Industrial High-Precision Brass Nozzle Solutions

Leading Brass Spray Nozzle Manufacturer in China

- 21 years experience in manufacturing precision nozzles made of brass.

- More than 100 modern machines such as Swiss CNC lathes, automatic lathes and a highly trained workforce of 125 employees.

- Tolerances as small as ±0.001mm dimensional repeatability and fine surface finish.

- Certified to ISO9001 and best possible ISO/TS16949 to guarantee stable operation and dependable reliability.

Brass Nozzle Manufacturer Experts in China

The CNC Swiss Masion is the largest manufacturer of brass nozzle in China and it is credible with brilliant nozzles which are produced with precision and dependability. The company provides all your project requirements with custom-made brass nozzles that are produced with superior production technology and a rigorous inspection procedure. They can be relied on to provide consistent quality to industries like automotive, plumbing, electronics and machinery. All the brass nozzle projects are focused on performance, accuracy, and cost-effectiveness without disobeying international norms.

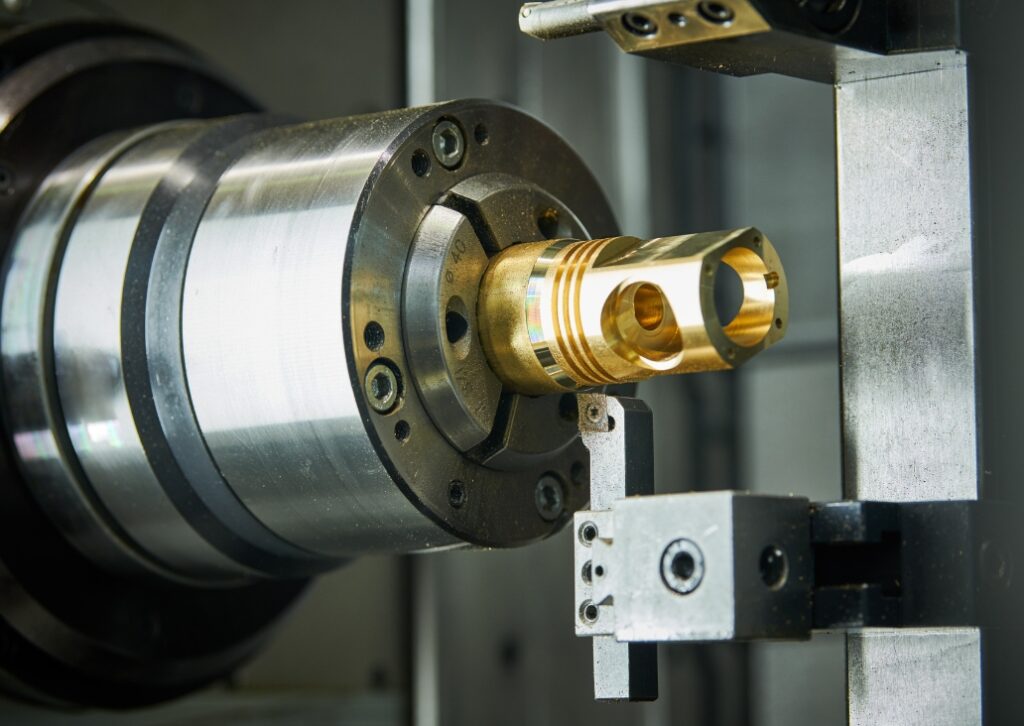

Brass Nozzle Machining Service

CNCSwissMasion offers high-quality machining of nozzles made of brass to ensure uniform quality. You get the nozzles that are exactly designed and are used in industry and commercial use. Our team works with complex designs with no tolerance to perfect work. You enjoy tailor made solutions, such as prototyping, material choice, and finishing choices. High efficiency and extremely high precision in each piece are guaranteed by advanced machinery. You can count on our experience to supply long lasting and high performance brass nozzles. Going between small-wave batches to large scale production, we ensure high quality output to meet your unique needs. Using CNCSwissMasion, you will obtain the highest level of machining services that is trusted in China, and even globally.

Materials

- H59-1

- H58-1

- H62

- C37700

- C36000

- C68700

- C69300

- CW721R

Machines

- H59-1

- H58-1

- H62

- C37700

- C36000

- C68700

- C69300

- CW721R

Surface Finish

- PVD coating

- Polishing

- Nickle Plating

- Golden Plating

- Silver Plating

- Chrome Plating

- Passivation

- Anodizing(C68700)

- PTFE coating

What is a brass nozzle?

The brass nozzle is a fine micro part that regulates the flow of fluids. You put it on equipment to direct liquids or gases. The nozzle guarantees constant production when required in industries, automobiles and homes. You count on its wear and tear resistance to last long. It gives you quality, efficient and reliable functioning in numerous applications.

Brass Nozzle Manufacturing Process

The manufacture of brass nozzles begins by choosing quality raw brass. The material is shaped by means of precision cutting, drilling, and milling machines. All nozzles are carefully turned to get the correct dimensions and smooth surfaces. You check each part to perfection and have a smooth flow and operation. Heat treatment makes the nozzle strong and it increases wear resistance to you. Lastly, polishing and finishing increase durability and leave the nozzle with clean appearance. You are given a high quality and dependable brass nozzle that can be used in industry or in the home.

The Pros and Cons of Brass Nozzles

In 3D printing, machinery, and fluid systems, brass nozzles are popular, and their thermal conductivity and durability make them a useful tool. The following are some of the benefits and drawbacks that you will experience using brass nozzles:

Pros

- You have got great thermal conductivity which provides quicker heating and even flow.

- Brass nozzles will offer durability to ensure that the nozzles will last longer without the need to be frequently replaced.

- You have the advantage of precision machining, giving correct nozzle and output.

- Corrosion resistance will guarantee longer life despite diversity of material use.

- You realize similar extrusion or spray performance among applications.

- Brass nozzles can work with very diverse materials.

Cons

- You can experience greater initial cost than some other nozzle materials.

- Soft brass may also wear more quickly when abrasive filaments are used.

- Heat sensitivity It can be sensitive to heat when working with very high-temperature applications.

- Big or specialized designs are hard to find or dispose of.

- You may experience clogging when material feed is not handled properly.

DFM for Custom Brass Nozzle

The early use of the DFM principles will make all brass nozzles designs manufacturable. Geometry to production capability matching helps in reducing redesign costs. The consistency of part and efficiency are enhanced by material choice and tolerance planning.

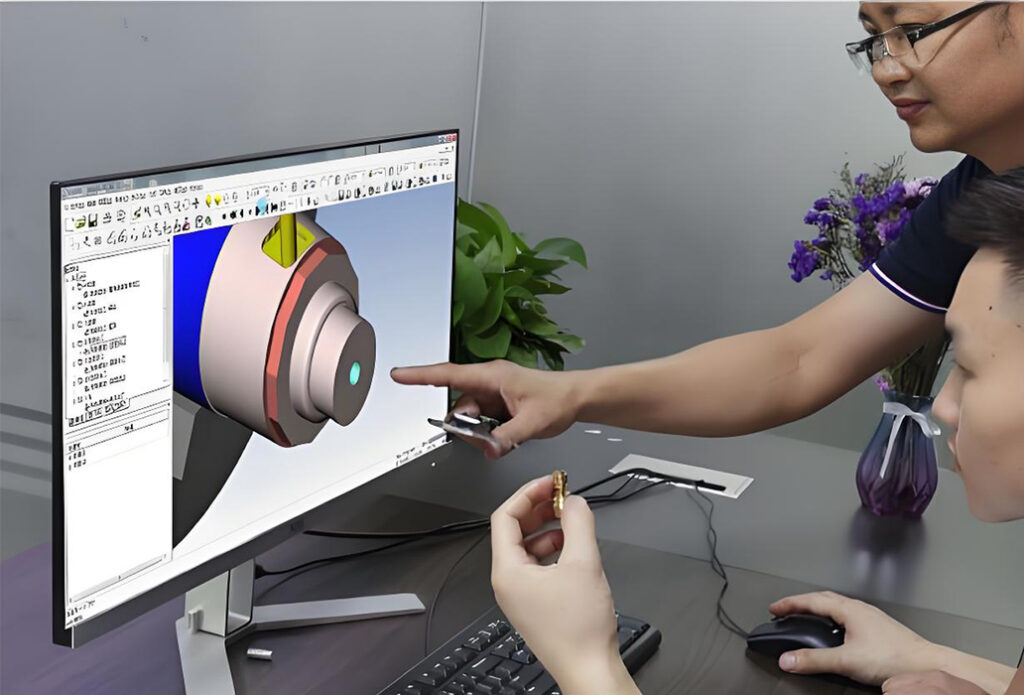

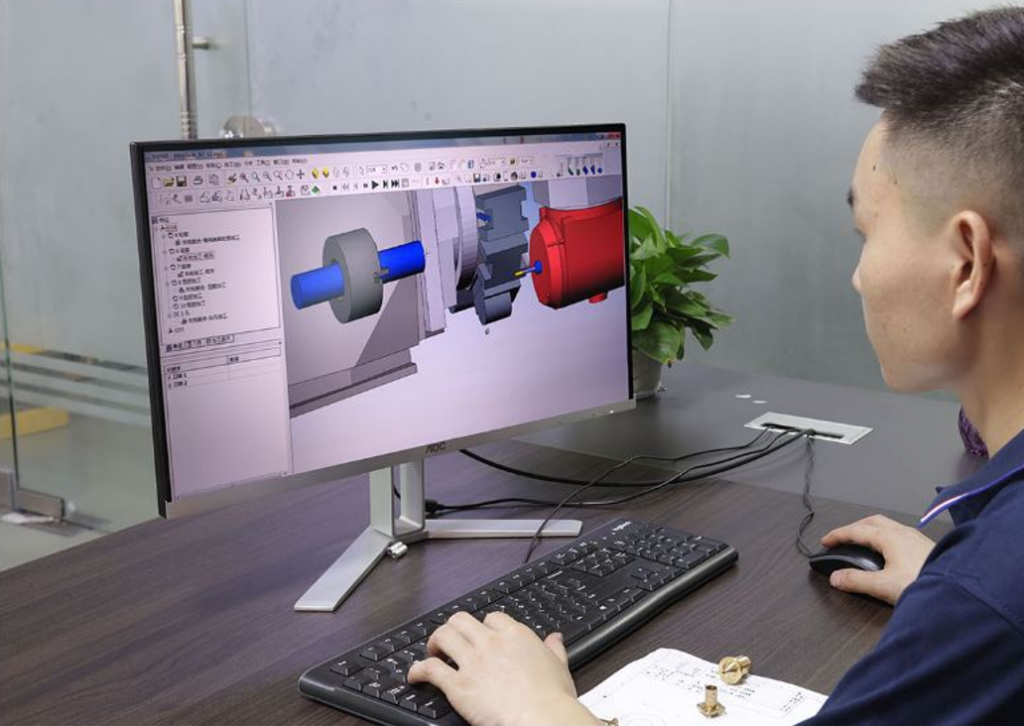

Design and Development of products: Nozzle features are validated by the engineers prior to the initiation of the production process. Functional specifications are aligned to manufacturing capability. This procedure minimizes risks, lead times and provides quality results.

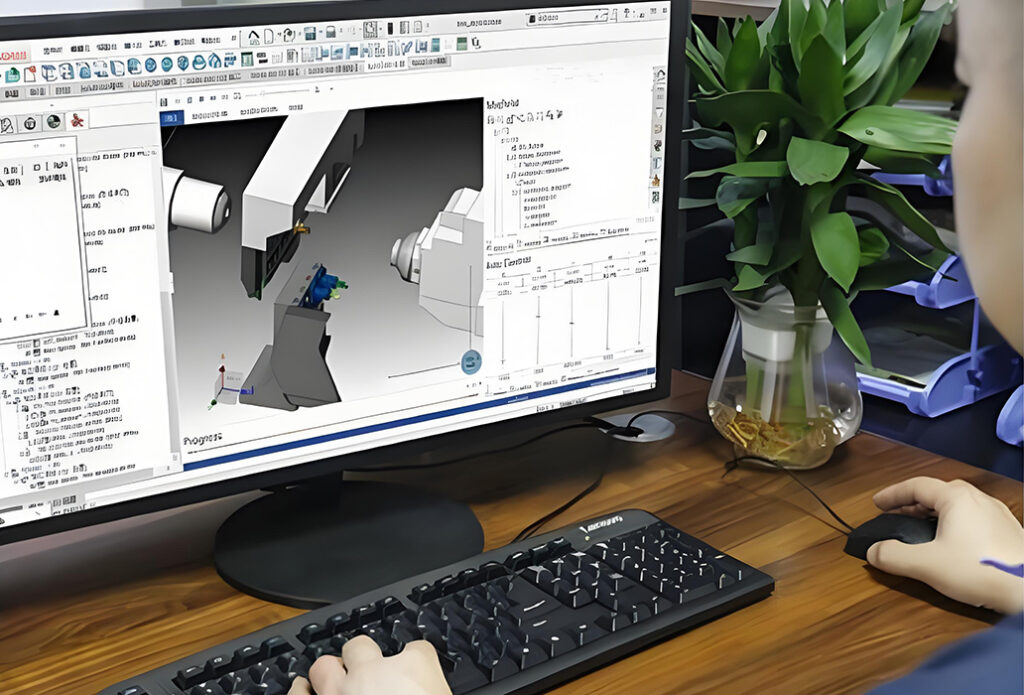

Part Geometry Optimization: The reduction of complex shapes reduces machining time and tooling costs. Equal thickness of the walls enhances stability and reduces deformation. Stress is minimized by adding fillets and rounded edges that increase the life of nozzles.

Material Knowledge and Use: Brass properties such as hardness, strength, and thermal behavior are looked into very keenly. Processing performance is taken into account to achieve stability in the production. Materials are chosen so as to be used effectively in practical situations.

Rational Tolerance Design: Tolerances are balanced to ensure that there is performance and an unnecessary cost reduction. Specifications are non-excessively precise. The approach reduces scrap, enhances consistency, and ensures consistent outputs.

Optimization of Tooling and Machining Process: The development of fixtures is based on the geometry of nozzles and the characteristics of brasses. Vibration and wear are minimized by tooling strategies. Precision, efficiency, and repeat quality production is guaranteed by optimized tool setup.

Workholding/Clamping Strategy: Clamping techniques hold parts without deformation during production. There is consistency in operations. Adequate workholding improves safety, productivity, and the quality of the surfaces.

Surface Treatment and Post-Processing: Coatings and treatments boost durability, resistance against corrosion, and beauty. Dimensional accuracy is maintained. Nozzles are functionally reliable and to industry-specific performance standards.

Mass Production Optimization and Cost Control: Wearing of tools and material use and work flow are strictly controlled. There is a decrease in cycle times and greater efficiency. Production at the standard level is maintained with high production in case of large orders.

Design for Assembly (DFA): Nozzle parts are made easier to assemble. User Interfaces are streamlined to minimize mistakes in assembling. This reduces expenses and enhances efficiency and reliability of products.

Why Choose Us for Brass Nozzle

Choosing the correct partner in regard to the manufacture of brass nozzles means successful, enduring outcomes. We integrate innovative systems, substantive knowledge and stringent quality inspections at CNCSwissMasion. You may rely upon us to be accurate, reliable in performance and durable parts. Huawei, Tesla, Novel, Hysis, Tuopu and Xusheng are the top companies that are using our services across the globe.

- Design Optimization: Our optimizing design tools will assist you in having flawless nozzle geometry. You enjoy reduction in errors, ease in production and speed in delivery. Every design is streamlined in that it reduces material expenditure and performance is preserved. Designs are easily adapted to specialized needs.

- ERP Management System: The ERP software in our system manages the scheduling, material movement, and production flow in an efficient manner. You have full visibility of all the steps of your project. It assists you in following resources and schedules without procrastination. You can always be sure of when something is ready.

- MES Production Monitoring: Real-time factory monitoring helps us to maintain speed and quality. You have few delays and you get products that have specifications that are precise. We have a system that identifies problems at their early stages so that you do not receive mistakes. you can keep track of progress and make arrangements with certainty.

- Quality Assurance with DFM Support: We check the manufacturability of every nozzle design prior to manufacturing them. You get optimized parts which are cost-effective, accurate and durable. DFM process minimises errors and provides smooth assembly. You may rely upon it that all nozzles are reliable under pressure.

- High-Volume Production: We have the capability to do high-volume production and custom orders with accuracy. You need not worry about the scale of production. Even on tight deadlines, our mature personnel makes sure that quality is maintained. You can get dependable results either in hundreds or in thousands.

- Large Material Selection: We are producing brass nozzles in numerous alloys and high-performance metals. You are able to choose materials that will be applicable to various industrial uses and purposes. Every option provides longevity, corrosiveness, and reliable operation. You are able to fit the material to the exact needs of your project.

- Full Processing Services: We offer full surface finish, cleaning, assembly and inspection all under one roof. With outsourcing, you save time and achieve a steady level of quality. The nozzles are prepared exactly to suit your needs. You get finished, trusted parts, right off our conveyor belt.

- Accuracy of Manufacturing Equipment: Our hi-tech machines have tolerances of up to 0.002mm. You get very precise nozzles even when it comes to the most demanding uses. Individual devices achieve symmetry, free flow and ideal fit to your system. It can be relied on to perform in harsh industrial environments.

- Automated Quality Testing: Each nozzle goes through an extensive automated test before their exit off of our plant. You will have confidence that every product is of our high quality standards. Defects are identified in the initial stages so that you do not get defective parts. You will only get high performance, reliable components, which are ready to use.

Brass Nozzle Permissible Tolerances

- Diameter tolerance: ±0.001 mm

- Concentricity: 0.002 mm

- Surface roughness: 0.2 to 0.4 and Ra 0.8 to 1.6 micrometers.

- Length size tolerance: ±0.005 mm

- Angle accuracy: ±0.05°

- Thread machining accuracy: ±0.002 mm

- Positioning accuracy: ±0.005 mm

- Precision: 0.001 mm

- Cylindricity: 0.002 mm

- Flatness: 0.002 mm

- Symmetry: 0.002 mm

- Circular Runout: 0.002 mm

Brass Nozzle Quality Control

The quality of brass nozzles should be controlled to assure reliability and performance. You will be assured that all the nozzles are manufactured according to the highest standards. This is achieved by stringent inspection and accurate measurement to produce consistency between batches.

Continuous 24-Hour Monitoring:

We have perpetual quality checks 24 hours a day. You enjoy automated inspection programs that monitor nozzle sizes and position in real-time. State-of-the-art sensors identify deviation as it occurs eliminating mistakes and increasing the precision of production.

Raw Material Verification:

Quality begins where the brass is concerned. A batch is checked prior to the production to ensure that it meets international standards such as REACH and RoHS. You can be assured that only of top quality material goes into the production line, free of defect.

Overall Process Control:

All nozzles are manufactured based on rigid design standards. Be careful to observe close attention at each stage. Results with measurements are taken and corrected to be accountable and provide insights to be improved upon.

Product Traceability:

You are able to trace all nozzles of raw material intake up to ultimate delivery. We will be sure of complete visibility of our products through our traceability system, enhancing safety and reducing possible problems.

Factory Quality Assurance:

Control in the production is ensured by random checks and verifications. You have a report of each delivery, quality and quantity are assured. Each step is verified by signatures.

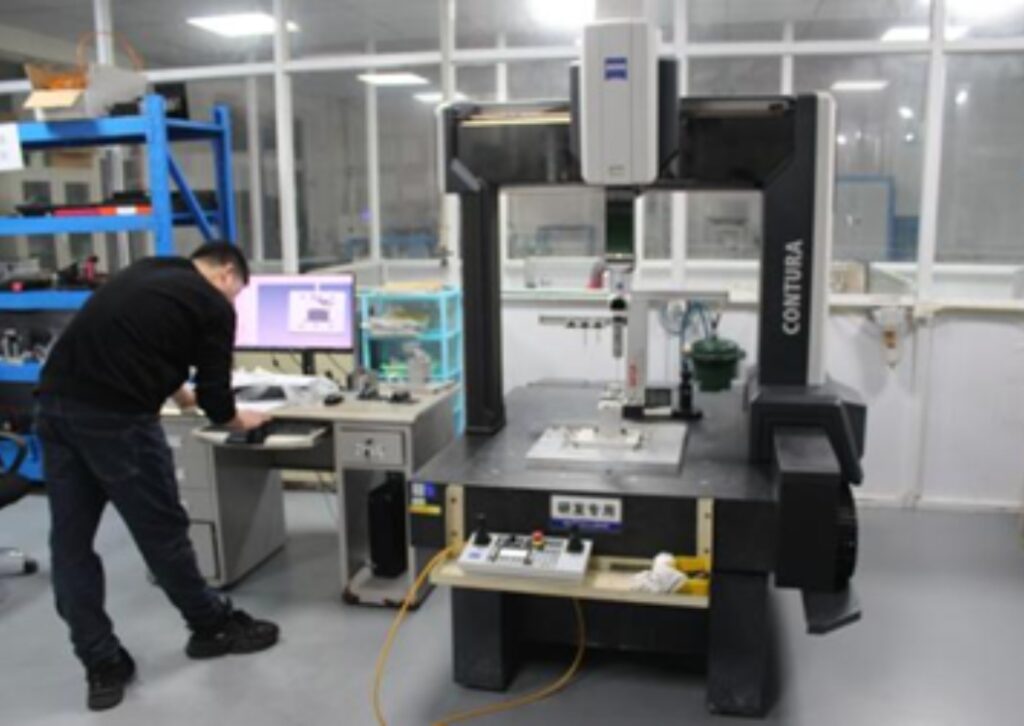

Modern Testing and Inspection Plants:

We have chemical, mechanical, and performance testing laboratories. You enjoy the high-precision instruments such as spectrometers, X-ray detectors and microscopes. This guarantees that all nozzles are of high quality in terms of their durability and performance.

Our Certificates

At Maison, we are dedicated to delivering the finest in CNC Swiss machining. With over 21 years of experience in custom Swiss machining and manufacturing of Swiss custom parts of high precision. It means we are committed to quality, industry standards and customer satisfaction through our certifications.

In fact, we have the ability to proudly boast key certifications that bear testament to our adherence to strict guidelines in different industries. This means that we are always up against the highest standards when it comes to CNC milling turning and small parts manufacturing.

- ISO 9001 Quality Management System

- ISO14001 Environmental Management System Certification

- Automotive Industry Quality Management System (IATF 16949)

- RoHS Restriction of Hazardous Substances (Available Upon Request)

- SGS Products Test – These tests are conducted to check the quality and if it matches industrial standards.

- Conformity to European standards: Solemn quality in CNC Swiss machining is CE marking.

Brass Fire Nozzle

Brass fire hose nozzle

Brass Nozzle for Mining Coal Shearer

Gas brass nozzle

brass nozzle

Gas brass nozzle

Gas brass nozzle

Gas brass nozzle

brass nozzle

Liquefied gas brass nozzle

Oil and gas brass nozzle

Brass Water Nozzle

sprinkler heads brass

hose brass nozzle

hose brass nozzle

brass water nozzle

brass sprinkler heads

brass spray nozzle

brass spray nozzle

brass nozzle spray

brass hose nozzle

brass garden hose nozzle

Brass Nozzle Packaging

The correct packaging will keep your nozzles of brass safe, minimize damages, and deliver safely. Packing will be determined by size, weight, and fragility. The following are the surest modes of operation that are often employed by CNCSwissMasion:

- Ziplock Bag Packing: Ideal when packing small and lightweight nozzles or individual nozzles. Parts can be easily counted, sorted, and manipulated. The bags provide protection to nozzles against dust, moist and scratches ensuring their safety during storage and transportation.

- Bubble Bag Packing: Can be used in delicate or polished nozzles of brass. You can count on bubbles to bear shocks. This packing keeps your products safe and undented, scratched, and lightly struck on the transport, ensuring that they are kept intact and ready to be used.

- Blister Packing: This is optimum when you desire visibility and organization. You are able to show each nozzle unambiguously and fix it in place. With this approach, mix-ups are avoided, it is well presented, and it will be easy when distributing.

- 5-Layer Corrugated Box Packing: Designed to take place of medium weight to heavy nozzle shipments. You are able to stack and carry boxes long distances without any harm. The 5-layer design safeguards against pressure, shock and rough handling during shipping.

- Pallet Packing: This is best when the volume is large. You can put a pallet of cartons and wrap them with stretch film. This technique conserves handling time, can be transported using forklifts and enhances efficiency in the supply chain.

- Wooden Box Packing: This is the most robust when it comes to the oversized or heavy brass nozzles. Shipping is easy because the wooden boxes are impact, moisture, and stack pressure resistant. This means that even when you are doing long distance or overseas deliveries, your products will be delivered safely.

What are brass nozzles used for?

Brass nozzles are versatile components that are used in most industries. You depend on their accuracy, stability and resistance to corrosion. By using high-quality brass nozzles, you will be assured of a good fluid and gas flow control. They are flexible, which makes them indispensable in various industrial and domestic applications.

The following are some of the key areas where brass nozzles affect a lot:

- 3D printing: The extrusion of filament is done with the help of brass nozzles, resulting in precision. You have uniform flow rates and optimum printing temperatures. Your prints are smooth, highly structural. You make your 3D printing process more efficient and nozzle-reliable.

- Automotive: You put in brass nozzles in fuel injectors, carburetors, and cooling systems. You maximize flow of fuel and spray patterns to engines. Your components are wear-resistant and heat-resistant. You enhance fuel economy, safety and vehicle performance.

- Gardening & Agriculture: You work with brass nozzles in sprinkler and irrigation systems. You manage the water supply and ensure that it is evenly covered. Your nozzles are corrosion resistant to fertilizers and minerals. You guarantee healthy crops and effective use of water.

- Firefighting Equipment: You trust in hoses and extinguishers with the brass nozzles. You get uniform spray patterns and high pressure water delivery. Your machine takes heat, blows, and beatings. You assist to save lives and properties.

- Industrial Cleaning: You have pressure washers and spray systems that use brass nozzles. You regulate the flow rates to clean surfaces. Your nozzles are anti-abrasive, anti-high pressure. You increase clean-up operations that are both faster and safer.

- HVAC/Plumbing: You fit in the faucets, valves and pipelines with brass nozzles. You manipulate the movement of water or air. Your components are anti-corrosive and anti-wear. You ensure efficiency in the operation and systems.

- Home Appliances: You use things with brass nozzles in coffee machines, humidifiers and water dispensers. You guarantee correct liquid or steam production. Your nozzles optimise performance and longevity of appliances. You offer secure and trustworthy home device functionality.

Checkout our Another Manufacturing Services

- Swiss Machining

- Custom Machining

- Micromachining

- Multi-spindle Machining

- Screw Machining

- Precision Machining

- CNC Mill/Turn

- Automatic Lathe Machining

FAQs

Is CNCSwissMasion certified such as IATF 16949 or ISO 9001?

Yes. You may rely on our certifications, ISO 9001 and IATF 16949.

What tools do you use to make the brass nozzles?

You have the advantage of: Automatic CNC Lathe, CNC Turning Machine, CNC Machining Center, Swiss CNC Lathe, CNC Turn-Mill Machine.

What do you use to make your brass nozzles?

Mainly, you get lead-free alloys of brass such as C3604 and C3771. C2800 is used in case of corrosion resistance. We tailor materials to your applications.

What is the corrosion resistance of brass nozzles? Is it possible to use them in sea water or chemicals?

Brass is moderate in corrosion but exposure to seawater ought to be avoided. In case of chemicals, electroless nickel plating or passivation should be selected. Navy brass (C46400) enhances the seawater resistance in your projects.

What is the high temperature limit of your brass nozzles?

They can be left on all the way to 200 o C (392 o F). They are dealing with the optimization of short-term steam exposure. Above 200C, you may consider stainless steel or bronze.

What is the tolerance you can get on nozzle orifice diameters?

Standard tolerance: +/- 0.02 mm. Precision tolerance: +/- 0.005 mm with micro-drilling or laser machining. Tolerance is a matter of your orifice size and depth.

Are you able to machine micro-holes less than 0.1mm?

Yes. Laser drilling (0.05-0.5 mm) or EDM drilling (0.1-0.8 mm) is an option. Your holes are 1:10 (depth:diameter) minimum aspect ratio.

What are the surface treatments of brass nozzles?

You may use: Nickel, Chrome, Silver plating; passivation or antique oxidation; PTFE or DLC coating; polishing or sandblasting.

What is your method of checking brass nozzles? Is it under your complete quality control?

Yes. You have the advantage of ISO 9001 and IATF 16949 quality systems. We have dimensional checking with CMM, orifice checking with optical comparators, and pressure testing. Certificates about materials are issued.

Are you in favor of custom brass nozzle manufacture? What is the lead time?

Yes. Prototypes are available within 1015 days. After approval of sample, mass production takes 25-30 days. Emergency needs can be expedited.

What do you require to quote out?

You must include: 2D/3D drawings with tolerances, annual quantity, material specifications, and surface treatments and testing standards.

What are the main industries of your customers?

You work with customers in: Automotive (fuel injectors, cooling nozzles), Medical (disinfector spray spray nozzles, Nebulizers), Energy (fuel gas nozzles, turbine cooling), Electronics (PCB cleaning nozzles, spray coating nozzles), Industrial (laser cutting head, spray coating nozzles).