CNC Milling – The Complete Beginners Guide

Today, CNC milling plays a leading role in the manufacturing industry due to that unparalleled precision and efficiency. If you’re just entering the automated milling world, it’s important to understand milling. You get a solid base to start working with everything from your basic tools to your advanced machines. In this guide, you will learn about the core concepts, step by step processes, essential operations, and key tools. This article will explain the basics so that if you’re only curious or just beginning to get your hands wet, you can get a grasp of the main aspects as well as increase your confidence in programmed milling. You will also be able to understand what do milling machines do and how they work

Table of Contents

ToggleUnderstanding CNC Milling

Computer Numerical Control milling is abbreviated as CNC milling. It is a very precise and automated process where a computer controlled rotary cutting tool is used to remove material from a solid workpiece. Instead of manually guiding the machine, you tell the machine what to do. You program it by instructing it to perform certain movements to create precise shapes. You will also be able to learn about the description of milling machine features here

CNC milling is different than traditional milling that requires high degree of manual control and operator skill. The machine follows exact paths without deviation of your design digital input. It not only decrease errors but increases production.

CNC Milling Process In-Depth

Designing

Design starts your milling journey. You first create a 2D or 3D model in CAD software. This is a model that has defined every detail of your part. Once created, you turn it into a CAM program. This outputs the toolpaths and translates to Gcode, the language your CNC machine can understand. How efficiently and accurately the machine operates is determined by your design decisions.

Workpiece Setup and Tool Installation

Your workpiece needs to be set up securely before you begin cutting. Hold it in place using proper clamping and fixturing. It can ruin precision if there is any misalignment here. Next, install your cutting tools into the machine’s spindle. Each tool has to be calibrated to the right dimensions. A properly aligned tool setup also provides a smooth operation and decreases wear. Knowing about the parts of a CNC mill will enable you to identify each machine component correctly.

Program Execution and Cutting Process

After you have your machine set, load your program and start the milling process. The G-code tells your machine to move the tool in specific directions, horizontal, vertical, or diagonal. Factors such as feed rate, cutting speed, and depth of cut are under your control. The settings depend on your material and tool type. In addition, they also influence surface finish and tool life. CNC provides uniform output for CNC milling cutting tools and smooth machining.

Types of Cutting Movements

There are several movement types used in CNC milling. In some cases, the workpiece moves and the tool stays still. At other times, the tool moves across a fixed part. Some require that both parties move together. But you have to select the appropriate method depending on part geometry and machine capabilities.

Climb Milling vs. Conventional Milling

However, in climb milling, the cutter moves in the direction of the feed. It provides you with a cleaner cut and longer tool life. Better for tough materials, conventional milling is where the cutter moves against the feed. For your project needs, you will often use both methods. Turning on milling machine techniques can apply in specific operations to achieve precise contours and shapes.

Finishing

You finish the part to improve its surface quality after the main cut, and you do so to meet tight tolerances. Polishing, deburring, or fine passes with smaller tools may all be part of this stage. The aim here is to make sure it looks good and works as intended. Proper finishing affects the performance of CNC milled parts.

Types of CNC Milling Operations

Face Milling

In face milling the cutting occurs at the end corners of the cutter. To produce flat surfaces, you use face mills and fly cutters. This is an operation most suited for high quality finishes on large, horizontal areas. Face milling is your choice if you need a clean, smooth top surface. It also allows for easy removal of material from the workpiece’s face. This method is common when we work with CNC milling components.

Plain Milling (Slab Milling)

In plain milling, the cutter’s axis is parallel to the surface being machined. This operation is normally carried out with slab mills. This is the simplest method to use if you want to create large, flat surfaces. This is commonly used for machining large parts where consistency of thickness is important. You’ll apply it most often surfacing plates or leveling stock. It is useful in CNC milling turning operations.

Angular Milling

Angular milling lets you cut at an angle different than 90 degrees. Depending on what angle you desire, you use single angle or double angle milling cutters. This technique can be used for making chamfers, grooves, or V-shaped slots. Flexible in designing angled features, without need for complex setups.

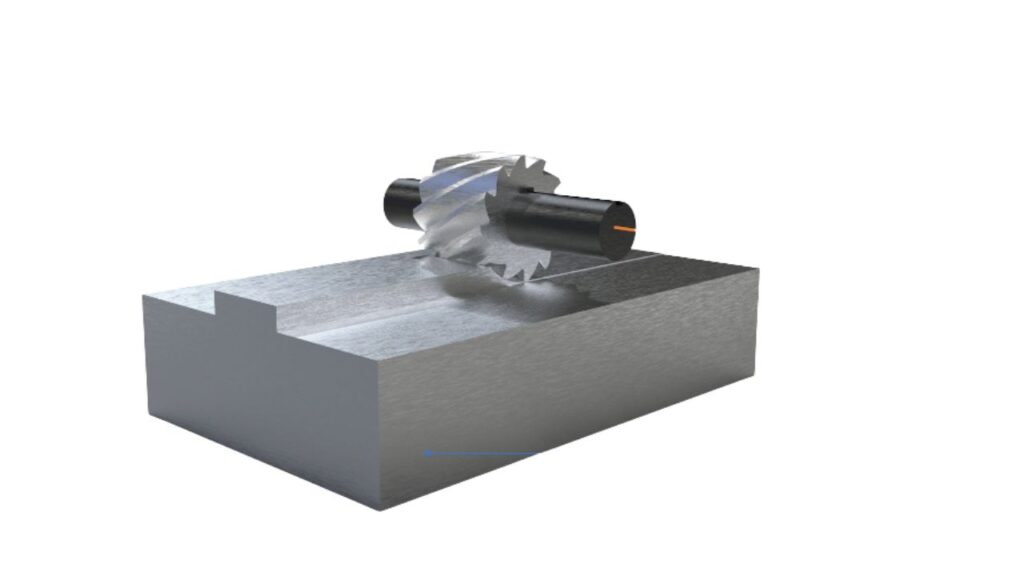

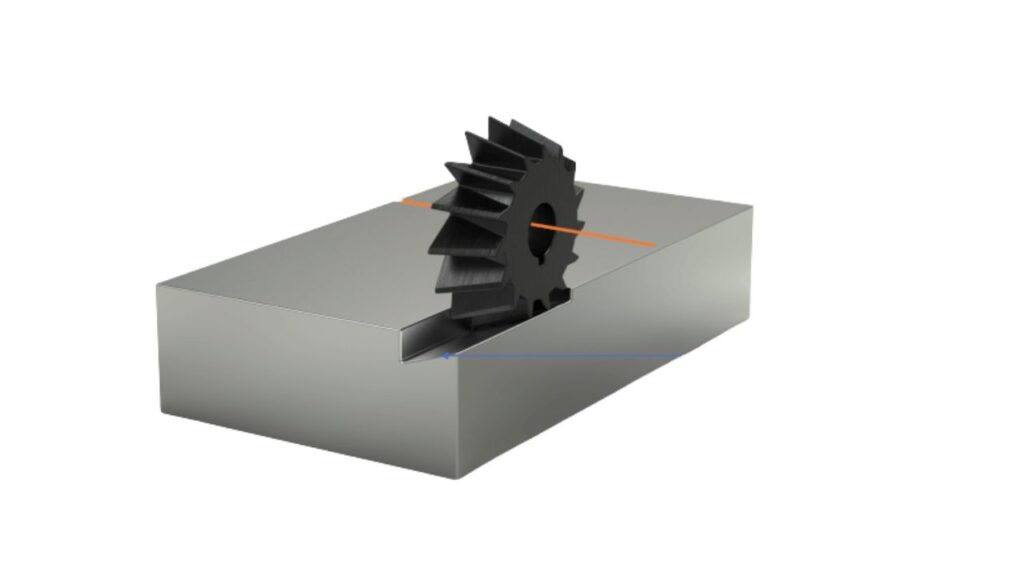

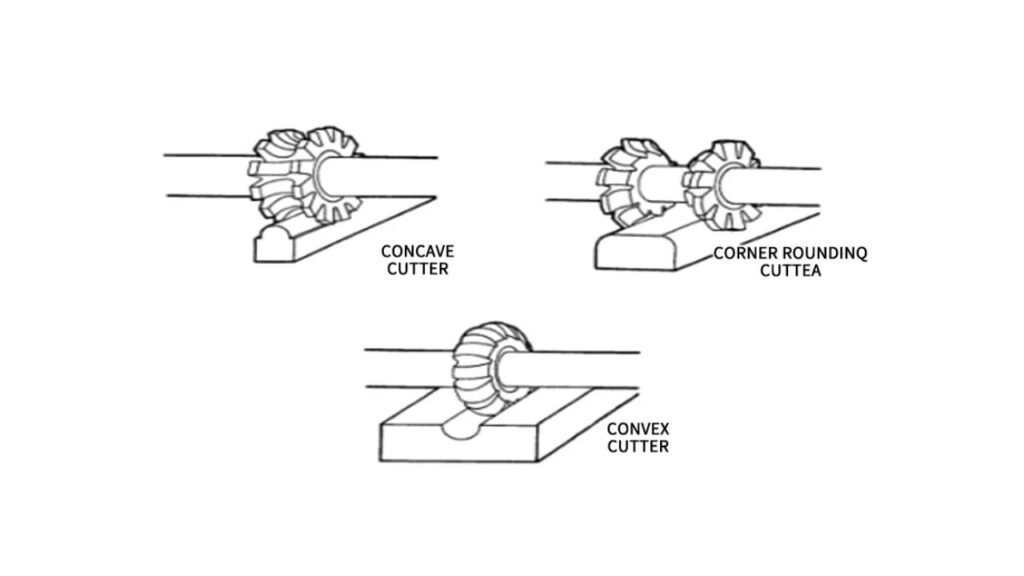

Form Milling

In fact, form milling is fantastic for making detailed shapes. Special tools like convex, concave, or corner rounding tools are used to cut you. Form milling will enable you to achieve complex contours, curves, or decorative profile in your part design. In its use for the production of molds, gears and ornamental parts, it is widely used. for complex contours in CNC machining milling.

Specialized Milling Operations

Gear Cutting

Gear cutting is a must know specialized milling operation that is required to produce mechanical components. CNC milling can be used to produce spur, worm, helical, and herringbone gears with high precision. The role of these gears is so important especially when transferring power within machines in a smooth manner. Form cutters or gear hobbing tools are used to make the gear teeth. After the given basic tooth profile has been milled, finishing processes such as deburring or grinding could be used to increase durability and performance.

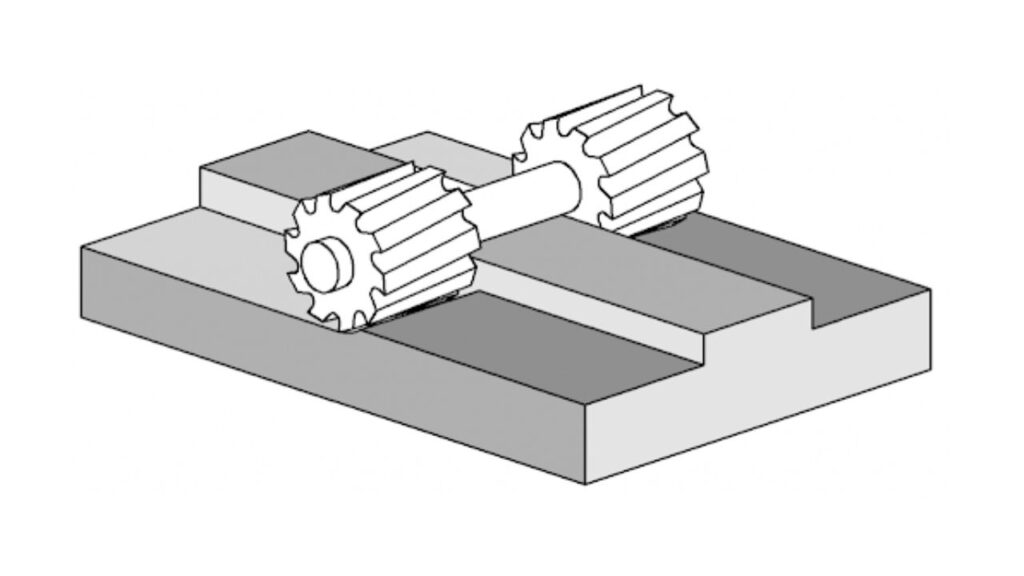

Straddle Milling

Straddle milling lets you machine the two opposite sides of a part at once. This is highly effective when you require a high degree of dimensional accuracy across symmetrical features. Coring between the two cutters is achieved by mounting two cutters on the same arbor and keeping spacing exact. This way takes up less time and also is parallel, which is especially useful when making slots, grooves, or rectangular blocks. If consistency in width and flatness matter, then it is a go to option.

Profile Milling

Profile milling allows you to work on a workpiece to make both 2D and 3D contours. This method gives you the control you need if you are working on mold cavities or decorative parts. Ball nose or radius end mills are used for smoother curves and detailed surface work and you’ll use them often. This is perfect for sculpture surfaces, intricate patterns or any design which requires depth and flow. CAM software enables the simulation and planning of each pass for best accuracy.

Gang Milling

The use of multiple cutters on the same arbor is termed gang milling. It allows you to cut several places in a single pass, thus increasing your speed and efficiency. Gang milling allows you to mill large or complex parts of a CNC mill faster while maintaining the accuracy. Face milling, slotting, and contouring can be done simultaneously for high volume production.

Other Specialized Methods

Depending on your part design, you can also explore T slot milling, thread milling, and helical milling. T slot milling is used to produce tracks for fixtures and jigs. Thread milling is a method of performing internal or external threading with a higher degree of control than ‘tapping’. For angled slots or complex helical profiles, helical milling is excellent. These methods, respectively, expand your machining possibilities to take care of the trickiest geometries with ease.

CNC Milling Machine Components

The structural backbone of the machine when working with a CNC milling components machine is the base, column, knee, saddle, and ram. The machine sits on the base and takes all vibrations away while cutting. The spindle, and other moving parts, are held in place on the column. The saddle allows the horizontal movement and the knee allows the vertical movement. The machine reaches further with the ram. Together these parts create a stable and precise platform for milling operations.

Worktable and Movement Mechanisms

You secure your workpiece to the worktable. You can move it along the X, Y, and Z axes on your machine based on what the machine is capable of moving. Ball screws and linear guides are used in this movement to ensure accuracy. To align to the tool path, you need to set up your workpiece properly.

Control Interface

You communicate with the machine with the control interface. Using this system you will use to upload G-code or from CAM generated programs. In most modern machines, an HMI (Human Machine Interface) makes it easy for you to see what’s happening, to change your parameters, and to troubleshoot it right away.

Spindle, Arbor, and ATC

Power is transmitted to the cutting tool by the spindle that also drives it. The arbor, that attaches to various cutters, is held by it. Tool magazines and automatic tool changers (ATC) come in handy for switching between tools quickly, making CNC milling turning faster and more efficient.

CNC Milling Tools and Cutters

Classification of CNC Milling Tools

The CNC milling tool is classified according to their geometry, teeth configuration, and function. There are tools made specifically for specific cuts, like face mills, end mills, and slot drills, for each of these, the machining process has its purpose. Cutting efficiency and finish quality depend on teeth type (single or multiple).

Milling tool performance is affected by the material used in the tool. Carbide is more wear resistant for hard materials, but High Speed Steel (HSS) is versatile and cost effective. Ceramic tools operate well at high temperatures while coated tools provide longer life and lower friction in the same applications. Selecting the appropriate material will result in maximum tool performance and longevity.

Common CNC Milling Tools

Roughing End Mill Cutter

The roughing end mill cutter is intended for material removal. It does this by rapidly cutting away large sections of material and leaving the final shaping to be done in later stages. This tool is best suited for clearing heavy material from a workpiece and preparing it for finer cuts.

Slab Mill Cutter

Broad surface finishing is done by a slab mill cutter. Great for large, flat surfaces when you are working on your workpieces. In situations where you need to machine a wide area quickly and evenly you’ll find it useful.

End Mill Cutter

There are two types of end mill cutters: center and non center. Center cut end mills are used to cut through the middle of the material, whereas non center cutters work best on the edge. Both are useful in different milling tasks and are very versatile.

Ball Nose Cutter

3D surface milling is best performed with ball nose cutters. Because of their rounded ends, they let you carve complex shapes and contours in your material. For tasks such as sculpting and molding, they’re great.

Hollow Mill Cutter

The hollow mill cutter works in a fashion similar to turning and works great for machining inside of surfaces. It’s great for making cylindrical shapes or hollow features.

Involute Gear Cutter

An involute gear cutter is essential if you need to cut gears. It is a gear tooth making company, specializing in making precise gear teeth capable of being used for different kinds of mechanical applications.

Face Mill Cutter

The face mill cutter is also your tool of choice for creating flat surfaces. The way it finishes large areas that have smooth, flat surfaces is very efficient.

Woodruff Cutter

The woodruff cutter is used for cutting key slots for your workpiece. Often used where keyways for mechanical assembly are required.

Thread Mill Cutter

The thread mill cutter is specially designed to create internal and external threads. Great for precision threading on a variety of materials.

Fly Cutter

Large, flat surfaces are best finished with fly cutters. They allow you to get a polished look over larger areas easily.

Slide and Face Cutter

For making long slots or deeper cuts, slide and face cutters are used. For those times when you want to machine deeper, or more intricate sections of your workpiece, they’re crucial.

CNC Milling Machine Configurations

Vertical Milling Machines

Spindle of vertical milling machines moves vertically along Z axis. For precision work and smaller parts this configuration is ideal. The main advantage is that a variety of operations, such as drilling, boring and slotting, can be performed with high accuracy. Aerospace and automotive are two industries that make extensive use of these machines as these industries require precision cuts in smaller, more detailed components.

Horizontal Milling Machines

Like other vertical machines, horizontal milling machines have a horizontally oriented spindle. For heavy duty material removal and larger parts this configuration is better positioned. They are often used for manufacturing large components in industries such as energy and defence where they excel at cutting thicker materials.

Universal and Gantry-Type Machines

Multi axis machining is offered by universal and gantry type machines which provides more flexibility. On account of their inherent precision and intricacy with which they can make cuts, they are ideal for complex, large workpieces. In industries like aerospace often, complicated designs are common and these machines are used.

3-Axis, 4-Axis, and 5-Axis Machines

3 axes machines can move on the X, Y, and Z axes for basic versatility. 4 and 5 axis machines, on the other hand, include another rotational axes for more complex movements. Precision industries, such as aerospace, medical, and automotive, are commonly produce CNC milled parts using these machines due to the importance of high level accuracy.

Materials Used in CNC Milling

Metals

CNC milling can be used with various metals. This most commonly includes parts that require low weight and strength, such as for aircraft parts or where weight or manufacturing efficiency is desired over higher strength parts. It is also lightweight, easy to machine, and is usually realized with an aluminum alloy. Mild, stainless and tool steel are all steel, which offers exceptional strength and durability for heavy duty applications. Brass has excellent machinability and aesthetic appeal so it is commonly used for decorative or precision components. Titanium has a high strength to weight ratio is what makes it ideal for industries that demand very high strengths with a low weight, such as aerospace. Electrical components are made from copper which is excellent conductor but also machinable with the right tools.

Plastics

CNC milling is very popular because of plastics such as ABS, POM, Nylon, and PTFE. Lightweight, corrosion resistant and easy to machine, these materials are suitable for prototypes and consumer products. They are often employed when you require parts that have a good balance of strength, flexibility, and chemical resistance.

Composites and Exotic Materials

For use in specialized applications, advanced materials are used such as carbon fiber, fiberglass and ceramics. Because of their strength, light weight and durability in extreme conditions, these materials are commonly found in defense, aerospace and other high performance industries.

Advantages and Limitations of CNC Milling

High precision and repeatability

You can produce parts with tight tolerances every time. CNC systems repeat the same process over and over again extremely accurately.

Capable of complex geometries

You can produce all kinds of intricate shapes and contours that are impossible or difficult to create on manual machines.

Suitable for prototyping and production.

CNC milling supports both testing a new design or producing at scale.

Reduced human error and labor cost

Once programmed up, the machine takes over. This reduces mistakes and reduces the need for constant supervision.

Limitations

High initial investment

CNC machines, software, and set up are going to cost you a lot upfront.

Not ideal for soft or highly elastic materials

Under cutting pressure, these materials may deform, and it becomes harder to mill these materials effectively.

Requires skilled programming and setup

To achieve accuracy, you must really know how to use CAD/CAM software and set up your tools properly.

Tool wear and maintenance costs

Over time, tools wear out. To maintain quality, you will have to regularly replace or maintain them.

Conclusion

Finally, CNC milling is paramount in modern production, thanks to its unmatched precision, versatility, and efficiency. Knowing its core concepts, processes, tools, and operation will put you in a position of confidence whether you are a beginner or seasoned professional in this field. Working from designing parts with CAD software to executing complex operations on various materials, automated milling increases productivity while also offering high quality. CNC machining milling is crucial for tackling various manufacturing problems with a variety of machine types and milling operations.