Precision Contact Pin Company In China

Specialized Contact Pin Manufacturing For 21 Years.

- More than 100+ CNC turning machines, 75+ Swiss CNC lathes, 50+ automatic lathes, and a skilled workforce of 125 people.

- Machining tolerance can reach up to ±0.007 mm for high-precision components.

- Certified with ISO9001 and ISO16949 quality management standards.

Contact Pin Manufacturer Experts in China

CNCSwissMasion is one of the reliable contacts pin manufacturer specialists in China, which provides global industries with accurate solutions. Based on a 5,000-meter premise, the company manufactures high-quality automotive, telecommunication, aerospace, industrial, and medical applications contact pins. These pins carry power, signal and electro-mechanical functions. CNCSwissMasion requires brass, pure copper and phosphor bronze with gold or tin plating to guarantee reliability, conductivity and dependability in a variety of connector assemblies.

Contact Pin Machining Service

CNCSwissMasion offers high-quality and precision contact pin machining services that are oriented towards precision, durability, and electrical reliability. The company manufactures high-tolerance contact pins using Swiss CNC machines, automatic lathes, and multi-axis turn-mill centers, made of brass, copper, phosphor bronze, and stainless steel. Close dimensional regulation provides uniform fit and conductivity. Nickel, gold, silver, tin and palladium plating surface finishes enhance corrosion protection, signal stability and long-term performance in demanding applications.

Materials

- H59-1

- H58-1

- H62

- C37700

- C36000

- C68700

- C69300

- CW721R

- BeCu

- Phosphor Bronze

- Cu-Ni-Si

- Silver

- Gold

- Palladium

Machines

- Automatic CNC Lathe

- CNC turning machine

- Swiss CNC lathe

- CNC turn&mill machine

Surface Finish

- Nickle Plating

- Golden Plating

- Silver Plating

- Tin Plating

- Palladium Plating

What is a Contact Pin?

A contact pin is an electrical connector element that is used to pass power or signals between devices. It is commonly made of crimp terminals so that when space is limited or soldering is hard, it can be easily used. Contact pins are modular, which means that they can be easily replaced or reused. They adopt different standards and can be linked directly to circuit boards. Ordinary materials are brass, pure copper and phosphor bronze, gold- or tin-plated.

Contact Pin Manufacturing Process

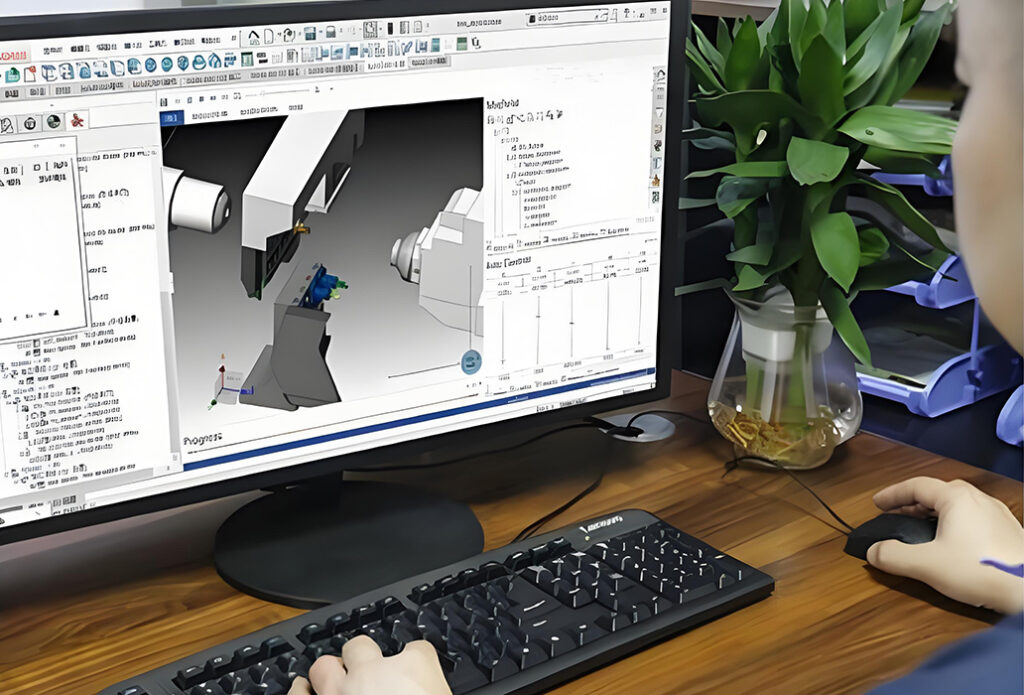

Step 1: Application review and design planning

It starts by a thorough evaluation of your application needs, such as electrical load, type of signal, mating cycles, and installation environment. Engineers consider connector design limitations to make sure that they fit with assemblies and perform optimally. The last design establishes pin geometry, dimensions, tolerances and mechanical properties. This is to confirm that every contact pin is both functional and industry standard.

Step 2: Material selection

Materials like phosphor bronze, pure copper or stainless steel are highly-performance materials selected with care according to the application requirements. Such factors as electrical conductivity, mechanical strength, flexibility and resistance to wear and fatigue are taken into consideration. The quality and endurance of the contact pin is directly influenced by the material employed in any application where it is used harshly or with high repetition. CNCSwissMasion guarantees that every batch of material can be traced and checked in terms of quality prior to production.

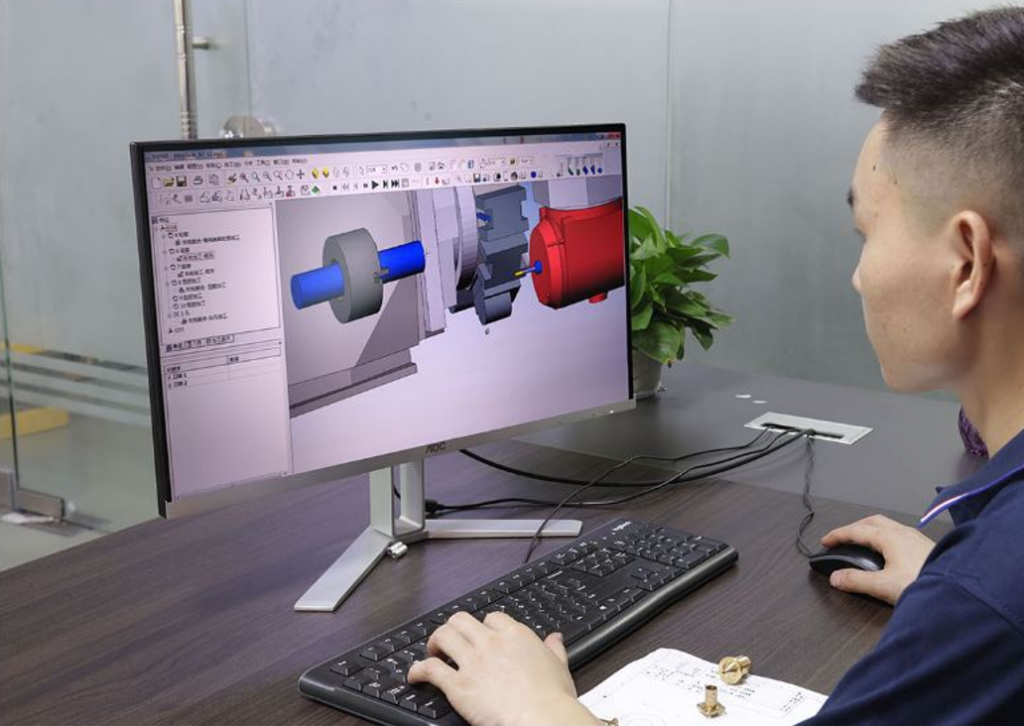

Step 3: Precision CNC machining

Advanced Swiss CNC lathes, automatic lathes and multi-axis turn mill centers are used to mold selected raw materials into contact pins. This machining process prevents errors in size, tip geometry, and contact characteristics to provide reliable connection. Close tolerances are also used to ensure uniform performance in high density connector assemblies. Complex designs and intricate features can also be made with complex designs through CNC machining and can meet the demands of modern electronics.

Step 4: Deburring and surface preparation

Machined pins are treated to eliminate burrs, sharp edges and irregularities on surfaces. This action provides even contact points, which minimize wear and friction when the mating occurs repeatedly. Surface preparation enhances adhesion to be used later in plating and avoids defects that might affect electrical performance.

Step 5: Electroplating and surface treatment

Pins are usually plated with gold, nickel, silver, tin, or palladium to enhance the conductivity of electricity and prevent corrosion. The plating is strictly controlled in terms of thickness and uniformity, with reference to the requirements of performance. Treatment of surfaces also ensures maximum mating performance, reduced contact resistance and resistance in a wide range of environments. CNCSwissMasion has strict quality checks which guarantee that the quality of the plating is the same in each batch.

Step 6: Dimensional and electrical inspection

Inspection probe is used to check all contact pins and critical dimensions, tip geometry and surface finish. Conductivity, load resistance and performance are established through electrical tests. The step will ensure consistency of quality, proper fit, and a reliable exchange of signals or power. The defective pins are either scrapped off or redid to ensure high quality standards are observed.

Step 7: Final quality control and packaging

A final quality control check is done on finished contact pins to ensure that they are compliant with specifications and standards. The pins are then washed and categorized and then packed in preservation materials to prevent contamination or demise. The packaging has been designed in a manner that it can be easily handled in the assembly and transportation process. CNCSwissMasion stipulates that no batch of any quantity is deployed to the world without being ready to be incorporated into connector assemblies.

Contact Pin Advantages and Disadvantages

Advantages

- Precise electrical links in transmission of power, signal and data among devices.

- Allows modularity, which easily replaces, or reuses without requiring soldering or complete assembly adjustments.

- Has high precision and tight tolerances, making it mate with consistency and stable.

- Can be gold plated, nickel plated, tin plated or palladium plated to ensure corrosion resistance and long life cycle.

- Flexible designs are able to fit into various connector types, cable sizes, and industrial applications.

Disadvantages

- Should be carefully chosen in terms of material and plating to avoid wear or indicator of material deterioration with time.

- Possibly costly compared to bare wire connection because of accurate machining and plating operation.

- Restricted to certain current and voltage values; inappropriate choice may influence performance in high-power applications..

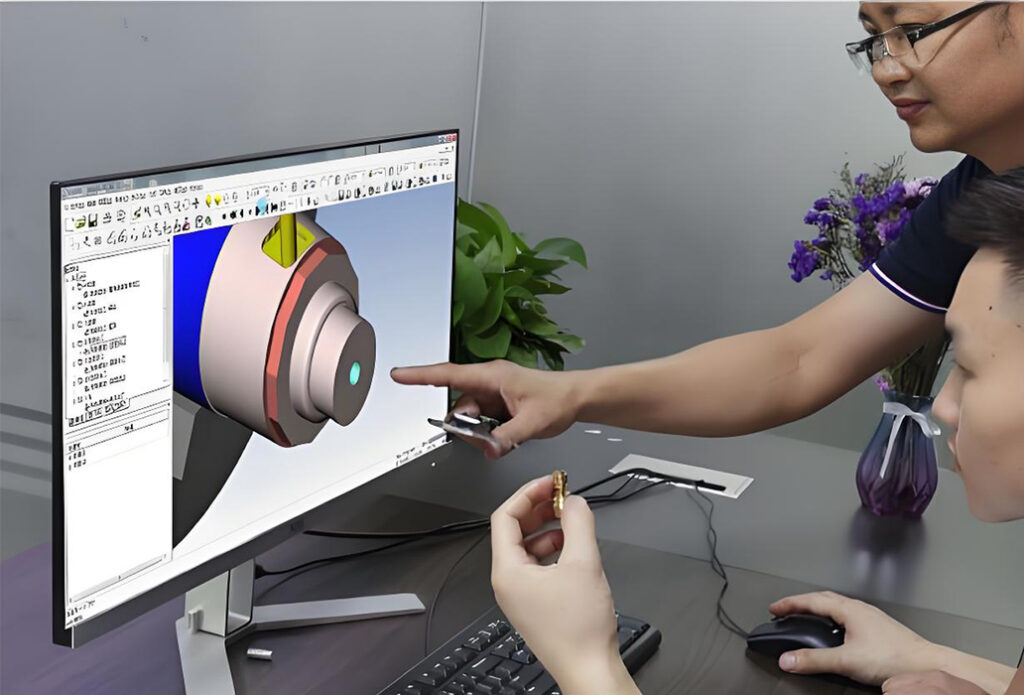

DFM For Custom Contact Pin

CNCSwissMasion provides Design for Manufacturing (DFM) services on custom contact pins, with a long history of experience in Swiss CNC machining, automatic lathes, and multi-axis turn-mill centers. Our engineering team assists in simplifying designs to make the optimal combination of performance, manufacturability and cost-effectiveness without sacrificing precision or reliability whether you are designing new contact pin designs or optimizing an existing design.

Contact Pin Component Design

Our experts assist in designing high-precision contact pins which include crimp terminals, plug-type pins, and modular connectors. Our mechanical performance is very good, and electrical contact is dependable with a long service life, but there is no compromise in manufacturing processes, and they can be easily scaled.

Design Evaluation

Your contact pin designs are inspected and made compatible with Swiss CNC machining and automated production methods. This evaluation would minimize risk, minimize potential re-work and prevent production process delays.

Material Selection

We recommend the suitability of material to be used which can be brass, pure copper, phosphor bronze or stainless steel depending on the electrical, mechanical and environmental specifications. Proper selection of material will ensure durability, conductivity, flexibility and cost effectiveness.

Cost Analysis

Cost analysis will show that there is an opportunity to reduce cost of machining, plating and assembly without losing functionality. We help to rationalize the production processes on a high level of quality.

Rapid Prototyping

CNCSwissMasion cn offer rapid prototyping to check contact pin designs. The prototypes are tested and perfected and modifications can be made before the entire scale production.

Testing and Validation

Every contact pin design is confirmed by dimensional checks and functional checks to satisfy industry standards and special needs of a given application. Conductivity, mechanical fit and surface quality is also analyzed to guarantee quality performance.

CNCSwissMasion has a long history of experience in machining custom contact pins, high-precision parts, and large-volume manufacturing and is the right choice when OEMs and electronics manufacturers need a single vendor to collaborate with. The designs of our DFM services are optimized to a high-performing manufacturing process, accurate tolerances, and scaled production to achieve performance and reliability demands on each contact pin.

Our Machines for Contact Pins

Swiss CNC Lathe

Our Swiss CNC lathes are used to produce high-precision and complex contact pins with the highest accuracy at CNCSwissMasion. These machines are capable of tight tolerances and high surface finishes, synchronized slides, live tooling and automatic bar feeding. The advantages are minimal waste of material, uniformity of part quality and efficiency in large volumes. Even the tiniest and the most delicate pins are very accurate in their size, and they are dependable in terms of critical electrical and mechanical usage.

Auto CNC Lathe

Auto CNC lathes are used to automate turning tasks to make contact pins efficiently and consistently. They suit medium to high production batches. The main characteristics are multi-axis control, automatic tool changers, and programmable machining sequences. This automation saves time taken to complete a cycle, lessens human resources, guarantees homogeneity of a batch to another batch, and allows the efficient utilization of materials. Complex pin geometries are also available and can be produced in a reliable and high productivity way.

Cam Lathe

Repeat contact pin design mechanical precision needs Cam lathes at CNCSwissMasion are excellent. They have variable cutting speeds, cam-driven profiles, and repeatable operations which enable them to run long production runs with minimum adjustment. The benefits are low maintenance, high accuracy, and low cost of production. These lathes make standardized, high quality contact pins at a fast rate and they fit well in large volume applications without affecting the performance.

Why Choose us for Contact Pin

Selecting the right partner to produce contact pin is the most important in the success of your project. CNCSwissMasion is not merely a machining service, but an ally that is concerned with precision, quality and efficiency. Everything in our manufacturing is directed to the delivery of quality and high performance contact pins. It is this dedication that has seen CNCSwissMasion become a trusted partner to OEMs and electronic manufacturers around the world.

Strong Quality Management

CNCSwissMasion embraces high quality control during the manufacturing process of the contact pins. Automated inspection and precise measurements are used to provide tight tolerances, consistent electrical operation, and consistent mechanical fit. Our quality systems have prevented the delivery of defective parts to our production lines, which have delivered quality pins to use in automotive, aerospace, telecommunications and industrial electronics.

Design and DFM Support

Our Design for Manufacturability (DFM) offering would help optimize your contact pin designs. The engineers will give you recommendations on tolerances, material, geometry and assembly considerations to make your designs workable, manufacturable and cost-effective. This ensures that components are produced to specification and are within budget.

Capacity for Large and Complex Projects

CNCSwissMasion supports both large volumes and small precision production, complex geometries and complex assemblies. Together with the large global companies, we work to offer solutions that can be integrated into strict deadlines and extremely high technical requirements. The machinery is state-of-the-art and the employees are well trained to handle big-scale and technical projects.

Wide Material Options and Sizes

We make our contact pins out of a broad range of materials that include:

- Brass, copper, phosphor bronze and aluminum.

- Stainless steel, special alloys and high-temperature alloys.

The pins of various diameters (1mm to 45mm) can be made with the following properties; high conductivity, corrosion resistance and mechanical strength to suit the differing requirements.

Comprehensive Machining and Processing Capabilities

Besides Swiss CNC machining, CNCSwissMasion offers:

- CNC milling and turning

- Multi-axis mill & turn

- Precision finishing, grinding.

- Surface treatment and cleaning.

All these services are integrated to create contact pins in improved precision, durability and quality surfaces.

Modern Swiss CNC Lathes for Precision

Our Swiss CNC lathes are state of the art and have tolerances up to ±0.003mm to ±0.001mm. The simplest or smallest contact pins are created with an extremely high level of accuracy. An increase in tooling and on-site tracking minimizes errors during production and maximizes the output.

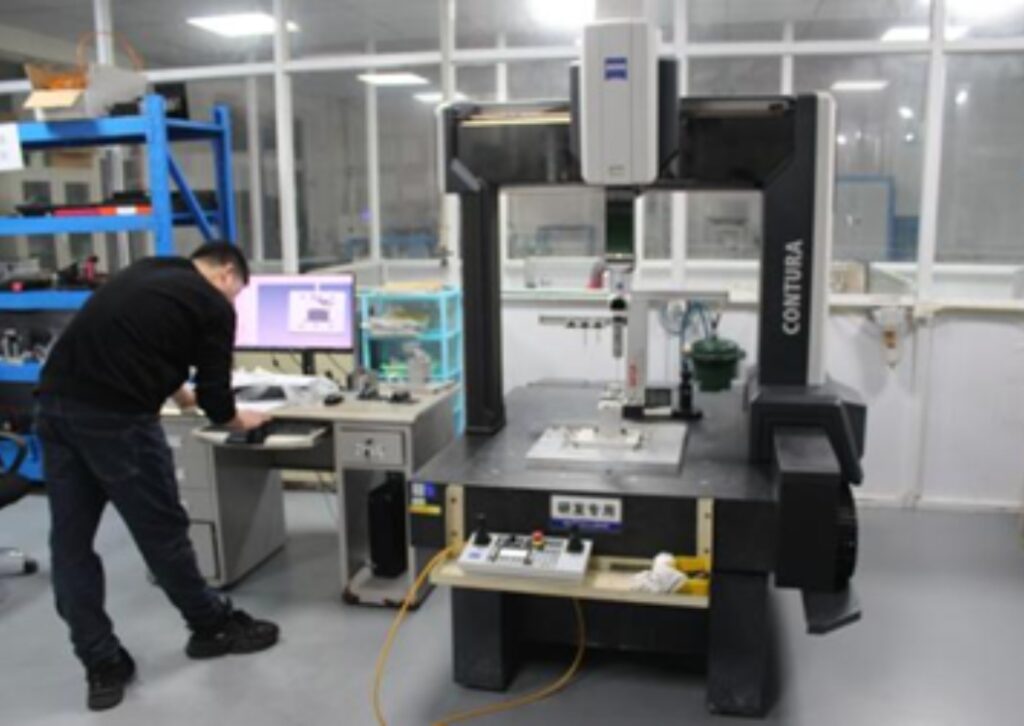

Automated Testing and Inspection

All contact pins are well tested with regards to dimensions, surface quality and material integrity. Automated inspections ensure standards, reduce defects, and provide traceable quality reports. This guarantees reliability in essential applications in automotive, aerospace, industrial and electronic applications.

Contact Pin Tolerance

Contact pin manufacturing at CNCSwissMasion depends on accuracy. That is why, such tight tolerances are encountered in all the contact pin production to assure uniformity in operations and reliability.

Supported Tolerances

- Pin diameter: ±0.005 mm to ±0.01 mm, based on the material and the use.

- Tip or contact area: optimum electrical contact of ±0.003 to ±0.007 mm.

- Crimp barrel or terminal section: ±0.01 mm to ±0.02 mm to ensure a tight fit between the wires.

- Pin length: (±0.02 mm) in very high precision assemblies, like board-to-board connectors or wire-to-board connectors.

Why Our Tolerances Matter

- Fits perfectly in PCBs, connectors or modular assemblies.

- Continuous and repetitive electrical contact during usage.

- Ensure checking the mechanical stability after a few cycles of insertion or compression.

Custom Tolerance Capabilities

CNCSwissMasion can accommodate tailored tolerances as per your design and application requirements. Tolerances may be tailored to high-frequency electronics, aerospace modules, medical equipment, or industrial control systems. Our engineers optimize the tooling, machining parameters and inspection to ensure such specifications.

CNCSwissMasion guarantees high-precision and dependable contact pins with the assistance of Swiss CNC lathes of the latest model, automated inspection systems and professional engineers, and the output of all applications is stable.

Contact Pin Quality Control at CNCSwissMasion

The quality control of the manufacturing process of contact pin is highly important at CNCSwissMasion. Contacts pins are thoroughly checked and tested to ensure that they are reliable, durable, and offer optimum electrical performance to the hostile environment in the automotive, aerospace, medical, telecommunications, and industry markets. Close care is taken in every batch to ensure that the quality and the compliance of the batch is met with the international standards.

Dimensional Inspection: The critical dimensions, tolerances, and geometries of all pins are checked by a precision measurement tool, such as coordinate measuring machine (CMMs), micrometers, calipers. Such a cross checking of the accuracy of CNC machining ensures consistency in between batches. It is also a precaution that will ensure that pins can be inserted easily in connector assemblies without alignment or mating problems.

Check Quality on Surface: Pins are observed using high-resolution optical microscopes, to determine surface defects, burrs, or variability. Surface roughness testers are also used to check smooth contact surfaces which will give low friction and good mating. Good surface quality will reduce wear and tear in the frequent insertion and removal of the pins and extend their service life.

Electrical Testing: Conductivity and resistance testing is conducted on the pins of contacts to check that the pins are capable of transmitting signals and power as required. Automated electrical test benches are employed to model real-life operating conditions to test performance. This will ensure that all the pins meet high electrical standards that will guarantee the transfer of current and signal in all applications.

Plating and Coating Verification: X-ray fluorescence (XRF) analyzers are applied in the measurement of the thickness and uniformity of plating of gold, nickel, tin, or palladium. This ensures that it resists corrosion, highest conductivity and longevity. Correct plating also prevents oxidation and provides good connections even in extreme conditions.

Mechanical and Lifecycle Testing: Special force gauges and lifecycle test machine are used to test contact pins in terms of spring force, mating cycles, and mechanical strength. This ensures that pins will not degrade when inserted and removed repeatedly. The tests also ensure the flexibility and mechanical integrity of the pin subjected to the different pressures during the normal operation.

Environmental Testing: Selected samples are subjected to temperature, humidity and corrosion tests to replicate extreme operating conditions. This guarantees automotive, aerospace, and industrial stability in the long-term. Environmental testing is used to monitor the functionality of the pins under extreme conditions and therefore the reliability of the pins is maintained throughout their service life.

These stringent quality control measures and high quality inspection machines make CNCSwissMasion convinced that all contact pins are of international quality and standards in precision, reliability, and performance before they leave the factory. The blend of both automated and manual inspection ensures that there are no defects and that production is a constant across the batches.

Our Certificates

At Masion, we are dedicated to delivering the finest in CNC Swiss machining. With over 21 years of experience in custom Swiss machining and manufacturing of Swiss custom parts of high precision. It means we are committed to quality, industry standards and customer satisfaction through our certifications.

In fact, we have the ability to proudly boast key certifications that bear testament to our adherence to strict guidelines in different industries. This means that we are always up against the highest standards when it comes to CNC milling turning and small parts manufacturing.

- ISO 9001 Quality Management System

- ISO14001 Environmental Management System Certification

- Automotive Industry Quality Management System (IATF 16949)

- RoHS Restriction of Hazardous Substances (Available Upon Request)

- SGS Products Test – These tests are conducted to check the quality and if it matches industrial standards.

- Conformity to European standards: Solemn quality in CNC Swiss machining is CE marking.

Explore Contact Pin Gallery

Battery contact pin

Contact pins

Battery contact pins

CNC contact pin

Contact pin

Custom contact pin

Custom contact pins

Hicnc contact pinsgh frequency pogo pin

Socket contact pin

Contact Pin Applications

Automotive Industry

Automobile connectors typically use contact pins to distribute power and send signals and sensor connections. They maintain consistent electrical functioning in the severe conditions, such as high vibration, temperature variations, and moisture or chemical exposure. Its uses are as engine control units, infotainment systems, and lighting modules and battery connections on electric vehicles.

Telecommunications and Data Communication

In telecommunications, contact pins are used as stable connectors in high-speed connection to LAN boards, telecom modules, and connectors. They facilitate power and data connections in network switches, routers and communication terminals. Low resistance, low signal loss and long-term reliability are guaranteed by high-quality plating and tight tolerances.

Aerospace and Defense

Aerospace uses are requiring high-performance contact pins in avionics systems, control panels and sensor interfaces. CNCSwissMasion contact pins can be used in high temperature and vibration environments to ensure signal integrity and power continuity. They are employed in the flight control system, navigation modules and satellite equipment.

Medical Technology

Contact pins are needed in medical equipment to provide small and reliable electrical connections. It is used in diagnostic devices, imaging devices, and wearable health monitoring devices. The materials are high-quality and corrosion-resistant, so the stability is long-term, signal transmission is accurate, and the safety standards are met.

Robotics and Industrial Automation

Contact pins are a component of industrial machinery and automation systems that allow connection of control units, sensors and actuators. They offer reliable power and signal transmission in factory automation systems, robotics and testing boards of IC modules. They have high durability and flexibility, which enables them to endure repeated mechanical cycles.

Consumer Electronics

Contact pins are employed in consumer electronics, such as smartphones, laptops and other smaller gadgets. They facilitate the dependable transport of power and signal in small connector groups. Precision machining and plating provide maximum conductivity and corrosion resistance to be used every day.

Power Supply and Energy Systems

Contact pins are used in energy equipment terminals, batteries, and evaluation boards in connection of power. They are safe and efficient in power transmission and they reduce resistance and heat production. Other materials such as pure copper and phosphor bronze are very good conductors and also mechanically reliable.

FAQs

What are the material and plating options?

Our contact pins are available in high quality materials like Phosphor Bronze, Beryllium Copper, Brass and Stainless steel. Plating choices are Gold Plating, Silver Plating, Tin Plating, Nickel Plating, and Palladium-Nickel Plating that guarantees high levels of conductivity, corrosion resistance and durability. The clients have the choice of the material and plating depending on their unique electrical and mechanical needs.

Are you able to make custom pins on our drawings or samples? How will the customization be done? What is the schedule?

Yes, we make special contact pins to your drawings or samples. In case any changes are required, we will give you notice before production. It includes inspection of the drawing, establishment of feasibility of production, manufacture of the parts, test, and dispatching the sample to your approval. The process of customization usually requires approximately 7-10 days.

Do you provide free samples? How long is the sample lead time?

We offer samples at a very low price and this can be refunded on your order after it is approved. Sample production lead time is 7-15 days, depending on the intricacy and difficulty of the sample design. This enables you to check quality before making bulk orders.

What design optimization recommendations do you have (assuming we have to optimize the design of our product (connector))?

Yes, our engineering team will be able to provide design optimization recommendations to enhance manufacturability, reliability, and performance. We make sure that the recommendations are compatible with the production process and electrical and mechanical functionality of the connector assembly remains.

What is your MOQ (Minimum Order Quantity)?

No strict MOQ is required in the case of samples, and you can test the product to begin with. In bulk production, the normal MOQ will be 50, which is both cost-effective and matches the production standards.

Are tooling (mold) costs in the quotation? Who owns the tooling?

Typically, we list the tooling and unit price as one when the part needs a custom tool. The tooling is owned by the client, which means that you own it entirely and can re-order later without any further issues with licensing.

What are your conditions of payment (e.g., T/T, L/C)

We provide common checks of payment such as T/T (Telegraphic Transfer) and PayPal. The terms of payments are not strict and vary with the size of the orders to facilitate transactions and trust with our customers.

What is your normal lead time? How do you handle rush orders?

Normal lead time relies on the quantity of the order and the bigger the quantity, the longer it usually takes about 25 days. In the case of rush orders, we use more than one machine to speed up production and delivery takes 15-20 days, and the quality remains the same.

How do you perform quality control? (e.g., IQC, IPQC, OQC)

We have stringent quality control measures that are certified by ISO9001 and ISO16949. We have an incoming quality control (IQC), in-process quality control (IPQC) and outgoing quality control (OQC) so that each contact pin has passed the dimensional and electrical standards.

Is it possible to give CPK (Process Capability Index), complete dimensional inspection reports, or material certification reports?

Yes, we can submit detailed CPK data, complete dimensional inspection records, and material certification records on request. This provides complete traceability and quality verification of critical applications.

What is the regular packaging? Do you offer anti-static or vacuumed packaging?

Our standard packaging is blister boxes, regular boxes, wooden boxes, and pallets in case of bulky or heavy parts. Anti-static and vacuum packaging can also be designed in such a way that the sensitive pins are protected during transportation and storage.

What is the process of returns or replacement in case we are received with quality issues?

Should products prove to have any standardized quality issues, then we will re-manufacture the parts and deliver the new parts free of charge. Our goal is to ensure that every order is to your satisfaction and that it is operational.

What is the length of time you will hold our committed tooling and production files? What about reordering in the future?

We archive specific tooling and manufacturing files as long as your project remains active. It is easy to reorder, since we can re-manufacture the same part in the same tooling with the same specifications.

Could you ensure that there is a stable production capacity should there be an increase in the market demand of our product?

Yes, CNCSwissMasion has the ability to increase production capacity as market demand increases. We invest in more machines and resources in case we need to sustain the production with constant output and a uniform quality.