CNC Machining Bronze 101 – Everything You Need to Know

Modern manufacturing also relies heavily on bronze machining due to the combination of durability, resistance to corrosion and machinability characteristic of bronze. With machined bronze you can make anything, big industrial bearings, or fine musical instruments. You have to learn the fundamentals of CNC bronze machining, including what bronze alloys to machine, how to deal with tool wear, and how to regulate the formation of chips to succeed. In this article, you will get to know the basic bronze properties, the most used bronze alloys, CNC machining techniques, machining tools, cost considerations etc. This guide provides all the necessary information to get a better outcome, reduce wastage, and select the appropriate machining strategy.

Table of Contents

ToggleBronze Properties That Affect Machining

There are special benefits to machining bronze. The alloy group has features that render the process effective and produce long lasting outcomes. This is what you need to know:

Strength and toughness: Bronze gives you a hard but workable material. It is resistant to heavy loads, so it suits bearings, bushings, and gears.

Wear resistance: Bronze alloys generally include tin, aluminum, or manganese, which provide them with a high level of friction and galling resistance. You experience long lasting components in sliding or rotating contacts.

Corrosion resistance: Bronze is naturally resistant to seawater, chemicals and weather conditions. This is why it becomes a popular marine hardware, valves, and outdoor choice.

Thermal and electrical conductivity: Certain types of bronze are good conductors of heat and electricity, so you can use them in electrical connectors and industrial parts.

Variations in machinability: bronze alloys are not the same. Bronzes that are free machined are easy to cut and the harder alloys can be left with stringy chips. You have to fit the alloy to your use.

Recyclability: Bronze is completely recyclable, as is the case with most copper based alloys. With its help, you contribute to the minimization of waste and sustainable production.

The Best Bronze to Machine

There are numerous alloy families of bronze, each providing a tradeoff of machinability, strength, and corrosion resistance. The option will be based on your project requirements.

Tin Bronzes

Some strong and wear-resistant Tin bronzes such as C93200 and C90500 are also available. Bushings, bearings and gears are also widely used. The machinability is average, but you do have good durability.

Aluminum Bronzes

C95400 and C95900 are aluminum bronzes that are stronger, tougher and seawater resistant. They suit perfectly well marine hardware, aerospace fittings, and pumps. They are more difficult to machine, but these grades provide outstanding performance.

Phosphor Bronzes

Phosphor bronzes such as C51000 and C54400 are characterised by high fatigue, elasticity and corrosion resistance. They do well with springs, fasteners, and electrical connectors. Machinability is reasonable, however, clean cutting tools enhance performance.

Silicon Bronzes

Silicon bronzes like C65500 are tough and very resistant to corrosion. They machine fairly well and find many applications in architecture, marine fasteners, and hardware.

![]()

Manganese Bronzes

The combination of very high strength and good corrosion resistance results in manganese bronzes, including C86300. They are more difficult to machine, and have to be of rigid arrangement, but are superior in heavy-duty load-bearing components.

Bronze Alloy Machining Comparison Table

| Alloy | Strength (MPa) | Corrosion Resistance | Wear Resistance | Machinability | Key Applications |

| C93200 | Moderate (~250) | Good | Excellent | Fair | Bearings, bushings |

| C95400 | High (~550) | Excellent | Very High | Moderate | Marine, pumps, gears |

| C54400 | Moderate (~400) | High | Good | Good | Springs, connectors |

| C51000 | Moderate (~350) | High | Good | Fair | Electrical, fasteners |

| C65500 | Moderate (~450) | Very High | Good | Moderate | Marine, architecture |

| C86300 | Very High (~700) | Good | Excellent | Poor | Gears, heavy-duty parts |

| C95900 | Very High (~800) | Excellent | Excellent | Poor | Aerospace, defense |

| C90500 | High (~450) | Good | Good | Fair | Valves, bearings |

| C90300 | High (~400) | Excellent | Good | Moderate | Pumps, marine parts |

| C22000 | Low (~250) | Moderate | Fair | Excellent | Decorative, architecture |

Bronze Machining Methods

Milling

Bronze milling CNC allows you to produce finely defined shapes, slot cuts, and lines. You are able to complete intricate designs with small tolerances. Sharp carbide or coated tools should always be used since bronze alloys may harden readily. Use consistent coolant to minimize thermal effects, tool wear and enhance surface finish. With the right toolpath and feeds, you will maintain a glossy evacuation of the chip and avoid surface tearing.

Turning

One of the most popular ways to make round components is turning bronze. On lathes you can make bearings, bushings, and shafts in an efficient way. The bronze works with high-speed turning, provided that your arrangement is fixed. Sharp inserts are used to reduce chatter and make sure long chips do not get entangled. Lubrication helps you get smooth surfaces and uniform tolerances.

Grinding and Polishing

Bronze grinding is necessary when you require very smooth finishes on load bearing surfaces. Grit wheels with continuous flow of coolant should be used. This prevents too much heat which distorts dimensions. Additional steps such as polishing can increase aesthetics and wear resistance. Bronze can be polished to a mirror finish that is best applied in the decorative arts or in musical instruments.

Drilling

When it comes to drilling bronze, chip control and lubrication must be considered. You can cut clean and precise holes when you use carbide or high-speed steel drills. Have a consistent feed and cooling to avoid welding of chips. Lubrication can be poor, leading to freezing of drills or rough surfaces. Using the optimum drilling configuration, you guarantee good reproducibility and tool longevity.

Tapping and Threading

Tapping or threading bronze requires sharp and lubricated equipment in order to prevent stripped threads. Bronze alloys such as phosphor bronze are great at thread bearing but have to be handled when machining. With cutting oil and correct speeds you can make strong and reliable threads. Always use a regular tap out to clear chips and also in order to prolong the life of the tools.

CNC Swiss Machining

CNC Swiss machining is a good option when it comes to small and accurate components made of bronze. You are able to manufacture narrow tolerances in electrical connectors, medical devices, and fasteners. Constant lubrication leads to smooth machining and eliminates the possibility of premature tool failure. Swiss machining saves time and money and is precise, as it minimizes secondary operations.

Automatic Lathe Machining

High-volume production of bronze is efficient with automatic lathes. You may program them to repeat operations with minimal error. Chip breakers are necessary since the bronze alloys could make lengthy stringy chips. You can get speed, consistency, and superb surface finishes on mass-produced parts with the correct set up.

CNC Mill and Turn

This is a hybrid milling and turning system. You save time since you do not have to re-fixture the part. Geometries that are complicated, like those in aerospace or automotive parts, are produced with less difficulty. Mill-turn machines help you handle less, achieve more precision, and be more productive.

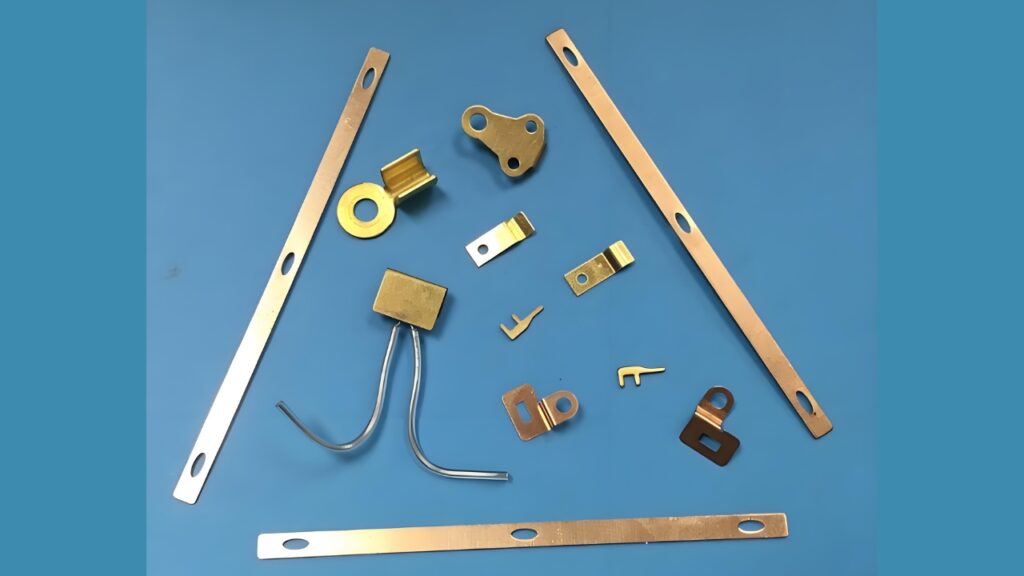

Stamping

Stamping is best applied to thin bronze. You may mold them into connectors, springs, or ornaments. Cracking and distortion are avoided through correct die design. When you keep your dies clean and use lubricants, you end up with smoother edges and less waste. High volume, low-cost production is particularly helpful with stamping.

Admissible Feed Rate and Speed

Bronze requires moderate speeds and feed rates in order to cut and eliminate heat buildup. One of them is turning speeds of about 200-300 SFM at feed rate of 0.1 to 0.2 mm/rev is also very effective in minimizing friction and tool wear. The following are some of the other recommended parameters.

| Process | Speed (SFM) | Feed Rate (mm/rev) |

| Turning | 200 – 300 SFM | 0.1 – 0.2 mm/rev |

| Cutting Off | 150 SFM | 0.08 mm/rev |

| Drilling | 150 SFM | 0.05 – 0.1 mm/rev (for 4.76 mm hole) 0.08 – 0.12 mm/rev (for 12.7 mm hole) |

| Reaming | <100 SFM | 3x the drill feed rate |

| Tapping | <100 SFM | Based on thread depth and diameter |

Admissible Bronze Chemical and Mechanical Characteristics

| Category | Property | Value |

| Chemical Composition | Copper (Cu) | Balance (~83%) |

| Tin (Sn) | ~7% | |

| Lead (Pb) | ~7% | |

| Zinc (Zn) | ~3% | |

| Iron (Fe) | ≤0.2% | |

| Nickel (Ni) | ≤1.0% | |

| Antimony (Sb) | ≤0.5% | |

| Phosphorus (P) | ≤1.5% | |

| Sulfur (S) | ≤0.08% | |

| Aluminum (Al) | ≤0.005% | |

| Silicon (Si) | ≤0.005% | |

| Other Elements | ≤0.05% each, ≤1.0% total | |

| Mechanical Properties | Tensile Strength | 240 MPa |

| Yield Strength | 125 MPa | |

| Elongation | 20% (in 50mm) | |

| Hardness | 65 HB (Brinell) | |

| Density | 8.91 g/cm³ | |

| Thermal Conductivity | 58 W/mK at 25°C |

The Basic Tools and Equipment for Bronze Machining

- Carbide tools: You are to use carbide tools all the time as they do not wear off and remain sharp more than regular high-speed steel. This is significant because bronze alloys may be abrasive on cutting edges. Carbide tools provide you with cleaner finishes and less tool change to save time and money.

- End mills and inserts: End mills and inserts are used in milling and turning operations, where you can shape bronze with a high level of precision. Select the most appropriate geometry to minimize cutting forces and enhance the flow of chip. When your tools are sharp, you limit chatter and get a better finish.

- Tool coatings: TiAlN or TiCN are used to reduce friction and increase the life of tools. They also inhibit the welding of chips which is a common issue with machining of bronze. With a choice of coated tools, you are able to run at the same level of performance and save time lost during replacement of tools.

- Lubricants and coolants: Bronze machining tends to produce heat and friction. To avoid chip welding and to increase the tool life you must have good lubrication. Coolant also assists you maintain the dimensional accuracy particularly when producing big runs. Always use it constantly to enhance the life of tools and quality of parts.

- Chip evacuation systems: Chips generated by bronze alloys can be long or stringy. Unless you remove them fast, chips may scratch your workpiece or break the tool. Chip evacuation systems will keep the production flowing and the tools free of breakage.

Bronze Best Practices for Machining

- Sharp carbide tools: sharp tools are imperative since dull edges generate heat and poor finishes on the surface. The sharpness of the tools should be checked at the beginning of every run. This guarantees a steady performance and eliminates the chance of chatter.

- Use a regular coolant or lubricant: It is recommended to use regular lubricant and have regular lubrication to minimize friction and prevent chip welding. When you forget to use coolant, your tool will wear out sooner, and your part will warp. As the cooling process is repeated, the quality of the surface and accuracy are enhanced.

- Clamp up your work: A firm attachment is important when machining bronze. Chatter and dimensional errors give you a vibrating workpiece. Secure fixturing is a method that enables you to cut at the most appropriate speeds without compromising on accuracy.

- Inspect regularly: You need to observe your tools during machining. Tool edges will wear off even with the best carbide. Frequent check-ups help to eliminate unexpected failures and a uniform quality of parts.

- Break chips with chip breakers: There are bronze alloys that form long, stringy chips, which may create machining problems. You ought to employ chip breakers in managing chip size and enhancing safety. This simplifies machining and makes it more predictable.

Problems and Solutions in Machining Bronze

Chip Welding: Chip welding is when bronze chips become embedded on your cutting tool. You can resolve this by applying cutting fluid and coated carbide tools always. This makes them less sticky and leaves your surfaces clean.

Vibration and Chatter: Bronze may lead to chatter when your installation is not rigid. Clamp down your workpiece and damped tool holders. This enhances the surface finish and life of a tool. Vibration can also be minimized by adjusting feed rates.

Heat Management: Overheating can cause distortion of parts. Always apply coolant in order to achieve constant temperatures. Heat generation is also minimized by reducing cutting speed by a small margin. You keep the tool and workpiece safe by controlling the heat.

Tool Wear: Bronze has a tendency to wear away tools. To avoid this, carbide tools that have protective coatings should be used. Frequent checking of tools will enable you to change the inserts in time to prevent expensive scrap.

Surface Finishing and Post Processing Methods

- Deburring: Bronze parts tend to develop burrs after machining and this may impact functionality. You ought to take them out to provide a safe handling and also give them accurate fits. Deburring can be done manually, by tumbling, or by machine. A rounded edge enhances aesthetics and functionality.

- Sandblasting: Sandblasting removes debris on the surface and cleans it ready to apply a coating or paint. It also can be used to make a matte texture. Doing this is also necessary to remove the oxides and debris to have a smooth finish that will stick to the coats.

- Polishing: Bronze can be polished to a bright reflective finish. This is also necessary particularly in decorations and musical instruments. Polishing compounds and buffing wheels are best used. Also polished surface not only makes a part attractive, but it also lessens friction on working parts.

- Plating or Coating: You can use plating or protective coating to increase corrosion resistance. These can be nickel plated, powder coated, or clear lacquers. These increase part life and durability. Preparation of the surface should always be done prior to or before coating to ensure greater adhesion.

- Laser Marking: Laser marking enables you to add serial numbers, barcodes or branding. It is accurate, permanent and does not affect the structural integrity of bronze components. It can be applied to industrial products as well as consumer products.

Uses of Machined Bronze Parts

- Aerospace and Aviation: Aerospace Bronze parts have to work with high stress and friction. You can apply them in landing gear, bearings and bushings. They are suitable in such harsh environments due to their wear resistance and durability.

- Marine Industry: Bronze is resistant to seawater corrosion therefore it is ideal to use on marine hardware. It is found in propellers, pumps, valves and fittings. The selection of bronze gives a durable performance under severe marine environments.

- Automotive Industry: Bronze can be used in gears, bearings and bushings in automotive. Its reliability is improved by its strength and anti-friction qualities. Parts that require strength and longevity are commonly made of bronze.

- Consumer Goods: Bronze is also utilized in: musical instruments, decorations, and hardware. Its beauty and stability make it suitable. You receive working, pretty, and durable products.

- Industrial Equipment: Gears, bearings, and hydraulic components of heavy-duty machines are made of bronze. Bronze endures use and wear, and therefore it is economical in the long run.

- Electrical Applications: Phosphor bronze is extensively employed in connectors, switches, and terminals. It is both conductive and durable. This guarantees good reliability in electrical systems.

Cost Factors in Bronze Machining

- Grade of material: Alloy grade of bronze differs in price. Higher-grade aluminum bronze such as high-performance costs more. The cost of added reinforcement and durability of the premium alloys should also be included in the budget when you select them.

- Tooling and machine time: Harder bronzes cause higher tool life and machining time. You must include additional tool changeovers and reduced cutting rates. This increases the cost of production.

- Part complexity: Complex parts take more time and sophisticated arrangements. The more complicated your design, the more costly it will be to manufacture. The simplification of geometry is inexpensive.

- Finishing requirements: Finishing such as polishing, coating, or plating are cost adders. External mirror finish will need additional labor and tools if your part needs it.

- Batch size: Producing a large volume of batches reduces the price per part. Small batches make it more expensive based on set up time. Where feasible, calculate bulk to save money.

Tips to Reduce Cost and Improve Efficiency

- Use Design for manufacturability (DFM): With simplified designs, you decrease the machining steps. This reduces wear on tools as well as time and wastes. Design needs must always be balanced with manufacturability.

- Write CAM software: Pre-machining toolpath simulation avoids expensive errors. You are able to detect collisions, optimise feeds and optimize efficiency. This action minimizes trial and error and maximizes output.

- Choose the right feeds and speeds: Speeds and feeds optimization prolongs the tool life and minimizes scrap. The instruction should be adhered to by the manufacturer and modifications always done according to particular bronze alloys.

- Use batch production: This means that manufacturing in large quantities will distribute the production costs among more units. When you bundle orders you save time and money.

- Regular maintenance of machines: When machines are well maintained, chances of failure and unforeseen breakdowns are minimized. With well-maintained equipment, you are guaranteed of consistent performance and enhanced efficiency.

Selecting the Right Manufacturer or Machining Service

- Knowledge on bronze grades: Never select a manufacturer that does not know the various bronze alloys. They have the experience to manage the machinability issues. This enhances quality and minimizes wastage.

- Certifications: check in ISO 9001 or AS9100 certifications. These demonstrate that the manufacturer has high quality standards. Certifications assure you of uniformity and predictability.

- Contemporary CNC machines: A good shop should be equipped with modern CNC machines. Modern equipment gives you higher turnaround, smaller tolerances and more sophisticated features.

- Inspection and quality control: Trustworthy manufacturers invest in quality inspection devices such as CMMs. This will make sure that each component is according to your specifications. Good quality management eliminates expensive rework.

- Communication and delivery times: An excellent machining partner is one that communicates effectively and on time. You need to examine their responsiveness and deadline capacity. Effective communication eliminates procrastination and errors.

Conclusion

Bronze CNC machining provides you with long, accurate, and flexible components across industries. With the right choice of bronze alloy and machining technique, you can attain tight tolerances, high-quality finishes, and economics. Bronze is another material you can rely on regardless of whether your project is marine parts, aerospace components, or decorative fittings. You will provide higher results and work to its full capacity with the appropriate tools, machining plans, and finishing techniques.

FAQs

What is the easiest bronze alloy to CNC machine?

C93200 and C54400 are the simplest since they slice easily and form manageable chips. You have clean finishes, but not too much wear on the tools. These are the types of alloys that novices or large-volume production lines that require consistency.

What can you do to stop tool wear in machining bronze?

Always apply coating and use sharp carbide tools and apply coolant. Check your tools periodically to remove dull edges and regularly replace the inserts before they fail. You also increase the life of a tool and lower cost of production by controlling heat and friction.

What is the reason to use bronze rather than brass or steel?

Bronze has better wear resistance than brass and corrosion resistance than steel. You may count on it when it comes to components in heavy load and in severe environments. This renders bronze a cost-efficient decision in the long term.

Which are the best finishing processes on bronze?

Polishing and plating are good in decorative pieces. To protect against wear and tear, sandblasting and coating add protection to be used in industry. Laser marking is a permanent form of identification with no harm to the material. Both techniques improve functionality and aesthetics.