CNC Turning – Everything You Need to Know

With CNC turning playing a dominant role in modern day manufacturing especially when it comes to fabricating precise cylindrical parts across industries such as the automotive, aerospace and medical. In-depth knowledge of Computer Numerical Control Turning (its parts, parameters, materials, operations and tooling) is vital to engineers, machinists and decision makers. Mastering precision CNC turning helps you achieve unmatched efficiency and accuracy. This article will be your comprehensive guide on computerized Turning and will teach you everything from its historical evolution, machine types, best practices to common problems and more. Keep reading to explore!

Table of Contents

ToggleHistorical Development of CNC Turning

The historical evolution of CNC turning center technology mirrors your industry’s turn to precision and automation. The primitive manual lathes needed hand operation, which affected your accuracy and pace. Numerical control (NC) machines appeared in the 1940s–50s, and they used punch cards to automate tool paths.

You still had programming problems and lacked flexibility. The real breakthrough was with CNC – Computer Numerical Control. Through integration of computers, you acquired quicker, more consistent turning process. You could now depend on CAD/CAM software to program and integrate the design for real-time. The rise of CNC machinist brought greater automation, tighter tolerances, and enhanced productivity – changing how you machine parts and guaranteeing higher standards throughout manufacturing operations.

How CNC precision Turning Works – What is Turning?

CNC precision Turning is a subtractive manufacturing process in which raw material is shaped into final part using automated machines. You count on digital programming to achieve precision.

- Role of Computer Programming

The process starts with CAD (Computer-Aided Design) where one makes a digital representation of the part. Next, CAM (computer-aided manufacturing) software will turn your design into a machining strategy. Finally, the system produces G-code – which are the precise instructions that your CNC lathe machine will follow. You enter this code into the controller to control every movement.

- Key Components Involved

You should know the components of the machine to work efficiently. As a CNC turner, you rely on the chuck to clamp your workpiece firmly in place. The spindle spins it so fast that the tools can shape the material. Equipment is attached to the turret that shifts between them when necessary. Additional support is provided by the tool post. At the center of it all is the CNC controller which processes the G-code and controls all processes.

- CNC turning Process Overview

First, you put the material into the chuck. Next, you create the toolpath using your G-code. When you turn the machine on, it cuts as provided. During the process, you monitor the operation and make real-time correction to maintain quality and accuracy.

Computer Controlled Turning Operations

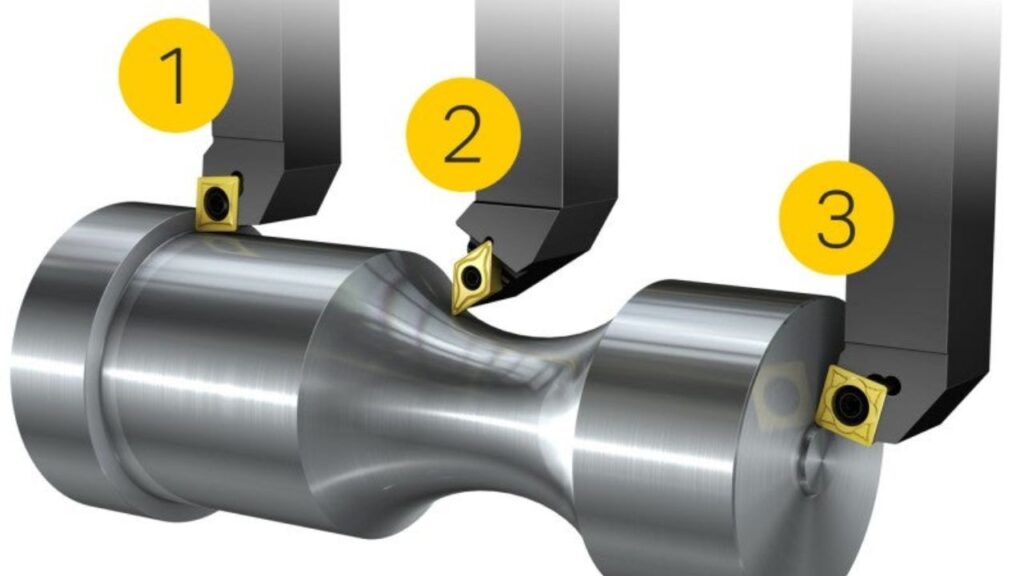

A. External Operations

CNC turning concerns the forming of the external faces of cylindrical workpieces. Such operations are of great importance when you wish to design accurate and functional parts for industries such as automotive, aerospace, and manufacturing. This is how each operation works and when you should use it.

- Turning

You employ general turning to form the outside diameter of a rotating piece. This is perfect for shafts, rods and bushings. The cutting tool travels over the entire length of the part, shaving away material uniformly to deliver a smooth accurate finish. It is the basic step for most turning processes.

- Hard Turning

Hard turning is done when the material you are working on is hardened to 45 HRC or above. It is an effective substitute to grinding. With the proper tooling and machine stability, you can hold tight tolerances and high surface finishes which is perfect for hardened steel gearing or bearing parts.

- Taper Turning

Taper turning enables you to make conical shapes. You will most of the time use this on automotive and piping systems where the tapered ends make for better alignment or sealing. You can change the compound rest of the lathe or use programmed angles to control the taper precisely.

- Facing

Facing produces a flat surface at the end of the piece. It’s the operation you call in if you need a purged and perpendicular surface, start of drilling or assembled face.

- Grooving

Grooving is a process in which narrow recesses are made on the outer diameter of the workpiece. This will be helpful when making slots for O-rings, retaining rings, or shoulders. Here, precision is very important, particularly in fluid or pressure-sealed applications.

6. Parting/Cut-Off

Parting is your last instruction when you want to separate the finished piece from the bar stock. It utilizes a thin cutting tool that slices through the material without splinters. You need to check proper tool alignment and feed rates so that you can prevent deflection or burrs during cut-off.

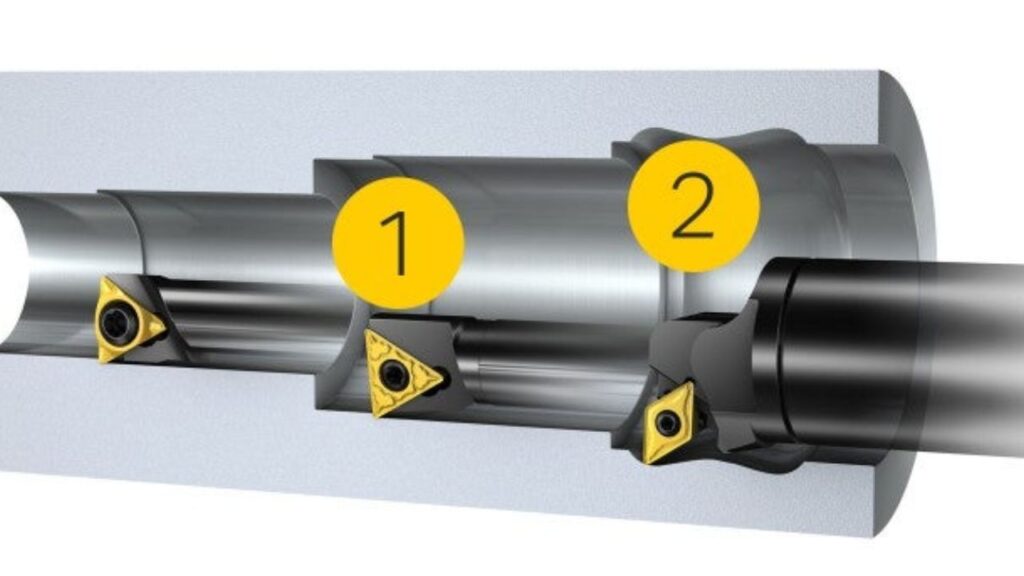

B. Internal Operations

- Drilling

Drilling is a method of producing new holes in the turning workpiece. It’s an essential operation for components with perfect hole placements. You can vary drilling depth and diameter in accordance with design specifications.

- Boring

Boring is the process of elaborating/pushing by enlarging and finishing already present holes. You use it to fine-tune your hole sizes after drilling to achieve a smoother more accurate result. Boring is very important when meeting tight tolerances.

- Threading

Threading creates exact internal and external threads on the work piece. You’ll use threading for producing screw threads; these are indispensable for fastening and assembling. CNC lathes are accurate in the thread pitch and depth.

- Knurling

Knurling gives patterns to the working surface for better grip or looks. It’s widely used on handles or knobs for a non-slip surface. This process also brings peculiar texture in parts.

- Reaming

Reaming smoothes and sizes drilled holes to finish them finer. This operation guarantees that the hole’s diameter will be within the given tolerance range. Reaming is important part of the process for parts that require a high quality surface condition and accurate sizing.

Types of CNC Turning Machines

Horizontal CNC Lathes

Horizontal CNC lathes are ideal for manufacturing cylindrical and middle-sized parts. These lathes have the spindle horizontally placed which makes them ideal for precision work. They are commonly used in aerospace, automotive and electronics industries.

CNC horizontal lathes provide high precision resulting in tight tolerances and fine details. They are multi-purpose and can machine various materials, from metals to plastics. The capability of producing less waste in terms of material is a significant advantage, making them appropriate for large volume production. (If your requirement is a machine that can cope with high-volume work this is a good option). If your requirement is a machine that can efficiently produce CNC turned parts with tight tolerance, this is a good option.

Prices for horizontal CNC lathes usually start from $30,000 and go up to $150,000, depending on the model and the features.

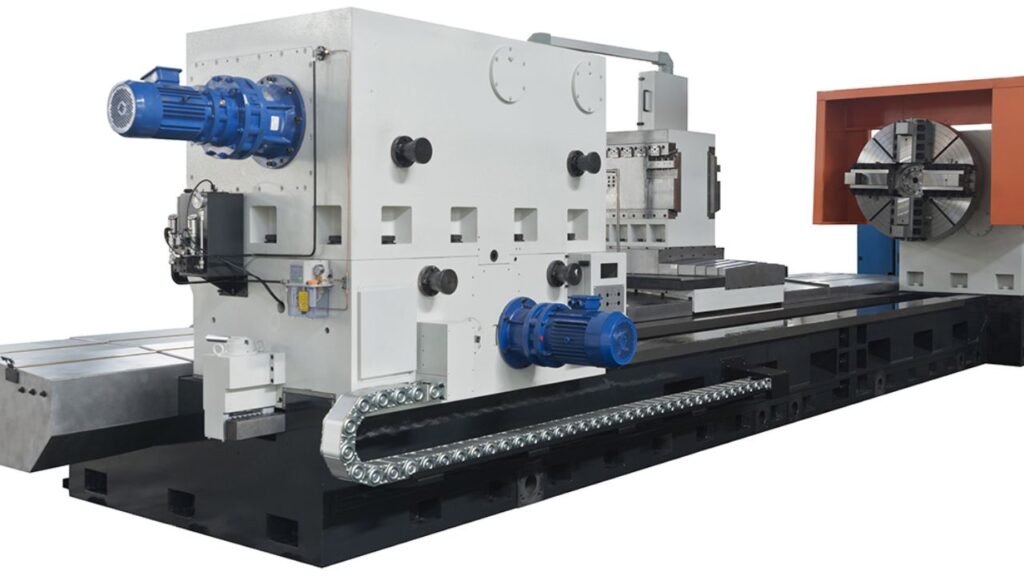

Vertical CNC Lathes

Vertical CNC Turning lathes are ideal for heavy and large diameter workpieces with excellent load capacity. Their spindle that stands vertically gives them additional stability while handling heavy components. These lathes are widely used in marine, wind energy, and heavy machinery industries.

The main benefit of the vertical type CNC lathes is their ergonomic design that facilitates the operators to reach and manipulate the big parts easier. They also have heavy-duty characteristics, guaranteeing accuracy even on large material sizes. If you want a machine, which can deal easily with big and heavy pieces, a vertical CNC lathe is the best choice. These machines come at a price of $40,000 to $200,000.

Horizontal Turning Centers

Horizontal turning centers integrate turning, milling, drilling and tapping, providing a flexible solution for complex parts manufacture. They are perfect for custom mechanical assemblies and tools, where multitasking is required.

What distinguishes horizontal turning centers is their capability of handling different processes turning milling operations included—in a single setup thus reducing setup time and increasing productivity. They offer flexibility for design change, meaning you can adjust easily to other specifications. Priced between $50,000 and $250,000 these machines offer great value to businesses seeking versatility.

Vertical Turning Centers

Vertical turning centers refer to special machines that combine high-precision turning, milling, and drilling in a single compact form. These CNC milling turning systems excel at handling complex geometries and are widely used in research and development, architectural parts and aerospace engines.

Their tiny footprint recommends them for spaces with limited room, while their ability to create complex parts with tight tolerances makes them irreplaceable for high-precision industries. Vertical turning centers can make all the difference when handling complicated designs or when floor space is at a premium. Be prepared to invest between $60,000 and $300,000 in one of these high-tech machines.

Common CNC Turning Tooling Types

1. Turning Tools

Turning tools are required for the formation of external work pieces. These tools are mostly produced from HSS (High-Speed Steel) or carbide which are more durable and accurate. You will use them to produce parts with a high degree of precision in the form of cylinders.

2. Boring Bars

Boring bars are used for internal diameter finish of the workpiece. They help in widening and running down pre-existing holes so that perfect finishes and correct dimensions are attained. Their work is necessary for accurate internal machining.

3. Parting Blades

Parting blades make sure that finished parts will be separated from the stock hence minimizing wastage of materials. Such blades are very important in dividing work pieces and making clean cuts without compromising quality of the work piece.

4. Thread Cutting Tools

Thread cutting tools generate screw compatible threads on internal and external surfaces. They are necessary for works that require threaded holes, enabling compatibility and functionality of mechanical assemblies.

5. Knurling Tools

Engraving surface patterns for a grip or for aesthetics uses tools for knurling. These patterns improve the functions of the workpiece commonly seen in handles or shafts where better finger grip is necessary.

6. Drilling Bits

Drilling bits are utilized in forming cylindrical holes in the work piece. You will need to use them often for secondary operations including precise hole making and alignment.

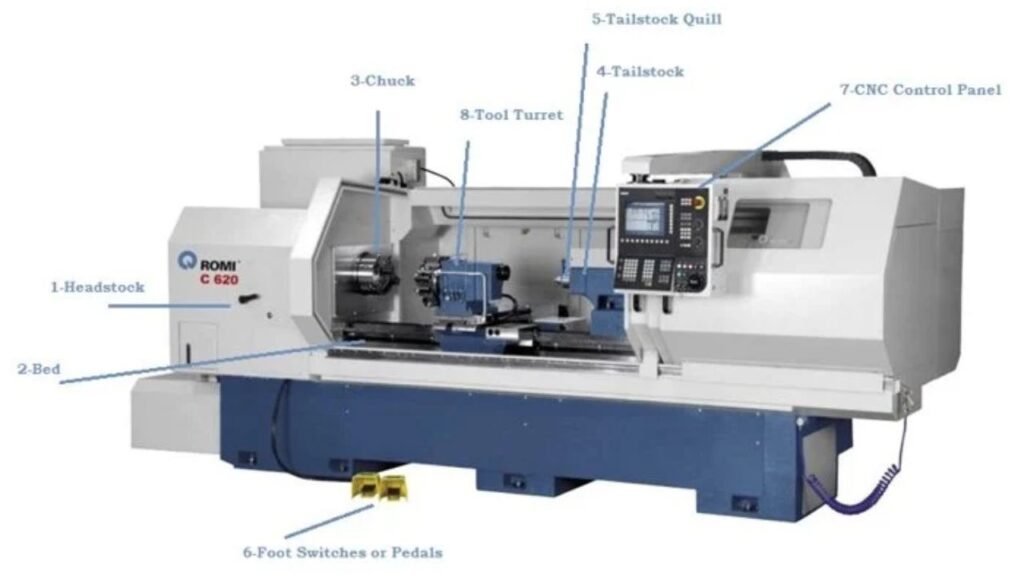

Essential Components of a CNC Turning Machine

The CNC turning and milling machine contains several vital parts for precision manufacturing.

CNC Control Panel

The CNC control panel is the hub of the machine. It accepts instructions, controls programs, and controls the accuracy and speed of movement. It is essential for repeatability and uniformity throughout the production, and parts are created according to their specifications.

Spindles

Spindles support workpiece during machining and rotate it. The speed control over the spindle impacts cutting performance and is crucial for dimensional accuracy. Correct spindle operation is responsible for the quality of finishing your parts with.

Headstocks and Tailstocks

The headstock is where there is rotational power and support to the workpiece and the tailstock is where there is adjustable support with special focus on long ones. Both help in making the machine stable while machining, thus making the cuts much precise.

Tool Turret

The tool turret has several cutting tools and has a feature of automatic tool change for multi-step machining. This increases productivity and minimizes manual intervention, which helps you to achieve faster and more efficient processes.

Chuck and Collet

The chuck can hold workpieces of any shape and size and the collet provides a firm grip to smaller fragile parts. Both of these ensure you have a secure hold of your workpiece during machining.

Lathe Bed

The lathe bed is the base of the machine. It sustains key elements including the headstock, tailstock, and carriage; it offers rigidity, which eliminates vibration and precision during the operations.

Carriage

The carriage governs the movement of the cutting tool. It has the saddle, the cross-slide and the tool post which enables you to shape your parts with controlled movements.

Key Parameters in CNC Turning

| Sr. No. | Parameter | Description | Impact on Operation |

| 1 | Cutting Speed | The speed at which the cutting tool engages the workpiece. | Determines the efficiency of the cut, surface finish, tool life, and heat generation. |

| 2 | Feed Rate | The rate at which the workpiece is fed to the cutting tool. | Crucial for controlling the rate of material removal, surface finish, and chip thickness. |

| 3 | Depth of Cut | How deep the cutting tool penetrates into the material. | Impacts the volume of material removed per pass, the final shape of the part, and the surface finish. |

| 4 | Tool Geometry | The shape and size of the cutting tool. | Influences the type of cuts possible (roughing, finishing, threading, etc.) and the resulting surface finish. |

| 5 | Workpiece Material | The type of material being machined (e.g., steel, aluminum, plastic). | Dictates the appropriate cutting speeds, feed rates, depth of cut, tool material, and coolant requirements. |

| 6 | Coolant Flow | The rate and method of coolant application to the cutting zone. | Essential for dissipating heat, lubricating the cutting action, flushing away chips, and extending tool life. |

| 7 | Spindle Speed | The rotational speed of the spindle (holding the workpiece or tool). | Plays a key role in determining the cutting speed based on the workpiece diameter. Affects surface finish and cutting forces. |

| 8 | Tool Material | The material composition of the cutting tool (e.g., high-speed steel, carbide). | Determines the tool’s hardness, wear resistance, heat resistance, and suitability for machining different workpiece materials. |

| 9 | Chip Control | The management and evacuation of chips produced during cutting. | Essential for maintaining a clean cutting zone, preventing damage to the workpiece and tool, and ensuring operator safety. |

| 10 | Machine Rigidity | The stiffness and stability of the CNC turning machine. | Affects the machine’s ability to handle different cutting forces and materials without vibration or deflection, which can impact accuracy and surface finish. |

| 11 | Tolerance Levels | The permissible variation in the dimensions and features of the machined part. | Represents the required precision and accuracy of the CNC turning process and influences the selection of parameters and machine capabilities. |

Advantages and Disadvantages of CNC Turning

- Advantages

CNC turning provides high level of precision and repeatability. It can count on producing the same parts over large run sizes. With rapid production, you’ll save time while machining several components. You can work with a wide variety of materials in computer-controlled turning starting from metals to plastics to offer you flexibility in manufacturing. You also receive quality consistency that helps to keep to product standards and minimize scrap.

2. Disadvantages

Nonetheless, CNC lathe machining has some downsides. You will incur a high initial cost of machines and setup. It is most convenient at machining cylindrical or symmetric parts, so your design options are not very diverse. Operation and maintenance of these machines also require skilled staff. You’ll need a CNC machinist with programming expertise and technical knowledge to facilitate a smooth and error-free process.

Key Design Considerations for CNC Turning

Cutting Speed

Balance between machine tool life and material finish has to be maintained when setting cutting speed. A too high speed may lead to an early wear of the tool, and a too slow speed maybe have an impact on the surface quality. For a CNC turner, maintaining this efficiency in speed guarantees smooth finish and increases the life span of the tool.

Feed Rate

The feed rate has a direct influence on both the surface roughness and the material removal rate. If you decide to use a larger feed rate, the material removal rate is improved, but the surface finish may become rougher. Tuning feed rate according to your desired finish is of utmost importance for making the right balance.

Raw Material Choice

Your choice of material for workpiece has a direct influence on the machinability and performance of the finished part. Softer materials are softer to machine and harder materials need more precise adjustment. Continuing with the right material you guarantee both the desired function and the efficiency of the machining of your part.

Materials Best Suited for Precision CNC turning

| Sr. No. | Material | Key Properties | Common Applications |

| 1 | Steel | Strong, durable, high tensile strength, wear-resistant | Gears, shafts, fasteners, load-bearing components |

| 2 | Aluminum | Lightweight, corrosion-resistant, good machinability, high strength-to-weight ratio | Aerospace components, automotive parts, housings, heat sinks |

| 3 | Brass | Excellent machinability, good corrosion resistance, good electrical conductivity | Fittings, valves, bushings, decorative hardware |

| 4 | Copper | High electrical and thermal conductivity, good corrosion resistance, ductile | Electrical connectors, heat exchangers, plumbing components |

| 5 | Plastics | Cost-effective, lightweight, good chemical resistance, versatile | Prototypes, low-load structural parts, housings, gears |

Precision CNC turning ensures these materials meet strict standards for mechanical parts.

How to Choose the Right CNC Turning parts Service?

Choose a provider with proven experience in CNC turning parts manufacturing, and be keen on several factors to ensure the best results and match your own needs

Experience and Expertise

Find a provider with a track record. These professionals bring special knowledge and skills to deal with complicated projects, and that means precision and consistency.

Quality Assurance

Ensure quality control of the service is followed strictly. Regular quality controls during production guarantee that each part will meet your standards.

Capacity and Capability

Make sure that the provider can support the size and complexity of your project. No matter whether it is a high-volume or complex parts, they should possess the required tools and resources.

Turnaround Time

Check their ability to adhere to deadlines. A respectable CNC lathe machining service must not sacrifice quality for schedule integrity. Always check references or reviews on their timeliness.

What are the Common Problems in CNC Turning?

| Sr. No. | Problem Area | Description | Impact |

| 1 | Tool Wear or Breakage | Gradual wearing down or sudden fracturing of the cutting tool. | Affects precision and part quality, causing unexpected downtime. |

| 2 | Surface Finish Issues | Poor texture or irregularities on the machined surface. | Can result in parts being rejected or requiring rework. |

| 3 | Dimensional Inaccuracies | Parts not meeting the specified measurements. | Impact usability and functionality of the part. |

| 4 | Chatter and Vibrations | Unwanted oscillations between the tool and workpiece. | Reduces tool life and affects part quality. |

| 5 | Material Deformation | Changes in the shape or form of the material during or after machining. | Can be caused by improper tooling or incorrect machine settings. |

| 6 | Chip Management Problems | Issues with the formation, evacuation, or disposal of machining chips. | Can lead to machine damage and affect part quality. |

| 7 | Programming Errors | Mistakes in the CNC program code. | Incorrect machining paths can cause material waste and defects. |

| 8 | Coolant Issues | Problems with the supply, type, or condition of the cutting fluid. | Can negatively impact tool life and part finish. |

| 9 | Mechanical Failures | Malfunctioning of mechanical components within the CNC machine. | Potential downtime from parts malfunctioning. |

| 10 | Electrical Issues | Problems with the electrical system of the CNC machine. | Can lead to operational halts and costly repairs. |

| 11 | Operator Errors | Mistakes made by the machine operator during setup or operation. | Can cause accidents, defects, or production delays. |

What Are the Essential Safety Measures and Best Practices in CNC Turning?

Regular Maintenance

Regular maintenance is important for both the longevity and safe operation of CNC machines. You have to do scheduled checks, such as cleaning and lubrication, to prevent breakdowns and guarantee that all parts work well. Regular upkeep of your machine turning components minimises the risk of malfunctions that may cause accidents.

Proper Training

Your operators should be properly trained in operating the machine and safety procedures. With no training, there are greater chances of making errors or accidents. It is important that everyone handling the machine knows how it works and how to use it safely.

Use of Protective Equipment

Protective gear is vital for protecting operators against accidents. CNC machines require that one wears personal protective equipment (PPE) such as gloves, goggles, and hearing protection at all times. PPE helps prevent you from getting hit by flying debris and sharp tools, as well as the loud noise.

Conclusion

Finally, CNC turning is a popular and indispensable process of modern manufacturing as it allows to gain accuracy, to be productive and to be flexible in industries like aerospace, automotive and medical. Knowing the basic components, operations, and parameters of computer-controlled turning, a person can get the maximum from the production and the best quality outcome. The problems associated with high initial cost and need for skilled operators, the benefits of CNC lathe work—including repeatability, speed and consistency ensure it is a useful tool in producing intricate high precision components. You can increase your manufacturing capabilities by adopting precision CNC turning and milling machines for versatile and efficient machining.