Precision CNC Mill Turn Machining Expert in China

- Masion operates 20+ mill-turn machines including 6 Doosan and employs 125 skilled professionals.

- Unmatched precision with diameter and hole tolerances of ±0.005mm.

- Our team delivers better surface quality that reaches Ra values between 0.4 and 0.8 micrometers.

- Masion operates under ISO 9001 and IATF 16949 certification to achieve the highest quality standards.

High-Precision CNC Mill Turn Center Manufacturers in China

Top Chinese manufacturers produce exact engineering parts through their milling and turning processes. You can depend on CNC machining technology to produce parts that meet industry standards for quality. Our advanced Swiss lathes and multi-axis milling systems create complex parts that meet precise measurements. Our experienced production team brings you top-performing and cost-effective equipment for any production level. Our production quality control and industry accreditations make parts fully prepared for aerospace medical and automotive applications. Select Chinese manufacturing experts for their excellent craftsmanship and quick delivery times.

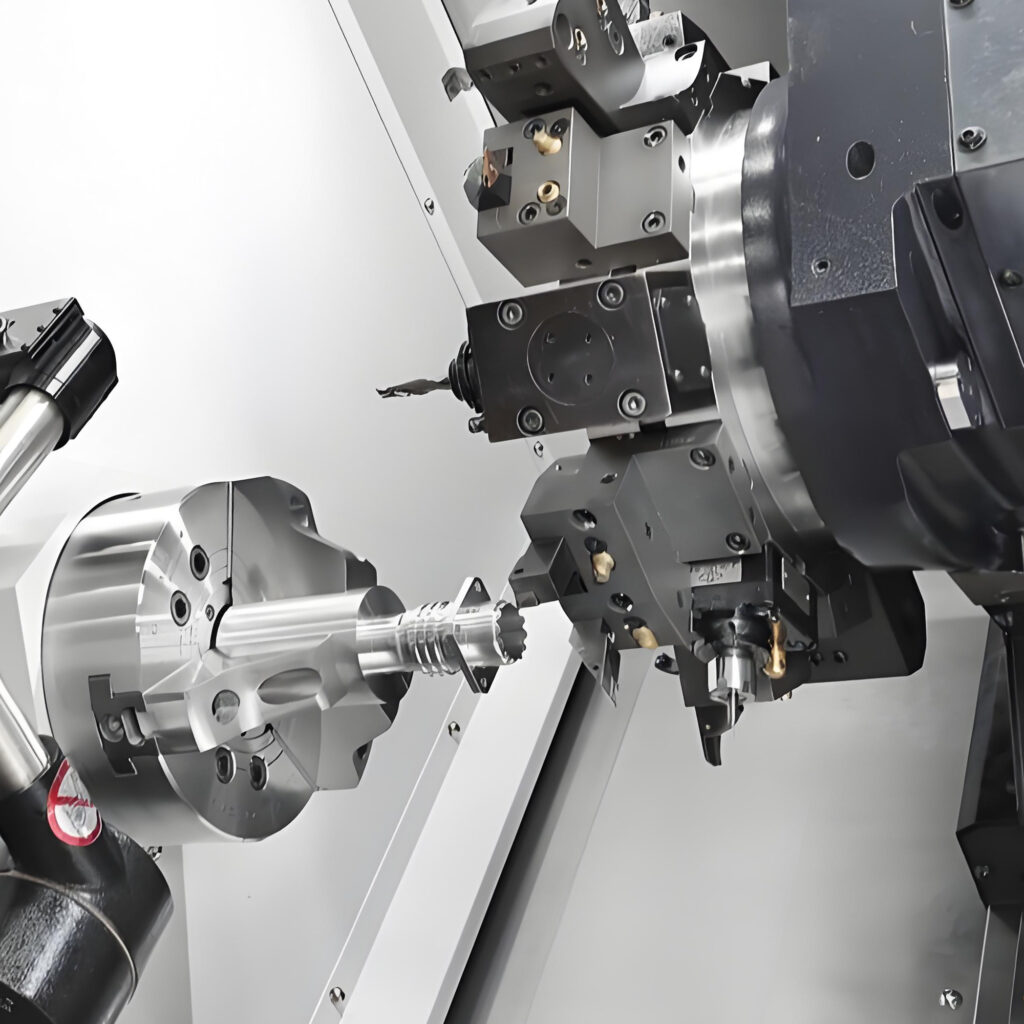

CNC Mill And Turn Capabilities

CNC turning and milling systems produce finely detailed precise parts for intricate designs. Our advanced CNC mill turn centers produce parts with exact dimensions that stay within tight tolerance ranges. A single machine setup helps boost productivity because it finishes tasks faster and creates better outcomes.

A single mill turn CNC machine enables manufacturers to produce precise parts rapidly across aerospace aviation, medical industry, and automotive production. The systems excel at processing both circular and flat materials to make parts with high precision.

Our experts at CNC Swiss Masion produce exceptional CNC turn mill work with dimensional accuracy of up to 0.005mm and surface roughness below 0.4 microns. Our approved quality systems ISO 9001 and IATF 16949 ensure you achieve the highest production standards. Our CNC turning and milling services meet the highest industry standards to produce both production parts and sample models.

Materials

- Alloy

- Aluminum

- Brass

- Copper

- Bronze

- Stainless Steel

- High Temp and Special

- Alloy

- Titanium

- Steel

- Plastic

Machines

- Doosan mill turn machine

- External cylindrical grinding machine

- Surface grinding machine

- Centerless grinding machine

- Passivation equipment

- Ultrasonic cleaning equipment

- Polishing machine

Surface Finish

- Golden Plating

- Zinc plating

- Silver plating

- Nickel plating

- Heat treatment

- Brass passivation

- Bead Blasting

- Polishing

- PVD coating

What Is CNC Milling And Turning?

CNC milling and turning machines make precise metal and plastic part designs using advanced machine tools. The CNC milling process turns cutters to make shapes while the CNC turning method spins the workpiece against tools to form shapes. The CNC mill turn machine combines milling and turning operations to complete work faster. Manufacturing processes like CNC turning and milling make products with exact size requirements and fantastic surface finishes. Main machining turning center companies run automated devices to achieve precise outcomes. You will get superior part results and high quality when you use our CNC mill turning center.

The Pros and Cons of cnc milling turning

The milling turning process generates exact parts at faster production speeds. A single CNC milling & turning setup combines milling and turning operations to create more precise products. Similar to other machining tools CNC turning and milling offer both strengths and weaknesses.

Advantages of Automated Milling Turning

- Advanced CNC turning and milling centers produce parts that meet tight requirements for demanding product designs. The technology delivers reliable exact results and maintains minimal dimensional deviations.

- A single CNC turn mill machine handles multiple production tasks all at once. Using this process allows faster production and reduces unnecessary setup operations.

- By handling intricate designs in one work cycle CNC machines decrease overall manufacturing expenses. The system creates higher output with less staff and requires reduced material usage.

- CNC milling & turning machines operate effectively on multiple materials to manufacture aerospace medical and automotive parts.

Disadvantages of Automated Milling Turning

- The initial cost of buying a mill turn CNC machine demands substantial financial resources. Your results depend on skilled workers who run the machines plus proper maintenance efforts.

- Operators need advanced training to manage mill turn, mill turn lathe setups effectively.

- A CNC mill and turn system can work with different materials yet requires special tooling or surface preparation methods for specific materials.

- A CNC turn mill center delivers fast production of both small and moderate product volumes. A business needs machines designed to produce many products simultaneously.

- CNC machines need regular tool replacement to keep working which creates production stops. Our machines stay operational through routine equipment upkeep.

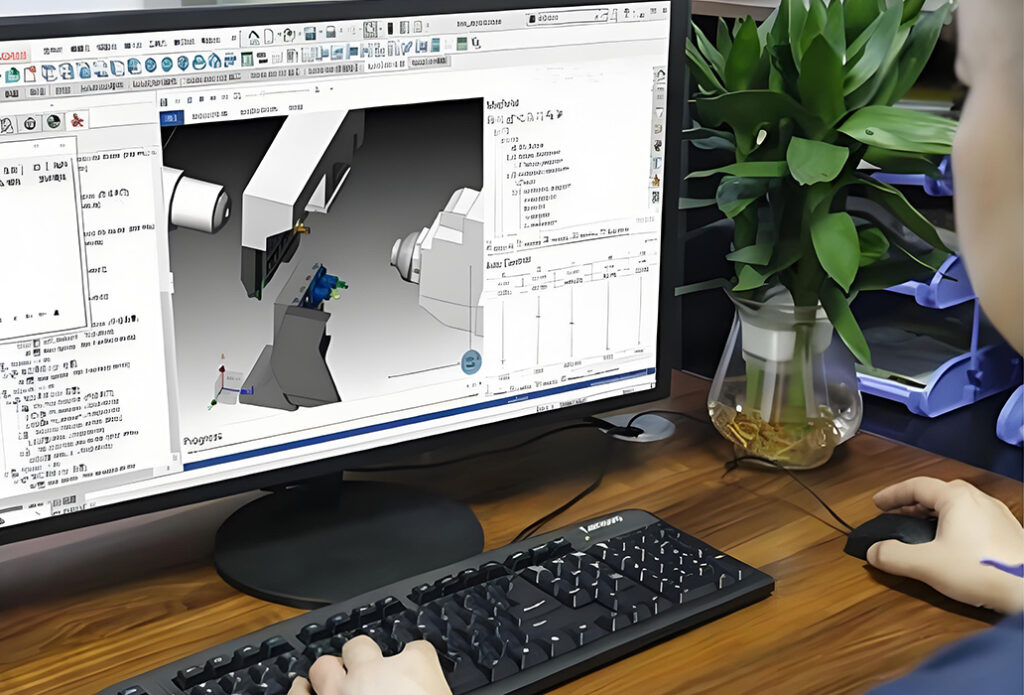

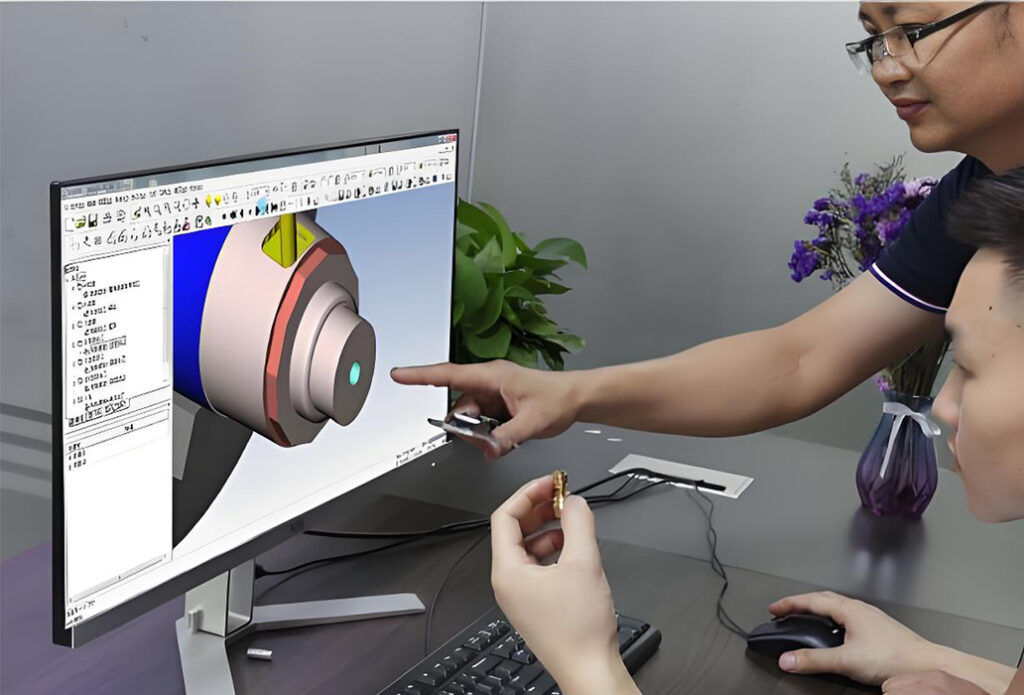

DFM for CNC Turn And Mill Parts

CNC Swiss Masion confirms your product’s compliance by working together with you. Our team shares product validation processes with your team to spot mistakes before they happen.

Material Knowledge and Application

The right materials must resist harsh conditions and perform exactly as intended. We study material behavior to pick the perfect option for your machining turning project.

Tool Design and Application

The precision machining start-up phase includes the creation of special equipment and fixtures. Our team builds unique CNC milling turning processes to work best with different material types and product designs.

Geometry and Tolerances

Accurate part geometry reduces errors. Our CNC machines deliver precise production that results in perfect outcomes.

Part Features & Machining Optimization

Fewer setups mean parts take less time to make and cost less. Our experience in CNC milling and turning lets us make intricate parts during one production cycle.

Deburring and Post-Processing

Our precise post-processing techniques deliver parts that work better and look better.

Solution Development & Cost Evaluation

We develop technical solutions that enable you to reach your project goals while paying less. We review all CNC machine mill solutions to find the ideal and least expensive way to make your parts.

Design for Effective Quality Control

Our CNC mill turn center inspects all manufactured parts under our rigorous quality testing system. Our ISO certification means we follow all quality standards during our production steps.

Why Choose us for Turned And Milled Parts?

CNC Swiss Masion delivers custom CNC mill turn parts that fit precise dimensions. Our CNC technology background lets us produce affordable parts that meet exact customer requirements.

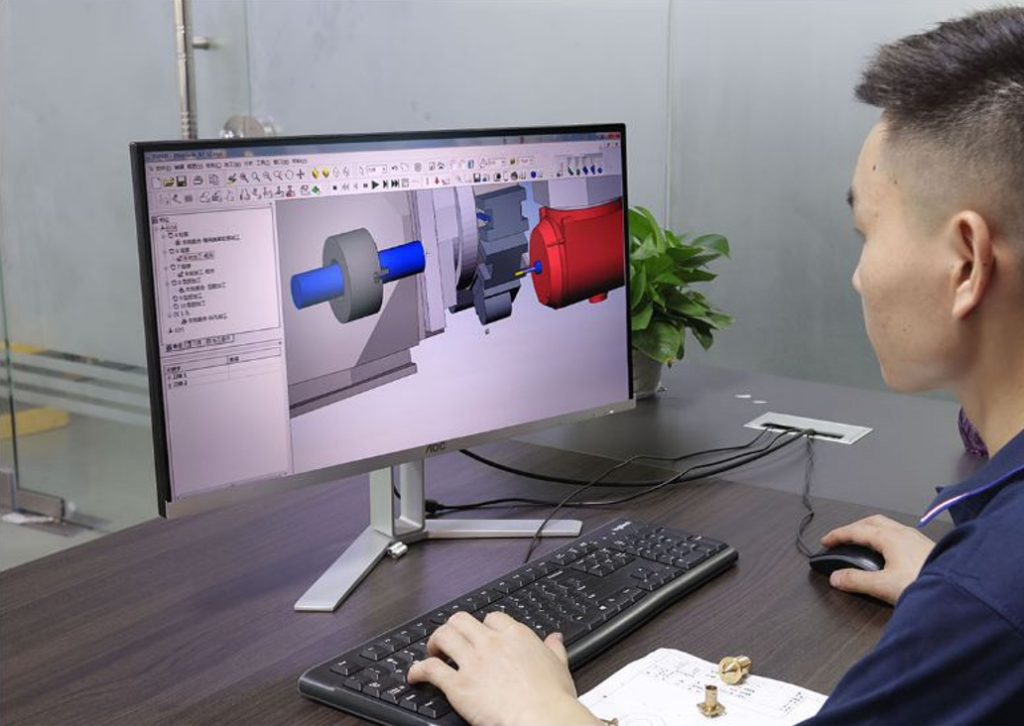

Cutting-Edge Technology for Precision

Our advanced system developers optimize tools paths for machine operations. Our production system enables manufacturers to lower operating costs while creating products more quickly. Our ERP system keeps our daily operations running smoothly and our MES system produces top-quality products in our factory.

Uncompromising Quality Management

Our quality control process looks at every part to ensure perfect delivery to customers. Our team conducts detailed analyses to shape components at exact specified measurements. Our mill turn CNC machine delivers parts with tolerances between 0.005mm and 0.01mm.

Expertise in Composite Processing

Our experts run mill turn, mill turn lathe operations on alloys, aluminum, brass, and steel materials Our Doosan turn mill machine handles challenging component parts successfully.

Trusted by Industry Leaders

Our business delivers components to Huawei, Novel, Hysis, Tesla, Tuopu, and Xusheng for their essential projects. Our mill turning process ensures identical high-rate production.

Customer-Focused, Customized Solutions

As a top CNC turn mill producer we create engineering solutions that precisely fit each project detail. CNC Swiss Masion creates precise CNC machined parts to match your strict requirements.

Turned And Milled Parts Tolerance

All CNC turning an milliing machines must uphold exact dimension requirements to function effectively. The system depends completely on parts needing exact shapes before it starts working. Advanced mill and turn CNC systems deliver exact results for all part dimensions simultaneously.

- Standard threads need measurement ranges between 0.01mm and 0.03mm precise dimensions but micro threads work well at only 0.01mm accuracy tolerance.

- High-end CNC tools make radii measurements with accuracy of ±0.01mm while standard CNC equipment achieves tolerances between ±0.02mm and ±0.05mm.

- Manufacturers create parts that stay within ±0.005mm to ±0.01mm of their target measurements but achieve special project accuracy to ±0.002mm.

- Our equipment produces standard holes and high-precision drillings that match their intended size within 0.01mm or 0.005mm of tolerance.

- Our axial dimension tolerance range goes from ±0.002mm at its best accuracy to a standard range between ±0.005mm and ±0.01mm.

- Standard tools create diameter variations between 0.005mm and 0.01mm while advanced ultra-precision tools can achieve a margin of error at 0.002mm.

- Our production method repeatedly makes parts that reach 0.8 microns (μm) polished surface quality standards.

CNC Swiss Masion runs exact component sizes through its mill & turn CNC centers. Our experts deliver exact part results by running CNC machine operations for turning and milling while mastering advanced finishing methods.

Turned And Milled Parts Quality Control

Constant CNC mill turn monitoring produces exact parts that follow reliable quality standards. The production process follows a set path that starts with choosing materials and ends with examining the finished output.

Material Inspection

Your parts will perform correctly when you select suitable materials. Make sure to test the materials and verify their composition and durability levels before you start working with them at the machine mill. Test all materials through spectrometer measurements and hardness tests to prove they meet product specifications.

Dimensional Inspection

Precision machining demands tight tolerances. The turning milling technology allows you to produce components that meet finer micrometer specifications with exacting precision. Dimensional checks include:

- Check all important part measurements directly after your first production piece to test your quality specifications.

- Look for alignment problems by checking parts at regular intervals throughout production.

- Verify if the finished piece matches its engineering requirements by measuring its exact dimensions.

Surface Finish Evaluation

The quality of surface finish determines both part functionality and durability. Use a profilometer to check surface roughness against standard CNC machine specifications for both turning and milling processes.

Non-Destructive Testing

Non-destructive testing methods detect hidden defects in parts through ultrasonic scans and magnetic particle techniques without harming the parts. The inspection phase keeps heavy-duty parts running reliably for their intended purpose.

Examine the Surface Finish

Heat-treated or coated parts require special quality tests alongside normal inspection processes. Inspection tests how well the product stands up to wear and tear by measuring its surface coating performance and product hardness while showing the layer’s total thickness.

Visual Inspection and Documentation

We complete quality control by checking if parts remain both structurally sound and visually correct. Record all test outcomes to confirm product meets quality specifications. Your milling turning CNC machine generates perfect parts because it makes identical duplicates at high levels of precision.

Our Certificates

From past 21 years Masion has provided CNC mill turn services that meet Swiss precision standards. Our commitment stays focused on making custom CNC parts while maintaining top quality service and satisfied clients.

Our CNC skills make us capable of meeting every small part manufacturing demand. Our modern CNC systems generate precise parts that customers depend on. Our certifications show how committed we are to excellence in our operations.

- Our CNC team follows ISO 9001 guidelines to assure exceptional production methods.

- ISO 14001 – Guarantees compliance with environmental management standards.

- IATF 16949 – Meets the automotive industry’s quality requirements.

- When our clients ask about it our business tests products to make sure they are RoHS-compliant and safe for them.

- SGS Product Testing – Verifies product quality and adherence to industrial standards.

- CE Marking – Confirms compliance with European safety regulations.

Explore Our Turned And Milled Parts Gallery

Turning and Milling of Optical Components

Turning and Milling Automotive Parts

Titanium Turning and Milling

Stainless Steel Turning and Milling

Stainless Steel Turn Mill

Stainless Steel Turn and Mill

Embossing Spindle

Brass CNC Turning and Milling Machine

Biped Robot Leg Joint Reducer Shell

Aluminum Alloy Turning and Milling

Turned and Milled Parts Packaging for Safe Delivery

Your CNC mill turn parts demand protective packaging to stay unharmed during shipping. Pick your packaging style depending on your parts size and material type along with shipping requirements. Carefully choose these two methods for protecting your CNC milling turning components:

- Ziplock Bag Packing – Small precision CNC parts need ziplock bags for safe shipping since they protect against both dust and moisture. Packing parts in ziplock bags prevents them from getting contaminated by dust or moisture while maintaining easy part identification.

- Bubble Bag Packaging – It defends sensitive CNC turning and milling machine components. The air-filled room inside the package helps keep parts safe from accidental damage during shipment.

- Blister Packing – Offers a secure and clear display for small precision components. The packaging system clearly separates parts so you can identify and find them quickly.

- 5-Layer Corrugated Box Packing – A 5-layer cardboard box prevents damage to CNC parts through effective crushing and impact resistance.

- Pallet Packing – Pallet Packing works best for large production runs of CNC turning and milling parts. The system spread weight evenly and kept products safe during their transportation path.

- Wooden Box Packing – The best choice for heavy-duty mill and turn CNC components. A wooden box offers total safety to protect items from accidental bumps plus external weather conditions.

Selecting proper packaging materials helps mill turn CNC center producers ship components safely and faster.

CNC Mill Turn Services for High-Precision Industries

Our team makes CNC mill turn parts exactly and with the highest quality standards. Our team applies CNC expertise to transform your designs into physical components based on decades of milling and turning experience. Our cutting-edge mill turn CNC system produces parts that meet the exact measurements you need.

Our company uses CNC technology to produce strong parts through turning and milling operations. Our team maintains the same production standards in every order no matter how different the project sizes may be. Our CNC machine centers produce custom precision parts quickly with perfect size control.

- Medical – Surgical instruments, implants, and diagnostic tools

- Electronics – Connectors, enclosures, and circuit components

- Automotive – Engine, transmission, and suspension parts

- Watchmaking Sector – The watchmaking sector needs precision-made parts which must match exact size boundaries.

- Telecommunications – Housings, waveguides, and connectors

- Home Appliances – Gears, shafts, and mechanical parts

- Robotics & Automation – Motion control and sensor housings

- Industrial Hardware – Fasteners, brackets, and custom fittings

Our mill turn experts work with advanced CNC equipment to create customized parts that fulfill the needs of every industry sector.

FAQs

Do you have the ability to make many tiny parts quickly using advanced CNC mill turn technology?

Our CNC mill and turn process delivers quick results at large manufacturing scales. Our CNC equipment delivers perfect results at top speed while maintaining consistent precision output.

What are the typical size limitations for small part manufacturing?

Our CNC machines produce small components that range from 1mm to 45mm in outer diameter. Our services deliver excellent results for industries needing tight specifications and precise dimensions.

What steps do you take to prevent excess material use throughout production?

Our CNC mill turn system uses advanced bar-feeding tools to use materials more efficiently. The method needs less raw materials which lowers production costs and helps protect the earth.

Can you develop prototype items ahead of full manufacturing runs?

Our CNC turn mill center allows us to produce rapid prototypes. You can test your product design using this service to make final adjustments before starting production so you can achieve perfect results.