Micro Machining Guide – Everything You Need to Know

Micro machining involves working with materials at a scale of micrometers or less. The field is very important for advancing the industries of medical devices, aerospace, electronics and MEMS. The guide will explain the basics, starting from its origins and describing the main types of machines, important materials and the latest trends. Regardless of your level of experience, this guide offers clear information about the present-day tools and guidelines of micromachining.

Table of Contents

ToggleHistorical Evolution of Micro Machining

Over the years, many innovations have helped microscale manufacturing to develop. Precision engineering grew strongly after WWII and then led to the invention of CNC technology in the 1950s and 60s. As the industry expanded, there was a need to make components even more precise. In the 1980s, MEMS played a key role in the industry, but in the 1990s and on, there were major breakthroughs such as micro-EDM, thermal machining, and micro-laser machining. You now use hybrid systems that use a combination of machining techniques. Using AI, you can now improve your tool paths, decreasing the chance of mistakes. Simulation, monitoring and adjustment with digital twins and Industry 4.0 make ultra-precision fabrication more intelligent and efficient than before.

Fundamentals of Micro Machining

Basic Principles

Miniature-scale material processing refers to the cutting and shaping of materials with dimensions ranging from 1 μm to 500 μm a capability often required by advanced machined parts manufacturers. Mechanical, thermal and chemical are the main interaction mechanisms you experience. Typically, ultra-precise cutting or abrasive processes are used mechanically, whereas with thermal methods, local heating is done by laser or EDM. Etching with chemicals does not involve coming into contact with the material being removed.

Essential Requirements for the Software

Sub-micron accuracy can only be achieved with the use of precise positioning systems. Machines use high-speed spindles to guarantee stability and help minimize the force needed when cutting. Tool runout and excessive vibration should be minimized so that surface defects are prevented. When the different elements are properly connected, the parts are precise, smooth and can be reproduced consistently, making them helpful for micro-scale manufacturing.

How Micro Machining Works

In micro machining, small amounts of material are cut to build very accurate parts. The first step is to clean and secure the workpiece so it stays in place. After that, you use CAD/CAM software to plan the precise path the tool will take. When machining, you utilize tiny tools to shave off material from the part. Next, you perform post-processing and check the parts to ensure they meet quality standards.

Accuracy and Tolerances

Machining with sub-micron accuracy is possible by making the machine stable and using sharp tools, a standard often achieved by leading precision machining companies. You should focus on the Ra and Rz values as part of surface finish. You need to manage the environment to ensure quality is maintained. Slight variations in temperature, humidity or vibration may influence the results. The right tools will enable you to produce high-quality parts for the medical, aerospace or electronic fields.

How Micro Machining Differs from Conventional Machining

Dimensional Scale

At the micro machining scale, things are made using sub-millimeter techniques. You are often concerned with features smaller than 0.1 mm, yet conventional machining uses much larger equipment. Because of this difference, extra attention needs to be given to how strategies are executed.

Equipment and spindle rotation

The tools used in micro machining are less than 0.5 mm in size. To be used effectively, these small tools need high spindle speeds that can go higher than 100,000 RPM. Ensure that the tools remain intact and do not allow heat to accumulate or the tools to malfunction.

Material Behavior

When you work at this size, the structure of the material plays a big role in determining your outcome. In small CNC machining, the surface quality and wear of tools can be affected by the size of the grain. You’ll come across issues with removing chips and dealing with burrs, as they are more challenging in the micro world.

Applications

Micro machining is necessary in fields requiring high accuracy, for example, microfluidics, stents, MEMS and biosensors. Big parts in the automotive, aerospace and industrial industries are still best machined using conventional techniques.

Key Technologies in Micro Machining Systems

Micro Machining Equipment

To create these tiny features, you use micro end mills, drills, grinders and laser heads. For precision work, especially in small CNC machining, it is important to select the right material for your tools. When you use tools with diamond coatings, they last longer and are better protected against wear, mainly for hard materials. If the metal is soft, carbide tools are generally more cost-effective and appropriate to use.

CAD/CAM and simulation software

Conventional software can’t handle tasks at this level. Your CAD/CAM system must have the ability to program very accurate tool paths. With these programs, you can imitate cuts, guess how hot the material will get and learn how it will react under pressure. Proper software allows you to achieve the same outcome with fewer trials and less risk of errors.

Feedback and motion control systems

A little bit can go a long way. Therefore, your miniature machine motion systems should include encoders with nanometer-level resolutions. They provide you with immediate updates on your location. You can move your tools effortlessly and with no extra vibration or friction, thanks to piezo actuators and air bearing stages. This way, you can expect your cuts to be the same each time.

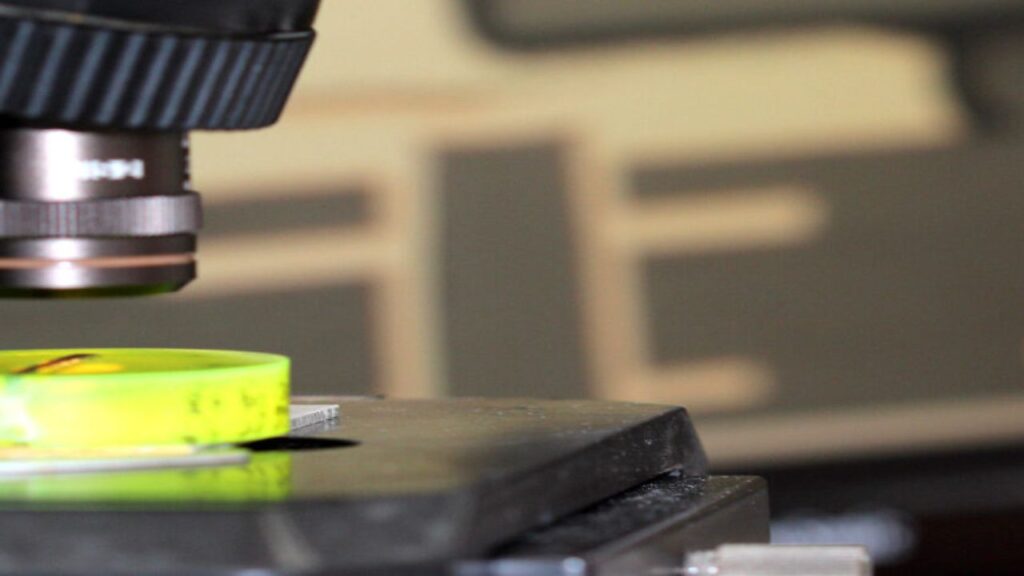

Monitoring and Measurement

The best way to maintain quality is to check it constantly. Miniature precision components can particularly benefit from interferometry and white light sensors allow you to observe the features as you cut them. If detailed checks are needed, using scanning electron microscopy (SEM) and atomic force microscopy (AFM) will help spot the surface roughness, any burrs and determine the exact measurement.

Important Methods in Micro Machining

To work with components on the microscale, you have to ensure precision and keep things in control. There are a variety of methods offered by mechanical micro machining to make small and detailed parts. Let’s look at the main techniques used in Impressionist art.

Mechanical Micro Machining

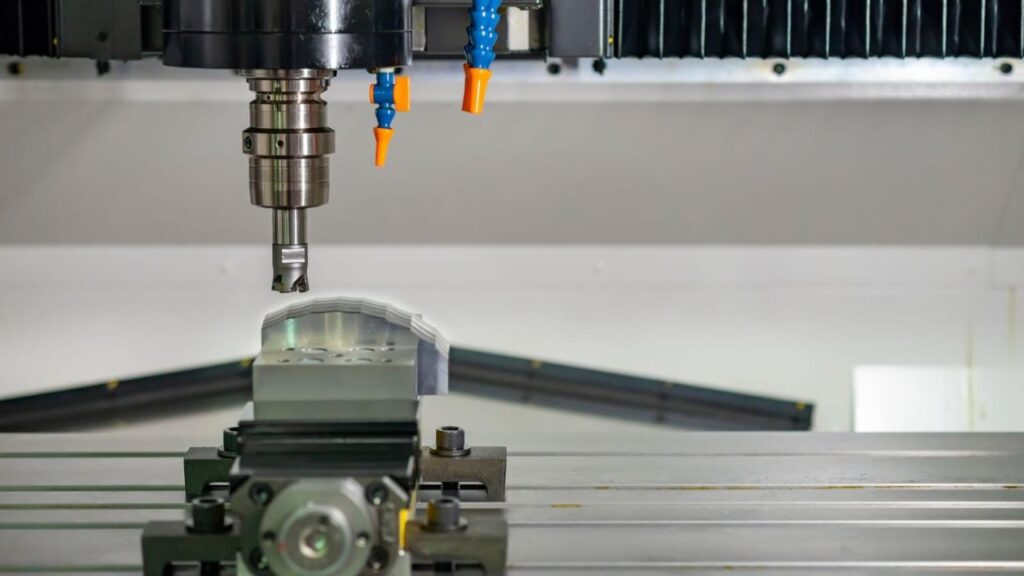

Micro Milling

Creating complex 3D shapes can be done most effectively with micro milling. It relies on several axes to ensure accurate cuts. You might design with aluminum, polymers or even strong metals such as titanium. With this approach, you can create fine surfaces and tiny details.

Micro Turning

The precision in making cylindrical micro parts is best achieved with micro turning. This technique is useful for making catheter tips as well as dental implants. While rotating the object for cutting, lathes ensure that results are symmetrical and even.

Micro Drilling

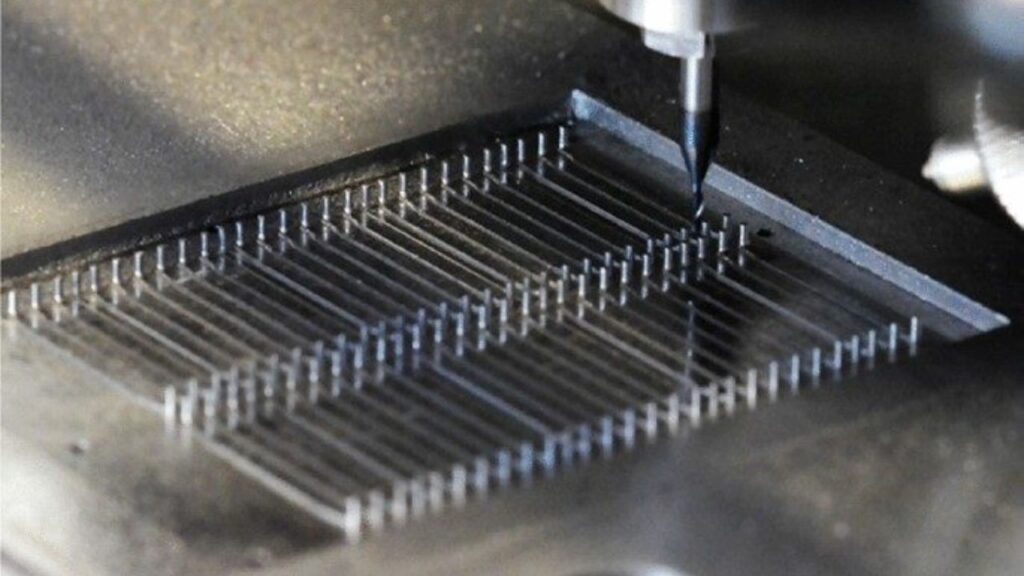

If the holes you need are smaller than 100 μm, you must use micro drilling. It is frequently used for etching vias onto printed circuit boards (PCBs) or making inkjet nozzles. With this method, you can produce fine and accurate holes on different types of materials.

Micro Grinding

For an exceptionally smooth finish on tough materials, make use of micro grinding. Using this method is best for optics, precise molds and materials such as sapphire and tungsten carbide. The finished parts are precise and look beautiful.

Micro Ultrasonic Machining (Micro-USM)

If your materials are either crumbly or non-conductive, you should choose Micro-USM. It involves moving the material with rapid vibrations and abrasive liquid. Different tools can be used to shape glass and ceramics without the risk of breaking them.

Thermal Micro Machining

Micro Electrical Discharge Machining (Micro-EDM)

Micro-EDM can be done from a distance without touching the part. Rather, it erodes materials by using sparks, making it a form of thermal machining. You can use it to work with hard and conductive materials like tool steel or titanium. For extremely fine 3D parts or dies, Micro-EDM gives precise results, with little or no impact on the tool’s lifespan.

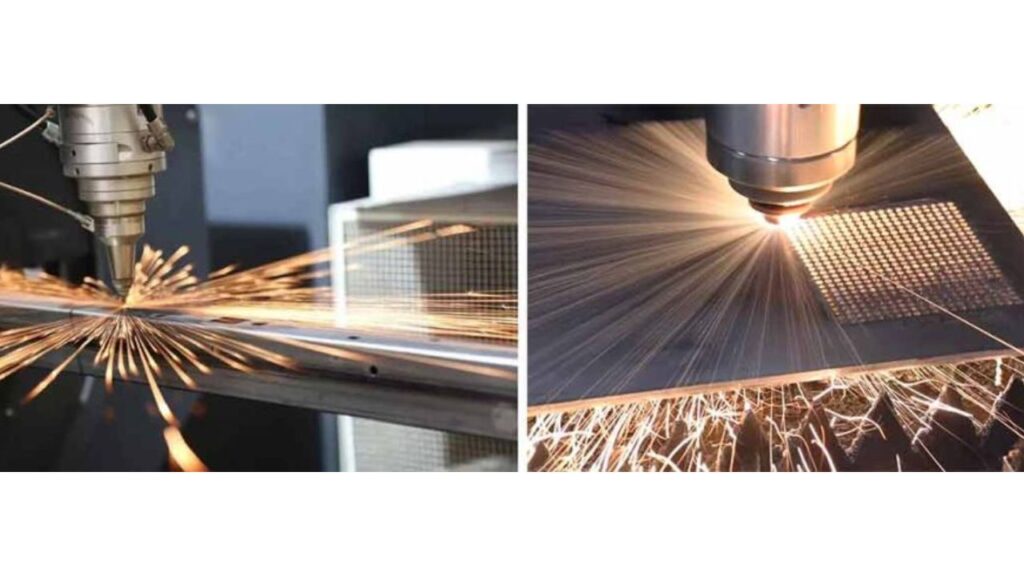

Micro Laser Beam Machining (Micro-LBM)

A laser beam is applied in Micro-LBM to cut or drill materials. This approach can be used for both opaque and transparent materials. It can be used to create small holes in medical tubing and to cut stents. It delivers excellent results for precision medical equipment.

Micro Electron Beam Machining (also known as Micro-EBM)

Micro-EBM constricts the electron beam until it is smaller than 1 μm. Because it works in a vacuum, it is ideal for the manufacture of aerospace components. The outcome involves corrections with high accuracy and smooth edges. When dealing with small details on top-quality components, Micro-EBM is the best approach.

Chemical and Electrochemical Micro Machining

Chemical Micro Machining

To remove material precisely in chemical micro machining, you use photochemical etching. It is done by putting a mask on parts you want to preserve and exposing the rest to etching chemicals. This method is most effective with thin foils and semiconductors, so you can make detailed patterns at micro-levels without worry of stress. You’ll notice how this lens can capture detailed images while minimizing any distortion.

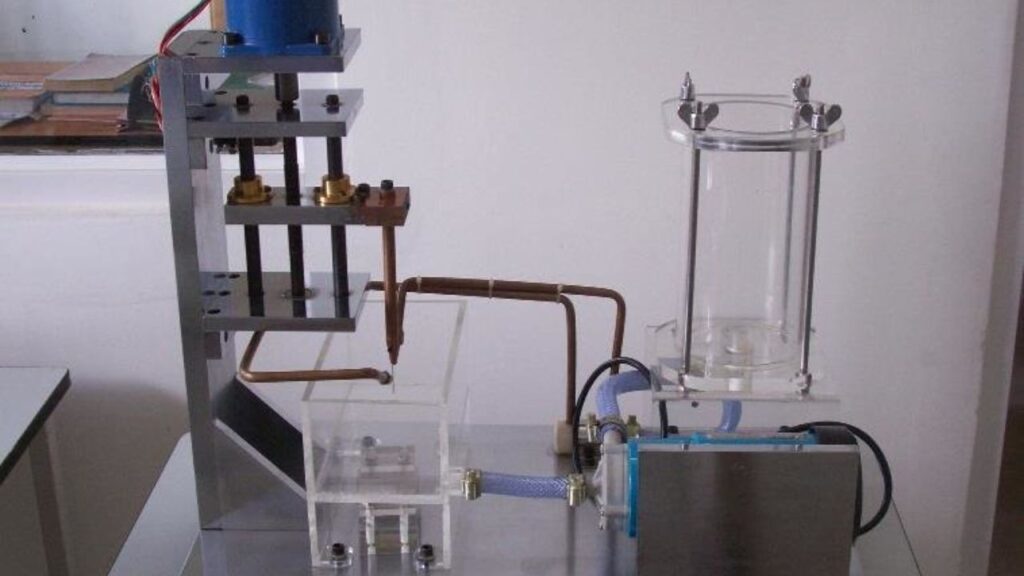

Electrochemical Micro Machining (ECMM)

ECMM combines an electrolyte solution and electric current to separate and remove some elements through the process of anodic dissolution. You don’t need equipment, so it never wears out. With this method, you get a smooth surface and precise tolerances which is perfect for finely detailed conductive surfaces.

Hybrid Micro Machining

Mixed Hybrid Techniques

In combined hybrid micro machining, more than one process is carried out at the same time. As an example, Micro-EDM used together with grinding can provide high precision and a smooth surface. This allows for making shapes with high detail and a smooth finish which neither process could do alone.

Assisted Hybrid Methods

Assisted hybrid methods increase the capabilities of traditional machining by using actual physical effects. In vibration-assisted milling, the cutting tool is constantly vibrated at high frequencies. Less force is needed to cut, chips are removed more easily and the surface comes out smoother. As a result, your tools stay sharp longer and your parts meet tighter specifications.

Synergy Benefits

When you use hybrid micro machining, you get several advantages. You can get more accurate results and remove more material in the same period. Your tools last longer, so you save money and time. As a result, hybrid techniques allow you to surpass the usual boundaries of micro machining without sacrificing accuracy, making them ideal for precision machining services.

Other Specialized Methods

Micro Abrasive Jet Machining is known as Micro-AJM

A stream of fast-moving abrasives in Micro-AJM rubs away material from the workpiece. The EDM process is useful for working with glass, ceramics and thin metals. Because it does not give off any heat, Micro-AJM protects your band saw blade from thermal damage. The accuracy depends on the size and movement of the particles, as well as their angle which allows for high-precision machining at the micron level and without needing contact tools.

Micro Focused Ion Beam Machining is also referred to as Micro-FIB

Micro-FIB uses a narrow ion beam to chip away at the material from the sample’s surface. With this technique, you can precisely shape and modify features at the tiny nanoscale. Micro-FIB is often employed in semiconductor processing, defect analysis and preparing samples. A vacuum environment helps you make clean cuts since you can avoid any contamination.

Micro Plasma Arc Machining

The technique uses a plasma arc to melt the material and turn it into vapor. Micro Plasma Arc Machining is necessary when it is challenging to machine tough or conductive materials mechanically. The procedure is quick and accurate, but you should pay attention to the heat to prevent any damage to fragile parts.

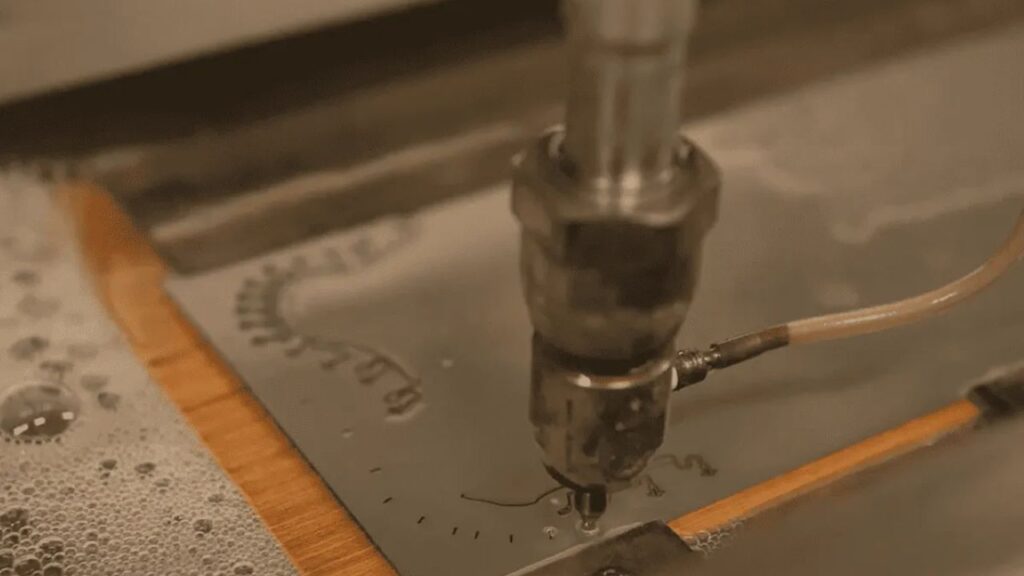

Water Jet Machining on a Micro Scale

Micro Water Jet Machining makes use of a fine and powerful jet of water combined with abrasives to cut materials without raising their temperature. Almost all materials, including composites and metals, can be machined without being affected by heat. This technique is used for applications where clean edges and no heat changes are needed.

CNC Machines for Micro Machining

High-Precision CNC Milling Machines

Most CNC routers use 5-axis control, making it possible to reach the workpiece from different angles. It allows you to design detailed geometries with little effort. They ensure all parts of the assembly are held at a constant temperature to prevent distortion. By monitoring the position and vibrations of the tools all the time, the system can maintain accuracy at the level of a micron. Because of this, the mills are well-suited for making aerospace parts, medical devices and electronics.

Micro Turning Centers that Use CNC

For making small cylindrical parts, you should choose a CNC micro turning center. They are designed with small tool holders and ensure precise movement of the rotary axis. They enable you to work with very tight accuracy on minuscule objects such as catheter tips or implants for teeth. Their smooth design allows you to spin at high rates with good stability, giving you a better outcome and consistent results.

CNC Swiss-Type Lathes

The unique feature of Swiss-type lathes is the sliding headstock. For this reason, they can act as a miniature machine, creating small, detailed components with complicated designs. They are particularly helpful when making medical and electronic components, as both their size and accuracy are important. Because the workpiece rests on the sliding headstock, the tools can move while the workpiece stays steady and vibrations are reduced.

Platforms Based on Ultra-Precision CNC

If you require a nanometer-level level of precision, ultra-precision CNC platforms can achieve this for you. They include feedback mechanisms that can monitor movements with great accuracy. You have the ability to meet the most exacting standards for both surface looks and dimensions. If your project requires precise attention to detail, use this technology.

EDM for Micro-machining

The EDM process is not the same as the one used in traditional CNCs. This equipment allows you to machine features as small as 50 microns without a physical tool coming in contact with the part. This is an appropriate method for cutting thick, metal materials and complicated shapes that can’t be cut mechanically.

Laser Micro Machining Centers

Femtosecond and picosecond lasers are used in laser micro machining to remove material with great precision and cause little heat damage. You can use these centers to manufacture small features, miniature precision components, and micro-holes in various materials such as metals and polymers.

Micro CNCs for desktops

Labs and prototyping facilities can rely on desktop micro CNC machines for their needs. They let smaller groups or individuals carry out micro machining, as they are cheaper than the standard industrial devices.

Key Features Enabling Micromachining

Thermal Stability Module

Precision in micromachining can be maintained only if the system has thermal stability. Precision machining companies are responsible for managing the temperature in the machine and its environment. If they are not there, measuring and cutting can result in errors because of heat expansion.

Anti-Vibration Damping

Vibrations cause problems with the precise micro-scale cutting process. Thanks to anti-vibration systems, vibrations are less of a factor and you can work with more precise and accurate results. This is vital when capturing small features because an barely noticeable tremble can affect the image.

Real-Time Control Software

Real-time software is used to oversee and promptly change the parameters during machining. With this software, tool paths are adjusted, speed is matched and feed rates are selected to prevent errors. You can manage the process very well with precise control.

Key Criteria for Material Selection in Micro Machining

To achieve precision and quality in micro machining, you should consider various important factors when choosing the right materials.

Machinability

Ensure the materials you pick are machineable. Because of this, the material should encourage chips to form, protect the tools and leave a high-quality surface behind. If the material is difficult to machine, you may break tools and obtain results that vary in quality which can be costly and time-consuming something machined parts manufacturers work hard to avoid.

Heat Transfer and Relaxation

Precision in machining depends on the thermal properties of the metal you are using. When the thermal conductivity of your materials is high, heat dissipates rapidly, ensuring tighter tolerances. On the other hand, materials with a high rate of thermal expansion may experience changes in their dimensions while being machined. Taking these aspects into account will prevent mistakes and help you achieve good stability.

Mechanical Properties

Hardness, the strength it has when stretched and elasticity are key factors in determining its response to machining. The material you pick should have the mechanical characteristics needed for your part’s purpose. To illustrate, using hard materials might cause your tools to wear out faster and resilient materials could get deformed during the machining process.

Resistance to Chemicals and Reactivity

If you are working in biomedical or chemical science, it is important to pick materials that do not react with chemicals. Utilizing precision machining services can help ensure components are crafted to exact specifications, promoting the reliability and safety of sensitive devices.

Application-Specific Demands

Lastly, make sure to pay attention to unique traits of your product such as how biocompatible it is, if it conducts electricity or how much weight it can bear compared to its strength. When you match your material to these requirements, you can ensure the end product functions correctly.

Metals Suitable for Micro Machining

Stainless Steel

Stainless steel is strong, does not corrode easily and is suitable for use in the body. Many surgical tools and orthopedic implants are made from titanium. For small but vital parts, aerospace often uses stainless steel. Ensure you use sharp tools and provide the metal with good cooling when working with stainless steel. Since the metal tends to get harder as you use it, this may cause your tools to wear down quicker unless you are cautious.

Titanium

Among its advantages, titanium is light, highly resistant to corrosion, strong and is safe for human use. Parts of jet engines and devices used in medicine like bone screws and dentures are examples. Because titanium does not conduct heat well, it gets very hot when machining. Temperature needs to be carefully regulated to prevent damage and ensure accuracy.

Copper

Copper is well-known for being able to transmit electricity and heat very efficiently. It works best for electronics such as PCBs, micro-coils and antennas. Copper is commonly used in heat sinks and microfluidic channels because of its cooling abilities. When machining copper, you should use sharp and accurate tools to prevent smearing that results in blurring.

Aluminum

Aluminum is considered light, not prone to corrosion and is easy to process. The material is often chosen for housing sensors and electronics in automobiles and airplanes. Since aluminum can be machined quickly, making sure there is no messy chip buildup is very important.

Nickel Alloys

Nickel alloys such as Inconel are strong and resilient at high temperatures, so they are used in turbine blades and sensors that face tough conditions. Be prepared for your tools to wear out quickly while machining these metals. You should prepare yourself with the right tools and approaches, including precision cnc milling, to be accurate and efficient.

Plastics and Polymers for Micro Machining

| Polymer | Properties | Applications | Machining Notes/Considerations |

| Polycarbonate (PC) | Impact resistance, optical clarity | Medical housings, optical lenses, protective casings | Prone to melting—requires careful heat management. |

| ABS (Acrylonitrile Butadiene Styrene) | Toughness, lightweight, low cost | Consumer electronics (phone casings), automotive interiors | Easy to machine, low melting point. |

| PTFE (Polytetrafluoroethylene) | Chemical inertness, low friction | Seals, gaskets, chemical industry components | Requires sharp tools, low feed rates. |

| PEEK (Polyether Ether Ketone) | High-performance thermoplastic with chemical and heat resistance | Implants, aerospace insulators | More difficult to machine, requires rigid setup. |

Ceramics in Micro Machining

| Polymer | Properties | Applications | Machining Notes/Considerations |

| Alumina (Aluminum Oxide) | Hardness, thermal resistance | Semiconductor: Wafer carriers, substrates; Mechanical: High-wear precision parts | Laser micromachining, ultrasonic machining. |

| Silicon Carbide (SiC) | High hardness, thermal conductivity | Optics, semiconductor processing, high-temp sensors | Best machined with EDM or abrasive techniques. |

Composites for Micro Machining

| Polymer | Properties | Applications | Machining Notes/Considerations |

| Carbon Fiber Reinforced Plastics (CFRP) | Lightweight, high stiffness | Aerospace panels, high-performance automotive parts, sports gear | Fiber pull-out, delamination; requires sharp, coated tools. |

| Glass-Filled Polymers | Enhanced stiffness and temperature stability | Structural electronic components | Abrasive—can lead to tool wear. |

Material-Machining Method Compatibility

| Material Type | Suitable Micro Machining Method(s) |

| Stainless Steel | Micro milling, Micro-EDM |

| Titanium | Micro milling, Laser machining |

| Copper | Micro milling, LBM |

| Polycarbonate | Micro milling, LBM |

| Alumina | Ultrasonic, Laser micromachining |

| CFRP | Micro milling (diamond coated), Abrasive jet |

Matching Materials to Application Needs

Biocompatibility Required: Materials such as titanium, stainless steel or PEEK are needed if you design or develop medical implants or devices. Thanks to these materials, there is a lower risk of the body rejecting or being infected by the implant.

High Precision Optics: When using lenses or optical components, pick silicon, quartz or alumina. The materials used are highly stable and clear which allows your optics to function properly in any situation.

Electrical Conductivity: If your project includes electronics or conductive materials, consider using copper, gold alloys and silver. With excellent conductivity, they can boost the efficiency of electronic devices, and precision cnc milling helps maintain tight tolerances for such components.

Weight-Sensitive Applications: Aluminum and carbon fiber reinforced plastics (CFRP) offer strength without increasing the size of your car.

Thermal Management Applications: Heat dissipation is best achieved with copper and silicon carbide. They allow you to control the car’s temperature and boost its efficiency.

Challenges and Considerations When Working with Each Material

Tool life and wear rate: Certain metals such as nickel alloys or composites, tend to wear much faster than other materials. Pick the proper tools and observe their wear carefully so your machine does not break down and remains accurate.

Burr formation tendencies: Stainless steel and aluminum often cause burrs which may result in poor quality parts. It is important to plan effective deburring or modify machining to keep this problem low.

Heat generation and thermal expansion: Swift-moving tools can heat up the sensitive materials. Controlling the temperature and selecting the right cooling will help maintain accurate dimensions.

Machining-induced stresses or deformation: Wear and tear during machining may bend or distort materials that are thin or flexible. Reducing stress on the machine can be achieved by adjusting the feed and using suitable fixtures.

Surface finish and dimensional accuracy: Many materials react differently to how they are machined with tools. You should strive for both speed and accuracy to achieve the quality of finish you want.

Cost and availability of raw materials: There are materials that might be hard to obtain because they are costly. Remember to plan for it when creating your project budget.

Conclusion

A good outcome in micro machining depends on your choice of material. Selecting the appropriate material allows you to fulfill design specifications, use the machines available including small CNC machining setups and satisfy conditions at the end application site. Correlating these factors helps ensure your metal is both strong, precise and efficient. Micro machining will continue to develop as new materials and mixing techniques are introduced. Following these advancements will help you achieve great things and do even better work with your projects. Your main focus should be on choosing materials for long-term success.