Density of Galvanized Steel – The Complete Beginner’s Guide

It is important to know the precise density of galvanized steel in order to do proper engineering and material planning. To estimate weight, make sure structure is stable, and manage cost, you require accurate values of density. Small variation in density during construction, automotive, and industrial work may influence performance and safety. In this article, you will read through the properties of galvanized steel, density, and zinc coating influence. Through reading, you will gain knowledge on how to measure, compare and use density data to make sound design and procurement decisions.

Table of Contents

ToggleWhat Is Galvanized Steel?

Galvanized steel is the steel that has a coating of zinc to prevent corrosion. You depend on this zinc coating to increase the life of the steel particularly in severe or outdoor conditions. Other popular galvanization processes are hot-dip galvanization whereby the steel is exposed to molten zinc, and electro-galvanization whereby an electric current is used to add the coating. Galvanized steel is used in roofing, fencing, automotive components and construction structures. Galvanized steel makes it durable, cheaper to maintain and keeps your projects out of rust.

Understanding Density as a Material Property

Density is an important material property, which quantifies mass/unit volume. You need to know it as it has a direct impact on structural integrity and mechanical performance. Density knowledge will assist you in estimating the load capacity, transportation optimization and efficient planning of fabrication. Density can be measured in grams per cubic centimeter (g/cm 3 ), kilograms per cubic meter (kg / m 3 ), or pounds per cubic foot (lb/ft 3 ). Density is an important consideration that will make you choose materials wisely in order to come up with safe and cost-effective designs.

Standard Density Values of Galvanized Steel

Accepted Industry Density Values

Standard density values of galvanized steel can be used in design and calculations. The density is usually 7.85 g/cm 3 or 7850 kg/m 3 or 490 lb/ft 3. These numbers are used by manufacturers to ensure consistency between sheets, coils and structural sections. Adhering to these standards, you can be sure of weight estimates and sound performance of materials in building or fabrication.

Density Comparison Across Unit Systems

Unit | Standard Value | Practical Use |

g/cm³ | 7.85 | Material comparison |

kg/m³ | 7850 | Structural and weight calculations |

lb/ft³ | 490 | Imperial system applications |

When Standard Density Is Sufficient

Most common calculations, including load estimates and material planning can be made using standard density. It is suitable in sheets, coils and structural sections. These accepted values save time when you need to check the design quickly, to check costing, or when you are making initial project checks. Detailed measurements are only necessary where high precision is needed, as in a narrow range of engineering work or in custom alloys. Working with standard figures helps you work with less effort but with reasonable accuracy.

Density Range and Practical Variations

Galvanized steel density is not a fixed thing and you ought to take practical changes. Real-world products will be found to have a normal range of 7.80 -7.88 g/cm 3. This density is affected by factors such as sheet thickness, weight of zinc coating and part geometry. You also have to consider the variation among manufacturers whereby production methods and materials may alter final weights slightly.

Zinc Coating and Its Effect on Density

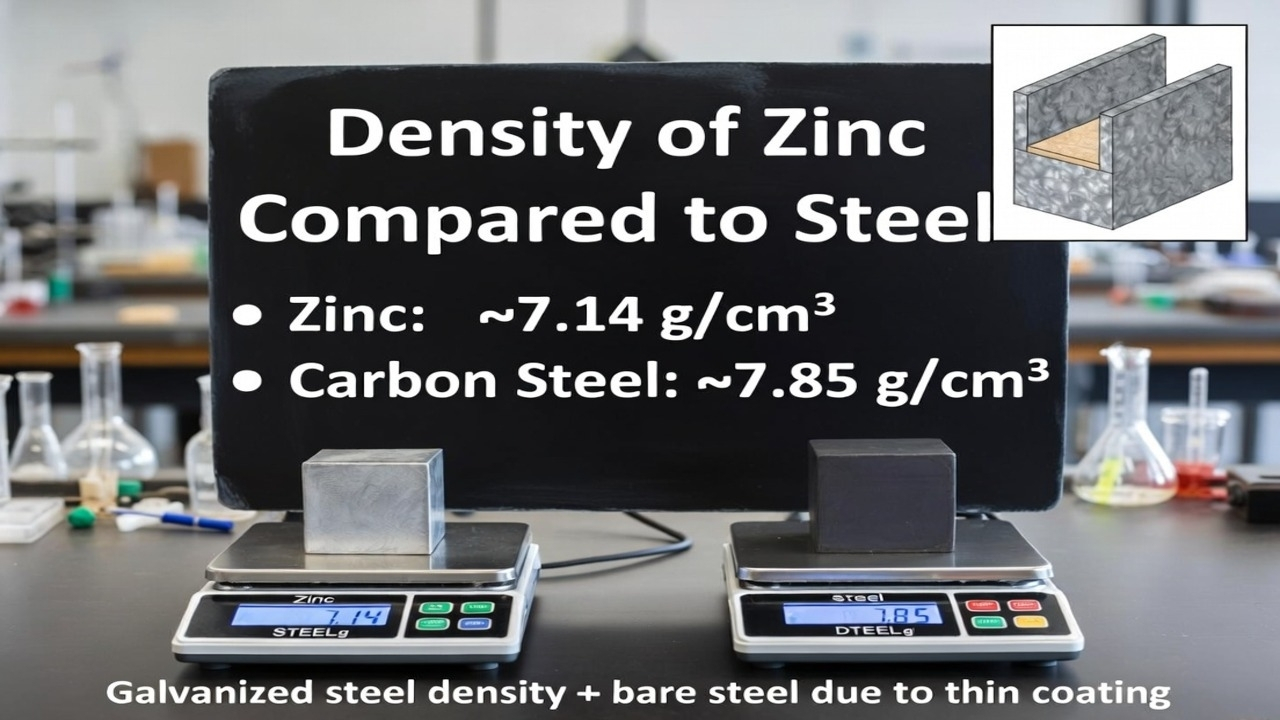

Density of Zinc Compared to Steel

You are to know that zinc is of less density than carbon steel. The density of zinc is approximately 7.14 g/cm 3 and carbon steel is approximately 7.85 g/cm 3. This variation implies that as you coat steel with zinc, the total density reduces slightly. Nevertheless, since zinc layers tend to be thin, the shift in overall mass is not significant. Most calculations may be done as though galvanized steel had the same density as bare steel.

Coating Thickness and Mass Contribution

The zinc thickness is a factor that influences its contribution to overall mass. Light layers can be applied without adding significant weight whereas heavier layers add a little weight. Note that coatings so thick can hardly be more than a few percent of total weight. This is the reason why the effect of zinc on density is normally insignificant and you can safely approximate the original density of steel in most practical applications.

Galvanizing Methods and Density Impact

Hot-dip galvanizing gives more uniform, thicker coats compared to electro-galvanizing. A little more mass contribution should be expected in hot-dip processes. Electro-galvanized layers are less thick and more controlled with minimal change in density observed. Coating uniformity influences mass distribution, however, in most cases, the implications of density are insignificant.

Base Steel Composition and Density Influence

Carbon Steel vs Alloy Steel

Carbon steel is a mixture of iron and carbon, and its density is approximately 7.85 g/cm 3. Alloy steel also contains other alloys such as chromium, nickel or molybdenum, which slightly changes its density. These factors increase strength, hardness, and corrosion resistance, which can make alloy steel either heavier or lighter based on the mixture. This knowledge can enable you to select steel that can be used in structural or mechanical applications.

Role of Chemical Elements

Silicon, phosphorus, sulfur, and zinc-iron reactions have an impact on the performance of steel. You should take into account the influence of these factors on the adhesion of coating and density uniformity. As an example, uniformity can be lowered by sulfur and phosphorus, and corrosion resistance is improved by zinc during galvanization. With good control, you are guaranteed of good density and surface quality on finished steel products.

Steel Grade Selection Considerations

Density can vary slightly in high-grade steels because of alloying variations. When selecting steel when working on projects, you should adhere to certain material specifications. Proper grade ensures structural integrity and performance at stress. Right grade selection is in line with strength, durability, and weight.

Manufacturing Process and Density Variation

Method of Surface Preparation and Cleaning

Educational surface preparation guarantees consistent coating and density. You are supposed to strip rust, oils and debris. Such methods as pickling, abrasive cleaning, or chemical operations alter the adhesion of zinc. Sanitary surfaces avoid blemishes and erosion. You may examine by visual or by chemical means. Regular reheating minimizes the occurrence of density variations and high durability.

Role of Heating, Immersion Time and Cooling

Zinc bonds with heating of steel to the proper temperature. Coating thickness is influenced by the immersion time. Quick or slow cooling may cause changes in density. Temperature and time are to be taken note of. Modulated heating and cooling creates uniform construction. Tilting of these parameters minimises defects and preserves target density.

Process Control Effect on Final Density

Good control of the process eliminates variation of the coating depth and steel density. The parameters to monitor include the speed of immersion, zinc composition and bath conditions. Consistency and reduced human error is enhanced through automation.

Tolerances and Density Drift in Manufacturing

Minor changes in dimensions or coating will also change density. Tight tolerances should be observed during production. Periodic test results can identify drift. Calibration is used to maintain density within specification.

Surface Treatments Beyond Galvanization

Surface treatment can be added to steel protection on top of galvanization (paint or polymer coating). These extra layers enhance resistance to corrosion and durability. Note that multilayer systems add a slight weight to your components. Also, performance in a density sensitive project depends on post-treatments, and hence you must choose the coatings with care to achieve a balance between protection and weight and structural performance.

Density of Galvanized Steel vs Plain Steel

Numerical Comparison

You would see that galvanized and plain steel have almost the same density values. The galvanized steel coating of zinc is very thin relative to the steel underneath, and thus the coating does not add a significant amount of weight. Both materials can be trusted to give similar structural calculations without modifications. It simplifies the process of planning and the choice of materials in your projects, be it machineries or structures.

Functional Differences Despite Similar Density

You also attain corrosion resistance with galvanized steel, even though the density is similar. You will use less money in maintenance and replacements in the long run. Its durability means that your constructions will withstand the worst weather or chemical exposure. The option of galvanized steel will assist you to safeguard investments and save expenditures in the long run. Although plain steel is powerful, it needs extra coating or treatment in an attempt to match these advantages. You are able to make decisions on material utilization depending on environment and anticipated longevity, rather than density.

Property | Plain Steel | Galvanized Steel |

Average Density | ~7.85 g/cm³ | ~7.85 g/cm³ |

Corrosion Resistance | Low | High |

Surface Protection | None | Zinc coating |

Typical Applications | Indoor structures | Outdoor and corrosive environments |

Density Calculation Fundamentals

Density Formula Explained

Density is computed as a ratio of Mass to Volume: Density = Mass / Volume. Always use proper units. When necessary, convert grams to kilograms or milliliters to liters. This provides uniformity and prevents calculation errors.

Importance of Accurate Measurement

The mass should be measured accurately with good scales. Volume must be calculated. Precise containers or instruments must be used. Proper measurements will guarantee that there are proper density values, which are important in selecting the material, engineering, and scientific calculations. Minor flaws may have great impact.

Weight Calculation for Galvanized Steel Products

Weight Formula for Sheets and Plates

Length, width, thickness and material density multiplied to compute sheet weight. This equation will get you the weight of the object right. With the help of this technique, you will be able to plan transport, storage and structural support requirements. Always use similar units of measurement to eliminate errors. The density value varies with the type of material used, i.e. steel, aluminum, or copper, which influences the final weight determination.

Parameter | Description | Typical Unit |

Length (L) | Sheet or section length | meters (m) |

Width (W) | Sheet width | meters (m) |

Thickness (T) | Material thickness | meters (m) |

Density (ρ) | Material density | kg/m³ |

Weight | Final calculated mass | kilograms (kg) |

Step-by-Step Sheet Weight Example

Take a sheet of steel 2 meters long, 1 meter wide and 0.01 meters thick. Divide these dimensions by the density of steel, 7850 kg/m 3. The resulting weight indicates the weight of the sheet and you may interpret load capacity. This calculation can be applied to various sheet sizes or materials. This approach offers feasible knowledge on project planning, procurement, and cost estimation in real life.

Density of Galvanized Steel Sheets and Coils

Coil and sheet density of galvanized steel normally presumes 7.85 g/cm 3 of flat products. You are to take into account that calculations of weight depend on geometry and form factor. Sheets and coils can be slightly different because of manufacturing tolerances. In planning projects or ordering materials, weight tolerance is something that you must take into account. Knowing these factors will enable you to estimate the requirements in load and transport. Understanding these factors helps you estimate load and transport requirements effectively.

Practical Importance of Density in Applications

- Construction and Infrastructure

The density has a direct impact on structural stability, which makes sure that buildings are safe to carry loads. You may evaluate materials to be used with accurate load-carrying needs. Adequate density choice decreases risk of structural failure and durability. You will enjoy the work of materials that are efficient in strength and weight.

- Transportation and Automotive

Vehicle weight optimisation improves fuel efficiency and performance. Materials that are safe and minimise mass can be selected. Adequate density guarantees enhanced manipulation and crash protection. Light and strong materials provide you with better longevity and reduced operational costs.

- Outdoor Installations and Fencing

Dense material is resistant to impact and offers durability in the outdoor environment. You have a choice of options that does not warp due to change in weather. Proper density makes fencing safe and protective. You enjoy less maintenance and enhanced structural integrity in the long run.

- Industrial Machinery and Equipment

Density influences the way that machinery responds to mechanical stress and vibrations. You are able to make sure that parts can support long-duration working loads. Proper density enhances efficiency and reliability of equipment. With the right materials, you reduce the breakdowns and maintenance.

Design and Specification Considerations

In the case of galvanized steel design, you can choose the thickness depending on your load and density. The coating weight required to inhibit corrosion is affected by environmental exposure. You need to make sure that the steel is compatible with other metals that it is attached to to prevent galvanic reactions. Adherence to such standards as ASTM A653/A653M ensures the quality and compliance with industry standards. Proper planning at this phase helps in minimizing mistakes in the fabrication process and also helps in the durability of the structure.

Cost Estimation and Material Planning

Density is important to provide an accurate estimate of the material costs. The weight of galvanized steel sheets or components influences transportation and handling. You can also save costs by ensuring that you order the correct density values to reduce unnecessary material orders. Proper planning will avoid wastage when cutting, bending or assembling. Understanding the real density will enable you to estimate shipping fees correctly and maximize your budget.

Common Misconceptions About Galvanized Steel Density

Some believe that zinc coating makes steel extremely dense, which is not true. Bare steel is much lighter than galvanized steel because of the thin layers of zinc. You need to know that the differences in weight in the real world are small and can be ignored in most of the applications. When these misconceptions are cleared, planning and material usage becomes more accurate.

Best Practices for Accurate Density Use

Density information on technical datasheets should never be relied upon without verification before design or purchase. Measure coating thickness where accuracy is essential. You are to liaise effectively with manufacturers and suppliers to make sure that the material that will be provided is suitable to your needs. The practices eliminate mistakes in weight estimation and structural calculations.

Conclusion

To get the design right, planning and cost control, it is important to understand the density of galvanized steel. Coating thickness, steel grade, and manufacturing method variations can cause slight variation on weight, therefore, you need to consider them when making calculations. Quality knowledge provides safe structural performance, effective material utilization, and streamlined transportation and handling. With the appropriate density values and best practices, you are able to make quality decisions, minimize waste, and choose the appropriate materials to use in construction, automotive, and industrial projects that are sustainable, cost-effective, and of high quality.

Frequently Asked Questions

How does galvanized steel compare to other metals?

Galvanized steel is a steel alloy that is corrosion resistant due to zinc coating. It is stronger and more resistant to rust compared to plain steel, and also less expensive than stainless steel. You can depend on it in structural and outdoor applications where durability and cut back in maintenance is a concern. Its mechanical characteristics are near to standard steel.

Does zinc coating significantly change density?

The zinc coating adds a slight density to the overall density of steel however, the difference is not that significant. When calculating the density of galvanized steel, you usually take galvanized steel density as being near to standard steel. The coating weight is only needed in the exacting engineering applications. The protective layer does not have a significant impact on structural performance or mass-based design considerations, but it does enhance lifespan.

How accurate are standard density values?

Most design and calculations can be effectively estimated using standard density values. They can be used in structural planning, weight estimation, and material selection. These are minor differences because of the coating thickness, alloy composition, or manufacturing tolerances. In critical engineering work, measure the actual density to be precise and prevent errors in prediction of performance.