Bronze Machining 101 – Everything You Need to Know

Bronze is important in machining due to its strength, resistance to corrosion, and its ability to avoid sparks. To achieve the optimal results, however, you will have to learn how to machine bronze properly. Poor finishes and tool wear may result when the incorrect tools or techniques are used. In this guide, you will learn all about bronze machining, including important alloy types and processes, hints, tolerances, and finishing methods. At the end, you will be able to know how to machine bronze effectively and select the most suitable methods to use.

Table of Contents

ToggleWhat is Bronze Machining?

Bronze machining is the process of machining bronze which is a copper alloy involving tin and commonly intermingled with aluminum, phosphorus, or nickel. You utilize CNC machines to attain high precision parts with good repeatability. Bronze is notable in its resistance to corrosion, its thermal conductivity, wear resistance, and non-sparking quality. This is why you will find it applied in Marine propellers, aerospace bushings, and electronic connectors. Bronze is more durable than brass, steel or aluminum in severe conditions. Whenever you require a material which is strong yet aesthetically pleasing, bronze provides you with a solid advantage in current manufacturing.

History of Bronze in Machining

Bronze has been a part of the machining history ever since it was discovered in 3000 B.C., at which point you would have witnessed it transform tools and weapons by casting and forging. With the development of machining, came the Industrial revolution with mechanized tools and in the 20th century, the capabilities of CNC technology gave you high precision bronze machined parts. Even today you continue to use the bronze because of its strength and resistant to corrosion particularly in marine and oil industries. Its versatility maintains its relevance and thus, bronze is an intelligent option to use in your high-performance machining requirements.

Bronze Machining Processes

Bronze machining has a variety of machining methods such as CNC milling, turning, drilling, grinding, sawing, broaching, EDM and waterjet cutting. All the methods have different uses depending on the shape, size and purpose of the part. It is necessary to choose an appropriate technique based on both alloy type and part geometry. This prevents any damage to tools and also makes the finish very good.

Material Selection

Begin by selecting the bronze alloy that will suit your project. Phosphor bronze is to be used in cases where precision and electrical conductivity is required. Use aluminum bronze to give high strength and wear resistance. The mechanical and environmental requirements of the application must always match your selection. In addition, think about the ease of machining the alloy.

Preparation

Cut the bronze into workable size with a saw or shearing tool before machining it. Next, prepare the surface by cleaning off any dirt or oil or oxidation. Before proceeding to machining, you ought to examine the material to ensure quality and consistency.

Machining Processes

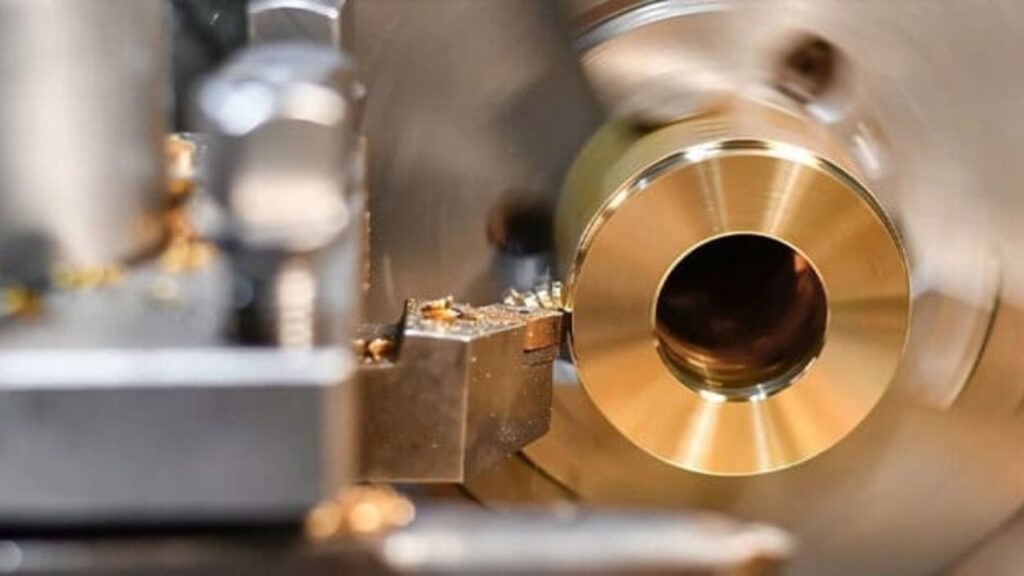

CNC Turning

Apply CNC turning in case you are producing round or tubular components such as shafts and valves. Bronze is turned on a lathe and a cutting tool is used to cut it. This is very effective in symmetrical components. CNC turning has great results in terms of smooth finishing and constant roundness.

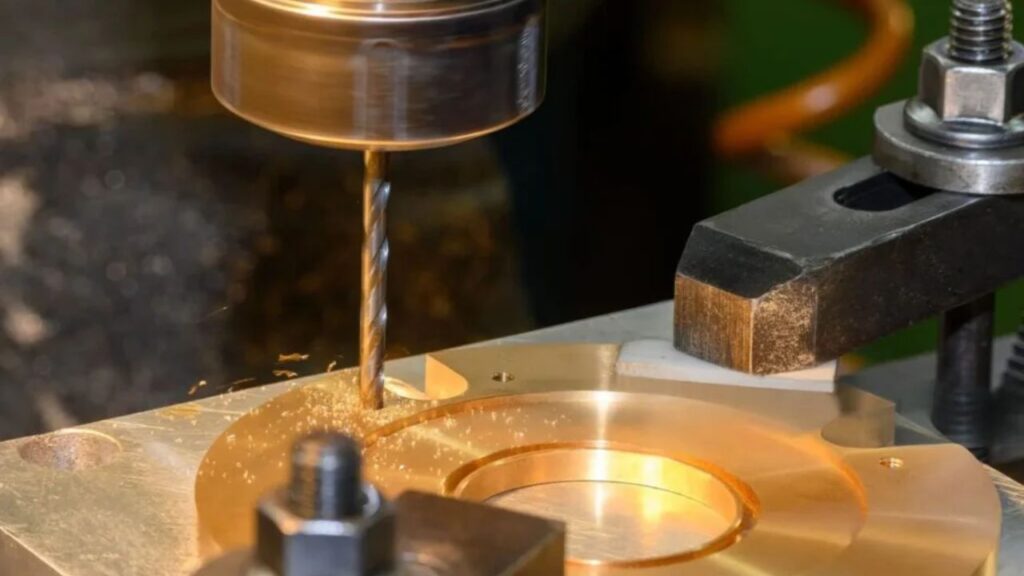

Drilling

When you require holes that will be used as fasteners or any fluid pathways, you should drill. It finds special use in the maritime field, where the corrosion resistance of bronze is put to the test. You can also obtain extremely precise hole diameters which is essential to pressure fittings and fluid-tight connections.

Grinding

Grinding is your solution when your part requires smooth surfaces or high dimensional accuracy. This is the abrasive machining which is used to remove small quantities of material to improve surface finish and friction reduction. It is perfect with low-clearance parts such as bearings and sliding systems.

Sawing

In case you have large bronze blocks or rods, start your machining by sawing. This will assist you to chop up the material to manageable pieces. Although it is not used in the finishing process, it is important in the preparation of stock to be further machined.

Broaching

Do you require internal slots, splines or keyways? Broaching assists you in making these features accurately. You run a toothed instrument into the bronze to cut the profile you want. It is particularly helpful in connectors and part of gears.

EDM – Complex Shapes by Spark Erosion

EDM (Electrical Discharge Machining) allows you to form non-contact bronze. You erode material using electrical sparks which is ideal in tight cavities, dies, or in fine contours. Apply it where conventional cutting tools are unable to access or parts may be destroyed.

Waterjet Cutting

When using bronze sheets or very thin plates use waterjet cutting. It cuts with abrasive particles in high-pressure water, and it does not produce heat. This leaves your bronze undistorted by heat, maintaining its mechanical characteristics.

Stamping

In the case of flat repeatable parts such as plates or washers, stamping is fast and precise. The bronze is pressed into shape using a die which works well in mass production. Although it is more prevalent in sheet metal working, bronze stamping is dependable with simple geometries.

Automatic Lathe Machining

You can apply automatic lathe machining when you need high-volume production of small, precise bronze components. The machine operates with minimal supervision, feeding the material and completing cuts automatically. This process ensures consistent accuracy, making it ideal for screws, fittings, and connectors. You save time and reduce errors while producing uniform parts at scale.

CNC Swiss Machining

Use CNC Swiss machining for extremely small and intricate bronze parts. The workpiece moves through a guide bushing, allowing you to cut with exceptional stability and precision. This is especially useful in medical, aerospace, and electronic components where tolerances are tight. You get clean finishes and reliable accuracy even in the most delicate geometries.

CNC Turn and Mill

CNC turn and mill gives you the advantage of combining both turning and milling in one setup. You can shape round profiles, cut slots, and drill holes without moving the part to another machine. This reduces setup time and ensures precise alignment between features. You achieve higher efficiency and accuracy in complex bronze components.

CNC Milling

When you need flat surfaces, slots, or complex 3D shapes in bronze, CNC milling is your solution. The rotating cutting tools let you remove material in layers, giving you great flexibility. You can create contours, cavities, and precise holes with excellent surface finishes. CNC milling allows you to handle both small-batch and large-scale production efficiently.

Post-Processing

A major step in bronze machining is the post-processing. It makes sure your parts are suitably functional, aesthetic and safe. Failure to spend time and effort on this step may result in poor performance or even rework.

Deburring

You need to eliminate sharp edges and burrs which are left after machining. Deburring enhances safety, eliminates injury, and makes parts fit well. Edges can be cleaned up with manual tools, tumbling, or abrasive brushes.

Polishing

You need to do polishing so that you get a smooth and beautiful looking surface. It lowers the friction, increases the appearance, and in some cases, it may protect bronze against tarnishing. Depending on the finish you require, you can utilize polishing wheels, compounds or buffing machines.

Heat Treatment

It is not essential in all bronze alloys, but where it is used, heat treatment enhances hardness, resistance to wear and stresses. You must use it in a careful manner to prevent distortion. It is always necessary to verify the type of alloy to find the appropriate temperature and process of cooling.

Inspection and Testing

Check all sizes and grades of every part before use. You will have to use equipment such as calipers, micrometers, and CMMs. Apply hardness testers or spectrometers when the performance of materials is important. Results should be always documented.

Types of Bronze Alloys for CNC Machining

Machining bronze requires selection of the appropriate alloy depending on your application. All of them have specific properties such as strength, resistance to corrosion, or simple machining. Phosphor bronze is the choice when you require high wear resistance. Aluminum bronze is the most suitable one to use in the sea. The alloy must always be in line with your needs in terms of performance, durability and budgetary considerations.

Aluminum Bronze (e.g. C95400)

Aluminum bronze is comprised of copper, aluminum, iron, nickel. This alloy is strong, has good wear properties and excellent corrosion resistance with salt water in particular. This is a good option when you need marine hardware such as propellers, or durable bushings on heavy machinery. It is hard yet machinable and therefore to make it efficient, we will use carbide tools.

Phosphor Bronze (e.g. C51000)

Phosphor bronze is made of copper, tin and phosphorus and is characterized by fine grain and excellent wear resistance. It is also electrically conductive and therefore useful in electrical connectors and springs. When machining small, high-precision parts you will find this alloy very easy to detail.

Silicon Bronze

This alloy is a mixture of copper, silicon, manganese and zinc. It is a popular material because of its resistance to corrosion, attractive surface finish, and the ease at which it can be machined. You will frequently find it applied in building work and fluid management systems such as pumps and valves. In case of both aesthetics and durability in your project, you can consider silicon bronze.

Manganese Bronze

This alloy is strong and wear resistant with copper, zinc and manganese. It fits well on gears, clutch parts and other high load parts. It is not the simplest to machine but the application of the right speeds and feeds will assist you to handle it.

Nickel Aluminum Bronze

This is an alloy containing copper, aluminum and nickel that is highly resistant to corrosion and fatigue. It is popular in aerospace and marine applications, particularly parts such as propeller shafts. This is the bronze to use when your application requires long-life under harsh conditions.

Leaded Bronze (e.g. C93200)

This common mixture consists of copper, tin and lead. It will be very easy to machine due to its great chip formation. Leaded bronze is excellent in bearings, bushings and sliding parts requiring low friction. Long service with smooth motion is what you get with this alloy.

Tin Bronze

This alloy is a combination of copper and tin-which may include phosphorus, zinc or lead-to provide strength and corrosion resistance. You will apply it frequently to gears, statues and marine hardware. It machines easily, more so with the correct lubrication.

Bismuth Bronze

This alloy contains copper, tin, and bismuth. It is characterized by good casting properties, low brittleness and machinability. You will find it in art, jewelry and precision instruments. Bismuth bronze is a favorite when you are producing detailed or decorative work.

Copper-Nickel Bronze

This alloy is made of copper, nickel, iron and manganese and performs well in salt water environments. It is also widely applied in shipbuilding, offshore platforms, and seawater piping. This is the kind of bronze alloy you want, in case your part has to survive long-term exposure to marine environments.

| Bronze Alloy | Composition | Properties | Applications |

| Aluminum Bronze (e.g., C95400) | Copper, aluminum, iron, nickel | High strength, corrosion resistance, wear resistance | Marine propellers, bushings, heavy machinery |

| Phosphor Bronze (e.g., C51000) | Copper, tin, phosphorus | Fine grain, wear resistance, electrical conductivity | Electrical connectors, springs, precision components |

| Silicon Bronze | Copper, silicon, manganese, zinc | Corrosion resistance, aesthetic finish, easy machining | Pump/valve components, architectural elements |

| Manganese Bronze | Copper, zinc, manganese | High strength, wear resistance | Gears, clutch components, heavy machinery |

| Nickel Aluminum Bronze | Copper, aluminum, nickel | Enhanced corrosion resistance, fatigue resistance | Propeller shafts, aerospace components |

| Leaded Bronze (e.g., C93200) | Copper, tin, lead | Low friction, high durability | Bearings, bushings, automotive components |

| Tin Bronze | Copper, tin, optional phosphorus/zinc/lead | Corrosion resistance, strength | Gears, bearings, statues, marine hardware |

| Bismuth Bronze | Copper, tin, bismuth | Excellent casting, machinability, reduced brittleness | Art, jewelry, precision instruments |

| Copper-Nickel Bronze | Copper, nickel, iron, manganese | Saltwater corrosion resistance, strength | Shipbuilding, seawater piping, offshore platforms |

Surface Finishes for Bronze Machined Parts

Surface finishing is something you cannot ignore once your part is expected to live in any harsh environments or impress visually. A quality finish reduces the number of surface defects, wear and corrosion resistance and improves the overall quality of the end product. Finishing is sometimes as important as the machining itself, notably when the part is exposed to the elements, or is to be aesthetically pleasing.

As-Machined

It is the raw finish out of the CNC machine. You will find marks and irregularities on the surface of tools and these are okay on non-cosmetic or internal parts. Select it when utility is more important than appearance.

Polishing

Polishing provides your part with a mirror finish. It is ideal in decorative parts or items where smoothness enhances performance. You will apply it in jewelry, architectural bronze and precision parts.

Sanding

Sanding will enable you to eliminate minor blemishes and tool marks. It offers a rougher surface upon which additional procedures could be applied such as painting or plating. The finish can be managed by the selection of grit levels.

Brushing

Brushed finishes have a fine parallel marking against the surface. Fingerprints and minor blemishes are concealed in this matte texture. Brushing is suitable when you are creating architectural features or a tone-down appearance.

Bead Blasting

The beads used in this process are small and are shot against the surface to give a uniform matte finish. This is what you will use to remove tool marks and create an even look. It is perfect on non-reflective, industrial components.

Chemical Coating

Bronze is covered by a thin film of protection made through chemical treatments. These are applied on areas that need enhanced resistance to corrosion and are usually applied outside or in marine environments. This will be handy in plumbing and ship building parts.

Anodizing

Anodizing is possible on some alloys, although unusual on bronze. It can add corrosion resistance and enables you to add color to your part. Apply this where your type of bronze warrants it.

Patination

Patination oxidizes the bronze, providing a green, brown or black patina. This is a ready-to-use in artistic works or architectural details one wants to have an antique appearance.

Electroplating

Bronze can be covered with gold, silver or nickel through electroplating. You will get additional hardness, corrosion resistance and a high-end look–perfect for precision and decorative applications.

How to Choose the Right Finish

Selecting a finish should begin by thinking about the environment and purpose of the part. Chemical coating or electroplating is the choice to take when you require corrosion resistance of marine or industrial applications. Patination or polishing may be more to your taste, as an art or display. Take into consideration cost, durability, and environmental impact as well. Be sure that your finish fits the purpose and cost you wish to get out of the finished article.

Applications of Machined Bronze Parts

Bronze is one of the best options when you require strength, corrosion resistance, and durability. When machining parts to be used in high-performance industries, bronze is the only choice that delivers reliability in an extensive variety of applications.

Bearings and Bushings

In bearings and bushings, you will make frequent use of bronze, which provides low-friction and wear resistance with time. This maintains machinery in smooth operation in high loads and rough conditions.

Valves and Fittings

Bronze fittings and valves have very good corrosion resistance in plumbing and industrial applications. Their resistance to moisture, chemicals, and changes in pressure will be beneficial to you.

Gears

Bronze gears are hardy and quiet, and can be used where precision is important, such as in clocks or industrial machinery. You can be assured of their wear resistance even in continuous use locations.

Sculptures and Statues

In case you are doing decorative work, bronze has got aesthetic value as well as the ability to resist weather. It is perfect when applied to outdoor art and building ornamentation.

Electrical Connectors

Bronze will show you its conductivity, and resistance to oxidation in electrical connectors. It guarantees long-term, reliable operation in electronic systems.

Marine and Aerospace Components

Bronze is fatigue resistant and saltwater resistant in marine and aerospace applications. It is applicable to propellers, bushings and structural components that are exposed to harsh conditions.

Oil and Gas Equipment

Bronze is pressure-loving. You turn to it when you want rugged dependable parts in oil rigs, pipelines, and drilling tools.

Challenges in Bronze Machining

Some of the Problems You Can Encounter:

- High Abrasiveness: Bronze particularly aluminum and manganese types abrades tools faster because it is hard.

- Unacceptable Chip Formation: You will tend to have lengthy, straggling chips that will get entangled with the cutting tool leading to its halting or breakage.

- Work Hardening: The bronze may harden after many passes on the same surface and subsequent cutting becomes very hard.

- Thermal Expansion: Bronze has a rapid rate of thermal expansion that can interfere with precision dimensioning aspects of precision parts.

The Ways You Can Solve These Problems:

- Use Carbide Tools: Carbide-tipped tools are highly resistant to wear, so they can help you work precisely and prolong the tool life.

- Maximize Cutting Speed: Achieve the correct speeds and feeds of the given alloy to minimize heat build-up and prevent work hardening.

- Use plenty of Coolants: Coolants not only cool but also wash away chips to keep your tools clean and your parts precise.

- Control Chips: Control chip shape by using chip breakers or adjusting geometry of the tools.

Best Practices for Bronze Machining

Tool Selection

Apply carbide-tipped tools because of their high strength and resistance to the abrasiveness of bronze. Select the appropriate tool geometry of the specific bronze alloy you would be using. It will aid in minimizing tool wear and cleaner cuts.

Cutting Conditions

Operate machines at high speeds to avoid work hardening about 200 ft/min with phosphor bronze is desirable. Vary the feed rates according to the hardness of the alloy e.g. 0.012 in/rev is appropriate to phosphor bronze. Use emulsion-based coolants at all times. They assist in the heat regulation and surface finishing.

Workpiece Handling

Clamp the workpiece firmly to eliminate vibration and ease of movement under machining. Possible inaccuracies and damages to the tools are caused by loose setups. The workspace should also be cleaned regularly to avoid chip build which might impede the cut.

Tool Maintenance

Check the tools frequently. Rough finishes and excess heat are brought about by worn edges. Use adequate lubrication during the procedure to eliminate friction and prolong the life of the tool. These steps will enable you to be more efficient in the process of machining bronze and achieve the most desirable results.

Safety Considerations

Safety should be your number one concern when machining bronzes. The hardness of bronze and its ability to create fine particles and sparks demand rigorous control. These are the things that you have to know to defend yourself and your workstation.

Important Safety Tips

Begin with adequate ventilation. To minimize the exposure to airborne particles, especially when grinding or cutting, you require constant airflow. Protective gear should always be worn, and that includes safety glasses to protect your eyes, gloves to protect against cuts or burns, and ear protection to protect against noise. Machine maintenance should not be ignored. Inspect your equipment regularly to prevent breakdowns and accidents. In addition, be ready to fire hazards. Have fire extinguishers at hand just in case sparks start flammable substances.

Protocols and Training

Ensure that you get training on the hazards of machining bronze. You ought to learn the way bronze reacts to various conditions and emergency reactions. Finally, remember to abide by the safety requirements of the work place, including OSHA regulations. These are not mere formalities but safeguarding to your health and smooth running operations.

Admissible Feed Rate and Speed for Bronze

The input speeds and feeds should be moderate and should be able to cut as much as possible and cause less build-up of the heat. Namely the tuning speeds of 100-200 SFM and a feed rate of 0.01-0.02 mm/rev. The other parameters are suggested as:

| Process | Speed (SFM) | Feed Rate (mm/rev) |

| Turning | 150-200 SFM | 0.01-0.02 mm/rev |

| Cutting Off | 120 SFM | 0.008 mm/rev (for 1″ hole) |

| Drilling | 100 SFM | 0.006-0.012 mm/rev (for 1″ hole) |

| Reaming | 90 SFM | 0.005-0.010 mm/rev |

| Tapping | Based on thread and diameter | – |

Admissible Bronze Chemical and Mechanical Characteristics

You should know the chemical composition and mechanical properties of bronze. Here’s the accurate data:

| Category | Property | Value |

| Chemical Composition | Copper (Cu) | 85-90% |

| Tin (Sn) | 5-10% | |

| Zinc (Zn) | 0-5% | |

| Lead (Pb) | 0-5% | |

| Phosphorus (P) | ≤ 0.05% | |

| Aluminum (Al) | 0-6% | |

| Mechanical Properties | Tensile Strength | 350-450 MPa (50-65 ksi) |

| Yield Strength | 150-250 MPa (22-36 ksi) | |

| Elongation | 10-25% | |

| Hardness (Brinell) | 60-120 HB | |

| Density | 8.8 g/cm³ | |

| Thermal Conductivity | 50 W/m·K |

Quality Control Measures

Quality of bronze machining is very important. You must make sure that the components are of specific specifications in terms of safety, performance, and durability. An effective process of quality control will assist you to minimize waste, prevent rework and supply dependable parts.

Methods of Inspection and Testing

In order to be consistent, it is essential to combine testing methods:

- Visual Inspection: The faults or flaws on the surface can be easily identified.

- Dimensional Measurement: Calipers, micrometers, and CMMs can be used to ensure that the part dimensions fit within design tolerances.

- Material Testing: Examination of hardness and spectroscopic analysis to prove alloy composition and mechanical properties.

Quality Control Processes

These are the key steps in quality management:

- Preliminary Material Inspection: Check the bronze alloy composition and physical states prior to machining.

- In-Process Monitoring: Monitor parts under machining to be able to detect deviations early and adapt parameters.

- Post-Machining Inspection: Measure dimensions and test mechanical properties at the end of machining to verify the accuracy.

- Documentation: Maintain records of checks and tests. This assists in traceability and creates confidence in your production process.

Costs of Bronze Machining

There are various cost considerations that you should take into account when coming up with a bronze machining project that may affect your budget.

Cost Drivers

- Process Costs: Bronze alloys have different costs. Leaded bronze is cheaper where nickel aluminum bronze can be considerably more costly.

- Machining Process: Less complex processes such as milling or turning are cheaper. Complicated processes such as EDM or broaching increase costs.

- Tolerances: The closer the tolerance, the more the setup, inspection, and quality control costs are incurred.

- Volume: Mass production lowers your unit cost. It is more costly to make a prototype of one part.

- Post-Processing: Polishing, patination, or electroplating are finishing processes incurring labor and material cost.

- Tool Wear: The abrasive qualities of bronze also cause tools to wear out quickly, raising costs of replacement.

Cost Estimates

- Small-Scale Prototyping: You might be charged between 50 to 500 dollars per part depending on the complexity and the alloy.

- High-Volume Manufacturing: When you manufacture in bulk at an optimized machining environment, costs can be as low as $5 to 50 per component.

Conclusion

Bronze machining remains essential to the production of high-performance components due to its wear resistance and strength as well as its non-sparking characteristic. Be it the aerospace industry or marine and electric industries, its versatility is robust. When you select the alloy, process, and finish, you will have an efficient production and durability in the long run. Becoming aware of the problems and engaging in good practices such as the use of carbide tools and coolants improves accuracy and tool life. Bronze machining is vital in the manufacturing of essential components as the technology changes. Collaborating with competent suppliers will bring even more impressive outcomes to your next project that involves durable and corrosion-resistant components.

FAQs

Does Bronze Machine Easier Than Brass?

No, bronze is usually tougher and rougher than brass. You will discover that machining bronze needs more powerful tools and slower feed rates. The softer brass machines readily and with cleaner finishes. But bronze is more durable, so it is used when parts must endure wear or friction or other harsh conditions.

Is 932 Bronze Easy to Machine?

Machinability of C93200, also referred to as bearing bronze is very good. It can be used with ease in the manufacture of bushings, bearings and other parts that need low friction and high strength. It is one of the easiest grades of bronze to machine.

Which are the Best Bronze Alloys to Use in High Precision Machining?

When you require tight tolerances, use phosphor bronze (C51000), leaded bronze (C93200) or aluminum bronze (C95400). These alloys are strong, wear resistant and easy to machine- ideal when you need to be precise and reliable.