Brass Passivation 101 – The Ultimate Beginner’s Guide

Passivation of brass is a prevailing theme in the performance and protection of brass parts in industries. When you deal with brass, you should realize the benefits of passivation that allows preventing tarnishing and enhancing corrosion resistance as well as preparing the surfaces to additional finishing. Obtaining transparent insights into this process, allows you to make more appropriate decisions, prevent expensive errors, and increase product life. In this guide, you will learn what brass passivation is, its mechanism, its available methods, and how you can use it efficiently in practice.

Table of Contents

ToggleWhat is Brass?

Brass is a copper and zinc alloy and you will find that its properties change depending on the amount of zinc. depending on the combination, you have such types as alpha, beta, alpha-beta, and leaded brass. To enhance machinability or durability, manufacturers frequently incorporate alloys such as lead, tin, aluminum, iron, or silicon. Once you learn about brass composition, you will be able to select the appropriate type to suit the strength, appearance, and corrosion resistance requirements of your project.

Properties of Brass

- Brass has very good mechanical strength and is used where durability is required but the part must not get too brittle. You will discover that it is pressure resistant, particularly in fittings and fixtures.

- It has electrical and thermal conductivity that enables it to transfer energy efficiently. Brass can offer you the performance you need without wearing out quickly especially when you are dealing with electronics or components that are sensitive to heat.

- You will also love brass because of its gold like appearance. It provides a luxurious look and feel, and your designs will look outstanding in both contemporary and retro environments.

- Brass is fairly resistant to corrosion, particularly in dry climates. But you must understand that it still may tarnish with time, and that is why such protective processes as passivation may be used.

Common Applications of Brass

- You will find brass frequently in plumbing fittings because it is resistant to corrosion and is easily machined. It is ideal to make leak-proof connections at homes or commercial installations.

- Brass is used in musical instruments such as trumpets and saxophones because of its sound and aesthetic value. Brass provides you with tone and beauty in case you are in that industry.

- Brass is used in architectural hardware, such as door handles, hinges and railing fixtures, due to its strength and luster. You can rely on it not to wear out and keep its appearance.

- Brass electrical connectors offer good conductivity and resistance to corrosion. Whether you deal with wiring or electronics, brass makes your parts reliable and durable.

- Brass is applied in decorative purposes such as lamps, frames and sculptures where its warm and elegant nature is desired. You will be able to carve, sand and complete to make an impression that lasts.

What is Passivation?

Passivation is a type of chemical treatment that involves the removal of contaminants on the surface of metals and the creation of a protective oxide layer. You apply it to stop any further oxidation and corrosion, particularly on metals such as stainless steel, copper and aluminum. It is becoming relevant in the brass finishing today. Brass can tarnish and dezincify, so you require passivation to enhance its resistance to corrosion and preserve its look. It also pre-treats the surface in case you intend to apply more coats or finishes. This will help your brass pieces to live longer and appear nicer.

Types of Brass Passivation

Knowing more about the varieties of brass passivation treatment allows you to select the most suitable procedure based on your requirements. Both have distinct advantages based on the application.

Chromate Passivation

You may apply hexavalent chromium-based or trivalent chromium-based solutions when you need high resistance to corrosion. The treatments create a visible film, yellow, green or blue, which protects brass surfaces and improves appearance.

Phosphate Coating

This procedure provides you with a matte finish and acceptable corrosion resistance. It is perfect on mechanical parts and where gloss is not needed as in military or industrial environments.

Citric Acid Passivation

In case you are interested in something environmentally friendly, citric acid is a good alternative. It eliminates free iron and impurities without any strong chemicals. You will appreciate it in cleaning surfaces safely and effectively.

Passivation Nitric Acid

Nitric acid is less effective on brass than on stainless steel although it is commonly used. Be careful with it, particularly with sensitive alloys.

Proprietary Solutions

You may choose to have custom mixes that are either decorative or functional. These may contain chelating agents, inhibitors and surfactants to fine-tune performance.

| Passivation Method | Chemical Agents Used | Effectiveness | Environmental Impact | Surface Appearance |

| Citric Acid Passivation | Citric acid, water | Moderate | Low | Slight shine, non-aggressive |

| Nitric Acid Passivation | Nitric acid, water | High | Medium to high | Clean, semi-bright |

| Chromate Conversion | Chromic acid, dichromates | Very high | High (regulated) | Yellowish or iridescent film |

| Phosphate Coating | Zinc/manganese phosphates | Medium | Medium | Matte gray or black |

| Organic Coatings | Polymer waxes, oils | Low to moderate | Low | Glossy or satin |

| Electrochemical Passivation | Controlled voltage and electrolyte | High | Medium | Consistent, smooth |

Equipment Used in Brass Passivation

In order to carry out an efficient and reliable brass passivation, you must have the appropriate equipment. All tools contribute to the cleanliness of the surfaces, chemical balance and quality in general. This is what you need to apply and why it is important.

Chemical Processing Tanks

You require tanks, which are resistant to corrosion, to store and combine chemical solutions. In the majority of configurations, high-density polyethylene (HDPE) or stainless steel tanks are utilized. These materials are resistant to acidic or oxidizing solutions and guarantee the process safety.

Ultrasonic Cleaners

A key factor before passivation is an appropriate surface prep. Ultrasonic cleaners can help you loosen oils, dust and metal particles lodged in small crevices. This measure enhances passivation and minimizes chemical contamination.

Drying and Rinsing Systems

It is essential to rinse with deionized (DI) water. To avoid spots and streaks following treatment, you will require DI water tanks and air knives or hot-air drying systems. This is also done to leave the surface clean to either be inspected or coated.

Filtration Systems

Filters are important to the chemical integrity of your passivation bath. Inline or cartridge filters should be installed to eliminate particulates, metal debris, and residues. Clean baths will result in predictable outcomes and minimize rework.

Personal Protective Equipment (PPE)

When working with acids or oxidizers involved in passivation, never compromise safety. You are to wear lab coats or aprons, eye protection and chemical-resistant gloves. To minimize risks by inhalation, use good ventilation or fume hoods.

Analytical Instruments

To monitor the performance of your bath during operation, you require accurate instruments: pH meters, conductivity meters ensure the optimum chemical balance, and XRF analyzers verify the surface composition. These tools guarantee process validation and quality control.

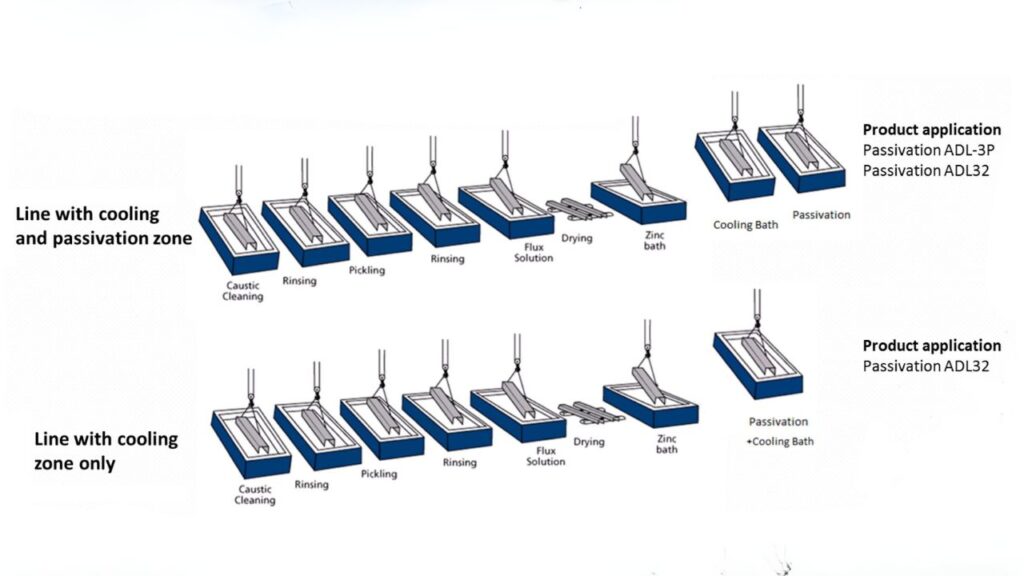

Step-by-Step Process of Brass Passivation

Step 1: Preliminary Cleaning

Begin with cleaning the brass surface of grease, oil and dirt. A deep clean can be achieved with commercial degreasing agents or ultrasonic cleaners. This is done to guarantee that there are no contaminants that can affect the passivation process. The surface should always be clear of any residue.

Step 2: Preparation of Surface

Then mechanically prepare the brass with abrasive pads or media blast. This roughs the surface a little and increases the adherence of chemicals. In case of oxidation or scaling, acid pickling should be done to remove further contamination of the surface. Before using acids, always check the compatibility with your brass alloy.

Step 3: Rinsing

Clean the brass using deionized (DI) water. This is to eliminate any remaining acids or cleaning debris. Tap water may contain minerals that will impact the quality of passivation. Rinse until the surface cleansed of all visible residue.

Step 4: Passivation Treatment

Now put the brass into the selected chemical solution. Regulate the temperature of the bath, time, and concentration of the chemical. This procedure creates a defensive oxide coating. Select a method, citric acid, chromate, or phosphate, depending on your end-use requirements.

Step 5: Final Rinse

Clean the part in DI water again. This gets rid of any chemicals that might be left on the surface. Be sure to rinse well, particularly in joints. Failure to rinse thoroughly may cause staining or corrosion.

Step 6: Drying

Dry the portion with forced air or oven dry. This measure avoids water marks or moisture corrosion. The drying should be quick and uniform. Do not touch the brass during drying to recontaminate.

Step 7: Inspection and Testing

Lastly, visually examine the brass to appear even. Conduct tests, such as salt spray or contact angle to ensure the quality of passivation. When outcomes are less than satisfactory, repeat or modify process.

Best Practices for Brass Passivation

- Always use clean and fresh chemical baths in order to obtain reproducible results. Contaminated solutions may lower the efficacy of passivation and spoil the brass surface.

- All rinsing steps should be done with deionized (DI) water to prevent spotting. Tap water may cause mineral deposits which affect the quality of the surface.

- Do not mix dissimilar metals in identical passivation bath. This may cause cross-contamination and result in an inferior surface finish or even unpredictable reactions.

- Use appropriate masking when you wish to treat only certain areas. This allows you to manage the chemical exposure and avoid treating sensitive areas unnecessarily.

- Perform routine quality control analyses such as adhesion or corrosion tests. These tests assist you in confirming whether your passivation process is per performance standards.

Considerations and Precautions

Surface Condition

Before passivation, you need to examine the surface roughness and machining marks. A polished surface enables even chemical reaction and improved oxide layer formations. Unfinished or dirty surfaces retain contamination, which causes unequal outcomes or loss of corrosion resistance.

Brass Grade Compatibility with Chemicals

All brass alloys do not necessarily react to identical passivation chemicals. High-zinc brass or leaded brasses can be unreactive with aggressive acids. Chemical compatibility should be checked at all times to prevent pitting, staining, or dezincification.

Environmental and Safety Concerns

Hexavalent chromium requires stringent safety measures as it is toxic. You must observe compliance regulations such as RoHS and REACH. Always dispose of waste in an appropriate way and think about less hazardous substitutes like trivalent chromium or citric acid.

Process Control Parameters

Accurate time, temperature, pH and chemical concentration control guarantees optimum passivation. These are variables that you need to watch. Uneven conditions may cause partial protection or spoilt surfaces.

Preventing Over-Passivation or Under-Treatment.

Brass left in the bath longer than necessary might become dull or etched. Inadequate treatment exposes it to corrosion. Use tested timing and concentration at all times to get the best finish.

Applications of Passivated Brass

Architectural Hardware

Passivated brass provides a long-term protection against tarnishing when used on door handles, hinges or railings. This protective coating ensures that the surface remains clean and polished even when subjected to a humid or polluted atmosphere. This gives it an advantage of being used both outdoors and indoors.

Electronics and Electrical Components

Passivated brass is commonly used in electrical terminals and connectors. It is not readily oxidized, contributing to the stability of its conductivity. This guarantees dependable operation in critical electronic applications, ranging between domestic wiring to industrial control panels.

Automotive & Aerospace Components

Passivation provides durability, unless you are working with decorative trims or functional brass fittings in cars or aircraft. It shields the components against bad weather, water, and chemicals allowing them to maintain their functionality and looks.

Medical and Laboratory Instruments

Passivated brass is a material you can rely on in sterile and precise applications. It is non-contaminating and non-corrosive, so it is safe to use with instruments in cleanrooms, labs, or surgical settings.

Art and Decorative Works

You will be surprised at the effect of passivated brass to bring out color, luster, and detail in Decorative items. It also does not cause tarnishing and pieces keep their beauty through the years.

Limitations and Challenges

Limited Protection in Aggressive Environments

The passivation treatment increases corrosion resistance but does not provide complete protection of brass in severe environments. You can not use it as an alternative to permanent finishes such as plating or coating. In case your application is exposed to harsh chemicals or moisture, consider further protection.

Chemical Handling Hazards

You should use passivation chemicals carefully. Chromates and acids are toxic and should be disposed of safely. To prevent health or legal problems, always observe safety procedures, use PPE, and make sure your facility complies with environmental regulations.

Surface Uniformity Issues

Complex shaped brass parts may not passivate uniformly. Chemicals are frequently retained in internal threads, sharp angles, or blind holes. This will require you to modify your procedure or employ agitation to enhance uniformity on all surfaces.

Incompatibility with Certain Brass Alloys

Certain brasses, particularly high-zinc alloys, can be poorly influenced by acidic treatments. You run the risk of dezincification, a weakening of the metal. Select chemicals safely and compatibility test beforehand.

Cost of Brass Passivation

The kind of chemical solution that you use matters a lot. Chromate based or proprietary mixtures can run between 20 to 80 dollars a gallon. Then you have the cost of equipment and setup, when you are doing it yourself. You can invest between 2,000 dollars and 15,000 dollars in tanks, filtration systems and drying systems. The batch size and throughput also count- the more you have processed the cheaper your part costs will be, usually between $0.10 and $0.50 per part depending on volume.

Another cost factor is labor and safety protocols. Personal protective equipment (PPE) and trained staff can increase your operational costs by $30 to 60 dollars an hour. Waste disposal and environmental compliance are also your concern. Complying with regulations, such as RoHS or EPA standards could cost you between 500 dollars to 3000 dollars a month to treat and document your chemical waste correctly.

When comparing in-house and outsourced, in-house passivation can typically cost you $0.10 to 1.00 per part. Outsourcing that involves labor and compliance management can range between $1.00 and $5.00 per part based on complexity and finishing requirements.

Brass passivation can be economical compared to other methods. Lacquering averages about $0.30 to $1.50 per part, electroplating averages $1.50 to 7.00 and powder coating can run $2.00 to $8.00 per part. Passivation is good value depending on your application when you want to increase durability without thick coating layers.

Conclusion

Passivation of brass is an important operation that allows you to improve corrosion resistance, maintain appearance, and increase the service life of brass parts. In electronics, architecture or decorative arts, the choice of a passivation method guarantees long-term protection and performance. When selecting a process, you have to consider a balance between technical requirements, cost effectiveness and environmental safety. By using the appropriate equipment and controlling the process, one can obtain repeatable results that correspond to the industry standards. When you know the basics, you can make smarter, safer, more cost-effective choices on your brass applications.