaces. In choosing a material, you have to think about such aspects as the hardness, the requirements of surface finish, and the abrasion resistance. These factors define the buffing wheel and compound to apply, which guarantees the best outcomes and avoids damage on the surface during the polishing process.

Process of Buffing Machines

Auto buffing machine – Coarse Grinding Process

Coarse grinding is used to remove burrs, mold lines, oxide skin, rust, marks and chamfers on metal surfaces. You get the material ready to be refined. Common abrasives are silicon carbide, aluminum oxide and coarse grinding pastes. Following coarse grinding, surfaces are made smooth with a rough feel, which is appropriate to further processing and better attachment of future polishing compounds.

Intermediate Grinding Process

Medium grinding guarantees clear transition, brightness and uniform color throughout the surface. It makes the workpiece ready to be polished or electroplated. Abrasives used to recommend are medium-grade aluminum oxide or chromium oxide pastes. This process is a balance between surface refinement and material removal to produce a uniform texture. You end up with a surface that is prepared to be finished to high precision with no scratches or irregularities.

Precision Grinding Process

High quality products are given a final surface finish or mirror effect through precision grinding. It is appropriate to electroplating, spray painting, or direct product delivery. Polishing oils imported are used to improve the efficiency of dry polishing and lower the friction and luster. Manual polishing is capable of fine control whereas machine polishing can provide consistent results at scale. You choose techniques based on surface tolerance, volume, and finish required.

Types of Abrasive Materials used in buffing automation

Polishing Abrasives

Abrasives are fine materials that are used to polish and smooth surfaces, and eliminate microscopic irregularities. They are used to enhance surface shine, texture and reflectivity. These abrasives act through material removal, which is done gradually without making deep scratches.

Brown Corundum Grinding Stone

For rough removal of material and initial surface shaping, you use brown corundum grinding stones. They are also high in hardness and durability and can thus be used with metals and hard alloys. They have rough grit that is effective in removing burrs and cleaning irregular surfaces. This abrasive is flexible in pre-polishing both in the industry and workshop.

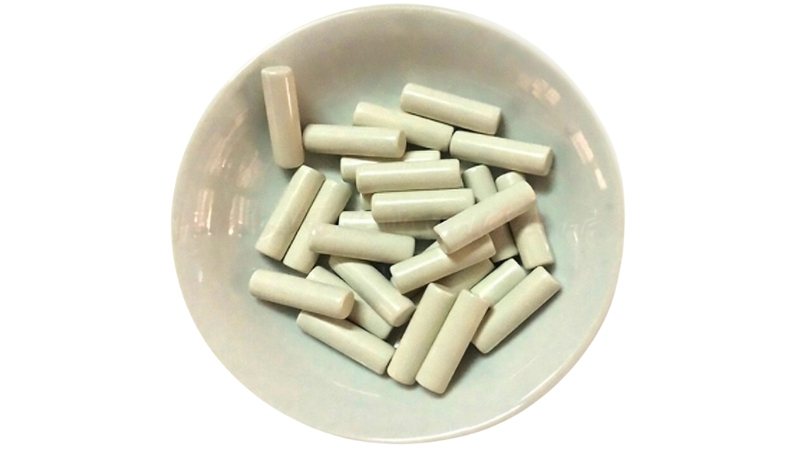

Ceramic Stone

Fine polishing of ceramic stones gives precise and consistent material removal. You have the advantage of uniform grain size which does not over-cut surfaces. They do not trap heat and thus minimal thermal damage to sensitive materials. Whether it is metal, ceramics, or composite, ceramic stones are ideal to finish them.

White Corundum Grinding Stone

White corundum stones are good finishers of delicate surfaces and precision parts. You get good surface fineness and low chances of scratching. They are not chemically reactive and therefore they do not contaminate polished materials. This is an abrasive that is effective on stainless steel, aluminum, and soft alloys.

Resin Grinding Stone

Resin-bonded stones compromise between grinding performance and quality of surface finish. You are able to polish flat as well as curved surfaces. They minimize vibration and heat and enhance operator control in polishing. Resin stones are popular in jewelry, tooling and precision metalwork.

High Alumina Ceramic Polishing Stone

The alumina stones are high and provide exceptional wear resistance during extended polishing. You do not have to replace stones with heavy-duty applications so often. They are kept at a sharp cutting edge to increase the rate of material removal. This abrasive can be used in aerospace, automotive and industrial parts.

High-Frequency Ceramic Polishing Stone

Besides automotive polishing machines, Ceramic stones of high frequency provide rapid material removal that is highly accurate. You are able to have smooth finishes with reduced cycle times. They reduce micro-cracks on the surface and enhance dimensional accuracy. These stones are used with high alloys and accuracy parts.

Steel Balls and Steel Needles

Vibratory and tumbling polishing machines use steel balls and needles. You are able to burinish, clean and polish metal surfaces at the same time. They fit well in intricate shapes and hollows. These media enhance consistency and minimise hand finishing time.

Other Abrasive Media

- Walnut shells

Walnut shells offer light abrasive in cleaning and polishing delicate surfaces. They can be used to remove rust, paint or dirt without damaging the base material. They are biodegradable, reusable and can be used in sensitive applications such as automotive parts or machinery finishes.

- Corn cob

Corn cob media is effective in light deburring, cleaning and polishing. You may use it on wood or metal, or soft alloys where you want to have a streak-free finish. It is eco-friendly and produces little dust when used.

- Bamboo pellets

Bamboo pellets are used to provide moderate abrasiveness in surface finishing and cleaning. They will polish metal, plastics, and composites in an environmentally friendly manner. Their regular form guarantees the same output and little surface erosion.

- Wood pellets

Pellets of wood serve as a low impact abrasive in cleaning and polishing. They can be applied in both industrial and delicate finishing to ensure that the surface integrity is maintained and that contaminants are removed effectively.

Grinding Compounds

Metal finishing and surface treatment require the use of grinding compounds. They improve luster, smoothness and durability. Each compound has a particular purpose or target metal and this gives specific results. The correct compound will enhance efficiency and increase the durability of the tool.

- Zinc Alloy Luster Agent

This compound improves the shine and surface of the zinc alloys. It also eliminates small scratches and oxidation. You will see a uniform reflective finish that is either decorative or industrial in use.

- Aluminum Alloy Luster Agent

This agent is made to be applied on aluminum and aluminum alloys, with an even gloss and a smooth finish. It avoids dulling and oxidation and enhances the durability of the surface. Its regular use guarantees durable, good-looking aluminum finishes.

- Stainless Steel Gloss Agent

It is a polishing agent that is used to clean stainless steel surfaces and eliminate fine scratches and marks. It improves corrosion resistance and provides a bright and mirror-like look. It is possible to attain professional quality finishes with very little effort.

- Cleaning Agent

An all-purpose agent that eliminates oils, grease and residues pre or post-grinding. It inhibits contamination that could occur to luster or bonding of coating. Its usage guarantees that the surfaces are clean and prepared to proceed with further processing.

- Copper Luster Agent

It is especially developed to work on copper and its alloys, improving brightness and eliminating oxidation layers. The compound enhances surface beauty and corrosion resistance. You will obtain even, reflective copper finishes.

- Iron Luster Agent

Applied on iron and mild steel, this agent increases metallic sheen and smoothness. It gets rid of surface flaws and it safeguards against early rusting. Frequent use will keep the iron finish in good condition.

- Anti-Rust Agent

Eliminates oxidation and corrosion on metal surfaces following grinding or polishing. It creates a protective coating without interfering with luster. It can be used to lengthen component life and maintain polished finishes.

- Grinding Agent

Minimizes friction between the workpiece and the tool, and facilitates the removal of a material. It reduces heat production and surface destruction. Its use enhances productivity and extends tool life.

- Cutting Agent

Helps in cutting and shaping of metals in grinding or machining. It eliminates overheating and makes the removal of the material smooth and precise. You will get better cuts and better measurements.

- Leveling Agent

Flatten rough parts and make the metal entirely glossy. It seals small cracks to a smooth, quality finish. It can be used to get professional, defect-free finishes on any metal.

| Name | Pattern | Number | Shape | Net Content | Purpose |

|---|---|---|---|---|---|

| Zinc alloy luster agent |  | J-804 | Paste | 50Kg/barrel | Polishing of various zinc alloys |

| Aluminum alloy luster agent |  | J-810 | Paste | Polishing of various Aluminum Alloys | |

| Stainless steel gloss agent |  | J-811 | Liquid state | Various Stainless Steel Polishing | |

| Cleaning agent |  | J-205 | Liquid state | Surface degreasing and cleaning of workpieces | |

| Copper luster agent |  | J-602 | Liquid state | Polishing of various Copper parts | |

| Iron luster agent |  | J-105 | Powdery | Polishing of various iron parts | |

| Antirust agent |  | J-103 | Liquid state | Rust prevention on various metal surfaces | |

| Grinding agent |  | J-803 | Liquid state | Used for rough grinding of general workpiece surfaces | |

| Leveling agent |  | JPZ-2 | Liquid state | Used for rough grinding of general workpiece surfaces | |

| Leveling agent |  | JPZ-2 | Liquid state | Quick roughening of metal parts |

Grinding and Polishing Pastes

- Coarse grinding paste (metal/plastic): Coarse pastes are used to rough surfaces quickly, so they are effective at leveling rough surfaces. You can finish metal or plastic parts which you can then finish further, remove scratches, burrs or uneven spots in a matter of seconds whilst maintaining a controlled abrasion and consistent results on all surfaces.

- Moderate grinding paste (metal/plastic): Contemporary moderate pastes are designed to polish the surface once coarse grinding has been done. You are able to get the finer finishes on metals or plastics and eliminate smaller scratches and flaws as you prepare the parts to the final polishing process without compromising the material.

- Fine polishing paste (metal/plastic): Fine pastes are made to provide high-gloss finishes; they remove micro-scratches and surface irregularities. Metal or plastic objects can be brought to a mirror finish, which improves both aesthetic value and practical ease, without compromising the integrity of the underlying material.

- Specialty pastes (stainless steel, titanium alloy, zinc alloy): These pastes are designed to be used with particular alloys, eliminating discoloration and surface damage. Stainless steel, titanium or zinc may be safely polished with a consistent and high quality finish without losing corrosion resistance or overall material strength.

- ENT oil: ENT oil is applied as a lubricant and cooling agent in the grinding and polishing of various components to minimize friction and heat generation. You are able to enhance surface finish, increase the life of the tool and provide a smooth and controlled operation of both the metal and plastic workpieces.

| Name | Pattern | Number | Shape | Net content | Purpose |

|---|---|---|---|---|---|

| Coarse grinding paste |  | JP-23 | Thick Fluid | 23 kg/drum | Rough grinding paste; Rough polishing of metal surfaces |

| Moderate grinding paste |  | JP-25 | Thick Fluid | 23 kg/drum | Moderate polishing of metal surfaces |

| Zinc alloy coarse grinding paste |  | JF-26 | Thick Fluid | 20 kg/drum | Surface roughening of zinc alloy workpieces |

| Fine polishing paste |  | JF-72 | Thick Fluid | 18 kg/drum | Fine polishing of various metal surfaces |

| Stainless steel polishing paste |  | JF-82 | Thick Fluid | 20 kg/drum | Fine polishing of stainless steel workpiece surfaces |

| Titanium alloy polishing paste |  | JF-92 | Thick Fluid | 18 kg/drum | Fine polishing of titanium alloy workpiece surfaces |

| Diluent oil |  | C-8 | Liquid | 16 kg/drum | Mixing ratio adjustment for coarse and fine grinding oil |

| Rough grinding paste for plastic parts |  | JGP-1 | Thick Fluid | 20 kg/drum | Used for rough polishing of non-metallic surfaces |

| Moderate grinding paste for plastic parts |  | JGP-3 | Thick Fluid | 20 kg/drum | Used for moderate polishing of non-metallic surfaces |

| Fine polishing paste for plastic parts |  | JSH-5 | Thick Fluid | 20 kg/drum | Fine polishing of non-metallic surfaces |

Polishing Aids

- Gloss Agents, Grinding Agents, Cleaning Agents – These agents enhance smoothness and shine on surfaces and eliminate shallow scratches and deposits. During mechanical or manual polishing, you will be able to increase the brightness and uniformity of the surface. They also ready the material to be subjected to other finishing processes and are useful in ensuring a uniform outcome of metals, plastics or composite parts.

- Polishing Oils – Polishing oils minimize friction between the polishing tool and the workpiece. You may regulate the amount of heat produced and reduce the surface flaws and enhance the performance of abrasives. They also help to create a more mirror-like finish without spoiling delicate materials.

- Rust Inhibitors – Rust inhibitors eliminate oxidation and corrosion on polished metal surfaces when storing or handling. You are able to prevent rust development on surfaces and still preserve the aesthetic appeal and integrity. They also provide durability of polished parts without influencing the further finishing or coating operations.

- Degreasers and Degreaser Powders – Degreasers are used prior to polishing to remove oil, grease and residues of workpiece surfaces. You can be sure of good adhesion of polishing compounds and even surface treatment. They are also useful in avoiding streaking or uneven finishes and they enhance efficiency of mechanical or manual polishing processes.

Advantages of Using Auto Buffing Machines

- Auto buffing machines increase the rate of polishing and can produce high volumes of output with even performance.

- Automated control guarantees the consistency of polishing outcomes of all parts and production batches.

- Automation reduces the operator participation and thus minimizes the errors caused by fatigue and enhances reliability.

- The machines can polish various materials using appropriate abrasives and compounds.

- Initial investment is compensated by lower labor costs, reduced rework and increased efficiency in the long run.

Maintenance and Safety Considerations for buffing machines

- Regular cleaning and inspections prevent buildup, detect wear early, and ensure stable operation of the auto buffing machine.

- Correct storage and use of abrasives preserve polishing quality and extend media lifespan.

- Protective equipment safeguards operators from dust, debris, and chemical exposure during polishing.

- Planned maintenance of polish machine reduces breakdown risks, extends component life, and ensures consistent machine performance.

- Dust control, noise reduction, and proper waste handling support compliance and a safer workspace.

Conclusion

Auto buffing machines change the way finishing is done by providing high quality and uniform finishes on surfaces in an efficient manner. They minimize hand work, time and increase productivity in metals, plastics and composites. Knowledge on the types of machines, how they should work, and their material, abrasives, and polishing facilitates the best performance and the longevity of their parts. Results are further improved by proper maintenance, safety precautions and the choice of appropriate compounds. With these insights, you can get professional finishes, avoid defects and maximize operational efficiency, and this makes automotive polishing machine inevitable in the contemporary manufacturing sector.

Frequently Asked Questions

1. What is the production capacity of your auto buffing machine?

CNCSwissMasion buffing automation are intended to be used in large scale production. You can handle hundreds or even thousands of parts per day depending on the model. The machines are very steady in their speed and accuracy, and can be used to meet the demands of industrial throughput without affecting the quality of the surface.

2. Which safety measures are needed when using automotive polishing machines?

When using automotive polishing machines, always wear protective gloves. Ensure eye protection to guard against debris and sparks. Use dust masks to prevent inhalation of fine particles. Keep hair and loose clothing away from moving parts. Maintain proper ventilation to reduce fumes and dust exposure.

3. Can the machine be customized for different part sizes or shapes?

CNCSwissMasion is customizable. Fixtures, buffing wheels and processing modules can be configured to suit various part geometries. Small, complex or large parts are accommodated. This flexibility means even size changes, shape changes, and weight changes of your production process can be finished uniformly.

4. What is the power consumption and efficiency of the machine?

These machines are energy saving and use minimal power yet are highly speedy. You enjoy low operating cost and maximized throughput. The motor systems developed are advanced and minimize energy wastage, which offers sustainable operation to industries. Efficiency does not reduce the consistency or quality of finishes.

5. Do you provide installation, training, and maintenance support?

Yes, CNCSwissMasion provides full installation and commissioning. You get on-site or distance training on operators and maintenance teams. Technical support and preventive maintenance schedules are the guarantors of their smooth operation. Such service reduces down time and extends the life of the machines in your facility.

6. Can the machine achieve mirror finishes without manual polishing?

No, high-gloss mirror-like surfaces are produced by fully automated polishing processes. You do not need to use any extra manual work to get professional finishes. The synchronized abrasive media, accurate rotation and controlled pressure of automotive buffing machines assure defect-free, smooth and reflective results throughout components.

7. What is the lead time and shipping cost for international orders?

Depending on the type of machine and customization, lead time is usually four to eight weeks. The online ordering system of CNCSwissMasion will provide you with correct shipping quotes. The logistics are facilitated internationally and the products are delivered on time and are well packed to ensure their safe delivery in your plant.

8. Are spare parts and consumables readily available for long-term use?

Yes, CNCSwissMasion has an extensive stock of spare parts and consumables. Worn parts, polishing media and abrasives can be easily changed. This ensures continuity in operations over the long term, minimizes downtime and ensures high-quality production remains at high levels over the years without interruption in the supply.