CNC Swiss Machining Services

- Specialized in Swiss machine parts manufacturing for 21 years.

- Equipped with 70+ advanced Swiss lathes and a skilled team of 125 professionals.

- Achieve precision with tolerances of ±0.003mm and grinding accuracy up to ±0.0002mm.

Leading CNC Swiss Machining Experts in China: Redefining Precision

Discover the top CNC Swiss machining specialists in China with over 21 years of experience in precision manufacturing. As a Swiss machine shop, we excel in providing unmatched accuracy in custom Swiss screw machining and small parts CNC machining. With our 70 plus advanced machines we produce high quality screw machine products that meet your exact specifications. We adhere to the highest standards, including IATF 16949 and ISO 9001:2015 to ensure consistency in quality and reliability. With our expertise and technology deployed, our screw machining services can offer you custom Swiss parts and production of small parts machining. Choose a Swiss screw machine shop that places importance on precision, quality, and fast delivery. We stand out in producing intricate screw machine parts used in many industry sectors. We promise to do so with undivided attention to craft and adherance to standards compliance. Take advantage of our automatic screw machine business right now!

Swiss Machining Services: A Comprehensive Overview

Swiss machining is a highly specialized manufacturing process where small parts are machined on Swiss style lathes with high precision. It features a unique way to turn, mill, and drill long and slender workpieces with minimal tool wear. In particular, Swiss machining is especially good for parts that have very tight tolerances and extremely intricate design, and the company claims to be able to achieve diametral accuracies of 1.5 micro inches and acceptance tolerances of 0.0002 inch.

Its especially advantageous to Swiss machining and is capable of producing thousands of similar parts at a fast pace; down to as small as 0.2mm in diameter. Swiss machines are incredibly accurate and versatile and can be found in almost every industry: medical, aerospace, automotive, electronics.

Materials

- Alloy

- Aluminum

- Brass

- Copper

- Bronze

- Stainless Steel

- High Temp and Special

- Alloy

- Titanium

- Steel

Machines

- Swiss Lathes

- Polishing machine

- External cylindrical grinding machine

- Surface grinding machine

- Centerless grinding machine

- Passivation equipment

- Ultrasonic cleaning equipment

Surface Finish

- Aluminium anodizing

- Golden Plating

- zinc plating

- silver plating

- nickel plating

- Heat treatment

- Brass passivation

- Bead Blasting

- Polishing

- PVD coating

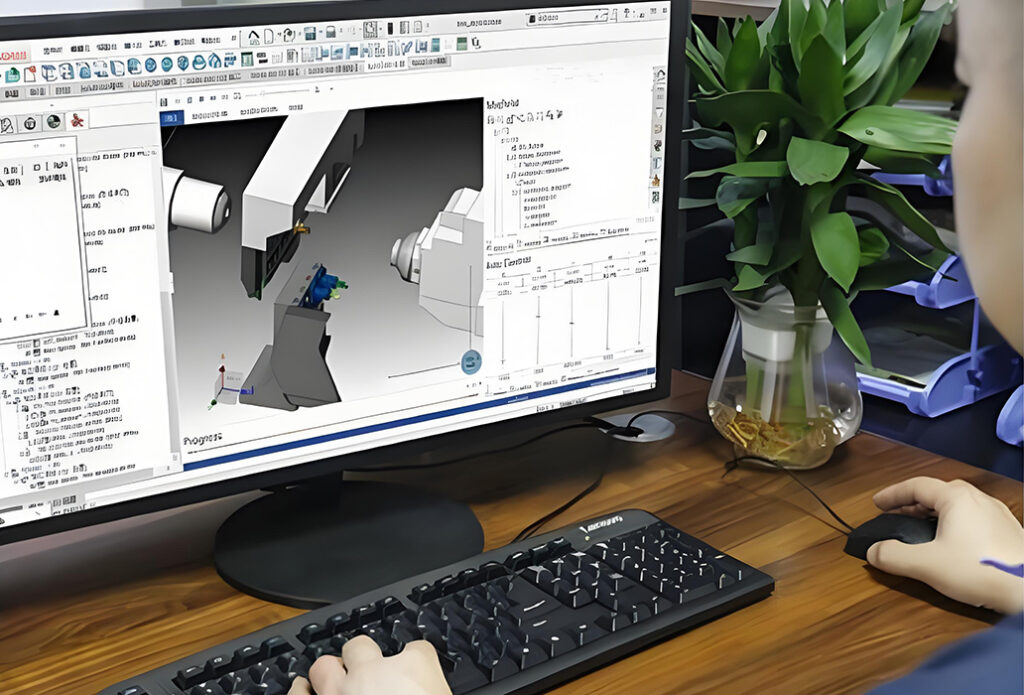

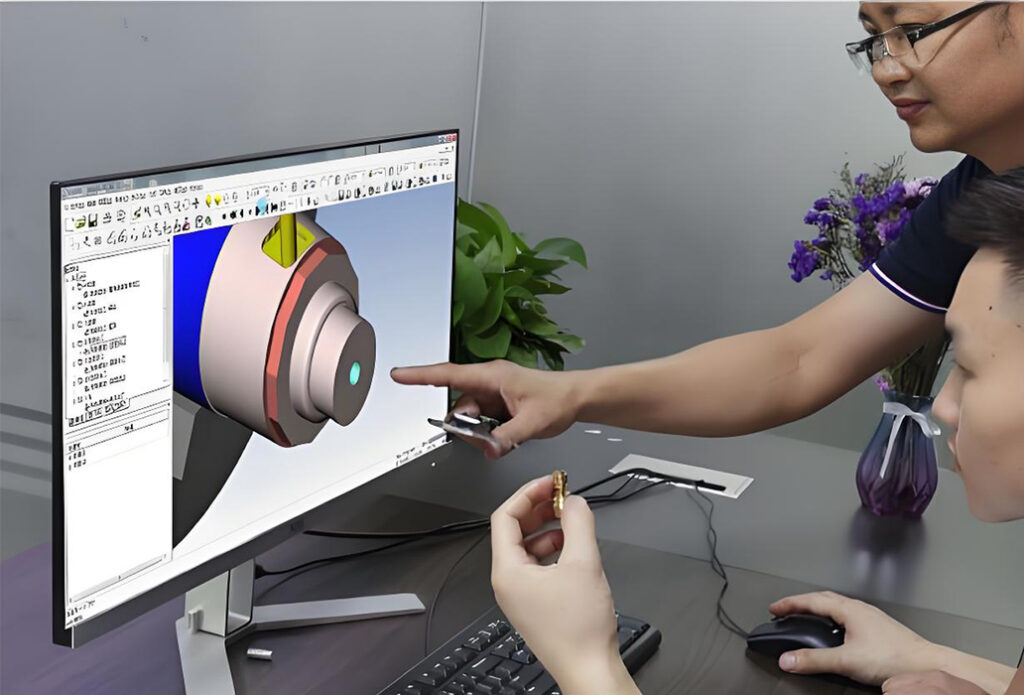

DFM (Design for Manufacturing) in Swiss Machining

DFM plays a very important role in helping to optimize the design for Swiss machining. In this way, you can early evaluate your design and ensure manufacturability and reduce costs. The given includes choosing of materials, complex geometry feasibility analysis, and the best part orientation and tool path. These designs are functional and manufacturable usually achieved through the use of advanced tools including CAD/CAM software.

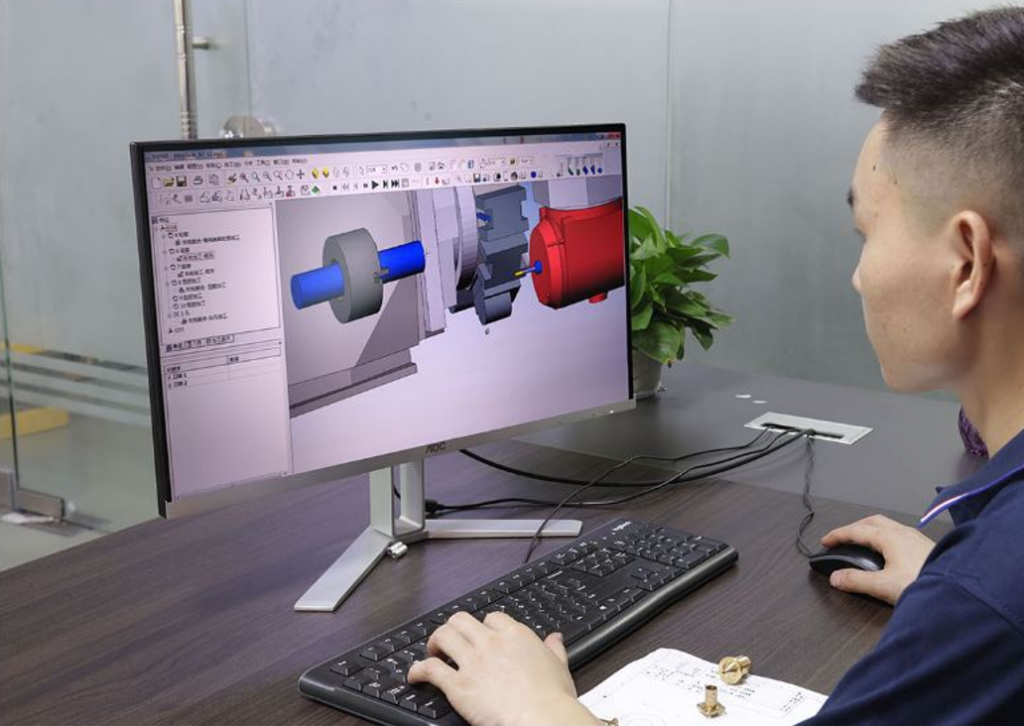

Advanced Swiss Lathes

5 to 12 axis Swiss lathes offer great flexibility. Additionally, they can process complex and multiple stages machining tasks, resulting in the reduction of the required number of operations. The Swiss lathe equipment advancements such as Masion equipment helps in the precision and efficiency to produce custom Swiss parts with tolerances as close as ± 0.0002 inch. These advanced lathes can serve industries with high volume production requirements, high precision parts such as Swiss screw machine parts, or custom Swiss screw machining services.

What is a Swiss Machine?

The Swiss machine is a form of CNC (Computer Numerical Control) machining equipment. It is best known for its precision and efficiency in cutting small parts. Long, slender arrangement is best for manufacturing short, slender, or custom small parts.

What is Swiss Machining?

Swiss Machining is a type of machining where a workpiece is attached to a collet and rotated while a cutting tool moves on multiple axes. It has been used to generate highly accurate complex geometries and tight tolerances. However, if you’re looking for Swiss screw machining or Swiss machine parts, you’ll want a Swiss machine shop. Small metal parts manufacturing and CNC small parts machining are core strengths of such shops.

The Pros and Cons of Using Swiss Machining

Small parts manufacturing requires precision and efficiency, and this is where Swiss machining offers it. It is the usual method used in various industries, including automotive, medicine and aerospace. Below are the pros and cons of cnc swiss machining:

Pros of Swiss Machining

- Precision and Accuracy: Small and intricate components are the forte of Swiss machining, referred to for their high precision. For the medical or aerospace industries, it has tight tolerances that are necessary for such industries that need extra tight tolerances.

- Efficiency: It is produced at high speed. This is why it offers shorter turnaround times to the conventional machining techniques. This method is very economical if you need high quantities of small parts like swiss screw machine parts.

- Versatility: Swiss machining is good because it deals with a wide variety of materials, from plastic to metal. Therefore, these machines can carry out custom swiss screw machining or cnc milling turning without setting them every time.

- Reduced Waste: Scrap minimizing – Swiss machining, which means that once the bar enters the machine, it’s used all the way through to the end. It is especially useful in running small metal parts and reducing material waste.

- Automated Operations: Swiss screw machine shops have automated their operations. It ensures Higher consistency and less human error in the production without requiring human labor. For high volume projects like custom swiss parts, this is ideal.

Cons of Swiss Machining

- High Initial Investment: Swiss machines can be expensive to purchase and maintain. If you’re a small parts manufacturer only just getting started, the cost may seem prohibitive. Once running though, the machine provides long term cost advantages.

- Limited to Small Parts: For really small parts, Swiss machining is great, but not so for large items. You may put it on traditional screw machine shop or other means for big parts in your production.

- Complex Setup: Setting up a swiss machine can be time consuming, especially if it includes special parts that are also needed to be machined. Skill is needed to set up the machine to make specific screw machine products and there is a learning curve for operators.

- Material Restrictions: While Swiss machines can machine many different materials, some of the more exotic or harder materials can be more difficult to machine. First, you have to figure out whether or not your materials are compatible with swiss machining.

- Limited Flexibility for Complex Designs: Extremely precise parts can be produced in Swiss machining, but the complexity of defining the shape it might not be able to do. Small parts cnc machining is a better option if a high degree of customization or intricate part features are required.

DFM for Swiss Screw Machine Parts

Swiss Screw Machine Parts DFM

Among the few partners to offer Design for Manufacturing (DFM) service with specialization in CNC Swiss Machining and CNC 3, 4, and 5 axis machining. Whether you are new to the processes or struggling with existing designs, we can help you in optimizing your processes in CNC Swiss machining. Our team of experts works with us to develop cost effective and efficient designs without losing precision and quality.

We offer a range of DFM services tailored to your needs, including:

Component Design: We promise to help you make great components that are all turned and milled and are all precise and of high quality, and are sure to be easy to work with and yield reliable results.

Design Evaluation: Our experts save you time and money by ensuring that your designs are suitable for manufacturing processes.

Correct Material Selection: Your product specs and standards become a benchmark to follow in your selection and use of the right materials that will withstand the wear and tear, durability and strength, and cost effectiveness of your product.

Cost Analysis: We’ll do a thorough cost analysis to help you understand the manufacturing costs in total as well as what can be saved in the production process.

Rapid Prototype Manufacturing: With our rapid manufacturing services, you’ll get your prototypes quickly. It lets you test and refine designs before committing to full scale production.

Testing and Validation: Validation and testing ensure your designs meet industry standards and run per designed specs.

Masion has the experience to do this if you are looking for custom Swiss screw machining, custom parts like small parts machining, or service you need are custom swiss parts and swiss screw machine parts. Swiss machine shops count on us as a reliable partner for screw machine products. You can ensure your designs fit into the screw machining process as neatly as possible and that your production is efficient and accurate.

Why Choose Us for Your Swiss Machine Parts

When you choose Masion you are actually choosing a reliable partner that features strong commitment to reliability, precision and quality. The key things you need to keep in mind are:

Strong Quality Management

Each of out product passes through a strict quality ensurance system. By using our systems you can eliminate experiencing defective and lower quality parts.

Design and DFM Support

The DFM support from Masion ensures produced parts served effectively and efficiently. Apart Masion keeps the costs under the economical broders and just as per your desired specs.

Big Projects Support

Masion has already worked with market reputable companies including Tesla, Novel, Huawei, etc. No matter if you need the smaller components or the larger components, you can do so with Masion built-in capacities and capabilities.

Material Variety and Dia

Masion offer a wide variety of materials to fuse into your products such as:

- Brass, Copper, Aluminum, Bronze, etc.

- You can get your parts designed in Special alloys, stainless steel, and even higher temperature alloys with dia ranging from 1mm up to 45mm.

Comprehensive Processing

You can get more than CNC swiss machining services at Masion. Some of the key services includes Grinding, CNC milling.CNC turning,CNC mill &turn, Cleaning, Surface Finishing, and more. Collectively all of these services ensure the high end quality in parts.

Modern Swiss Lathes

High end precision and reliability enable you to harness quality products at Masion. You can experience the parts with tight tolerances ranging from ±0.003mm up to ±0.001mm. All thanks to the latest and up to date machine collection.

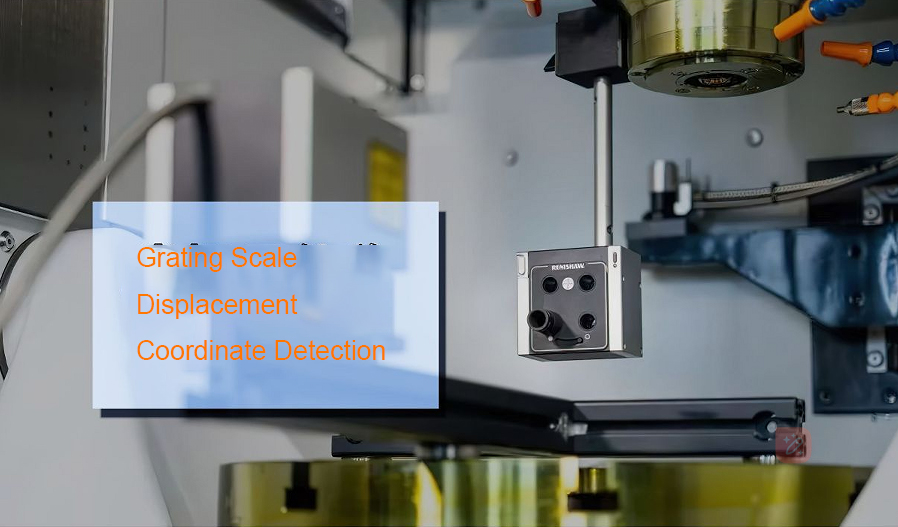

Automated Test Equipments

You can use fully automatic testing quipment. This will eventually ensure that you will get swiss screw machining projects that are exactly as per standard compliance.

Swiss Machining Tolerance

Small, complex parts require precision and therefore Swiss machining tolerance is needed. Here’s an overview of key tolerance types to consider when working with a Swiss machine shop:

Diameter Tolerance: For example, Swiss machining also involves extremely tight diameter tolerance, like ±0.002mm, which requires components in the medical device and electronics industries to dial out perfectly in assemblies. The accuracy of diameter measurement on CNC milling turning is quite high.

Concentricity: This refers to how well the center of one feature touches another, and the particular case is called the concentrically toleranced feature or concentricity rule of tolerance. Now, for custom Swiss screw machining, this tolerance will normally be on the order of 0.002 mm or less in the case of very high precision applications. It ensures that when parts are joined they will spin, and not stick. This can be done easily in a Swiss screw machine shop.

Surface Roughness: Part performance and appearance depend on surface roughness. Thus, generally speaking, surface roughness tolerances are 0.2 µm to 0.8 µm. In critical applications for Swiss machine parts, these smooth finishes are essential for reducing friction and wear.

Length Size Tolerance: Swiss machining is good for length tolerance of ±0.002 mm but uniform small metal parts manufacturing is essential.

Angle Accuracy: For parts that have specific angles like Gears and Brackets, angle accuracy is important. Tolerances are usually run within ±0.1° to ±0.2°. This level of accuracy can be achieved through small parts CNC machining.

Thread Machining Accuracy: Screw thread machining allows a tolerance of ± 0.01 mm. This is important for screw machine parts manufacturers that make threaded parts.

Positioning Accuracy: Its ability to move features at very close tolerances. Plus or minus 0.01 mm is the tolerances. Next, it is important for parts like these custom Swiss parts which have to be placed in assemblies at the assembly line, where the part must be put in a certain spot.

Swiss Machining Quality Control

In Swiss Machining, small parts manufacturing and other industries that deal with quality control, using the right equipment is necessary because it will dictate the level of precision of your work. Here’s how various tools can help:

X-Ray Material Tester: It scans internal structures to check for material integrity. The precision of material is usually within ±0.01 mm tolerance, required for custom swiss screw machining and swiss screw machine parts.

Industrial Microscope: With a tolerance of ±0.002 mm, this is important when inspecting the small parts machining of your custom swiss parts to maintain precision.

Digital Projector: If you produce small metal parts, it projects accurate contours of your parts. It has ±0.01 mm tolerance.

Optical Automatic Inspection Sorting Machine: It automates sorting of parts for screw machining services or swiss machine parts to a tolerance of ±0.005 mm, inspecting parts to verify they meet specifications.

Flash Measuring Instrument: It is a fast measurement tool, that can measure parts to a tolerance of ±0.005 mm, which is very useful for screw machine products and small part CNC machining.

Roundness Tester: It checks the roundness with a tolerance of ±0.001 mm for small parts manufacturer and swiss screw machine shop needs.

Mitutoyo Surface Roughness Tester: It can provide the surface finish precision of ±0.0005 mm needed by a manufacturer of screw machine parts.

Hardness Tester: It also ensures that the material hardness is precise and that the parts such as swiss screw machine parts meet the quality standards.

Concentricity Tester: Consequently, parts are aligned with a tolerance of ±0.001 mm for custom swiss parts and screw machine shops.

Pin Gauges: The specifications include a tolerance of ±0.002 mm on hole sizes.

Micrometer: This is a ±0.001 mm tolerance with applications in screw machining services.

Callipers: The tolerance of this is ±0.02mm. For accurate parts, they are necessary for small parts machining.

Our Certificates

At Maison, we are dedicated to delivering the finest in CNC Swiss machining. With over 21 years of experience in custom Swiss machining and manufacturing of Swiss custom parts of high precision. It means we are committed to quality, industry standards and customer satisfaction through our certifications.

In fact, we have the ability to proudly boast key certifications that bear testament to our adherence to strict guidelines in different industries. This means that we are always up against the highest standards when it comes to CNC milling turning and small parts manufacturing.

- ISO 9001 Quality Management System

- ISO14001 Environmental Management System Certification

- Automotive Industry Quality Management System (IATF 16949)

- RoHS Restriction of Hazardous Substances (Available Upon Request)

- SGS Products Test – These tests are conducted to check the quality and if it matches industrial standards.

- Conformity to European standards: Solemn quality in CNC Swiss machining is CE marking.

Explore our Swiss Screw Machine Products Gallery

Swiss Machine Parts

Swiss CNC Machining Part

Custom Swiss Machining

Custom Swiss Machining Parts

Custom Swiss Machine Parts

Custom Precision Transmission Shaft

Custom Long Shaft

Custom Eccentric Shaft

CNC Swiss Parts

Swiss Machine Products

Swiss Machining Industries

When you need high precision Swiss parts made in China, you can count on Masion for top quality custom Swiss screw machining. We do business in the manufacture of customized Swiss parts, CNC milling turning and also, if you require a specific shape, material or finish, we’ve got you covered. And if you have a design, our advanced Swiss machine shop can bring it to life.

Masion is a Swiss screw machine parts manufacturer specializing in custom parts with a focus on industries that require high precision and efficiency. The size of your project is not an issue, whether it is small, medium or large, we make sure the parts are crafted to work reliably and last longer.

We serve a variety of industries, including:

- Medical Industry

- Electronics Industry

- Automotive Industry

- Watchmaking Industry

- Telecommunications Industry

- Home Appliance Industry

- Robotics and Automation Equipment.

- Hardware, Industrial Parts

FAQs

What role will CNC milling play in Swiss machining?

Complex geometries can be efficiently machined using CNC milling turning. Nothing but a combination of turning or milling process which contribute to high end swiss screw machining.

Do you have the capacity to manufacture large quantities of high volume, small parts?

Yes, Masion a Swiss screw machine shop can provide automatic operations, and this makes them perfect to handle High Volume Production of screw machine products while maintaining precision.

What is the normal range of sizes for small parts machining?

Swiss machining excels in manufacturing intricate and precise components with outer diameters from 1mm to 45mm.

Why opt for a Swiss Screw shop over conventional machining methods?

You can get transform your small parts ideas into reality at Swiss screw machine shops. This is because it is not possible with the conventional machining shope. They even have tolerances as tight as ±0.003mm and they use advanced Swiss lathes to achieve it, ideal for intricate designs.

Are your Swiss machine shops involved in reverse engineering or creating custom designs?

Now most of the screw machining services are concentrated on making parts that have been specially moulded for your own needs to get the precise and reliable results that you envisage.

How do you ensure there’s as little waste involved in the process as possible?

The bar feeding process of Swiss machining is a cheap and environmentally friendly manufacturing route that cuts down on material waste.

Can you make any prototypes before full production?

Yes, series of screw machining services are able to offer rapid prototyping to get designs down to a fine point without committing to a scale of manufacturing for the sake of accuracy and customer satisfaction.