Performance Oriented Automatic Lathing Services

Automatic Bar Machining Services At Precision

When seeking an automatic bar machining factory in China, you should go to a factory that has a record of expertise and precision. This is why this factory is unique:

- You can enjoy stable machining solutions with 21 years of dedicated experience.

- It has more than 75 Swiss and 100 high-end automatic lathes, and 125 experts.

- You may order parts with a diameter of between 1/16” and 2 5/8”.

- Tolerances are exact: +-0.001mm, with micro-holes, wall thickness and surface finishes as small as Ra 0.2 to 0.4µm and Ra 0.8 to 1.6µ

- You have the advantage of stringent quality measures supported by ISO9001 and ISO16949 certifications.

Automatic Bar Machining Experts In China

When seeking the Automatic Bar Machining Experts in China you seek an element of precision, reliability and proven expertise. These specialists excel in bar milling and automated production operations with tight tolerances. You share in sophisticated procedures, high quality control, and ISO certified practices. Each component is manufactured according to your specifications, both in small diameters and complicated bar machining jobs. With efficient packaging solutions and a heritage of industry experience, you get reliable automatic bar machining services that are customized to your requirements.

Automatic Bar Machining Services

Automatic bar machining solutions provide you exact and efficient solutions to intricate parts. There are the advanced automatic bar machines and bar milling to ensure dimensions. Tolerances as tight as +/- 0.001mm and surface finish to Ra 0.05um means that you get the same results each time. Experienced technicians at CNC Swiss Masion in China assure that all parts are manufactured to high ISO9001 and ISO16949 standards. You also have variety of packaging options such as ziplock, bubble, and wooden box to ensure the safety of your bar machining parts.

Materials

- Alloy

- Aluminum

- Brass

- Copper

- Bronze

- Stainless Steel

- High Temp and Special Alloy

- Titanium

- Steel

- Plastic

Machines

- Swiss Lathes(Citizen,Citizen,Star etc)

- Taiwan Advanced automatic lathe

- CNC automatic Lathe with truss

- Polishing machine

- External cylindrical grinding machine

- Surface grinding machine

- Centerless grinding machine

- Passivation equipment

- Ultrasonic cleaning equipment

Surface Finish

- Golden Plating

- zinc plating

- silver plating

- nickel plating

- Heat treatment

- Brass passivation

- Bead Blasting

- Polishing

- PVD coating

What is Automatic Bar Machining?

Automatic bar machining involves high-precision, high-speed production of large quantities of metal bar product in a variety of industries. This is done by you placing the bar through the spindle of the lathe, and a collet firmly grips the bar as it passes through the cutting tools of automatic bar cutting machine that shape and form it in a continuous process. You get superior efficiency and close tolerances, which is ideal in small parts such as bushings, screws, and other threaded parts. The automatic bar machine moves the bar, cutting off finished pieces with little manual work required.

The Pros and Cons of Automatic Bar Machining

Pros

- Efficiency: You accomplish a higher level of production through automated operations.

- Accuracy and Repeatability: You are able to maintain strict tolerances and repeatable parts.

- Improved Labor Costs: You reduce the cost of manpower at a significant level.

- Versatility: You can also machine different materials, including metals and plastics with ease.

- Scalability: You can increase production to meet high volumes in a very short time.

Cons

- Large Initial Investment: You are exposed to large initial investment in equipment and setup.

- Complex Maintenance: You handle complicated maintenance that would need specialized personnel.

- Inflexible: You are not able to make rapid adjustments to designs or special orders.

- Material Waste: You can also experience waste due to continuous cutting of bar stocks.

- Skilled Operator Dependency: You require skilled operators to program and monitor machines.

DFM for Automatic Bar Machining

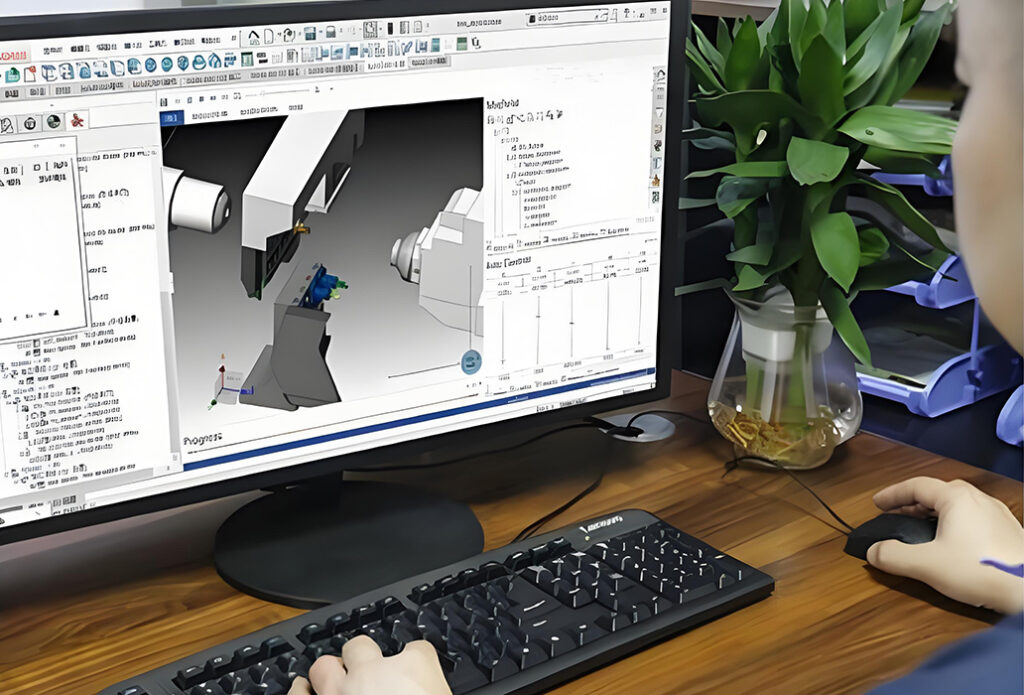

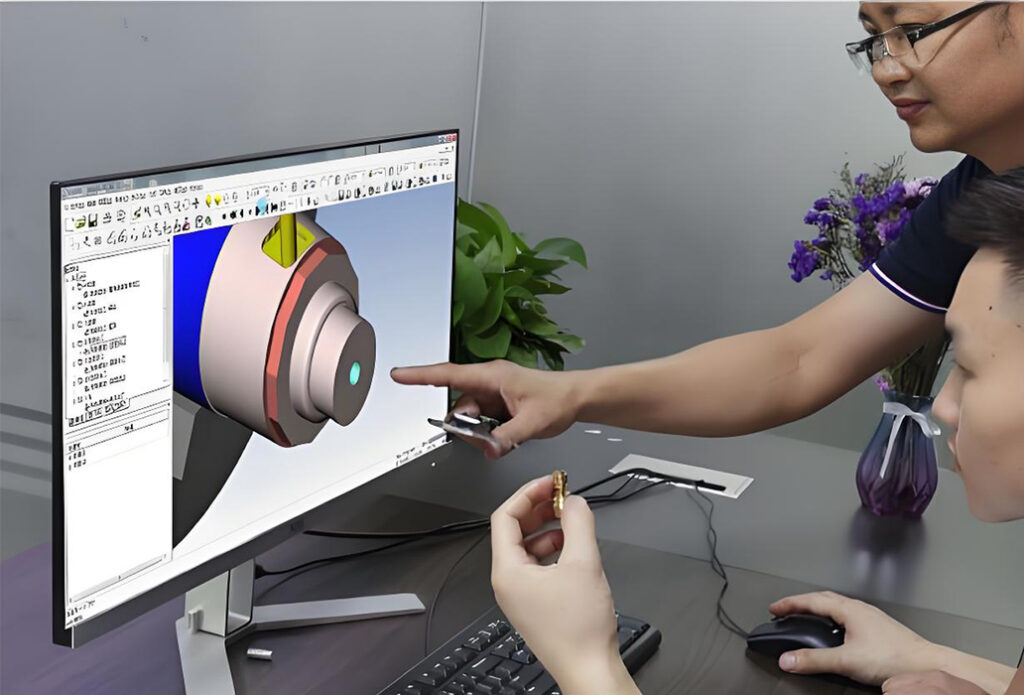

Product Design and Development

The design and development of products start with shared reviews by company and client teams. You validate design features and product quality attributes at each step. In the case of an automatic bar bending machine, you guarantee the same precision of forming the production of the bars. This method will assist in matching the final design to the functional needs and the customer demands. A collaboration minimizes error and enhances efficiency in the transition between concept and production.

Learning and Applying Materials

You examine the composition and processing characteristics of raw materials in order to find the most suitable applications. This involves researching on industrial applications, functional applications, and strength. You will know how to choose the material to improve performance, cut costs, and make the products more sustainable with a good grasp of material science.

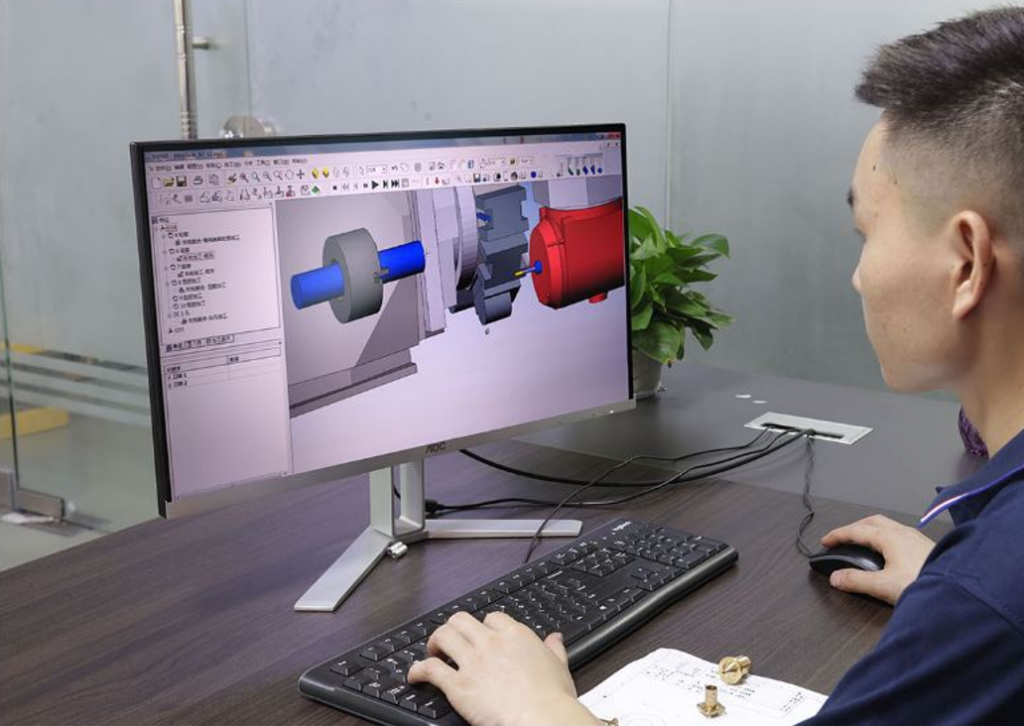

Tool Design and Use

Tool design is the process of developing special tools and fixtures to fit particular material and structure. Designing the right tools, you guarantee accuracy, efficiency, and consistency in the course of manufacturing. Quality tooling has a direct impact on production quality and minimises machining errors.

Optimization Processing and Optimization Programming

The production is only efficient with technical programming. You do simulations and optimize the process prior to mass production. Calibration, re-checks and verification measures guarantee precision. This minimizes idle time and avoids rework and costly corrections in the manufacturing process.

Quality Control and Inspection

You have high standards of digital and visual production control. Automated inspection technology can be used to monitor quality of production in real-time. Such initiative will make all products meet stringent specifications and international standards.

Solution Development and Cost Evaluation

To come up with the appropriate solution, collaboration is essential You cooperate with the professionals to determine the most effective technical solutions. Cost analysis is also done together with development to ensure that quality is not sacrificed in order to be competitive.

Technical Research and Advanced Training

Investigations underway enhance technical capacity You learn new ways of mechanical analysis and process application technologies. Ongoing learning and global interactions with technical teams are the means through which you stay innovative and ahead of industry trends.

Why Choose Us for Automatic Bar Machining?

Intelligent Programming System: With a sophisticated intelligent programming system, you can optimize the toolpaths of machining jobs to be most efficient. This minimizes excessive movements, minimizes production time and reduces costs. With smarter programming, you can have greater precision and easier workflow.

ERP office management system: The ERP office system offers a full data integration. You are able to streamline scheduling, inventory, and project management all on one platform. This guarantees a more effective management and decision-making ability.

MES Factory Management System: MES factory management system is centered around optimizing production. You will be able to follow each stage of the process in real-time and enhance the efficiency of the process as well as the quality of the product.

Quality Management System: There is strict quality management at all stages. Internal DFM (Design for Manufacturability) and design review will provide you with improved reliability with prototypes and mass production.

Ability to handle big projects: You can count on a large portfolio of successful projects in big-name clients like Huawei, Tesla, Tuopu, Novel, Hysis, and Xusheng. These collaborations point to the ability to work on complex and large-scale projects.

Material and Size Variety: You have access to a large variety of materials of alloy, aluminum, brass, copper, bronze, stainless steel, titanium, and high-temp special alloys in varying sizes. The factory processes outer diameters of 1mm-38mm.

Broad Processing Ability: In addition to automatic lathe parts machining, you also have access to secondary processes such as cleaning, grinding, and sophisticated surface finishing. This guarantees that you get full parts that are ready.

High-end automatic lathes: The workshop is stocked with high-end CNC Swiss lathes like Citizen and Star, and Taiwan MY advanced lathes. These machines ensure sound and well-performing performance.

Fully Automatic Testing Equipment: All components are highly inspected with fully automatic testing equipment. This provides uniformity, accuracy, and error-free outcomes in all orders.

Automatic Bar Machining Tolerance

- Diameter tolerance: ±0.005 mm to ±0.02 mm

- Concentricity: 0.01 mm to 0.05 mm

- Surface roughness: Ra 0.2 to 0.4µm and Ra 0.8 to 1.6µm

- Length size tolerance: ±0.01 mm to ±0.05 mm

- Angle accuracy: ±0.1° to ±0.5°

- Thread machining accuracy: 6H/6g per GB/T 197-2003

- Positioning accuracy: ±0.0025 mm to ±0.01 mm

- Precision:+-0.01mm

- Cylindricity:+-0.02mm

- Flatness:+-0.02mm

- Concentricity:+-0.02mm

- Symmetry:+-0.02mm

- Circular Runout:+-0.02mm

Automatic Bar Machining Quality Control

Automatic bar machining needs a stringent and sophisticated quality control mechanism to ensure a high degree of accuracy and consistency. You can be assured that all of the steps are followed closely and they are examined with the help of the most modern technologies and well-established inspection procedures.

Automatic Detection 24/7

A daylight detection system is implemented to provide constant overseeing of machining precision. You can get the benefit of real-time error detection and minimize downtimes and ensure the product reliability.

Laser Tool Setting and Detection

Laser systems can calibrate and check the tools automatically. This enables you to attain greater accuracy on every cut, reducing wear on the tools and enhancing productivity.

Online In-Machine Automatic Measurement

In-machine measurement is used to check parts as they are produced. You end up with uniform dimensions and spare the cost of rework or wastage of material.

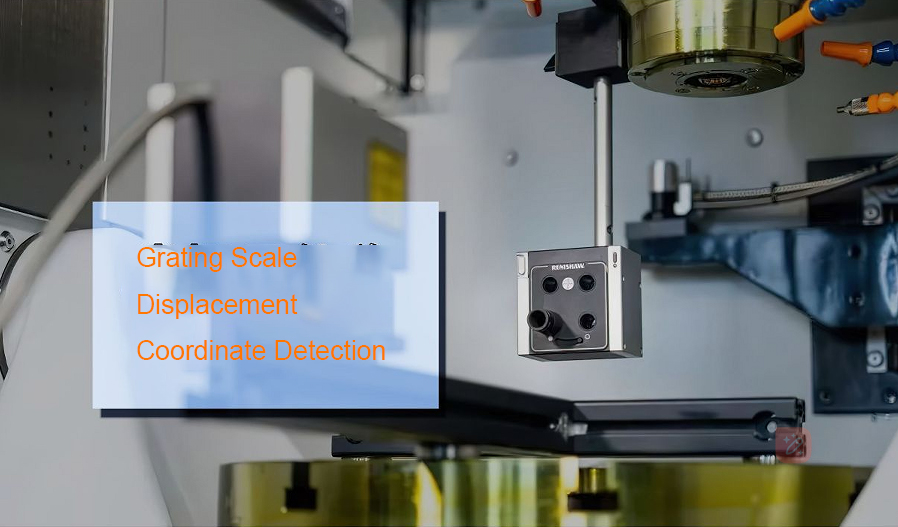

GSD Coordinate Detection Grating Scale Displacement

This technique offers very precise feedback of coordinates. The precision of displacement reading can be trusted to be accurate and tolerance is maintained at a ±0.001mm level.

Raw Material Feed Control

The secure supply system checks all raw materials prior to storage You are assured that you will not face any risk to quality because each material is compliant with REACH and RoHS regulations.

Finished Product Process Control

Manufacturing is done according to design specifications All our products are carefully checked and every detail is reported to you so that you have a clear picture on the end product.

Product Traceability

All the parts can be traced back to the raw material and to deliveries. You can also easily track back the production history and this makes it accountable, safe, and quality maintained.

Quality Assurance

Random re-inspections, documents verification and signature by the responsible people ensure that your order is of good quality and quantity. You will receive inspection reports to assure you.

High-driven Testing Facilities

You have access to excellent laboratories with metrology, physical and chemical testing facilities. Such tools as vacuum direct-reading spectrometers, X-ray flaw detectors, hydrogen analyzers, CMM, and contour measuring instruments as well as optical microscopes are used to guarantee the performance, longevity and safety of the products.

Our Certificates

At Masion, we are dedicated to delivering the finest in Automatic Bar Machining. With over 21 years of experience producing custom high-precision components, we remain committed to quality, industry standards, and customer satisfaction through certified practices.

In fact, we have the ability to proudly boast key certifications that bear testament to our adherence to strict guidelines in different industries. This means that we are always up against the highest standards when it comes to precision bar manufacturing.

- ISO 9001 Quality Management System

- ISO14001 Environmental Management System Certification

- Automotive Industry Quality Management System (IATF 16949)

- RoHS Restriction of Hazardous Substances (Available Upon Request)

- SGS Products Test – These tests are conducted to check the quality and if it matches industrial standards.

- Conformity to European standards: ensuring precision and reliability across every product

Explore Our Automatic Bar Machining Gallery

Custom Shaft

Custom Shaft 1

Custom Shaft 2

Custom Shaft 3

Custom Shaft 4

Custom Shaft 5

Custom Shaft 6

Custom Shaft 7

Custom Shaft 8

Ejector Pin

Automatic Bar Machining Industries

In modern manufacturing, automatic bar machining and bar turning of industrial parts serve as essential processes that ensure exceptional precision, reliability, and efficiency. With the use of advanced Swiss lathes, CNC systems, and bar machines, manufacturers can produce highly complex components with tolerances as tight as +0.001 mm across a wide range of industries.

These are the major industries that use automatic bar machining:

- Automotive Industry: You are provided with accurate engineered shafts, bushings, and connectors which enhance the safety and performance of vehicles.

- Aerospace Industry: Strict tolerances are required to produce critical parts such as fasteners, pins and housings to meet safety and durability requirements.

- Medical Industry: You are a beneficiary of highly machined surgical instruments, implants and micro-products that are biocompatible.

- Electronic Industry: Miniature connectors, housings, and heat sinks are produced with precision through advanced CNC machining.

- Industrial Machinery: High-strength parts such as gears, bolts and custom fittings are manufactured to withstand heavy-duty tasks.

- Energy Sector: You can have long-lasting components of turbines, pumps, and valves that can operate in harsh environments.

Automatic Bar Machining Parts Packaging

You require packaging that is resistant to scratching, contamination, and deformation in addition to parts arriving in perfect condition. Various packaging are utilized based on the size, weight, and shipping requirements:

- Ziplock bag packing: This is handy with small precision parts, keeping the parts clean, organized, and free of dust.

- Bubble bag packing: This offers cushioning to delicate surfaces to guard against small impacts or scratches.

- Blister packing: It makes sure that small parts are securely packaged and can prevent shifting of parts and ensures visibility.

- 5-layer corrugated box packing: Bulky shipments are secured in strong boxes that can withstand external pressure.

- Pallet packing: This is good when the shipment is heavy or has large volumes, and it will be stable during transport.

- Wooden box packing: provides the best protection to high-value, delicate or export cargo.

Checkout Our Another Manufacturing Services

- Swiss Machining

- Custom Machining

- Micromachining

- Multi-spindle Machining

- Screw Machining

- Precision Machining

- CNC Mill/Turn

- Automatic Lathe Machining

FAQs

Why would you consider automatic bar machining as opposed to traditional machining?

Automatic bar machining is more efficient, provides uniform accuracy and less labor is required. It is used to manufacture complex parts faster hence suitable to industries that require high volumes of products.

What are the considerations to OEMs when selecting a precision bar manufacturing partner?

You must look at industry certifications, experience, equipment capacities, material range, and quality control systems. This makes you receive dependable and constant parts.

What are the benefits of surface finishing that improve the performance of machined parts?

Finishing enhances durability, friction and appearance. You also gain protection against corrosion, which means an extended service life of the critical components.

How important is material selection in automated machining processes?

Selecting the appropriate material means strength, functionality and cost-effectiveness. It has a direct influence on machining speed, tolerance rates, and the ultimate performance of the final product.

What is the role of packaging in determining the quality of machined bar parts when being delivered?

The right packaging keeps out the damage, scratches and contamination. It makes sure that you get parts in an excellent condition, ready to be used without further reworking.