Golden Plating – Everything You Need to Know

Gold plating is a key process used in luxury, electronics and high precision manufacturing. You see it in jewelry or circuit boards, its value is not limited to appearance. And that’s why you need to understand golden plating in depth — the methods, the materials, how it impacts your designs. This guide will take you through how gold plating works, where it’s employed, what are its advantages and how to pick the proper process. With this article, you are going to have a better idea on how to make smarter choices when working with or investing in gold plated components.

Table of Contents

ToggleUnderstanding the Basics of Golden Plating

What Is Golden Plating?

Electrochemical process of applying a thin gold layer on base metal is called golden plating. Commonly you’ll see 14K, 18K or 24K gold, with 24K being the highest end or the purest, at 99.998%. It coats the surface, not the core and what’s below still counts. If someone told you that thick gold layers were standard, you would probably believe them. In reality, gold layers are mostly just microns thin. Knowing this helps you pick the right type of gold and steer clear of unrealistic expectations.

Purpose and Value of Golden Plating

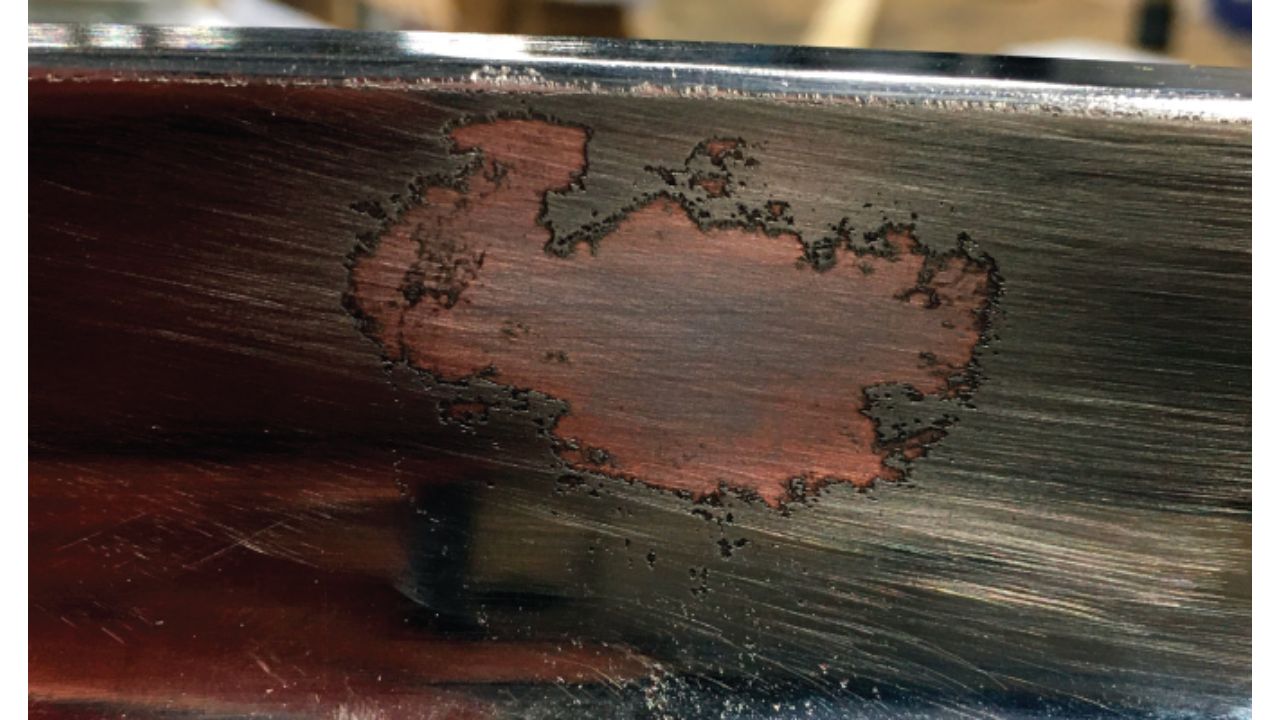

It is both decorative and functional. It gives you a rich, high luster finish that adds to the visual appeal. It does more than looks, enhancing electrical conductivity and protecting against corrosion – perfect for electronics and connectors. The surface durability is provided by hard gold plating, rated around 120 Vickers. It is worn resistant, but keep in mind its limitations when used on thin layers. These characteristics help you find the best gold plating for style and performance.

Available Plating Types

Gold Variants

Water Gold Plating (Aesthetic Focus)

Water gold plating is mostly used on decorative items. When applied, it produces a thin, shiny layer of gold that looks soft and fluid. This is the type to go for when durability or conductivity doesn’t matter as much as looks.

Real Gold Plating (Industrial Applications)

If you need gold for other technical reasons, like corrosion resistance or conductivity, you’re going to want to go with real gold plating. Instead, it uses higher-purity gold and thicker layers, ideal for electronics and aerospace parts.

Bright and Matte Gold Plating

Then you can pick a glossy or satin finish according to your design goals. A mirror like shine is provided by bright plating and a soft, elegant look comes from matte plating. The two types excel in jewelry and premium consumer goods.

Rose Gold and Champagne Gold (Color Aesthetic Use)

They are alloy based gold platings. Champagne gold is a subtle, pale wash and rose gold is a blend of gold and copper for a warm tone. These you might choose for jewelry, watches or high end décor where color counts.

Vacuum Titanium Gold (High Adhesion and Brightness)

Vacuum titanium gold is a good choice when you need extra surface bonding and brightness. It bonds gold tightly to metals using PVD (Physical Vapor Deposition). Perfect for wear resistant, high visibility items like luxury trims or watches.

24K Hard vs. Soft Gold Plating (Mechanical and Electrical Distinctions)

Soft 24K gold is an excellent conductor of electricity, best suited for contacts and circuit boards. Trace metals used in hard gold add durability and are used in wear prone parts such as switches or test probes. You choose according to the stress you expect your component to undergo.

Technological Comparison

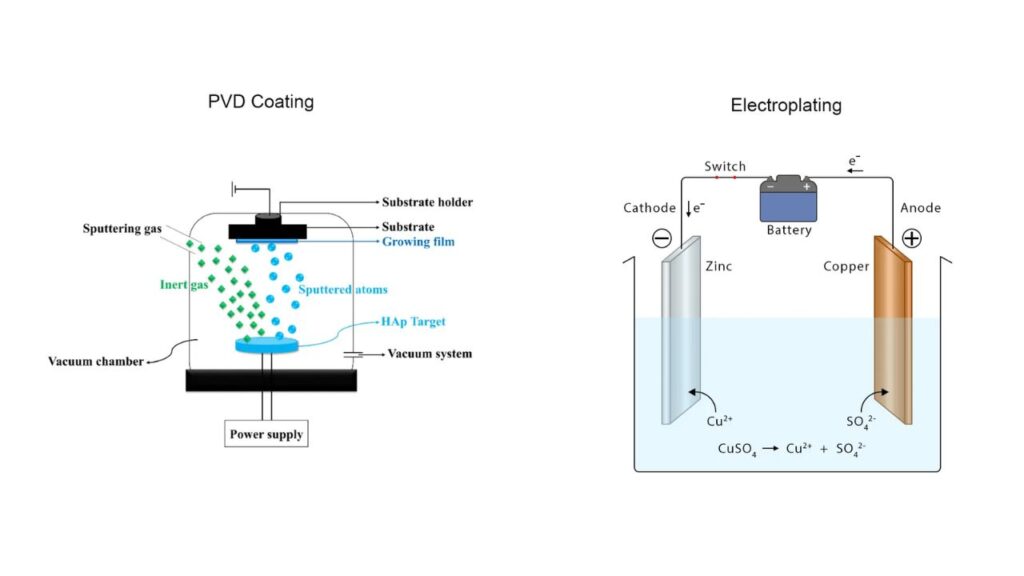

Electroplating vs. PVD Vacuum Plating

Gold electroplating is a wet process wherein gold ions bond with a conductive surface using electricity. It is versatile and cheap. In PVD vacuum plating, ultra thin, uniform layers of vaporized gold are applied to a work piece in a vacuum chamber. But it’s cleaner and has better adhesion.

Advantages and Limitations of Each Method

Electroplating gives thick coatings and flexibility in finish type. However, it is hazardous and uses more waste. A durable and bright finish is provided with fewer pollutants, but the process is expensive and limited in coating thickness.

Use-Case Mapping of Plating Type to End-Product Function

Your plating should match the product’s function. Electroplating is used for electronics, connectors and jewelry where depth counts. For scratch resistant consumer goods like watches or trims, PVD is best. Bright and matte gold are great for decorative coatings, real gold and hard 24K are needed for critical components.

Plating Techniques and Application Methods

Hanging Plating

Hanging plating is suitable for plating large or odd shaped components as it provides control and uniformity. Each piece is suspended on conductive racks and you can deposit gold evenly on complex surfaces. This process provides consistent thickness and is especially well suited for automotive trims, architectural hardware and luxury watch parts.

Barrel Plating

Barrel plating is used when you have to plate large batches of small parts efficiently. Components are loaded into a rotating drum which moves them through the plating bath. Even coverage is provided by the tumbling action making it ideal for electronic connectors, screws and pins. It is cost effective and scalable.

Shake and vibratory Plating

Vibratory plating offers gentle part handling if your parts are delicate or highly detailed. You put the items into a vibratory bowl with conductive media which helps with the gold and not damaging the items. This method is used for jewelry, small decorative items or fragile electronic parts that need precision and little abrasion.

Spot or Selective Electroplating

That doesn’t mean you have to plate the entire part. Gold can be applied to specific regions such as contact tips or connector ends without wasting material via spot plating. It is ideal for parts where some critical surfaces require gold, but also improve conductivity and wear while reducing cost overall.

Brush Plating

Freedom of hands on control when coating specific areas or making a quick fix. The metal is brushed onto the target surface with a wand like tool that is dipped in the gold solution. It is especially useful for prototypes, touch ups and complex assemblies where masking is impractical or not needed.

Continuous Plating

Continuous plating allows high speed precision when working with flexible materials such as metal strips or films. You feed the substrate through multiple stations for cleaning, rinsing and gold deposition. In PCB production, uniformity and throughput are critical to performance and this technique is used extensively.

Process Selection Considerations

When selecting a plating method, you need to consider several key factors that directly affect quality, efficiency, and cost. Here are the main points to guide your choice:

- Size and Geometry of the Workpiece

Choose a method that suits the physical dimensions and shape of your part. Large, irregular items often need hanging plating, while tiny parts work better in barrels or vibratory systems.

- Tolerances and Precision Requirements

If your parts require tight tolerances, opt for processes that offer better control over plating thickness, like selective or brush plating.

- Batch Size and Production Volume

Use mass-production methods like barrel or continuous plating for high volumes. For prototypes or low-volume needs, consider brush or spot plating.

- Cost-Effectiveness

Balance material use, labor, and equipment costs. High-speed methods reduce per-part costs, while selective plating saves gold by targeting only critical areas.

- Surface Finish Quality

Match the process to the finish you want. Vibratory and brush plating are great for intricate surfaces, while hanging plating offers consistent finishes on larger items.

- Functional Requirements

Think about what the coating needs to do—improve wear resistance, boost conductivity, or enhance corrosion protection—and choose the method that best meets those demands.

Gold Layer Thickness Specifications

Gold plating thickness is 0.025μm to 3μm. For shine for decorative items, use thinner layers of 0.1μm–0.5μm. For electronics, pick 1μm or up for durability and conductivity. Always use thickness to match.

Industry Thickness Standards

For reliable results use ANSI/AAMI or ASTM standards. You should also understand unit conversions: 1μm = 39.37 microinches = 10,000 angstroms so that you can be precise. These standards keep you consistent and error free.

Product Tolerances Impact

Plating adds thickness so it will affect your part’s final dimensions. If you need tight tolerances, adjust your design accordingly. When using multiple layers, consider total buildup to avoid fit or function issues.

Maximum Size and Production Scale Considerations

Size Limits

- Dependent on equipment capacity, you can plate components up to 850 mm.

- For even gold distribution, current density and orientation must be carefully controlled for the larger parts.

- Agitation or controlled flow of solution should be used to prevent uneven buildup on flat or vertical surfaces.

- Change anode placements and plating time for complex shapes to keep the thickness constant.

Uniformity on Large Surfaces Techniques Used

- Use auxiliary anodes or shields to direct current flow and minimize edge effects.

- Uniform exposure is maintained by rotating racks or controlled movement.

- Monitoring solution agitation and bath chemistry is critical.

- Real time verification of coverage and thickness with test coupons.

Consistent Output Process Planning

- Set clear specifications for bath chemistry, plating temperature and plating time.

- Keep cleaning, activation and pre plating step consistent across batches.

- Similar parts should be grouped together by size and shape for uniform results.

- Make sure to have detailed batch logs such that you can quickly detect and resolve variations.

Uniform Exposure by Jigging and Masking

- Tighten secure parts so that electrolyte flows evenly and there is no shadowing.

- Protect areas not meant to be plated with non conductive masks.

- Position parts precisely, repeatably, using custom jigs.

- Plating quality and consistency improves directly through good jigging and masking.

Equipment Used in Gold Plating

Pre-treatment Stations

Prior to gold plating, pre treatment is required for adhesion. Degreasing is used to remove the oils and dirt from surfaces. Following this, acid cleaning removes oxides and contaminates. Finally, all residues are removed by thorough rinsing, making your parts ready for plating.

Plating Equipment

Hanging racks, barrels and vibratory sieves are the core plating equipment. Larger or irregular items are hung on racks for uniform coating. Small parts are mass plated by tumbling them in barrels to ensure even coverage. Fragile or intricate items are moved through plating baths without damage with vibratory sieves that gently move these items.

Pre-plating Nickel/Copper Tanks

Normally, you begin with nickel or copper pre plating tanks to form a smooth base layer. This step enhances corrosion resistance, especially on steel or brass substrates and improves gold adhesion.

Gold Plating Tanks and Recovery Stations

The precious metal solution where electroplating takes place is stored in gold plating tanks. You also need recovery stations to recover and recycle gold from the bath which cuts down on waste and cost.

Drying Systems

Drying after plating is important to avoid spots and oxidation. Dryers are essential for removing moisture without damaging your delicate finishes and ensure your gold layer is flawless.

Equipment by Technique Type

Setup Differences: Hanging vs. Barrel vs. Vibratory Plating

If you are using hanging plating, you arrange the racks to hang the parts directly in the solution. For continuous movement of rotating barrels filled with small parts the barrel plating is necessary. Vibratory plating setups consist of sieves that gently move parts, making them perfect for delicate parts.

Batch vs. Continuous Production Configurations

Batch production is where you perform work in fixed quantities at a time and suits smaller runs or variable parts. Continuous production allows roll-to-roll or conveyor systems for plating large volume, consistent quality and speed. Select the configuration according to your production scale and efficiency requirements.

Step-by-Step Gold Plating Process

Hanging Plating Workflow

Firstly, you degrease the parts thoroughly to remove the oils and contaminations. Then you activate the surface to increase adhesion, typically with an acid treatment. Next, a nickel undercoat is applied for durability and to prevent corrosion. And finally, you go ahead with the gold plating. Consistent plating requires careful control of bath parameters such as pH, voltage and temperature. It is critical to rinse between steps to avoid contamination and gold recovery systems help you save precious material.

Barrel Plating Workflow

When you plate many small components, barrel plating is the best choice. The parts are loaded into a rotating barrel and the barrel tumbles to ensure even gold coverage. Plating uniformity is affected by rotational speed and load density, so it needs to be carefully balanced. When you plate, you dry the parts thoroughly to prevent spotting. You then closely inspect each batch to make sure they meet thickness and adhesion standards.

Vibratory Plating Workflow

Fragile or intricately shaped items are suited to vibratory plating. You start off with a combination of ultrasonic cleaning and chemical treatments to gently but effectively prepare the surfaces. Next, the parts are cascade rinsed to wash off residues and enhance adhesion. Corrosion resistance is strengthened by a final passivation step. Using this workflow ensures minimal damage and lays a smooth, uniform gold layer.

Testing & Quality Control Instruments

Thickness Gauge

To accurately measure the gold layer, you use thickness gauges. These are magnetic induction or eddy current devices. To check for consistent plating thickness across batches, you perform spot checks or statistical sampling. It assists you to maintain quality and achieve industry standards.

X-Ray Fluorescence (XRF) Analyzer

You can verify the gold purity without damaging the part with XRF analyzers. The exact gold content is confirmed by this non-destructive elemental analysis. With XRF you can verify that the plating meets appearance and function specifications.

Adhesion Testing Devices

Gold adhesion testing tests how well the gold sticks to the substrate. Bond strength can be evaluated by applying tape tests or micro-scratch testing. By measuring peel force you can quantify adhesion to ensure durability under real world conditions.

Microscopic and Surface Analysis

Optical microscopes are used to inspect the plating surface for defects or unevenness. Scanning electron microscopes (SEM) show advanced surface morphology for deeper analysis. With these tools, you can look at texture and coating uniformity at a microscopic level.

Corrosion and Salt Spray Chambers

Corrosion resistance is tested using salt spray chambers to simulate harsh environments. Here, you use accelerated lifecycle tests to predict how plating will perform over time. This enables you to choose the right gold plating for durability under certain conditions.

Cross-sectional Analysis

Metallographic samples are prepared by etching for cross-sectional analysis. Under a microscope, this process reveals the layer structure and thickness. With this, you validate the integrity and uniformity of the plating to ensure it meets your precise technical requirements.

Applicable Materials for Gold Plating

Metals

- Iron and Steel

Automotive and functional parts are common. Gold plating can be used to improve their corrosion resistance and appearance, thus increasing their durability and attractiveness.

- Stainless Steel

Stainless steel is widely used in surgical tools and jewelry and its biocompatibility and premium look are enhanced by gold plating. You’ll be protected and style at the same time.

- Copper and brass

These are popular substrates in electronics. Gold plating enhances conductivity and prevents oxidation, both important characteristics for reliable electrical connections.

- Aluminum and Zinc Alloys

These are pretreated before plating. In lightweight components, you must apply barrier layers such as copper or nickel to ensure good adhesion and prevent corrosion.

- Magnesium and Titanium Alloys

These alloys are used in a variety of aerospace and medical fields and require specialized plating techniques. The use of these sensitive materials will benefit from gold’s biocompatibility and corrosion resistance.

- Precious alloys.

Composites with silver and platinum bases can also be plated. It will increase their surface durability and aesthetic properties while conserving their inherent value.

Non-Metals

- Tungsten Steel

Tungsten steel is known for its durability and can be gold plated for high wear applications. It will improve surface hardness and corrosion resistance, thereby increasing the life of your parts.

- Ceramics

Vacuum deposition and adhesion promoters are used for gold plating on ceramics. Ceramics do not naturally bond with metals, so you’ll need these specialized methods.

Application Examples and Case Studies

Jewelry Industry

Rings, bracelets, necklaces and earrings come in gold plating. Adding luxury and protection from tarnish, it helps your jewelry look elegant and last longer.

Watch Components

Bezels, cases, crowns and dial markers are gold plated. You benefit from a durable, scratch resistant finish that makes watches look great over time.

Decorative Crafts

Home décor, religious artifacts and other sculptures are gold plated to enhance them. You make bright, long lasting finishes that preserve the beauty and add value.

Electronics & Conductive Use

Connectors, probes, connector probes, switches and circuit boards will benefit from gold plating which provides excellent conductivity and corrosion resistance. By doing so, you increase the device reliability and performance.

Automotive Industry

Gold plating is used to make luxury emblems and trims look stylish and protect from wear. You keep vehicle details durable and prestigious.

Architectural Hardware

Door handles, light fixtures and handrails are elegantly gold plated for corrosion resistance. Beauty and long lasting strength are your combination.

Cost Analysis and Pricing Factors

The cost of golden plating helps you plan your budget better. About 40–50% of total plating cost is gold itself. In plain English, the bottom line is that the fluctuations in the gold price directly affect what you pay. Currently, gold prices are at about $60 per gram, but these prices can change daily and affect your bottom line.

Price Drivers

Gold Market Rate Fluctuations

You have to track rates of gold market. That’s because you pay more for plating when gold prices rise. Small changes add up too, particularly for thick or large coatings.

Surface Area and Film Thickness

Gold use and therefore cost goes up the larger surface you plate. For instance, plating a 100 cm² surface with a 1 micron gold layer costs much more than a smaller or a thinner coating. Optimize thickness without sacrificing quality and you control costs.

Complexity and Tolerance Requirements

Plating gets more difficult when your parts have tight tolerances or complex shapes. You will pay more because there is an extra care and time needed to get uniform coverage and meet the specification.

Additional Factors

Material Type and Shape

You have to pay for certain base materials such as aluminum or titanium, to be pretreatment which adds to your costs. Oddly shaped or delicate parts also need customized handling and this can drive up pricing, too.

Cleaning and Pre-Treatment Level

The plating is better the cleaner the surface. Higher charges are expected if you need to clean your parts intensively or if multiple pretreatment steps are required. Investing in proper prep pays off when you don’t plate defects.

Batch Size and Repeat Orders

Setup and labor increase costs per piece with small batches. The more you order or more frequently you order, the lower the price per unit. Planning batch sizes and using volume discounts saves you money.

Quotation Customization

One-Time vs. Recurring Project Pricing

The pricing is higher for a one time project because the setup costs are divided among fewer parts. If you repeat business with a supplier, they will give you a better rate because you are a steady customer.

Efficiency from Production Scale

Streamlined processes and better resource use are possible at larger production scales. With economies of scale, you lower plating cost per item as you produce more.

Conclusion

The functional benefits of the golden plating are corrosion resistance and improved conductivity, while the aesthetic appeal is evident. Knowing the different techniques (electroplating to PVD) and selecting the proper technique for your application needs is critical to getting the best result. The proper process control and quality testing ensure durable, uniform gold finishes whether for jewelry, electronics or industrial parts. Through an understanding of golden plating’s fundamentals, materials and equipment you will be able to produce high quality coatings to meet exacting standards enhancing product value in a wide variety of industries.