High Volume CNC Screw Machining Services

CNC Accurate Screw Machining for Every Industry

In seeking accurate screw machining services, a reliable high-volume screw machine products manufacturer is a must that ensures accuracy, capacity, and uniformity. These are the things you get when you come to us:

- A 21-year old specialized high-volume screw machine parts manufacturer with reliable quality and experience.

- -Well-established production capacity of 75+ Swiss Lathes, 120+ CNC turning machines, 100+ Cam Automatic Lathes, 100+ Screw Machines, a highly qualified team consisting of 125 professionals.

- Close tolerances of ±0.01mm, minimum diameter of ±0.02mm, micro holes of ±0.02mm, wall thickness of ±0.02mm and excellent surface finish to Ra 0.05mm.

- CNCSwissMasion offers complete quality assurance with certifications including ISO9001/ ISO/TS16949 collectively for CNC screw machined parts.

High Volume CNC Screw Machine Shop - CNCSwissMasion

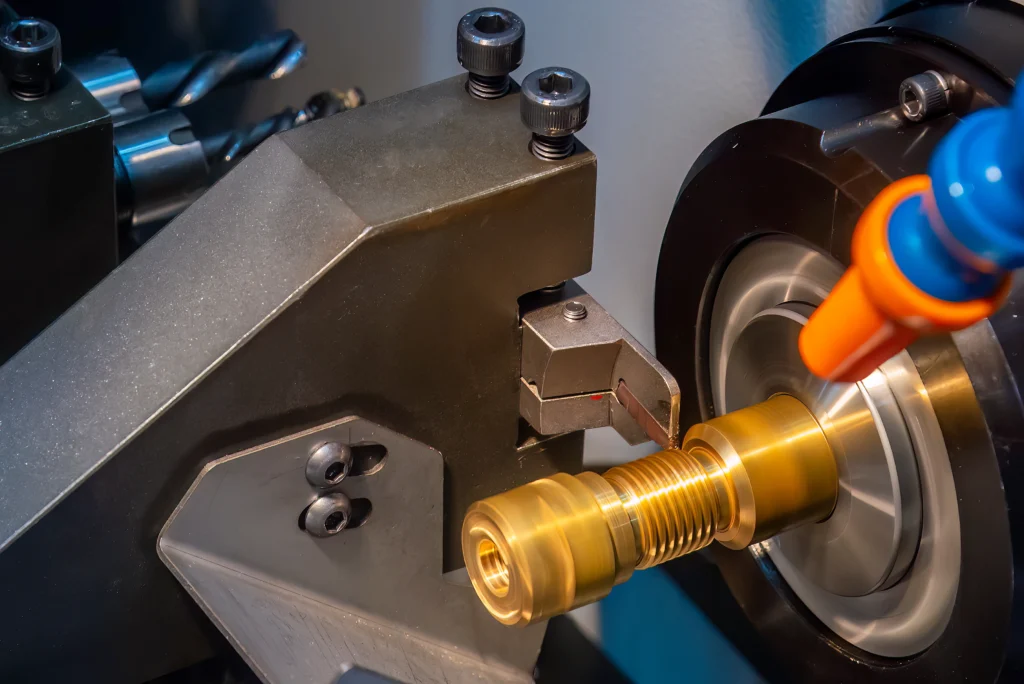

You can completely trust and rely on the screw machining services that CNCSwissMasion offers. With more than a century of experience in the area of precision machining, we can offer you solutions that perfectly match your requirements. You will have 100 + cam automatic lathes, 120 + CNC turning machines, 22 CNC automatic truss lathes and 75 Swiss lathes. We have a 24-hour automatic screw machining that will maintain 24-hours production of up to 1.05 million parts weekly. Regrardless of the industry you are going to serve tolerance and flawless performance is assured. By choosing us, you are guaranteed of good quality, short lead time and expert guidance on all your screw machining jobs.

Custom Screw Machining - Why CNCSwissMasion Is No.1?

CNC Swiss Masion provides full scale screw machining services in large production quantities. You receive the help in the first idea to manufacturing with professional advice at each stage. Critical design advice is given by our engineers to ensure you perfect designs before machining. You realize speed, precision and repeatability on the large-scale projects with the sophisticated Swiss machines. There is also a team you collaborate with that will be strict in following industry standards. All the details are controlled in such a way that you will get quality and reliable parts on time. When you decide to use us, you achieve efficiency, save on costs and keep operations running smoothly.

Materials

- Alloy

- Aluminum

- Brass

- Copper

- Bronze

- Stainless Steel

- High Temp and Special Alloy

- Titanium

- Steel

- Plastic

Screw Machines

- Swiss Lathes

- Taiwan Advanced automatic lathe

- Polishing machine

- External cylindrical grinding machine

- Surface grinding machine

- Centerless grinding machine

- Passivation equipment

- Ultrasonic cleaning equipment

Surface Finish

- Golden Plating

- zinc plating

- silver plating

- nickel plating

- Heat treatment

- Brass passivation

- Bead Blasting

- Polishing

- PVD coating

What Is High Volume Precision Screw Machining?

High volume precision screw machining is a manufacturing technique that involves quality production of large volumes of small and intricate parts with high precision. It deals with highly sophisticated screw machines which cut, shape, and thread metal or plastic materials into small screw-like components. This process is consistent in quality, efficient, and less human error as opposed to manual methods. High volume accurate screw machining is best suited to industries that demand high-quality parts on a large scale, like aerospace, automotive, and medical device manufacturing, where tight tolerances and consistent performance are essential to functionality and safety.

The Pros and Cons of High Volume Screw Machining

High volume screw machining is fast and consistent when used to produce large quantities of goods, but it has some disadvantages. Knowing both sides will make you know whether to use it or not in your manufacturing.

Pros

- Provides superior accuracy and uniform dimensions in thousands of components.

- Enables quick production rate, which saves on lead times.

- Reduces unit costs when mass production is involved and is thus very cost effective.

- Offers even finishes on surfaces applicable in end-use.

- Best in industries that require high mass production with high tolerances.

Cons

- Initial equipment and machinery may be costly.

- Small batch or custom part orders have limited flexibility.

- Needs experienced technicians to do the programming and adjustments.

- Tool wear and replacement may result in continuing costs.

- Unsuitable with very complex or irregular parts.

DFM for High Volume CNC Screw Machined Parts

DFM is crucial when machining high volume CNC screw machined parts. It helps you to maintain uniform quality, low production costs, and economical production. Each of the process steps is closely coordinated, technical and precise.

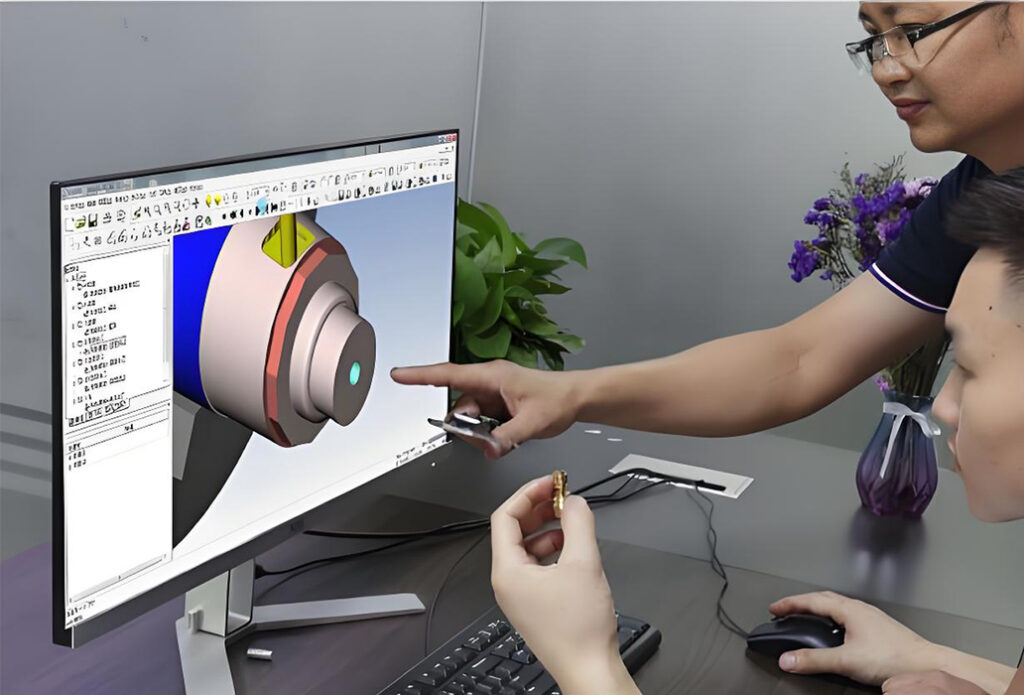

Development and Design of Products: You should begin with a good design base. The quality characteristics of the product features and design attributes are reviewed with your team and the CNCSwissMasion professionals.

Materials Knowledge and Usage: You should know the properties of raw materials, their structure and processing properties. This can be done by knowing their functional applications and applications in the industry, this way, you can have the right materials to use in your screw machined parts.

Tool Design and Application: You are specific when the tools and fixtures are designed to be applied to specific materials and structures. CNCSwissMasion has designed custom tooling systems, which are effective and streamlined with the entire manufacturing process.

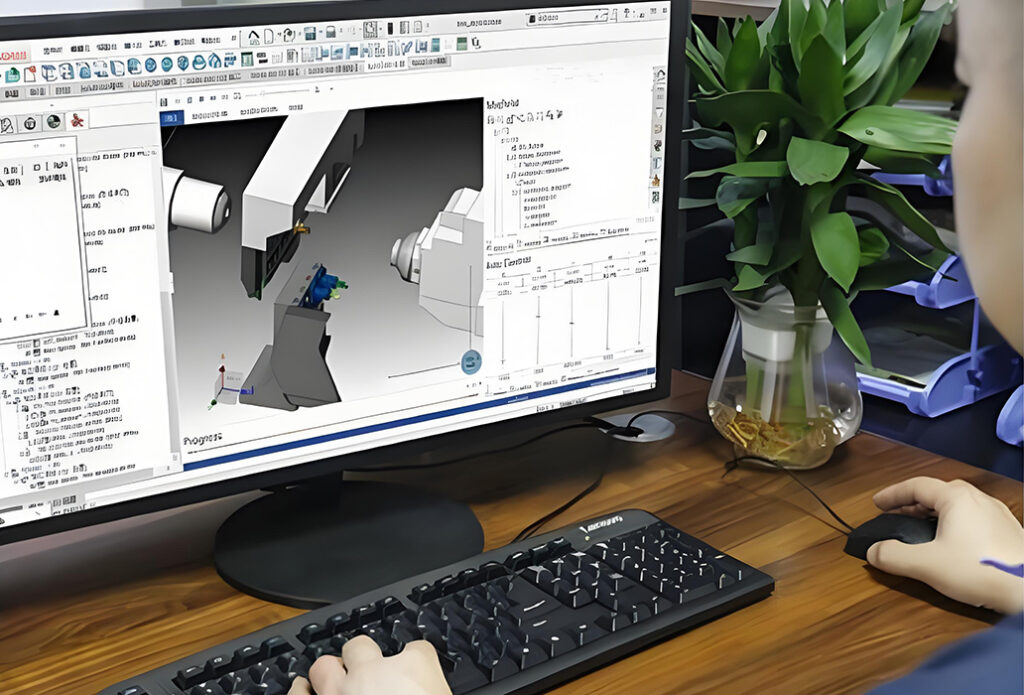

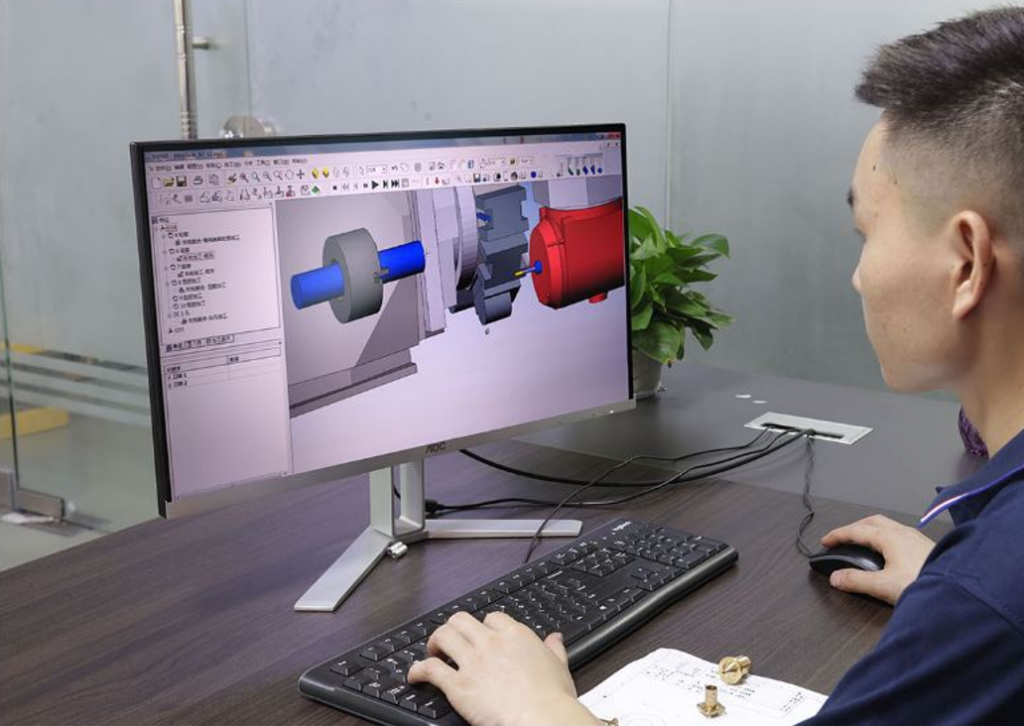

Optimization and Processing of Programming: You have the privilege of smooth-sailing programming, simulations and tweaking. Before commencing the bulk production engineers monitor, caliberate, carry out inspections, and even verify. The measure consumes less time, and it does not lead to a costly error.

Quality Control and inspection: Computerized inspection systems and electronic production control provide standardization. Such operations reduce the likelihood of failures and improve the overall reliability.

Solution Development and Cost Evaluation: You work in cooperation with technical staff members to test solutions and cost estimates. This alliance guarantees that your screw machined components are quality at a reasonable cost.

Advanced Training and Technical Research: Due to the constant research and improved training, you remain competitive. CNCSwissMasion is in contact with the international technical departments, as we provide you with the innovative process technologies and solutions.

Why Choose Us for High Volume Screw Machine Parts

CNC Swiss Masion offers a fully integrated solution to your high volume screw machine parts production requirements. We make all processes efficient, accurate and cost-effective. With our advanced systems, expertise, and equipment we are able to provide precision components at scale and meet the highest industry standards.

Intelligent Programming Tools:

You can optimize tool moves, reduce scrap, decrease turnaround and reduce expenses. This maintains accuracy in production and allows you to make large runs in a short period of time.

ERP Office Control:

You receive a full service to control data and daily activities. It helps you to monitor workflow, resources, and jobs in order to make better decisions.

MES Shop Management:

You are able to automate all the production processes to have smooth processes. This produces quicker output, uniform quality and utilization of all the available resources.

Quality Control System:

You may count on rigid control to comply with the necessary requirements each time. This ensures that every lot remains the same and is of your specifications.

In-House DFM and Design:

You can rely on our design and engineering capabilities to make your screw machine components more manufacturable and reduce errors and improve performance.

Large Project Support:

As a company that has been involved in the work of large-scale clients such as Huawei, Novel, Hysis, Tesla, Tuopu, and Xusheng, you can be sure of quality work on high volume projects.

Material and Outer Diameter:

You can choose a huge variety of materials, including Alloy, Aluminum, Brass, Copper, Bronze, Titanium and Steel. We have a diameter of 1mm to 20mm on the outside of our parts.

Complete Processing Facilities:

You can also obtain secondary processes such as cleaning, grinding and surface finishing to fit exact specifications in addition to high volume screw machine parts.

Fully Automatic Testing Equipment:

You have the advantage of fully automated testing equipment with tight tolerances and uniform quality. Each component is checked and checked to ensure high levels of repeatability in large volume production.

Large Volume Accuracy Screw Machining Tolerance

- Precision: ±0.01mm

- Cylindricity: ±0.02mm

- Flatness: ±0.02mm

- Concentricity: ±0.02mm

- Symmetry: ±0.02mm

- Circular Runout: ±0.02mm

- Diameter tolerance: ±0.01mm

- Surface roughness: 0.2 to 0.4µm and 0.8 to 1.6µm.

- Length size tolerance: ±0.01mm

- Angle accuracy: ±0.05°

- Accuracy of thread machining: <0.01mm.

- Positioning accuracy: ±0.01mm

High Volume Screw Machining Quality Control

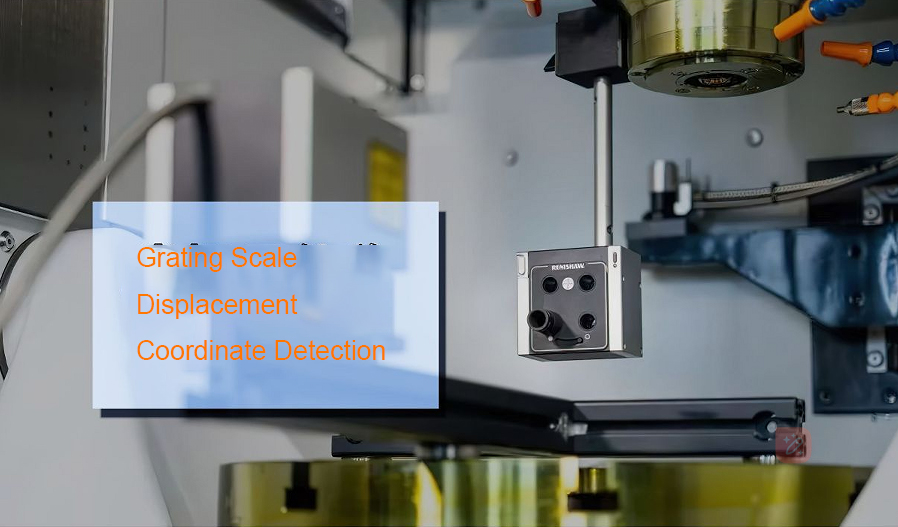

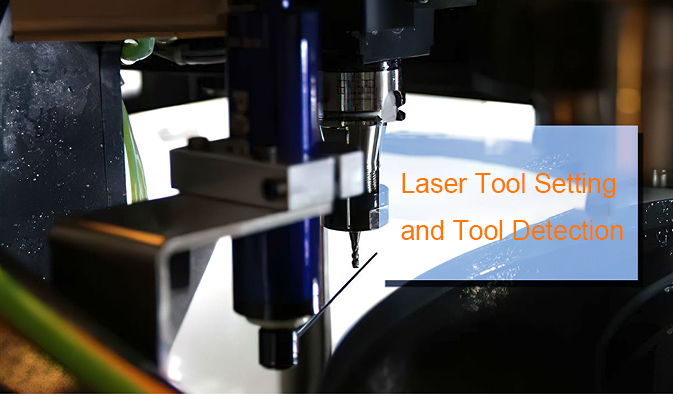

The foundation of reliability of all the components supplied by way of the decision to use high volume cnc machining is quality control. The 24-hour full automatic detection, laser tool setting and tool discovery, in machine online automatic measurement, and grating scale displacement coordinate detection are applied in CNCSwissMasion, the largest screw machine services supplier, to ensure the accuracy at all stages of production.

Raw Materials Feed Control

The process starts with raw materials. A secure and stable feed system checks each batch on entry and then stores it. The materials are of a high quality regarding compliance to REACH and RoHS. This will guarantee the consistency of downstream machining which is free and free in production.

Process Control

Each machining step is undertaken to the letter. The results of inspection are automatically captured and the operators check accuracy. Detailed analysis reports do not only confirm compliance, but also reveal performance trends, allowing constant improvement and transparency.

Product Traceability

Our developed traceability system tracks down the complete path of any product- starting with the raw material being introduced all the way to the final delivery. Such transparency would help prevent the occurrence of any problem because it can be promptly detected and fixed at the point, which would protect the quality and offer reliable and safe products to the customers.

Quality Assurance

Random re-checks support process integrity. Information is validated by authorized personnel and confirmed by signatures, which makes it timely, reliable, and accountable. Every delivery is supported by full inspection reports, which provides the customers with confidence in quality and quantity.

State of the art testing and inspection laboratories

There are more than just conventional checks on products. CNCSwissMasion has complete metrology, physical and chemical laboratories. Lifespan and performance testing emulates the actual conditions. State of the art equipment: Vacuum direct-reading spectrometers, X-ray flaw detectors, coordinate measuring machines (CMM), hydrogen analyzers, contour measuring instruments, and optical microscopes identify internal flaws and reinforce long term reliability.

Our Certificates

At Maison, we are dedicated to delivering the finest in precision manufacturing and CNC Swiss machining. With over 21 years of experience in custom Swiss machining and manufacturing of Swiss custom parts of high precision. It means we are committed to quality, industry standards and customer satisfaction through our certifications.

In fact, we have the ability to proudly boast key certifications that bear testament to our adherence to strict guidelines in different industries. This means that we are always up against the highest standards when it comes to CNC milling turning and small parts manufacturing.

- ISO 9001 Quality Management System

- ISO14001 Environmental Management System Certification

- Automotive Industry Quality Management System (IATF 16949)

- RoHS Restriction of Hazardous Substances (Available Upon Request)

- SGS Products Test – These tests are conducted to check the quality and if it matches industrial standards.

- Conformity to European standards: Solemn quality in CNC Swiss machining is CE marking.

High Volume Screw Machining Industries

High-volume CNC machining plays a key role in industries where consistency, efficiency, and precision are essential. With the automatic bar machining technology, you will be able to produce the dependable and accurate parts that have high standards. Such a versatility renders screw machining essential in various sectors.

- Automotive Industry: High-volume machining ensures durable, high-strength components such as fasteners, engine parts, and connectors. These components provide stability, enhance vehicle operation and withstand harsh working conditions.

- Aerospace Industry: In cases where weight and tolerance are crucial, precision CNC machining provides low-weight, high-tolerance products such as turbine elements, fittings, and fasteners. These components are constructed in such a way that they can withstand harsh conditions.

- Electronics Industry: Miniature components like pins and housings and contacts require precise tolerances. Swiss machining offers predictable and consistent results, which enables electronic devices to operate perfectly with scale.

- The Industrial Machinery: Shafts, bushings, and fittings need to be long lasting and consistent. Automated machining makes you keep the equipment efficient, minimize machine downtime, and increase machine life.

- Consumer Goods: Large-scale manufacturing of everyday products, including watch parts, fasteners, and small hardware, is done under high-precision manufacturing. You get uniform quality, accuracy, and dependability to satisfy the mass-market requirement.

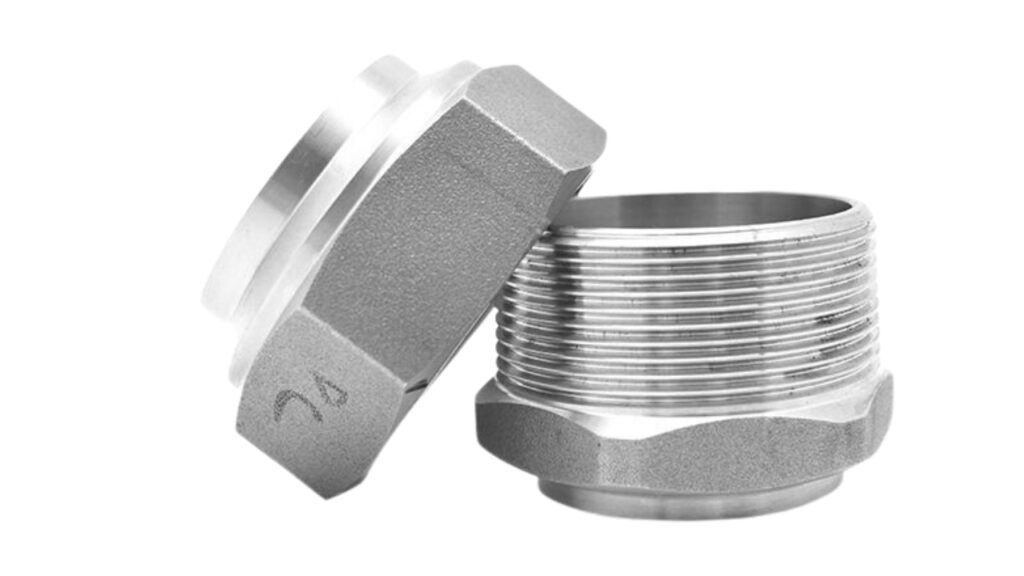

Explore Our CNC Accurate Screw Machining Products Gallery

Screw Machining Product

Screw Machining Custom Product

CNC Swiss machining Products

CNC Swiss machining Parts

CNC manufacturing products

High-precision product

Precision manufacturing parts

High volume cnc screw machined parts

Accurate screw machining parts

CNC machining products

Checkout our Another Manufacturing Services

- Swiss Machining

- Custom Machining

- Micromachining

- Multi-spindle Machining

- Screw Machining

- Precision Machining

- CNC Mill/Turn

- Automatic Lathe Machining

FAQs

Can high volume screw machining be used to make custom shapes?

Yes, you can. Precise and complex designs can be created using high volume screw machining. You are able to customize sizes, threads, and features to fit precise project demands.

What is the response time to create accurate screw machining parts?

You enjoy the advantage of quick cycle times intended to run in bulk. The speed of production is determined by the type of material, the complexity of parts and the size of orders, but screw machining is the most efficient when it comes to high volume requirements.

Can we mix up various materials in one sequence?

Yes, you can. You can also order parts in brass, aluminum, stainless steel, titanium or plastics as part of the same order to make production simple.

What can I do to be certain that the parts will fit into my assembly?

Tight tolerances and rigorous quality inspections can be counted on. Design testing and machining accuracy will make sure that all the components will fit perfectly in your assemblies.

Are surface finishes customizable?

Yes, there are polishing, plating, anodizing, bead blasting and coating finishes. These alternatives assist in achieving both the visual appeal standards and the functional requirements.

Can high volume cnc screw machining services be applied in new industries?

Yes, they are very versatile. The high-volume screw machining capabilities of industries such as aerospace, medical machinery, electronics, and green technology are precise and scalable.