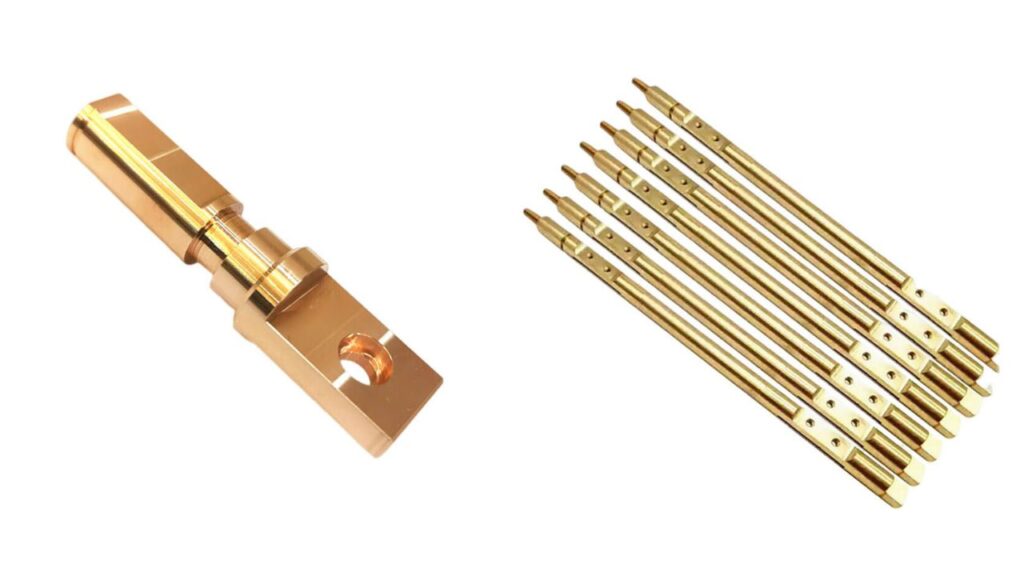

Brass Machining 101 – Everything You Need to Know

Brass machining is a critical part of the contemporary manufacturing industry due to the excellent workability, strength and aesthetic quality of the material. Whether you are manufacturing precision components or decorative components, the correct utilization of brass makes them durable, functional, and economical. This is why proper knowledge on brass machining is important- you must know about the material, its grades and proper methods of machining in order to prevent mistakes and wastage. This tutorial will take you through all the basics of machining brass as well as tips and tricks of the trade. You will get to know about top brass grades, machining techniques, surface finishes and even how to select the most appropriate CNC partner in your project.

Table of Contents

ToggleWhat Is Brass Machining?

Brass machining is a process whereby brass (copper-zinc alloy) is machined into accurate parts by either the use of manual machining tools or CNC machines. Manual machining can be used when simple tasks are required, however, CNC machining is more accurate, faster and more repeatable. Plumbing, electronics and automotive industries widely use CNC. Brass can be easily machined due to its softness, high conductivity, resistance to corrosion and ease of cutting. Brass provides you with a smoother surface finish, reduced tool wear and rapid chip clearance compared to aluminum, steel, or copper. When you want to achieve high quality results with very little downtime, brass gives you an edge on efficiency and performance.

Benefits of Brass in CNC machining

Exceptional Machinability

One of the metals that are the simplest to machine is brass. It is able to be run at high speeds without compromising quality. It generates small chips that are easy to handle, and it lowers tool wear and maintenance requirements. This implies that you will waste less time changing tools and more time cutting parts.

High Dimensional Precision

In machining brass, tight tolerances can easily be obtained. It is particularly helpful when your components require accuracy. You also receive great repeatability with CNC systems. That would guarantee every component in your manufacturing line fits.

Weather resistance and Corrosion

Brass is durable in marine, humid or outdoors. In case your project is about plumbing, HVAC, or marine components, you will have the advantage of its resistance to rust and scaling. Its inherent resistance to corrosion assists in maintaining the life of your parts in extreme environments.

Electrical and Thermal Conductivity

Brass is dependable in electronic and heat sensitive work. Its conductivity renders it ideal in terminals, relays or heat exchangers. There is also reliable relay performance in circuits and assemblies where the stability of conductivity is important.

Aesthetics and Appealing Aspects

Brass provides a natural gold finish. It may be highly polished to a mirror finish, or plated decoratively. This renders it suitable to functional as well as design-intensive components. It is one of the most preferred options in visible parts where aesthetics are of importance.

Economy and Efficiency

Your production time is reduced by the brass. It is quickly machined and needs little finishing. Moreover, reduced tool wear and shorter cycles will reduce the overall costs. You have dependable performance, never at the cost of cost or lead time.

Grades of Brass used in Machining

C260 (Cartridge Brass)

C260 is a material of great ductility and formability. It will be helpful to you when your drawing is deep drawing or intricate bending. It also gives a smooth surface finish that is suitable on decorative or functional parts.

C360 (Free-Cutting Brass)

C360 is popular in CNC machining because it is more machinable. It produces compact, fragmented chips and results in little tool wear. Use this alloy when you are dealing with a high-speed production or tight-tolerance parts.

C464 (Naval Brass)

C464 is marine-rated, which means that it is highly resistant to salt water and corrosion. This grade is to be used in underwater fittings, ship parts or components subjected to humid or corrosive environments.

C353 (Leaded Brass)

C353 is a lead bearing material and this makes it very strong and relatively easy to resist corrosion. The grade is perfect in case you require parts that can endure mechanical load without losing its good machinability.

C230 (Red Brass)

Red brass is highly solderable and also corrosion resistant. When constructing plumbing or electrical parts, C230 simplifies your work load and your finished product will last longer.

C377 (Forging Brass)

C377 is hot forged. It is strong enough and can be shaped into intricate designs without cracking. This grade will be needed when you are doing a lot of forming or shaping of your application.

Admissible Feed Rate and Speed

Moderate speeds and controlled feed rates are necessary to machine brass at the best speeds in order to maximize the tool life and avoid overheating. As an example, turning speeds of circa 200-250 surface feet per minute (SFM) and a feed rate of circa 0.005-0.010 inches per revolution (in/rev) will assist in reducing friction and tool wear. The following are other parameters that are suggested:

| Process | Speed (SFM) | Feed Rate (in/rev) |

| Turning | 200 – 250 SFM | 0.005 – 0.010 in/rev |

| Cutting Off | 180 SFM | 0.004 – 0.006 in/rev |

| Drilling | 150 – 200 SFM | 0.003 – 0.007 in/rev (for 1/4″ hole) 0.004 – 0.008 in/rev (for 1/2″ hole) |

| Reaming | ~120 SFM | 2x the drill feed rate |

| Tapping | ~100 SFM | Based on thread depth and diameter |

Admissible Brass Chemical and Mechanical Characteristics

| Category | Property | Value |

| Chemical Composition | Copper (Cu) | 60.0% – 63.0% |

| Zinc (Zn) | Balance (~37.0% – 40.0%) | |

| Lead (Pb) | 2.5% – 3.7% | |

| Iron (Fe) | ≤ 0.35% | |

| Aluminum (Al) | ≤ 0.5% | |

| Other Elements | Trace amounts, ≤ 0.3% | |

| Mechanical Properties | Tensile Strength | 380 – 450 MPa |

| Yield Strength | 170 – 310 MPa | |

| Elongation | 15% – 25% (in 50mm) | |

| Hardness | 80 – 150 HB (Brinell) | |

| Density | 8.4 – 8.7 g/cm³ | |

| Thermal Conductivity | 100 – 120 W/m·K at 25°C |

CNC Turn & Mill Brass Process

- Material Preparation: Cut to size and select brass stock (e.g. C36000). Make sure that the workpiece is tightly inserted into the chuck.

- Machine Preparation: The brass workpiece is mounted in the CNC lathe that has milling capabilities. It may require alignment, with a tailstock or steady rest.

- Tool Selection: Fit carbide or high speed steel tools that are appropriate to work on brass. Select turning tools to work on outer diameters and milling tools on slots or flats.

- Program Input: Download a G-code program with the speeds (200-250 SFM) and the feeds (0.005-0.010 in/rev). Add turning and milling tool paths.

- Rough Turning: Begin the process by rough turning to discard the surplus. Avoid overheating by using moderate speeds and coolant.

- Milling Operations: Go into milling mode. Slot or profile cuts with very accurate tool motions. Keep the feed rates similar.

- Finishing Pass: Make a last turning pass on smooth surfaces. Adjust feeds and speeds (e.g. 180 SFM) to achieve a fine finish.

- Inspection: Measure with calipers or CMM. Check tolerances and surface finish.

- Cleanup: Junk the component, deburr and clean with solvent.

CNC Brass Swiss CNC machining process

- Material Loading: Insert the brass rod (e.g. C36000) into the guide bushing of the Swiss CNC machine. Fasten it to stability.

- Tool Setup: Install several tools (e.g., carbide) in the gang tool post on the machine. Place position tools near the guide bushing.

- Program Entry: Enter G-code speeds (150-200 SFM) and feeds (0.003-0.008 in/rev). Explain simultaneous turning and milling paths.

- Turning Operation: Start with the bar stock rotating. Longitudinal cuts and diameters should be performed using live tooling.

- Milling and Drilling: Use live tools to cross-drill or mill features with complex shapes. Keep accuracy with short tool travel.

- Part Ejection: Shear off the completed part during the movement of the bar. Catch it in a parts catcher.

- Quality Check: Check dimension and surface finish with gauges or micrometers.

- Maintenance: Clean off chips and grease up the machine. Get ready to the next cycle.

How to Choose the Right Grade

To select the appropriate grade of brass, look into the mechanical requirements of your part, the environmental conditions as well as the fabrication requirements. Do you require resistance to corrosion? Take C464 or C230. Requiring speed and accuracy? The best is C360. Consider your industry as well, what will be successful in plumbing might not be aerospace. When using them, always grade to your purpose to get the most performance and value.

Brass Machining Industries and Applications

Brass machining crosses many industries, because brass is highly machinable, resistant to corrosion, and conductive. When you are dealing with precision components, decorative parts, or performance based hardware, brass can give the best performance.

HVAC and Plumbing

Machined brass is a common element in fittings, valves, and connectors of pipes. It is not scalable and not corrosive, so it is ideal in hot water systems and HVAC installations. Brass parts may improve long-term reliability and safety, in case you are in this field.

Automotive

Brass is essential in automotive products such as sensors, radiators and engine components. These components have very close tolerances and brass enables you to meet them quickly. Brass can be depended upon to provide strength and dimensional accuracy.

Electrical and Electronics

Brass is what you need when you manufacture terminals, relays, and circuit connectors. It is electrically conductive and does not corrode, hence it suits sensitive electronic environments. It guarantees steady performance and low maintenance.

Aerospace

Aerospace requires materials that are able to work in extreme conditions. Hydraulic parts and machined brass fasteners are very strong, stress-resistant, and pressure-reliable. You will have a stable performance at high altitudes.

Musical Instruments

There is no brass to match it in acoustic accuracy and beauty. Brass is used in musical instruments such as trumpets, clarinets and saxophones to have rich sound and have beautiful tops. You enjoy the sound quality as well as the visual appeal.

Architectural and Decorative

Brass gives a luxurious feel in case you are creating hardware such as door handles, locks, or furniture decorations. It can be machined to custom shapes easily and is able to be finished with any finish to provide long-lasting shine.

Marine Applications

Brass machining is valuable when operating in a saltwater environment. Brass is used in propellers, underwater fittings, marine hardware due to its corrosion resistance. You are durable and functional in severe marine conditions.

Tooling and Brass Machining Methods

Brass CNC Turning and Milling

In machining brass, you will be using CNC turning to produce parts that are cylindrical and CNC milling to produce parts with complex geometries. In turning, the brass is rotated on a lathe, and is shaped by cutting tools. Milling, however, entails the rotation of tools that travel in a variety of directions to cut elaborate designs. Select turning to make symmetrical parts and milling to make flat or multi-angled parts.

Brass Swiss CNC Machining

You utilize Swiss CNC work to make small, exact brass components with close tolerances. Move the brass stock over a slider headstock and tools cut with very high precision. This technique is used on small, complex parts with small diameters such as watch parts or medical equipment. Regulate feed rates and speeds to ensure the quality of surfaces. Swiss machining offers optimized efficiency and precision of your production.

Brass Milling

Use brass milling to create complicated shapes and smooth surfaces. Rotate multi-point tools in different directions across the workpiece made of brass. Choose carbide tools to be durable and speeds to be adjusted to best results. Make sure to use coolant so that the heat and chip buildup can be controlled. This technique is appropriate in your demand of detailed non-symmetrical parts of brass.

Brass Automatic Lathe Machining

You apply automatic lathe machining in high-volume brass fabrication where little supervision is done. Install a lathe to automatically feed and cut a brass stock into a round shape. Define the tool paths of programs to achieve uniformity in output and efficiency. Track the wear of the tools to ensure quality on large batches. This technique makes your process more efficient when you need to do the same things at high speed.

Brass Turning

Turn brass to make smooth, cylindrical brass parts easily. Hold the brass on a lathe, and spin it against sharp cutting tools. Modify the speeds and feeds to suit the grade of brass to achieve optimum results. Coolant should be used to minimize heat and have clean cuts. The method will provide consistent, symmetrical components to your applications.

Successful Brass CNC Machining Tips

Choose the Correct Brass Alloy

Begin by selecting the appropriate brass grade in terms of mechanical strength, resistance to corrosion, and formability of your project. E.g. when you require high machinability, use C360. C464 (naval brass) is preferable when to be used in the marine. Using the wrong alloy will result in inefficient performance or increase costs.

Apply Proper Tool Finishes

Brass is soft though yet it wears tools. Apply TiN (Titanium Nitride), TiCN (Titanium Carbonitride) coated tools. The coatings lower friction and heat, which enables you to prolong the life of your tools and achieve consistent finishes.

Tune Machine Parameters

Choose your feed rates and cutting speeds. The most frequent results are high speeds and low feed rates. You shall minimize vibration, avoid chatter, and a smooth surface finish.

Heat Management

Never operate without coolant / good lubrication. Brass does not get as hot as harder metals, but can still become subject to thermal expansion or warping due to poor heat control. You desire uniformity of part quality, particularly in close tolerance applications.

Planning of Surface Finish

Consider post-processing during machining. Should you polish your parts or plate them, adjust your tooling and operations to help achieve a cleaner finish in the early stages.

Test of Prototype Before Mass Manufacture

Test run a prototype. It aids you in checking tolerances, strength and final fit. When you switch to production, you will not make expensive errors.

Brass Machined Parts Surface Finishes

Polishing

Brass can be polished either by hand or with automatic instruments. You have control with manual polishing and you can have large batch polishing on the same level with automation. Polishing should be used when the desired finish is mirror-like smooth. It is suitable in ornamental pieces or components that require low friction.

Electroplating

Nickel, chrome or gold electroplating increases durability and beauty. Gold plating is best in case you want a premium finish. Nickel and chrome provide a hard, protective corrosion layer, which is ideal in functional and exposed parts.

Powder Coating

Select powder coating when you require something beyond good looks. It provides a protective coating that is wear resistance, chemical and weather resistant. It is also possible to choose between a variety of colors to fit branding or design requirements. It is an excellent finish where you require even texture and stability of surfaces over time.

Passivation and Lacquering

Coat the brass with passivation or lacquer to maintain the natural brass shine. These finishes minimize tarnish and will maintain your parts looking new. They come in handy when you are making parts to be displayed indoors or architectural detailing.

Problems and Remedies in Brass Machining

Galling and Tool Wear

Brass is relatively easy to machine compared to several other metals, yet even high-speed cutting may result in tool wear and galling. You can see that material can stick to the cutting tool, which makes it less precise. To prevent this, proper lubrication must always be used. Select coolants or cutting oils, which minimize friction and keep the tool cool.

Burring and Edge Finish Problems

Burring is possible, even with brass excellent machineability, particularly when it is drilled or threaded. Edge quality may be enhanced by application of deburring tools or additional finishing passes. The sequence will assist you in getting clean, smooth edges without breaking part geometry.

Long Runs Tolerance Drift

Tolerance drift can be a result of thermal expansion and tool wear in large-volume production. This can be avoided by in-process calibration and frequent measurement verification. This aids in accuracy with time.

Workpiece Holding and Fixturing

Brass is soft and thus it can move with improper fixing. Be sure to employ very stable fixturing to maintain the workpiece securely during high-speed machining. This gives greater repeatability and surface finish.

Things to Consider Before Brass CNC Machining

Application Needs and Material Properties

You should apply mechanical, chemical, and thermal characteristics of brass to the functionality of your part. That is, you would want to use a brass grade that suits your application. Example, when your application requires high conductivity or corrosion resistance, you would want to use a brass grade with those requirements. Before choosing a material always consider your end-use needs.

The feasibility and complexity of design

The geometry of your part has a direct influence on the success of machining. Advanced tooling and more machining time is needed in deep holes, tight corners, or undercuts. In the event you are having a complex design, make sure that it is something that your machinist can handle.

Cost and Volume of Production

Volume makes a difference whether you are prototyping or in full production. Larger batches will reduce your unit costs and small runs can add to your setup and tooling costs.

Machine Capability and Tolerance

Various machines have varied accuracy. Depending on your needed tolerance, you can then select equipment, micro-machining will give fine detail, industrial CNC will give larger pieces.

Supply Chain Planning and Lead Time

Certainly check quantity of brass stock available, and allow time in machining. This will assist you to meet deadlines and prevent expensive delays.

Environmental and Recycling advantages of Brass

Sustainable material: Brass

Another metal that is eco-friendly is brass. It can be recycled over and over again without losing any quality or strength. That is why it is an intelligent option in case you are concerned about environmental footprint. Brass, unlike a number of other materials, does not lose its properties during recycling.

CNC Machining Waste Reduction

Brass provides near-net-shape machining and assists you in reducing wastage during the manufacturing process. You are very economical with the material and reduce the amount of scrap. Efficiency helps in sustainability, and it also reduces your costs of production.

Recycling of Brass Chips

Machined chips can be reused as well. It is possible to collect, recover, and remelt them, and transforming waste into valuable raw material once again.

The Cost Factors in CNC Brass Machining

Material Costs

In machining brass, you will see that various grade such as C360 or C260 are charged at different prices, which is normally charged in dollars per lb or kg. The scrap recycling prospects of brass are very high, and this can be used to cover the cost of the materials once you are well versed with waste management.

Machine Time and Labor Time

Labor and machine time are directly influenced by your design complexity. Complex components require more tool paths, extend the run time and may involve more than one setup. The cost is further incurred with machine availability, set up, particularly when you are on a tight schedule.

Finishing and Post-Processing

There will be additional budgetary requirements in case you decide to use surface treatments, such as polishing, plating or coating. These finishes improve performance, and increase the total cost.

Quantity and Batch Size

The smaller batch orders will be more costly per unit because of the set up costs. But you enjoy economies of scale when you engage in mass production. Designing your batch size assists you in reducing your machining costs.

Selecting the Most Appropriate CNC Machining Partner

Seek Tested Experience

What you require is an ally who has a good history of accuracy in CNC machining. Look at experience with brass particularly because it is difficult to machine efficiently without issues with tool wear or burr.

Verify Certifications

Make sure that the providers you pick are certified under quality standards such as ISO 9001 and defense related standards such as ITAR. These guarantee consistency, traceability, and compliance.

Evaluate Equipment and Capabilities

Inquire on their CNCs, software, and tooling. A modern shop with multi-axis equipment is capable of machining intricate geometries and close tolerances.

Request Case Studies

See examples of previous brass projects. This will inform you about their quality, level of detail and experience in the industry.

Conclusion

Brass machining provides an intelligent compromise of accuracy, strength, and beauty. No matter what type of brass alloy machining you are utilizing whether it be 360 brass alloy machining, 27450 brass, 353 or 443 grades, all have distinct benefits depending on your project requirements. Brass is useful in industries due to its good machinability, resistance to corrosion, and cost-effectiveness. In applying the brass CNC machining, it is important to take into consideration the most suitable grade, the complexity of the design, the finishing options and the machining parameters. When selecting a competent brass CNC machine shop such as CNC Swiss Mansion, the results will be high quality and reliable.

FAQs

Which is the optimal brass grade to be CNC machined?

C360 (Free-Cutting Brass) is the best option you can use when you want the most machinable brass alloy. It has traces of lead that enhance chip formation and tool life. This grade enables you to work with tight tolerances with little effort. It can be used during high-speed turning, milling, and drilling with a very good outcome.

What is the comparison between brass and aluminum with CNC machining?

The aluminum tends to be difficult to machine in comparison to brass. Brass will give you less wear on tools and improved finishes on surfaces. Although aluminum is cheaper and lighter in weight, brass has superior dimensional and corrosion stability. Brass is the material to use when precision and high-end finish are required.

Is it possible to weld machined brass?

Brass is welded, but carefully. Brass is a soft metal with a low melting point and when overheated, it releases toxic fumes due to the presence of zinc in it. Brazing, or soldering, should be an option instead of welding. These methods are safer, and more applicable to post-machining assembly.

What is the normal tolerance of brass machining?

You can get tolerances as fine as +/- 0.001 inches ( +/- 0.025 mm) with suitable CNC equipment. The stability and machinability of brass enables you to stay accurate throughout your production runs particularly as you use optimized tool paths and cooling systems.