Inside a Leading CNC Machining Parts Factory: Precision at Scale

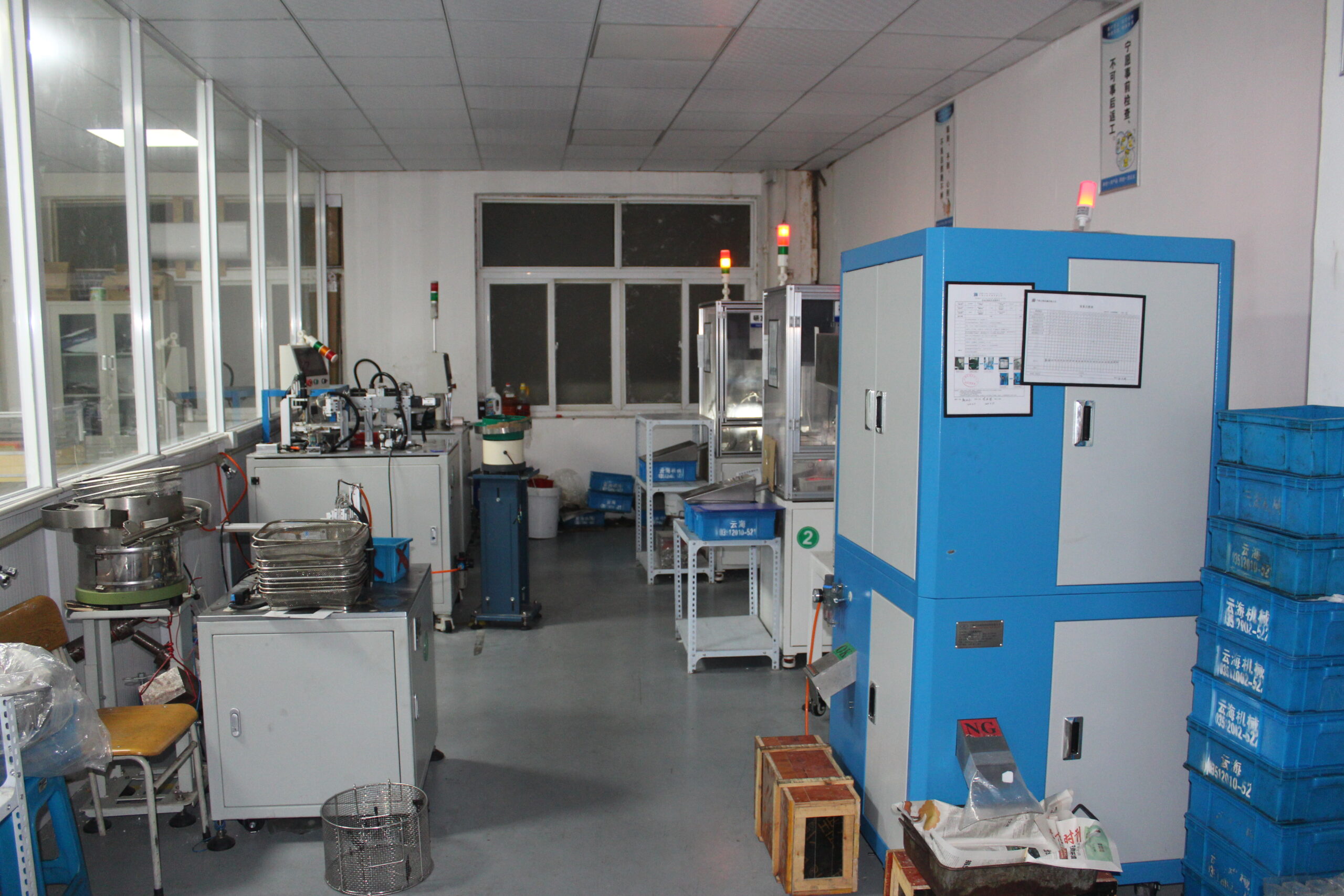

Masion is an excellent CNC machining part factory in Ningbo, China. We have a plant of 5,000 square meters with more than 125 qualified workers. We have installed modern equipment in our location to fulfill all of your manufacturing requirements in an efficient and accurate manner.

We participate in all steps of the process, including design and machining, surface treatment, and assembly, having a vertically integrated in-house production system. The same arrangement enables us to test sheet metal components on-site. Consequently you enjoy improved turnaround times, quality and reduced cost of production.

Not only do you receive parts when you work with Masion, you get a partner that is precise, fast, and reliable.

Experience the Masion Difference in Premium CNC Machining Parts

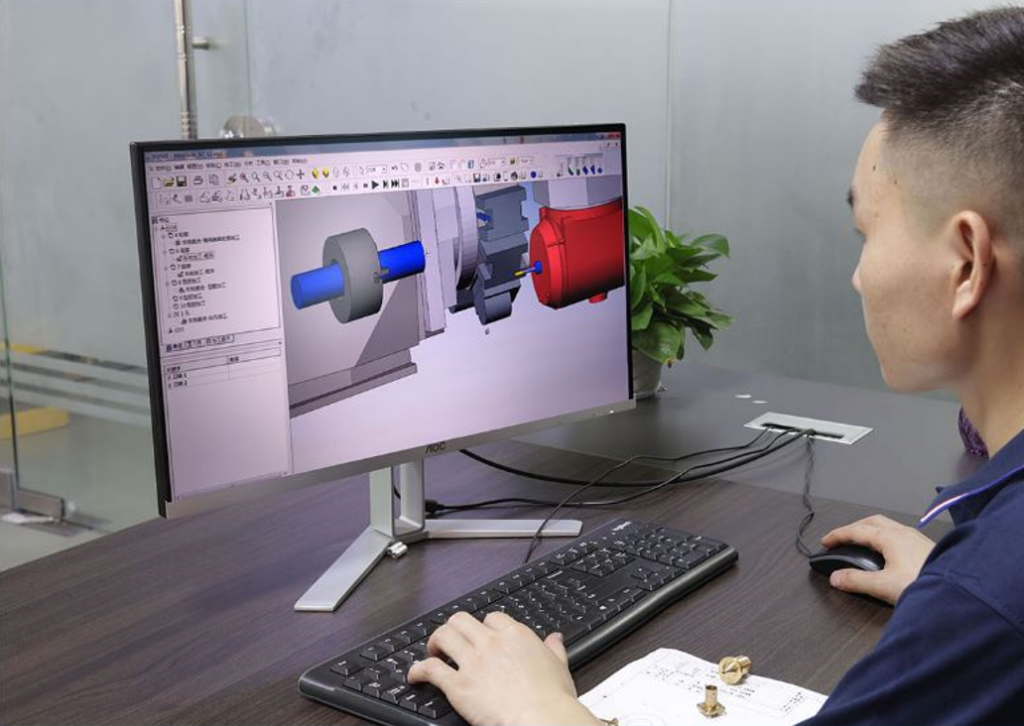

Masion is fuelled by modern CNC machine tools and an expert R&D and production force. We are dedicated to the production of high-precision, intricate CNC components that have quick turnaround and competitive advantage. Using a robust supply chain management system based on ERP, we guarantee effective and smooth production at each level.

We have been in business because of experience and the confidence of our valued clients, such as you. We are working to address your manufacturing problems and bring valuable contribution to your company. We lead the pack with leading-edge equipment and a keen understanding of the industry and new technologies, which leads to your lead.

Masion does not merely manufacture components; it assists you in becoming a market leader. So how can we help with what you are trying to achieve and how can we differentiate yourselves against the competition?

Our Machines

Masion occupies more than 5,000 sq. meters and is equipped with a broad variety of high-tech CNC machines. High precision, automated systems that are efficient and accurate are on each unit. Having this arrangement, we offer you the latest technology in CNC manufacturing solutions that is personalized to your needs.

Our Facility & Equipment

- Standard CNC Machining: We pay attention to all the details and provide consistent and high-quality production of your parts.

- DFM Support: We collaborate with you in the design stage where we maximize design and manufacture.

- Custom Manufacturing: These are custom made and we make them based on your drawings and provide reliable products each and every time.

- Unrivaled Production Quality: You get components that are of the best industry standards, particularly in the production of sheet metals.

- Short Lead Times: Our deliveries are fast, and it will help you to get to the market faster and cut down total costs.

- Tight Quality Control: Specific inspection procedures are carried out by our team to secure the highest quality of every batch.

- Optimization of Costs: Due to our in-house production, you enjoy the advantages of simplified processes and improved cost control.

- Tracking of production: You have complete visibility on your orders which makes it transparent and get it on time.

The benefits enable us to provide you with effective, affordable, and high-quality CNC machining services.

What We Do Best?

The Machine Lineup You’ll Find in a High-Performance CNC Factory

3 & 4 Axis CNC Machines

- 3 Axis CNC machine

- 4 Axis CNC machine

- 4 Axis CNC machine 2

- 4 Axis horizontal machining centre

- DOOSAN 4 axis CNC turning and milling machine

- GROMAX CNC machining centre

5 Axis CNC Machines

- 5 Axis machine

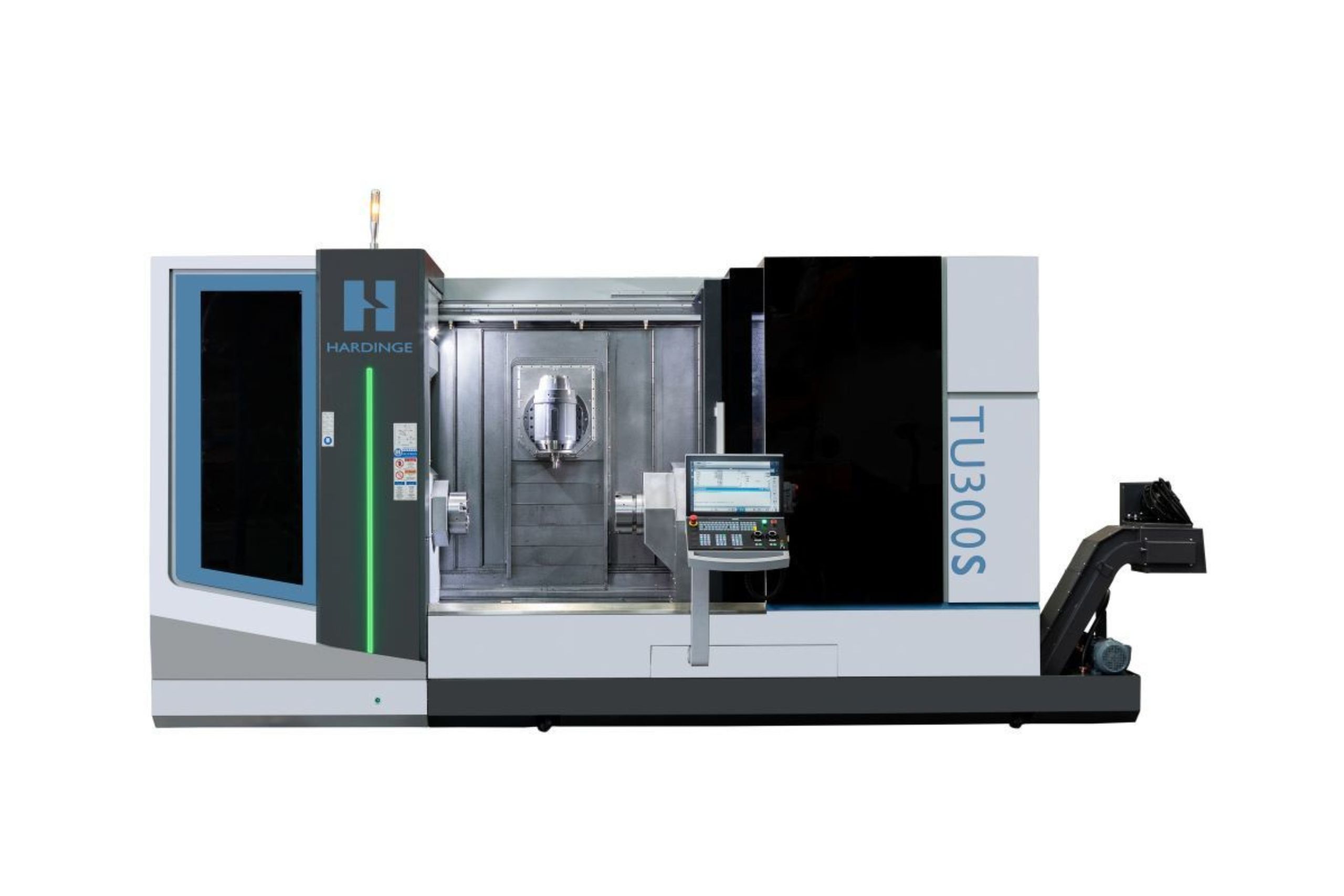

- Hardanger turn and mill machine

Swiss-Type CNC Lathes

- Citizen Swiss lathe

Star swiss lathe

TSUGAMI swiss lathe

CNC Lathes & Turners

- CNC lathe

- Cam automatic lathe

- CNC Milling & Turning Machine

Automatic Screw Machines

- Screw machine

- Screw machine 2

- GFIR Automatic lathe with truss

General CNC Equipment

- CNC machine

- Big CNC machine

- Ifine CNC Drilling machine

Grinding & Finishing Machines

- Surface grinding machine

Ifine Drilling Machine

- Ifine CNC Drilling Machine

Uncover the Technology Behind Our CNC Precision Machining Factory

3 Axis CNC Machine

- Max Travel Speed: X/Y/Z: 30 m/min

- Precision: ±0.01 mm

- Working Area: 1000×500×500 mm

- Spindle Speed: Up to 10,000 rpm

- Application: Ideal for basic milling and drilling operations

4 Axis CNC Machine

- Axis Range: X/Y/Z + A rotation

- Precision: ±0.008 mm

- Table Size: 1200×600 mm

- Spindle Power: 7.5 kW

- Feature: Adds rotary movement for side milling and holes

4 Axis CNC Machine

- Travel Capacity: 1000×500×500 mm

- Rotary Axis (A): 360° continuous

- Positioning Accuracy: ±0.005 mm

- Max Load: 500 kg

- Use Case: Complex contours and multi-face machining

4 Axis Horizontal Machining Centre

- Pallet Size: 500×500 mm

- Tool Capacity: 60 tools

- Spindle Speed: 15,000 rpm

- Precision: ±0.005 mm

- Benefit: Suitable for machining deep cavities and dies

5 Axis CNC Machine

- Motion Axes: X, Y, Z, A, C

- Precision: ±0.003 mm

- Table Diameter: 600 mm

- Simultaneous Axis Control: Yes

- Feature: Enables full 3D contouring in one setup

Big CNC Machine

- Working Area: 3000×1500×800 mm

- Max Load: 3000 kg

- Spindle Power: 15 kW

- Precision: ±0.01 mm

- Application: Large part machining, mold bases, panels

Cam Automatic Lathe

- Max Turning Diameter: 20 mm

- Max Bar Length: 200 mm

- Spindle Speed: 6000 rpm

- Operation Type: Mechanical cam-driven

- Ideal For: High-speed, repetitive turning tasks

Citizen Swiss Lathe

- Max Bar Capacity: 32 mm

- Axes: Up to 10

- Spindle Speed: 8000 rpm

- Tool Stations: 25+

- Specialty: Ultra-precision for small, intricate parts

CNC Lathe

- Max Turning Diameter: 300 mm

- Chuck Size: 10″

- Spindle Speed: 4500 rpm

- Tool Turret: 12 stations

- Use Case: Cylindrical components, shafts, bushings

CNC Machine

- Control System: Fanuc/Siemens

- Spindle Motor: 11 kW

- Travel Size: 1000×500×500 mm

- Tool Magazine: 24 tools

- Function: Versatile general-purpose CNC platform

CNC Milling & Turning Machine

- Turning Diameter: 250 mm

- Milling Capability: Vertical + Y-axis

- Spindle Speed: 6000 rpm

- Live Tooling: Yes

- Advantage: Combines mill and lathe in one setup

DOOSAN 4 Axis CNC Turning & Milling Machine

- Axes: X, Y, Z + C

- Spindle Motor: 18.5 kW

- Turret: BMT 12 stations with live tooling

- Max Work Diameter: 300 mm

- Benefit: Complex part machining in fewer setups

GFIR Automatic Lathe with Truss

- Bar Capacity: 25 mm

- Automation: Robotic truss loading system

- Output Efficiency: High-volume

- Use Case: Automated cycle for precision turned parts

GROMAX CNC Machining Centre

- Table Size: 900×450 mm

- Spindle Speed: 10,000 rpm

- Tool Capacity: 30 tools

- Axis Configuration: 3+1

- Purpose: Efficient for medium-sized batch runs

Hardanger Turn and Mill Machine

- Turning Diameter: 150 mm

- Milling Axes: 5

- Tool Stations: 20+

- Spindle Speed: 7000 rpm

- Highlight: High-accuracy hybrid operations

Ifine CNC Drilling Machine

- Max Drill Diameter: 50 mm

- Spindle Speed: 3000 rpm

- Table Size: 700×400 mm

- Features: Depth control, coolant system

- Usage: Vertical/horizontal high-speed drilling

Screw Machine

- Max Bar Diameter: 25 mm

- Multi-Spindle: Yes

- Cycle Time: 2–5 seconds/part

- Tooling Stations: 6–8

- Suitable For: Fast, automated screw and pin production

Screw Machine

- Bar Capacity: 20 mm

- Spindle Configuration: 6-spindle automatic

- Speed: High-volume runs

- Specialization: Short cycle repetitive parts

Star Swiss Lathe

- Bar Size: 20 mm

- Tool Posts: 25+

- Axes: 9+

- Live Tooling: Included

- Ideal Use: Medical, aerospace, precision micro-parts

Surface Grinding Machine

- Grinding Area: 600×300 mm

- Spindle Speed: 2800 rpm

- Accuracy: ±0.002 mm

- Surface Finish: Ra 0.2 µm

- Use: Flatness, finishing, and fine tolerance surfaces

Masion: The CNC Prototype Machining Factory Built for Speed and Accuracy

Maison has 17 years of practical experience and is one of the most excellent sheet metal and CNC machining factories in China. We can assist you in most of the client initiatives, whether small or large, in multiple industries, including Geely Auto, Bull Group, and CRRC. Regardless of the scale of the project, you get the same quality, attention to detail and delivery.

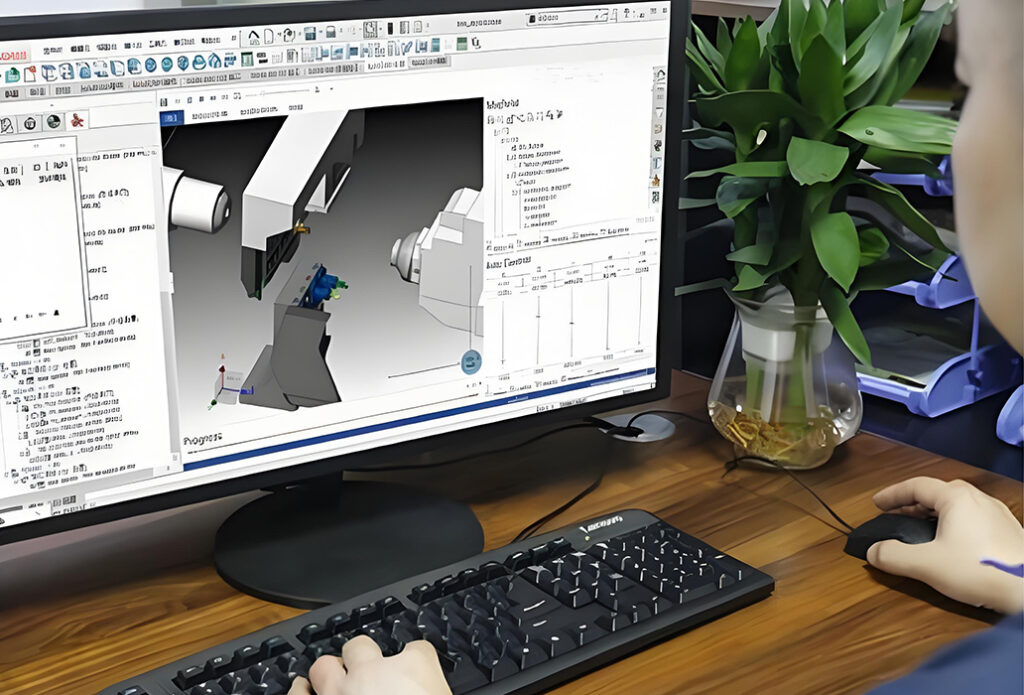

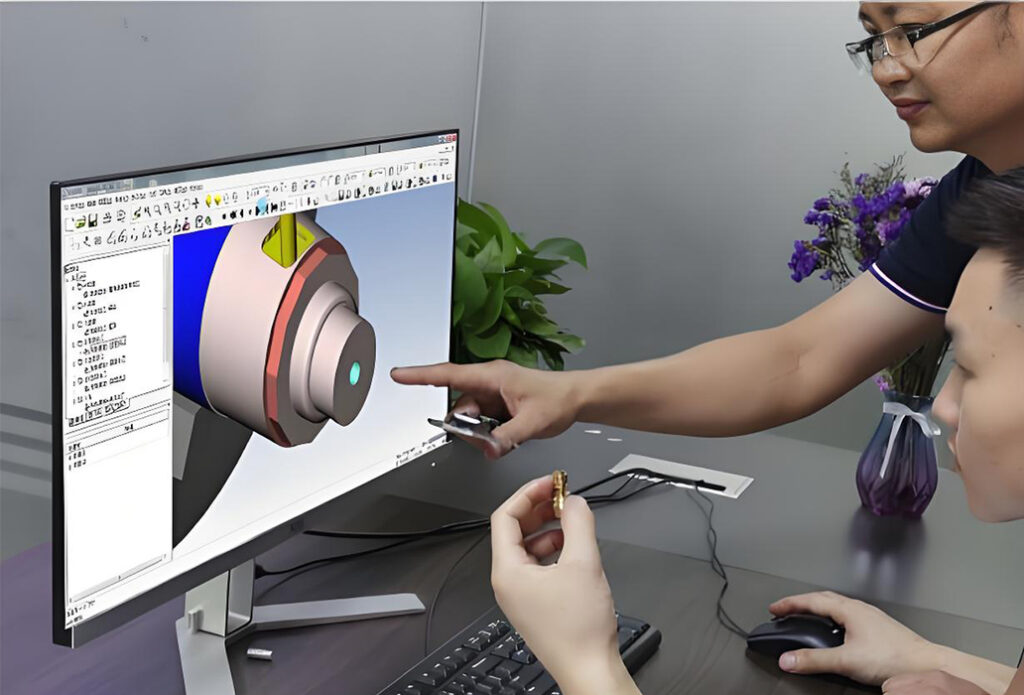

DFM Design Support: No worries about design drawings. We have an experienced research and development team that will take you through the process. We assist you in developing intelligent and economical sheet metal designs, simplify production processes and lower your manufacturing expenses.

Modern Machinery to Efficiently Produce: Our sheet metal parts are produced at high speed and high accuracy with the help of automated loading robots, welding arms, laser cutters, and CNC bending machines. This equipment will streamline your project throughout the process.

Senior Technical Team: You have the advantage of our in-house engineered team of mold designers, inspectors, and production operators. We ensure that your parts are ready, and are met to every requirement and timeline: Starting with initial design, prototyping, inspection, mass production, and final assembly.

Vertical Integration In-House: We take care of the entire sheet metal processing cycle including cutting, stamping, bending and welding to surface finishing and assembly. We have complete in-house control, and we can trace every stage, which will assist you in avoiding any doubts in production or quality.

Reputable On-Time Delivery: Our optimized production tracking and planning systems assist us in adhering to your project schedules. You will receive it on time and with no quality sacrifices.

Tight Quality Control: The quality is non-negotiable. We are certified by ISO9001:2015 and ISO16949. We implement stringent checks at all levels and give traceable documentation to assure you of parts that are of global standards.

Mold Design & Real-time Changes: You will collaborate with our own in-house mold engineers to design and modify stamping molds on the fly. This reduces your lead time, enhances communication and minimizes cost on molds.

General Material Processing: You are required to use stainless steel, aluminum alloy, cold-rolled steel, copper, or titanium alloy parts- we will supply them to you. No matter how small your order is or how complex it is, we can assist you in going through challenging moments and achieving consistency.

What Sets a CNC Machining China Factory Apart in Quality Control Standards?

We are Masion, not only a manufacturer of CNC parts, we are an engineering confidence. As one of the top CNC manufacturing China factories, we have established our reputation through a high level of quality control that makes every part of our work to match your expectations. This is what makes Masion different in the world of CNC precision and reliability.

1. ISO Certified Quality Systems

Masion is certified on ISO 9001:2015 and IATF 16949 quality systems in order to provide the complete compliance and control. Such systems support all processes, including incoming material and final inspection. You will have repeatable, similar results in every CNC production run.

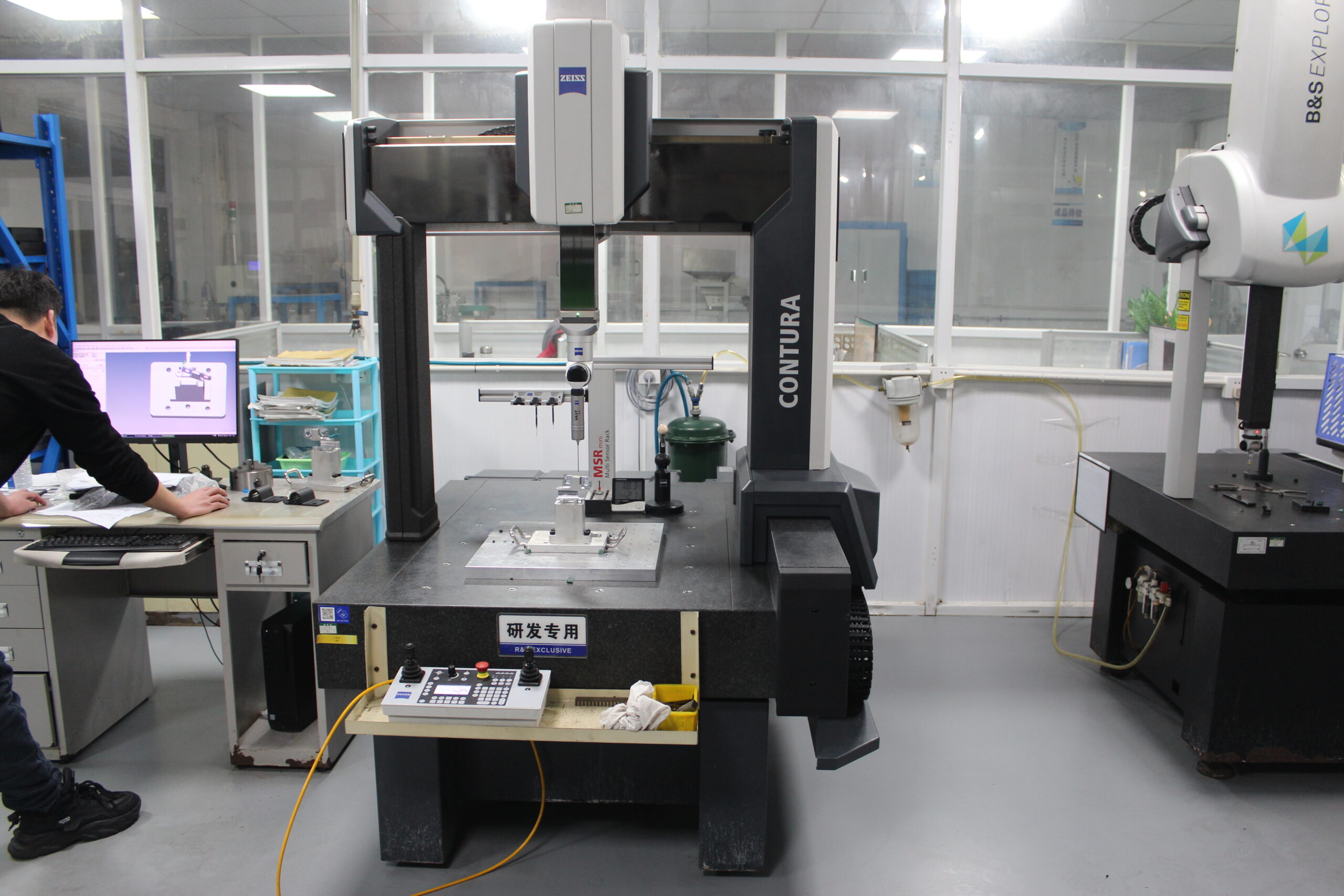

2. State of the Art In House Inspection Equipment

We have high precision inspection equipment like CMMs, micrometers, digital calipers, X-ray analyzers in our facilities. They allow us to inspect the tight tolerances and material integrity with confidence. Your components are shipped out of our plant to the most demanding dimensional and structural specifications.

3. First Article Inspection (FAI) Protocol

Prior to mass production, Masion does a rigorous First Article Inspection on samples. This is a process used to verify each critical dimension, material specification and functional feature. You get complete documentation reducing risk and output matching to your initial design.

4. Process Monitoring in Real-Time

Our smart manufacturing tools and IoT sensors to monitor cutting parameters, tool condition, and environmental variables. This real-time observation increases process control and minimizes variance. You enjoy quick turn and consistent accuracy at volumes.

5. Operator-Led Self-Inspection

At Masion, quality control is greatly enmeshed in the activities of the trained operator; checks are made after every stage of machining. This practical supervision guarantees the prompt solution of difficulties. You get standard and custom tolerance parts on the spot.

6. In-Process and Intermediate Quality Audits

We have a team doing dimensional and functional checks during the production process. We measure consistency on-the-fly via devices such as CMMs and go/no-go gauges. Your machining becomes more comfortable when you put this layered control in the longer or intricate machining cycles.

7. Client Specific Testing

Industry-specific testing – Masion supports industry specific testing – salt-spray, pressure, hardness or load testing, whether you require components of a 5 axis CNC machining factory or a custom CNC machining factory. Your products are certified to aerospace, automotive and medical grade standards.

8. Complete Traceability Quality Reports

All inspection procedures are documented and stored. We offer full traceability, starting with material certificates, to finished performance tests. You get high quality reports per batch and complete compliance with your project and regulatory requirements.

B&S Explorer CNC Bridge-type CMCs

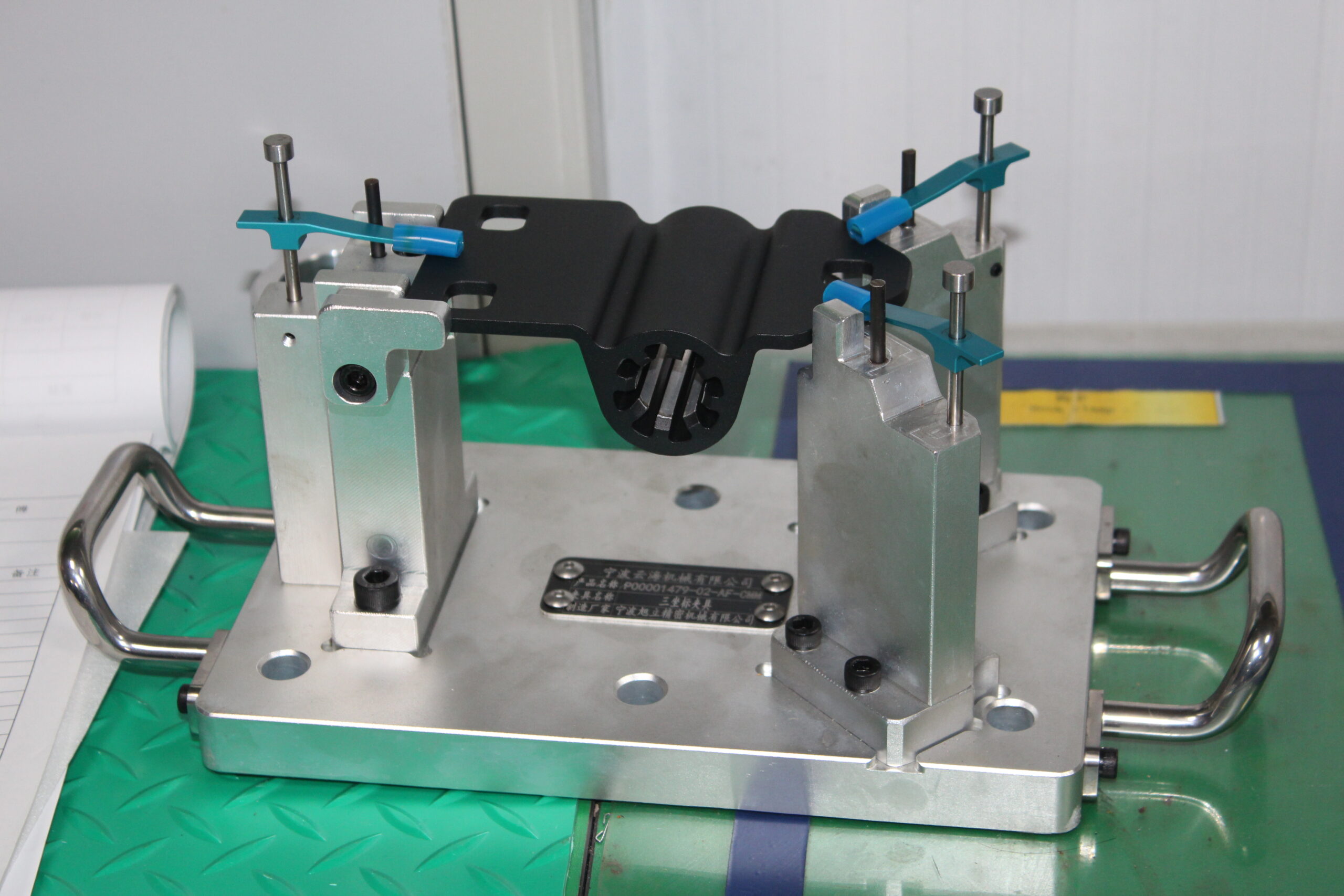

CMM Fixture

Digital Brinell Hardness Tester

Digital Micrometer

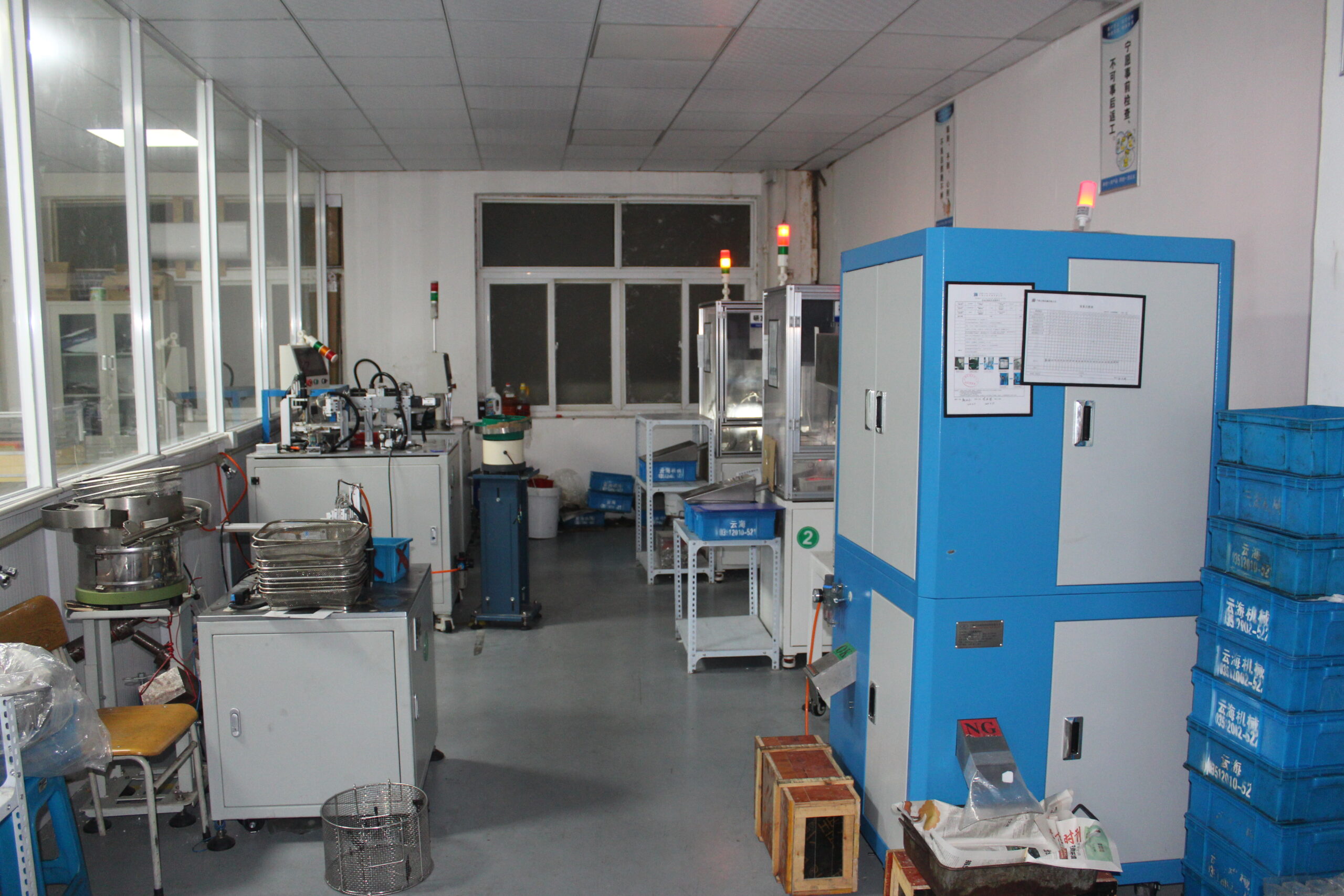

Fully Automatic Testing Equipment

Height Gauge

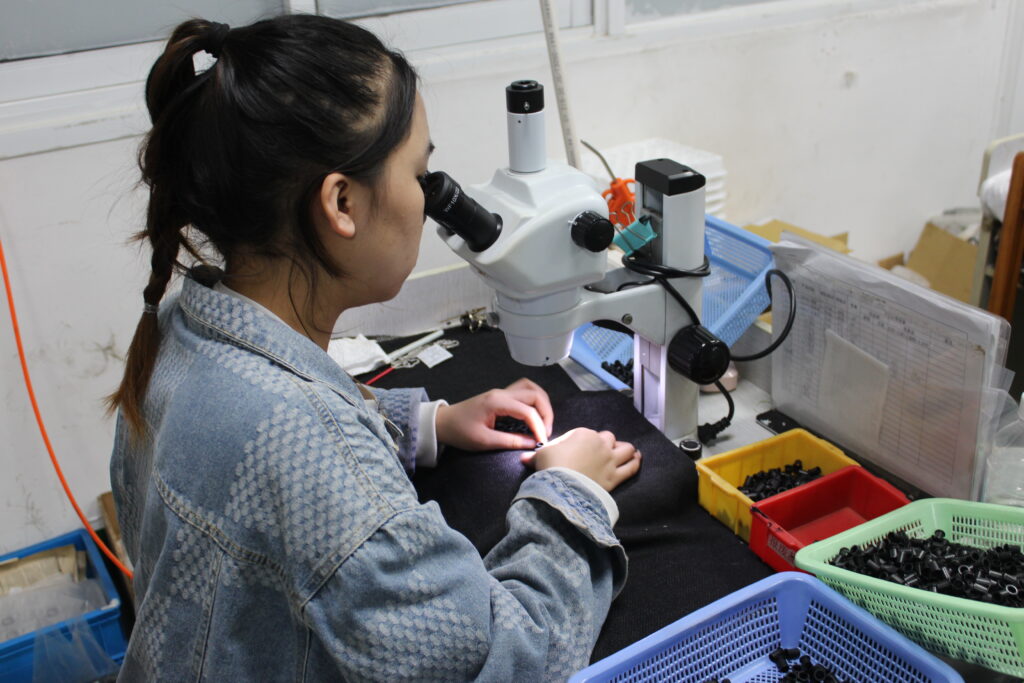

Microscopic Detection

Mitutoyo Roughness Meter

Runout Gauge

Profile Measuring Machine

Profilometer

Salt Spray Tester

Tztek VMM

ZEISS CONTURA CMM

Automatic Visual Inspection Equipment

Inspection Tool and Guage

Our Certifications

With 21 years of experience working with CNC machining, Masion produces precision parts that are of high quality. We have industry certifications that represent our dedication to excellence and dependability in each project.

- Quality Management System ISO9001

- ISO14001 Environment Management System Certification

- TS16949 Quality Management System in the Automotive Industry

Explore Our Range of Products

Frequently Asked Questions

Yes we do provide professional Design and Engineering services and we also have very highly qualified R&D and Manufacturing Engineering personnel. This is the way we can help you:

- DFM (Design for Manufacturability) Support: We assist in streamlining your designs with your blueprints. Our team offers viable, pocket-friendly solutions regarding the production of sheet metal components. You reap the benefits of lower cost of production, and enhanced quality of products.

- Custom Design Services: No blueprints? No problem. Our R&D design team will be able to help you create production ready designs. Our specialty is streamlining the production so that you can reduce your expenses and make production easy.

- Higher Level Engineering Support: Our manufacturing, R&D, and mold engineers collaborate to guarantee high quality standards to your project. They are also able to diagnose problems fast and provide an effective resolution, keeping you on schedule and within budget.

- SOTA Manufacturing Equipment: You are provided with the best equipment, such as automatic loading, welding robots, laser cutters, CNC punch, bending tools, riveting machines, spraying lines, and complete assembly lines. This guarantees quality and delivery on schedule.

- Vertically Integrated Production: We process all of our work internally-cutting, stamping, bending to welding, surface treatment, and final assembly. It implies quicker turnaround, improved quality control and easier tracking of each step in your production.

We have a vast scope of sheet metal equipment and have a lot of categories of sheet metal covered accurately. When you require CNC machining parts, they are easily accessible to you with us. We are additionally specializing in the production of body lines of CNC machineries in the automotive industry. Our CNC machining parts are:

Adaptor

Attachment

Bearings

Blocks

Body Conductor

Body Piston

Boss

Bushing

Cap

Connector

Coupling

Cover Valve

Cup

Cylinder

Dolly

Dowels

Fasteners

Hub

Insert

Knob

Locator

Main Shaft

Mount

Nose

Nozzle

Nut

Nut Flange

Pin

Pin Disk

Piston

Plate

Plug

Plunger

Ring

Rods

Guide

Roller

Seal

Shackle

Shaft

Sleeve

Spacer

Stem

Stud

Support

Swing Joint

Tie Rod Shaft

Tube Holder

Tube, End Fitting

Valve Body Part

Valve Check

Valve Holder

Valve Seats

Washer

We manufacture parts according to your individual needs and standards and our machines can serve different industries. When you have unique requests or are seeking specific details regarding our CNC machining capacity, please contact us. We also promise to provide you with the best CNC machining services with utmost quality and precision.

We could perform CNC 3.4.5 axis machining, Swiss lathe machining, Screw machining, CNC turning, CNC milling and CNC mill turn machining. Surface grinding, External cylindrical grinding machine, Surface grinding machine, Centerless grinding machine.

Stainless Steel:

Typical Grades: e.g. 201, 304, 316.

Applications: Employed in places where high strength and corrosion resistance would be of value.

Aluminum:

Includes Alloys: These include the 6061, 5052 and 7075.

Applications: It may be applied in applications that require a lightweight construction with the

intensive contact of corrosive components.

Brass:

Different Grades: It encompasses H58, H59, H62 and the rest of them.

Applications: Used in products that need good electrical conductivity and good thermal conductivity.

Copper:

The Grades: C11000, C86100, etc.

Applications: Electric and power industries or in any place where there are parts of electrical

and power devices.

Titanium Alloys:

Examples: TC4, TA1, TA2.

Applications: Aerospace, Medical, automotive and other high-end markets.

Our equipment is highly versatile which allows us to satisfy various manufacturing needs of various materials.

Yes, you may customize a processing capability of certain pages depending on your project needs. The following is a brief description of the custom process:

1. Send Inquiry

When you have sheet metal design drawings, you can simply forward it to us. Our R&D will be technically checking and our sales will give you a price estimate. In case you do not have design drawings, you can just tell us about your idea. We will draw up your idea in detail and convert our notation to AutoCAD files to be approved by you.

2. Sample Manufacturing Rapid Prototype

We make rapid prototype samples according to your design drawings. These samples are designed to comply with your specifications both in the form and functionality that will accord your company a high competitive advantage.

3. Small Batch versus Mass Production

Small batch production is a small quantity of a certain need. Mass production, though, concentrates on high production. After you approve the samples, we go into desired volume. Regardless of the size, we possess the know-how of producing high quality sheet metal parts.

4. After-Sales Service

In case you have problems after delivery, you may reach us. We also solve technical or quality issues and provide instant solutions.

5. Mold Design and Manufacture

In cases where your parts involve the development of molds we are able to design and make molds using your drawings. This increases the efficiency of production and makes the parts of uniform quality.

Of course, we can consider the release of small releases of products. Whatever you think of small or large project, what you need in material to your item, we could lie it to you and deliver to you high quality and accurate sheet metal parts.

Our normal CNC punch press is in tenths of an inch, or less, plus or minus. 1mm. In progressive die, accuracy may be as much as +or- 0. 05mm. This is to meet various needs and requirements of sheet metal punching.

Our company follows the ISO/TS 16949 and the ISO 9001:2015 quality management system. You will have the benefit of intensive product audits that attract credible sheet metals performance. Our most significant inspection processes are as following below.

Inward Goods Checking

- Material Verification: We make sure that material quality reports are used to verify material grade, size, properties and chemical composition. X-ray detectors also apply in making sure that what you receive is as per the standards of material specified.

- Other Inspections: We check the material coming to your design drawing. This involves examining the size, appearance, functionality and performance.

First Article Inspection (FAI)

- Inspection Content: A first sample is used to check that all the relevant characteristics and sizes, material and functions match your design requirements prior to production.

- Report Records: We record every measurement that we take, every inspection tool we used and the inspector. This gives you a complete history of the quality of materials and the accuracy of the processes.

In-Process Inspection

- Process Monitoring: We monitor our most important process parameters in real time after each production step with sensors and controls.

- Self-Inspection by Operators: Operators inspect work as they progress during production, and this feature enables you to remain on target in terms of size and process specification.

Intermediate Inspection

- Dimensional Inspection: In order to measure key dimensions at the production level, we make use of calipers, micrometers, and coordinate measuring machines (CMM). This will help you to be precise all the time.

- Function testing: We also perform performance testing on semi finished goods as required, to fit your design requirement.

Final Check Inspection

- Full Inspection and Sampling: All the finished parts are either inspected by inspection or random sampling based on the complexity of the product or at your request.

- Performance Testing: We perform pressure tests, salt spray test and others, as necessary, to meet your special requirements.

Pre-Packaging Inspection

- Appearance Check: We ensure that before packaging, the product is without flaws such as scratches, dents, or missing edges so that you can have clean and professional products.

- Quantity Check: We also check the quantities of products before packaging to enable you to receive what you ordered.

Pre-shipment Inspection

- Final Review: Our quality control team ensures that it can trace all the inspection records material to final product. This saves you the mistakes.

- Quality Report: All results are fully logged and we provide a final inspection certificate to make you confident in what you are getting.