Precision Lathing for Every Component

CNC Automatic Lathe Machining Solutions

When seeking a reliable automatic lathe parts manufacturer in China, you need a partner which can assure accuracy, expertise and dependability. Here is what you receive when you choose us:

- A 21-year experienced special automatic lathe parts manufacturer that provides dependable quality.

- High level capacity with more than 100 automatic lathes and a highly skilled team of 125 professionals at your service.

- Tight tolerances to +/- 0.01mm with minimum ID/OD +/-0.02mm, micro holes +/-0.02mm, wall thickness +/-0.02mm, and surface finish as small as Ra 0.2 to 0.4 and Ra 0.8 to 1.6 micrometers.

- Quality assurance which is certified by ISO9001 and ISO/TS16949 standards, which ensures that you can have full confidence in everything that you get.

Automatic Lathe Parts Experts In China

CNC Swiss Masion is the China-based company that you can trust when you need automatic lathe parts experts. We have years of experience in providing precision machining that exactly suits your requirements. You will have sophisticated automatic lathes, experienced engineers and rigid quality control at all levels. Whether you require parts to be used in the medical, automotive or industrial sectors, we guarantee close tolerances and precision finishes. By selecting us, you will ensure quality results, quicker turnaround time, and professional assistance on each of your automatic lathe parts projects.

Automatic Lathe Parts Services

CNC Swiss Masion provides you with the full automatic lathe parts services, including design and manufacturing. You take advantage of DFM (Design for Manufacturing) advice to streamline parts prior to the start of machining. Advanced automatic lathes are characterized by precision, high velocity, and repeatability in all projects. Our engineers are highly qualified and collaborate with you to make sure that your parts are within precise tolerances and industry standards. Working with us, you can be sure of quality reliability, cost-effectiveness, and confidence to grow your business without any issues.

Materials

- Alloy

- Aluminum

- Brass

- Copper

- Bronze

- Stainless Steel

- High Temp and Special Alloy

- Titanium

- Steel

- Plastic

Machines

- Swiss Lathes

- Taiwan Advanced automatic lathe

- Polishing machine

- External cylindrical grinding machine

- Surface grinding machine

- Centerless grinding machine

- Passivation equipment

- Ultrasonic cleaning equipment

Surface Finish

- Golden Plating

- zinc plating

- silver plating

- nickel plating

- Heat treatment

- Brass passivation

- Bead Blasting

- Polishing

- PVD coating

What Is Automatic Lathe Parts Machining?

Automatic lathe parts machining is a highly accurate manufacturing process, which involves the automatic cutting, shaping, and finishing of metal or plastic products. Automatic lathes are efficient and do not require a lot of human attention like the manual lathes, which involves a lot of time and inconsistent production. This technique can be employed to make complicated parts with tight tolerances, which makes it suitable in medical industries, automotive industries, and electronic industries.

The Pros and Cons of Automatic Bar Machining

Pros

- Produces parts with high accuracy within tight tolerance.

- Gives higher production rates with less cycle time.

- Reduces workforce expenses by automating and creating uniform production.

- Offers good finish surfaces and repeatability.

- Performs well in high-volume production runs in all industries.

Cons

- High initial investment in advanced machines.

- Requires experienced operators and engineers to setup and monitor.

- Not as cost-effective when run in small batches or in one-off parts.

- Maintenance and repairs may be costly and time consuming.

- Less versatile as compared to manual or hybrid machining techniques.

DFM for Automatic Lathe Parts

When manufacturing automatic lathe parts, DFM is necessary. It assists you in ensuring quality, reducing costs and enhancing efficiency. Every stage of the process involves teamwork, technical skills and meticulousness.

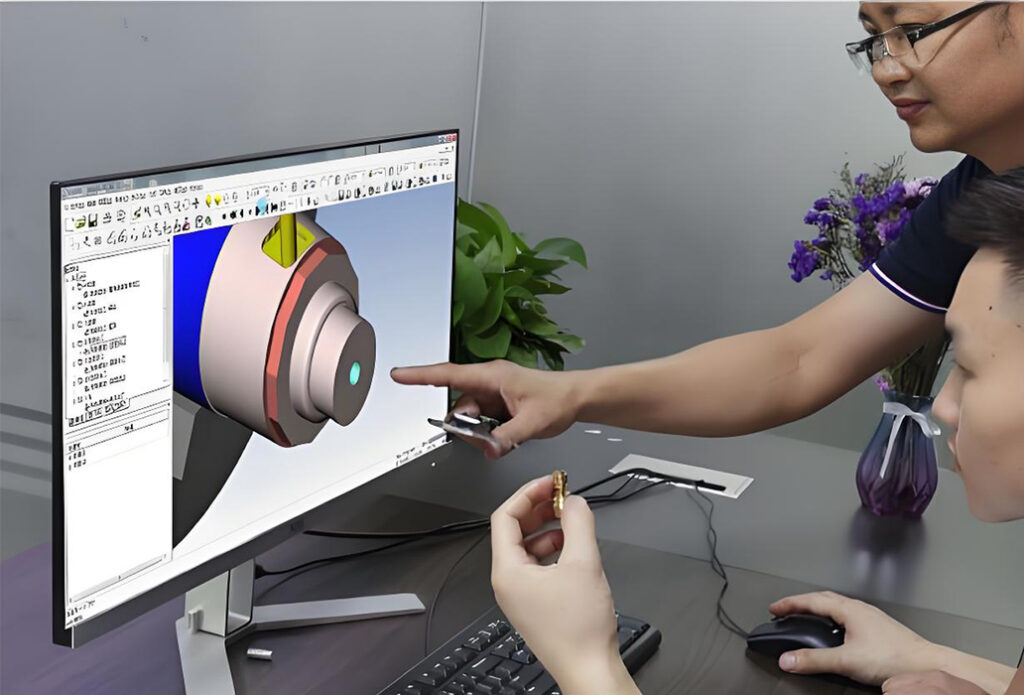

Product design and development

You should have a powerful design base Joint inspection of your team and the manufacturer verify quality attributes and design features. This will make sure that the finished product fulfills your requirements before machining commences.

Knowledge and application of materials

You have to study the properties of raw materials, starting with their composition up to their processing behavior. Knowledge of the performance of materials in various industries aids in making the right choice of materials in your parts.

Tool Design and Usage

You acquire accuracy when appropriate tools and fixtures are developed so that they suit a particular material and structure. Tooling is custom-made, and this will guarantee efficiency and uniformity in the entire manufacturing process.

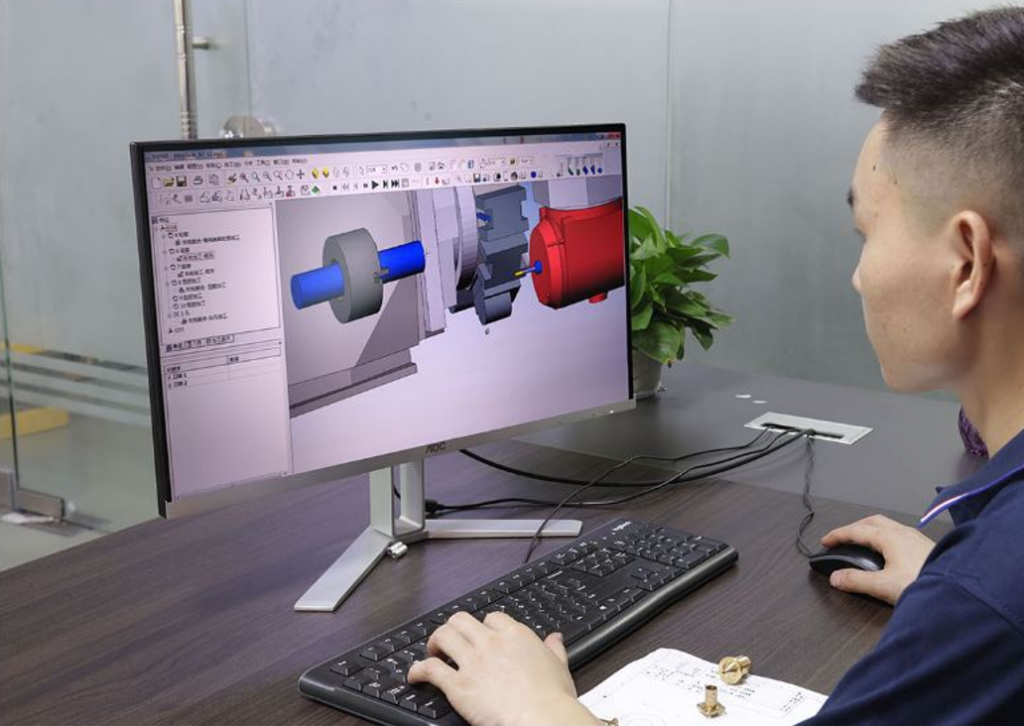

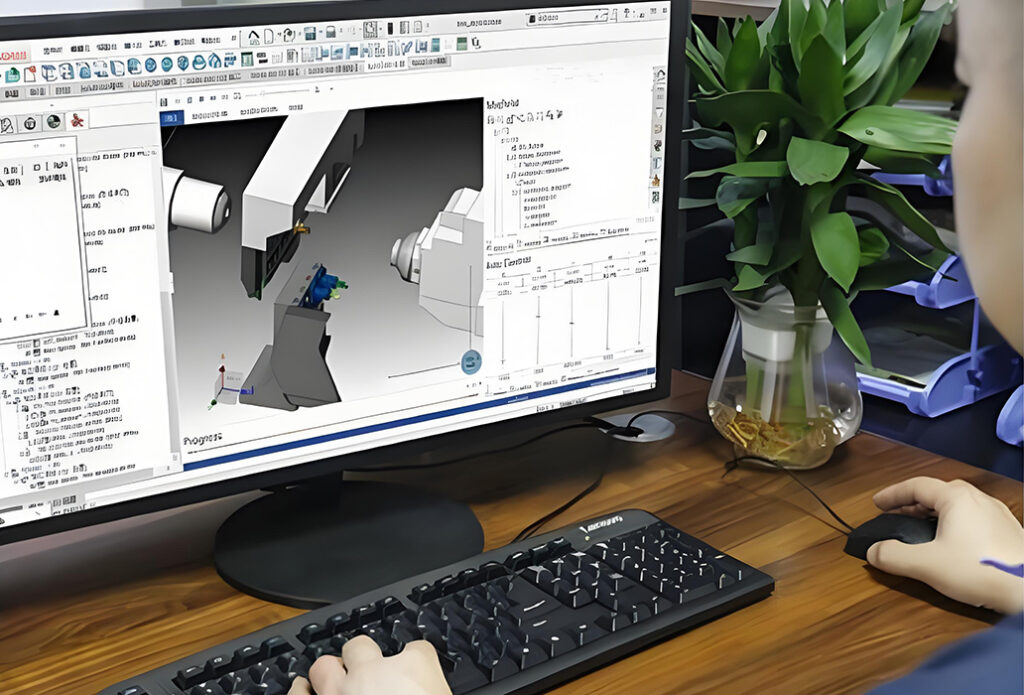

Programming Optimization Processing

You can have the advantage of optimized programming and simulations. Before entering full production, engineers calibrate tools and perform checks and verify correctness. This action saves you time and avoids the expensive mistakes.

Quality and Inspection

Digital systems and automated inspections are something you can trust to monitor production. Such processes ensure uniformity and minimise the possibility of flaws.

Solution Development and Cost Evaluation

You closely collaborate with experts to test technical solutions and estimate costs. This partnership will make your parts high quality and cost-effective.

Technical Research and Advanced Training

You need continuous research and training to be ahead. The manufacturers implement mechanical research and keep contact with international technical departments, providing you with access to high-tech solutions to automatic lathe components.

Why Choose us for Automatic Lathe Parts Machining

CNC Swiss Masion offers all the solutions to your manufacturing process to make them more streamlined, efficient, and of high-quality. You can count on our state-of-the-art systems and equipment to streamline each step in the production process, drive down expenses and enhance accuracy.

Intelligent Programming System: You can streamline machining toolpaths, shorten cycle times, and waste reduction. This system will assist you in increasing production efficiency and reduce operation costs

ERP Office Management System: You access information management in a holistic manner that enhances your control of operations. You are able to track projects, resources, and workflow to extend management capabilities and decision-making.

MES Factory Management System: You can optimize the management of production and trace all the stages. This will guarantee better quality of products, better turnaround time as well as better utilization of resources.

Quality Management System: It provides you with a high level of quality control over all processes so that all parts are up to your specifications and the industry standards.

Internal DFM and Design: You have the advantage of using in-house design and engineering talent to improve manufacturability, decrease errors and improve part performance.

Experience with Large Projects: You have the advantage of involvement in large projects, such as Huawei, Novel, Hysis, Tesla, Tuopu, and Xusheng, assuring you of confident experience in large-scale, high-volume projects.

Material and Outer Diameter: The range of materials with which you can work includes Alloy, Aluminum, Brass, Copper, Bronze, Stainless Steel, High Temp and Special Alloy, and Titanium. We process parts between 1mm and 20mm outer diameter.

Complete Processing Services: In addition to the automatic lathe parts machining, secondary processing services can be availed to clean, grind and finish the surfaces to precise specifications of your parts.

Taiwan MY Advanced Lathes: You will have access to Taiwan MY advanced lathes which guarantee precision and consistency and efficiency in all your machining requirements.

Fully Automatic Testing Equipment: Using fully automated testing equipment will allow you to measure your parts to the tight tolerances and quality levels that are required, and it will deliver those results on a repeatable basis each time.

Automatic Lathe Parts Machining Tolerance

- Precision: ±0.01mm

- Cylindricity: ±0.02mm

- Flatness: ±0.02mm

- Concentricity: ±0.02mm

- Symmetry: ±0.02mm

- Circular Runout: ±0.02mm

- Diameter tolerance: ±0.01mm

- Surface roughness: Ra 0.2 to 0.4µm and Ra 0.8 to 1.6µm

- Length size tolerance: ±0.01mm

- Angle accuracy: ±0.05°

- Thread machining accuracy: ±0.01mm

- Positioning accuracy: ±0.01mm

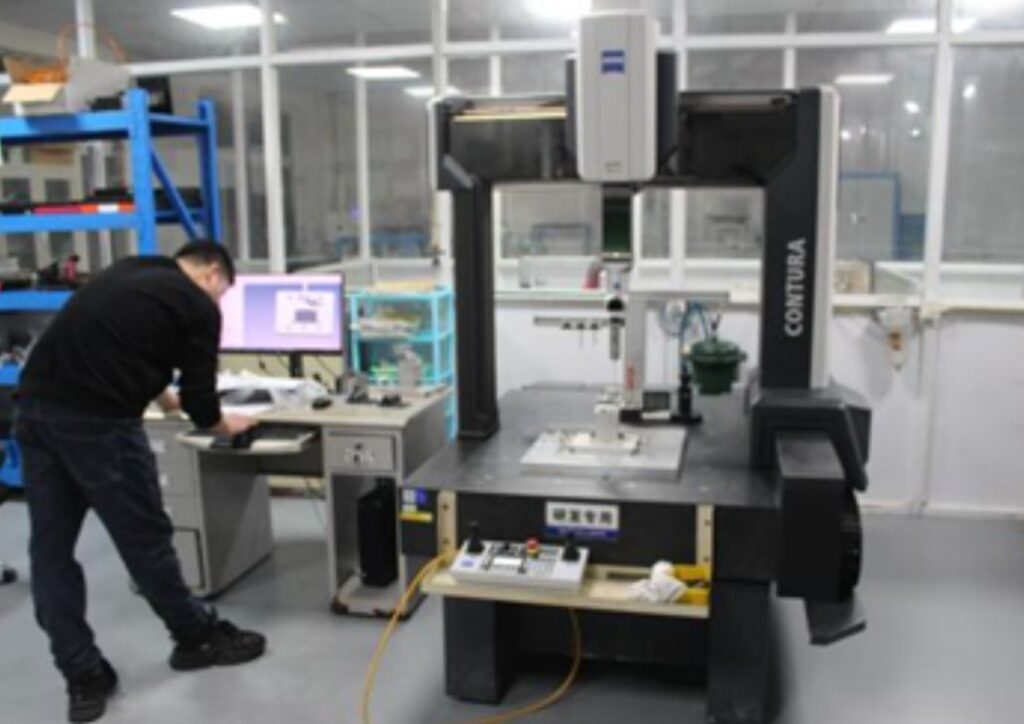

Automatic Lathe Parts Machining Quality Control

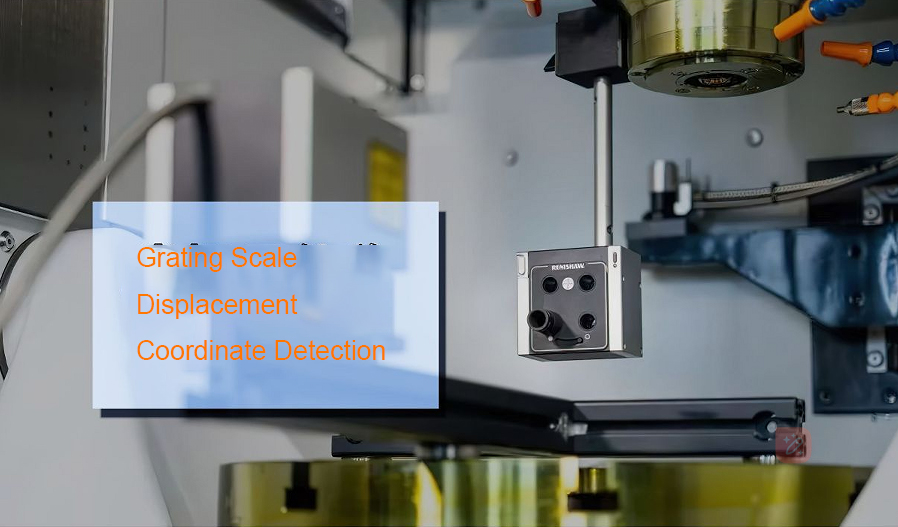

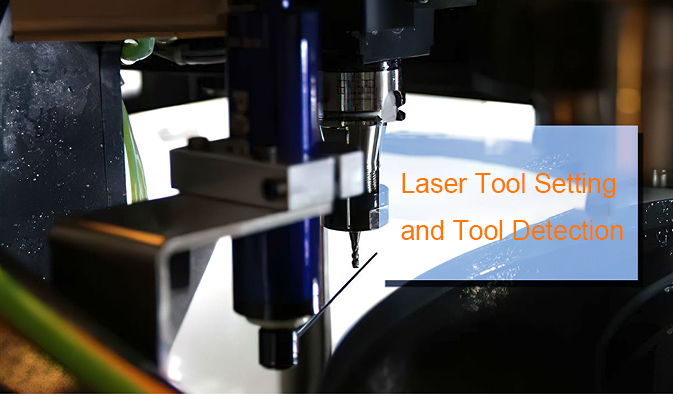

By selecting auto lathe machining, the quality control is what determines reliability of each part delivered. The present systems combine 24-hour automatic detection, automatic setting of the laser tools, automatic detection of the tools, and online measurement in-machine. The grating scale displacement and the coordinate detection give you precise results throughout all the stages.

Feed Control of Raw Materials

You begin with raw materials in your production. A safe feed system inspects each batch prior to storage All the materials have to adhere to stringent REACH and RoHS compliance reports. By doing this, you insure downstream processes against the defects and ensure uniformity.

Process Control of Finished Product

All processes in machining are done according to specifications. Inspection results are recorded automatically, and the operator confirms the correctness. You receive elaborated analysis reports, which indicate not only compliance but also trends of improvement. This will enable you to track quality, not measure it.

Product Traceability

In a traceability system, you will be able to trace the progress of every product, starting when it is being taken in as raw material to the time it is delivered. Each stage is recorded In the event of any problem, it can be easily determined where the problem is originating and it can be corrected promptly. This is because this transparency will mean that your customers will always get safe and high-quality products.

Quality Assurance

Random re-inspections serve to keep processes straight. Releases are signed by responsible persons and checked against information to confirm signature. You get the advantage of timeliness in delivery and assured quantity and quality. Included in each shipment are inspection reports to be kept by you.

State-of-the-art Testing and Inspection Labs

Your products are subject to more than cursory inspection There are well equipped laboratories where metrology, physical and chemical tests are conducted. Lifespan and performance testing represents real-life use. You also have confidence in more sophisticated equipment such as vacuum direct-reading spectrometers, X-ray flaw detectors, CMMs, hydrogen analyzers and contour measuring instruments and optical microscopes. These systems uncover latent defects and reinforce product dependability.

Our Certificates

At Masion, we are dedicated to delivering the finest in Automatic Bar Machining. With over 21 years of experience in custom Automatic Bar Machining and custom parts of high precision. It means we are committed to quality, industry standards and customer satisfaction through our certifications.

In fact, we have the ability to proudly boast key certifications that bear testament to our adherence to strict guidelines in different industries. This means that we are always up against the highest standards when it comes to Automatic Bar Machining.

- ISO 9001 Quality Management System

- ISO14001 Environmental Management System Certification

- Automotive Industry Quality Management System (IATF 16949)

- RoHS Restriction of Hazardous Substances (Available Upon Request)

- SGS Products Test – These tests are conducted to check the quality and if it matches industrial standards.

- Conformity to European standards: Solemn quality in Automatic Bar Machining.

Explore Our Automatic Lathe Parts Gallery

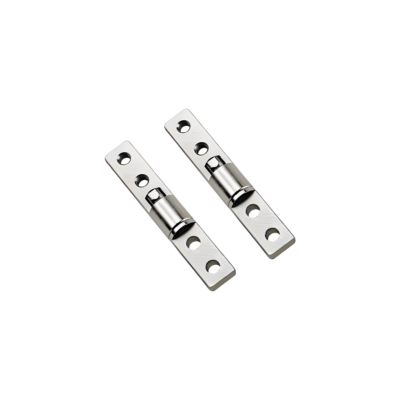

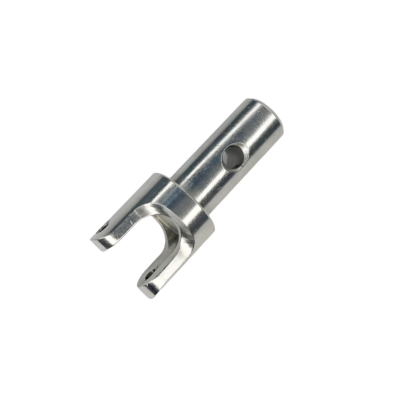

automatic lathe part

automatic lathe parts 1

automatic lathe parts 2

brass bushing

Brass Hexagonal Tower Screw

Brass Jag for Gun Cleaning Kit

custom Brass Nut

custom screw

custom screw 1

spool Drive cup

Automatic Lathe Parts Machining Industries

Automatic machining of lathe parts is essential in the various sectors where precision, speed, and consistency are paramount. With the application of the latest lathing technology, you will be able to create high-quality components, which have a high standard. Such versatility leads to automatic lathes having a diverse number of applications.

Here are some of the major industries in which you find the most significant impact:

- Medical Industry: You can trust on automatic lathe parts in surgical instruments, dental tools and implants, orthopedic implants and micro-components where precision can save lives. This will guarantee patient safety and adherence to stringent healthcare policies.

- Automotive Industry: You can ensure quality production of high strength and durable parts that can work under pressure-engine parts as well as transmission components. You also get a standardized quality which enhances vehicle performance and reliability.

- Aerospace Industry: In this industry precision counts You are the beneficiary of automatic lathes that produce light, high-tolerance products such as fasteners, turbine products, and connectors. These components can endure harsh environments and remain safe.

- Electronics Industry: In the miniaturisation of components like pins, connectors and housings, it requires close tolerances which automatic lathing is the only solution. This enables you to attain uniform functionality in delicate devices.

- Industrial Machinery: Shafts, fittings, and threaded parts are always made with durability and repeatability, enabling you to sustain equipment performance. You also minimize downtime with quality, high-quality components.

- Consumer Goods: Consumer goods that are produced in large quantities such as watch parts, fasteners and hardware depend on automatic lathes to ensure mass production and quality. Without compromising precision or efficiency, you can meet large consumer demand

Automatic lathe parts Packaging

The correct method of packing saves you money, eliminates returns, and keeps your customers happy. Here is how you can choose the right solution to your needs:

- Ziplock Bag Packing: Small, lightweight, and single-piece parts can be placed in ziplock bags. They protect against dust, moisture and scratches. This is also easy to count and handle during assembly or shipping.

- Bubble Bag Packing: To cushion delicate or polished parts, use bubble bags. During the transit, the air-filled bubbles absorb shocks. This is a good way of reducing surface dents and scratches.

- Blister Packing: Blister packing is the best when you need a clear view. You are able to present the parts in an organized manner but each piece remains firmly in place. It also avoids confusion in distribution.

- 5-Layer Corrugated Box Packing: In bulk shipping, you are able to have strength and stacking capacity with these corrugated boxes. The 5-layer construction makes it more durable. You can move medium to heavy components safely over a longer distance.

- Pallet Packing: Pallet packing is efficient when you have large volumes. You can stack several cartons on a pallet and place them with stretch film or strapping. This decreases handling time and assisting of the forklift.

- Wooden Box Packing: Wooden boxes are the best protection on exported or heavy parts shipment. You can entrust them with long-distance shipping or shipping abroad. They protect against impact, humidity, and stacking pressure.

Checkout our Another Manufacturing Services

- Swiss Machining

- Custom Machining

- Micromachining

- Multi-spindle Machining

- Screw Machining

- Precision Machining

- CNC Mill/Turn

- Automatic Lathe Machining

FAQs

Is it possible to make custom shapes with automatic lathe machining?

Yes, you can. Automatic lathes can enable you to create intricate shapes and tailored designs with a high degree of precision. You can customize dimensions and patterns to suit your specific requirements.

How fast can I have parts produced?

You also experience higher machining speeds than in manual machining. Turnaround times vary with complexity, batch size, and material but the automatic lathe maximizes efficiency.

Is it possible to combine different materials in a single order?

Yes, you can. You may order parts in aluminum, stainless steel, and brass, or titanium or even plastics in the same production run based on your needs.

How can I be sure that the parts fit into my assembly?

You can trust on tight tolerances and DFM instruction. Proper part design reviews and planning will ensure that parts fit perfectly.

Do surface finishes have customization options?

Yes, it is possible to select finishes such as polishing, plating, bead blasting and PVD coating. This makes components fit aesthetic and functional specifications.

Are automatic parts of lathe applicable in new industries?

Sure, you can apply them in new industries such as robotics, wearable devices or green energy. Great precision and flexibility make them adaptable to innovation.