Micro Machining Services/Miniature-Parts

Miniature Machine Shop In China

Your go-to miniature machine shop in China and one of the trusted machined parts manufacturers with over 21 years of experience in producing micro precision components.

- We offer top tier precision micro machining services utilizing over 70 advanced Swiss lathes and a talent of 125 skilled professionals.

- We can achieve tight tolerances of +-0.01mm for minimum diameter, +-0.03mm for micro holes, and +-0.02mm for wall thickness. Ra 0.05µm maximum surface finish.

- Micro machining by means of CNC processes and production of micro parts are performed at the highest standards with ISO 9001 and ISO 16949.

- Our miniature precision components are ideal for precision machining companies that rely on micro manufacturing, CNC machining and precision parts machining.

Micro Machined Parts Experts in China

Precision CNC machining to a variety of industries is Masion’s forte, particularly in the production of high-precision micro machined components. Masion has more than 21 years of experience in ultra precision micro milling solutions with advanced equipment, including Swiss lathes and CNC milling machines. The company is capable of producing parts with tolerances down to ±0.0002 mm, and has expanded its expertise in manufacturing high quality and consistent parts in areas such as aerospace, medical and electronics. Masion is capable of micro machining and custom Swiss screw machining for small and large scale production. The company adheres to strict industry certifications, including ISO 9001:2015 for precision and reliability in every part.

CNC Micro Machining Services

CNC micro machining allows you to obtain precision parts for different domains, ranging from mini to high performance micro precision components. With DFM (Design for Manufacturability), your designs will be optimized for the best machining results. This helps in reducing the production time and cost and your micro parts are both time and cost effective.

Advanced Swiss lathes are required for high precision in micro machining. It allows for the making of sophisticated, high precision components, such as mini probes, micro CNC components, and miniature precision components. Swiss lathes are excellent for making tight tolerance parts in the aerospace, medical and electronics industries.

Additionally, you can harness if your machining needs entail different surface finishes, such as golden plating, silver plating, beading, PVD coating for durability and appearance. For specialized applications, thermal machining techniques like laser and EDM processes can also be used to achieve precise results without mechanical stress. Whether you need alloy, aluminum, brass, titanium or any other material, there are such advanced machines as external cylindrical grinders, polishing machines etc that can be used for such materials. Masion provide micro precision machining services with high quality and precision.

Materials

- Alloy

- Aluminum

- Brass

- Copper

- Bronze

- Stainless Steel

- High Temp and Special Alloy

- Titanium

- Steel

- Plastic

Machines

- Swiss Lathes

- Polishing Machine

- External Cylindrical Grinding Machine

- Surface Grinding Machine

- Centerless Grinding Machine

- Passivation Equipment

- Ultrasonic Cleaning Equipment

Surface Finish

- Golden Plating

- Zinc Plating

- Silver Plating

- Nickel Plating

- Heat Treatment

- Brass Passivation

- Bead Blasting

- Polishing

- PVD Coating

What is precision micromachining?

Micro precision machining, or micro machining, is a process for fabricating highly detailed miniature parts with extreme accuracy. Advanced processes such as CNC turning and micro CNC machines are used to produce micro parts and components. For industries like electronics, aerospace, and medical devices, this precision is essential. The services of micro machining at CNC Swissmasion offer you the opportunity to develop a micro precision component design with fine details and very close tolerances, at the highest quality.Fsteel If you are looking for precision micromachining then Masion provides standardized miniature parts manufacturing.

The Pros and Cons of Micro Manufacturing (Micro Machining)

Pros:

- High Precision: Micro precision components with tight tolerance can be produced by micro machining. This also avoids inaccuracies in intricate designs.

- Versatility: It is used to make very small things such as micro probes, small machine parts. Its versatility makes it useful for applications in the aerospace, medical devices and electronics sectors.

- Cost-Efficiency: Micro machining can reduce material waste and reduce production cost. This is a cost effective choice for small parts manufacturing in small quantities or in prototypes.

- Advanced Technology: CNC Micromachining helps you to produce products with very small details using CNC machines. One of the ways parts can be manufactured to very precise specifications is by micro precision machining, which can improve total product performance.

- Reduced Assembly Time: This is due to the use of micro machined components, which typically require minimal post-processing and help you to save manufacturing time. It is well suited to support reduced assembly time in micro-precision machining.

Cons:

- Limited Materials: Not all the materials can be micro machined to within defined accuracy. There are some materials that may not be machinable on scales small enough.

- High Equipment Cost: CNC micromachining is very expensive. If you’re not in volume production yet and still with a small machine shop or a startup then this can be a big investment.

- Skill Requirements: CNC precision parts machining is suitable for micro machining, but the operator needs to be skilled and he has to know subtlety of micro machining. Getting experienced talent is difficult and the learning curve is high.

- Slow Production Time: Fine detailed machine works are needed for micro machining which is more time consuming as compared to the traditional manufacturing methods. However, in some instances, this will not always stretch out the production time frame when in each single micro machine shop, machines consists of more complicated parts, yet can increase production time as well.

- Machining Challenges: It is challenging to work with such small scale and fragile micro parts. Therefore, the actual implementation of these projects is more complex, and such tools are required for that.

DFM for Miniature Precision Components

To produce high quality results, manufacturing miniature precision components requires a structured process. Masion is a micro machining services specialist, providing the highest precision micromachining to its customers for their micro parts and mini probes. This is how we do it from start to finish.

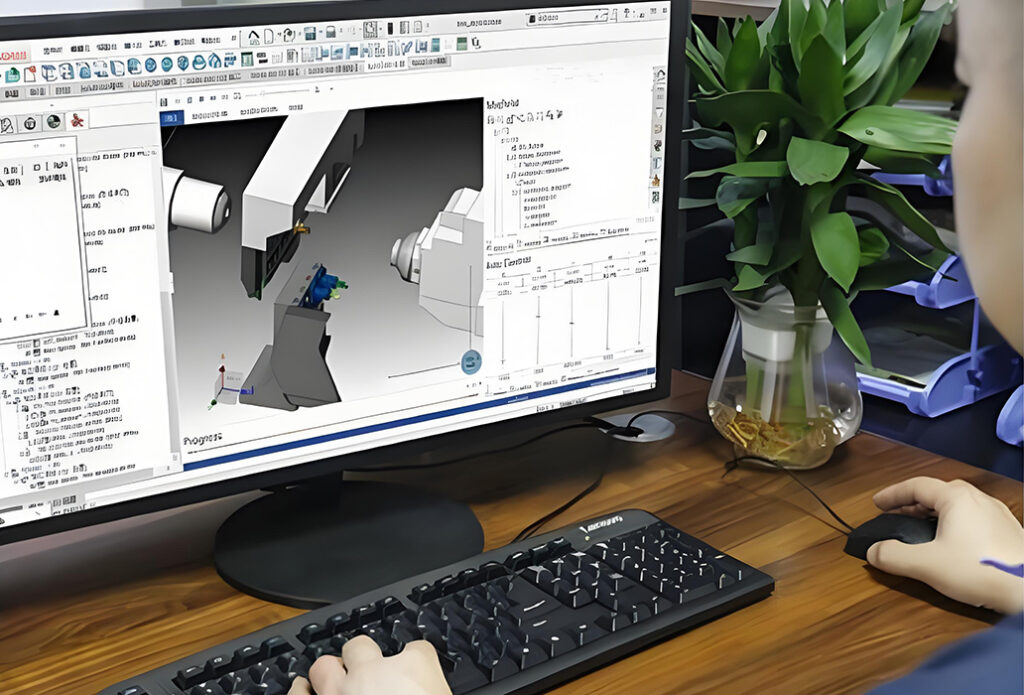

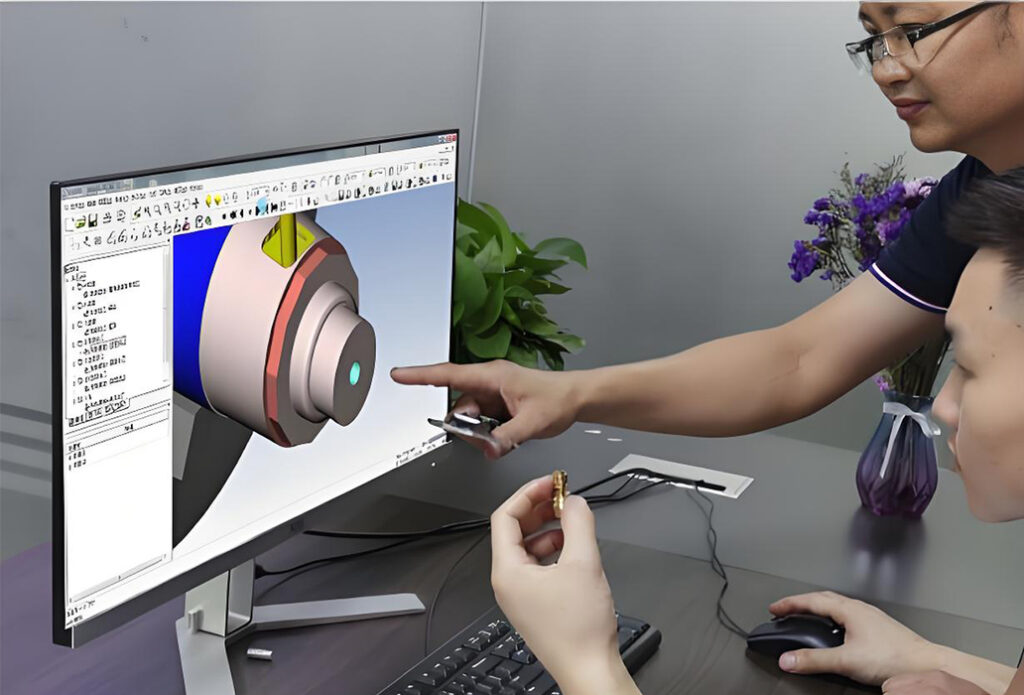

Product Design and development

We then begin by talking to the design team to make sure that the product characteristics and design attributes meet. We review together with your team to make sure the final design is what you expect.

Knowledge and application of materials

We understand whether these raw materials fit your product by assessing composition, processing characteristics, and industrial applications. Knowing the use we will always select the best option for your miniature precision components.

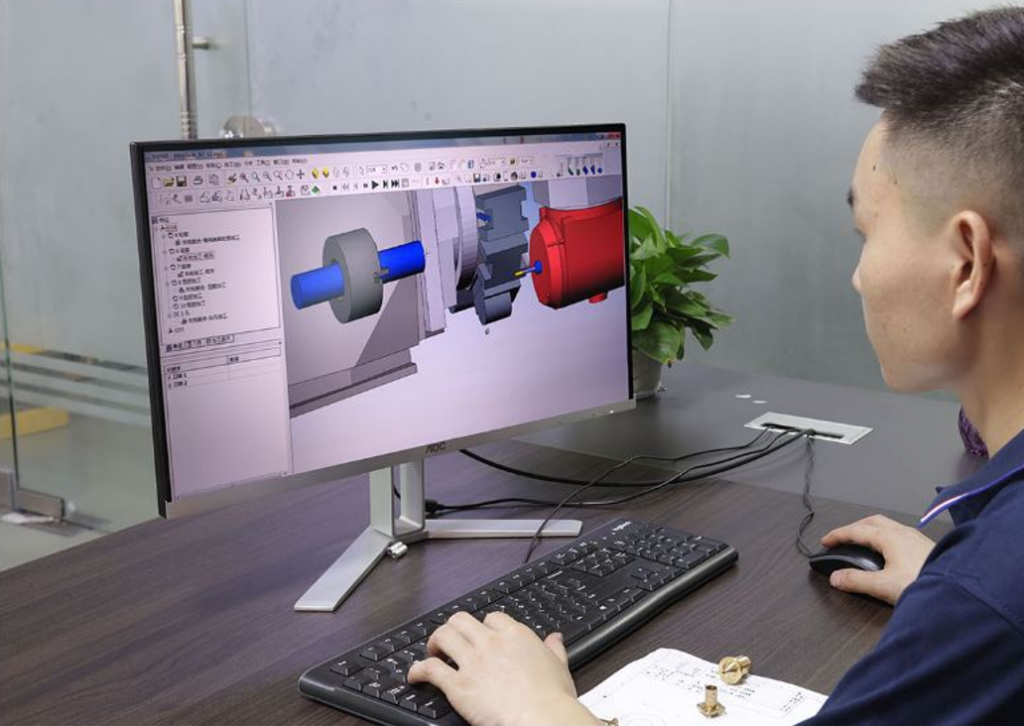

Tool Design and Application

We skin our tools and fixtures to your components’ materials and structures. It allows for precision micromachining, and high quality micromachined products.

Optimisation and Processing

Technical programming and simulations are used to optimize the machining process. We then adjust the tools and do inspections to make sure everything is ready for production.

Quality control and inspection

Through digital and visual production control methods, we implement automated inspection technology to ensure that quality standards are met on every step of the process.

Solution Development and Cost Evaluation

We will work together with you to arrive on a quality and cost based technical solution.

Technical Research and Advanced Training

Time after time we will go through mechanical analysis studies and share our knowledge with international teams, so you will have access to the latest processes applications.

Why Choose us for Small Parts Manufacturing?

Masion is an expert in the manufacturing of high quality small parts with precision and efficiency. From miniature parts and micro components to precision micro machining services, our advanced miniature machines system and capabilities make possible the best products available to you. The following are our reasons for why you should hire us for manufacturing.

An Intelligent Programming system

An intelligent programming system is used to optimize machining toolpaths. Improving production efficiency helps reduce the overall cost. With this system, we take care of making sure that your projects are successfully completed every time. It will provide you with the best precision machining without compromising on the quality.

ERP Office Management System

Our ERP system manages comprehensive information for our operations and management. This system is very efficient such that we communicate well during all stages of production, thus we are always on time and never compromise on quality.

MES Factory Management System

Our MES helps us better manage production, increasing efficiency and ensuring product quality. This allows for the real time monitoring of production processes so that you don’t experience any delays and receive only the best quality products.

Quality Management System

All our pieces are made with precision through a robust Quality Management System (QMS). We partner with your internal DFM and Design teams to meet your unique needs. It is capable of handling large projects with our notable clients including Huawei, Tesla and Novel.

Comprehensive Processing Capabilities

We offer more than just Swiss CNC machining. We also offer secondary services including cleaning, grinding and surface finishing. With this complete approach to making products, your products are made with absolute precision and perfection.

Advanced Swiss Lathes

And our Swiss lathes are very much advanced that we provide a precision of upto 0.001mm machining tolerances. We guarantee the highest level of quality in micro parts, and micro precision components.

Miniature Machining Tolerances

Micro machining is used in creating miniature parts with exceptional precision.The services of micro machining offered by Masion based upon tight tolerances and high quality standards.

Diameter Tolerance

In micro precision machining, exact diameter measurements are of utmost importance. For instance, a typical CNC miniature machine can guarantee a diameter tolerance of ±0.001mm to ensure very tight fits for miniature parts.

Concentricity

For Concentricity, it is how well the center of one feature matches up to the center of another. Our micromachined parts have 0.002mm concentricity tolerance and guarantee for micro CNC and micro precision parts.

Surface Roughness

In small parts manufacturing, the surface finish is paramount. Masion’s surface roughness Ra 0.1µm or better will provide a smooth finish perfect for smaller applications such as mini probes.

Length Size Tolerance

Controlling the length tolerance is essential for precision machining. Our micro CNC machine has a length tolerance of ±0.005mm, and we can manufacture parts according to their length specifications.

Angle Accuracy

Where accuracy in angles is critical, the precision for alignment of parts is very important. For micro parts, we maintain angle accuracy of 0.002mm to ensure perfect symmetry.

Thread Machining Accuracy

For high precision applications like miniature micro machining, we have a thread machining tolerance of ±0.002mm for threaded parts.

Positioning Accuracy

Positioning accuracy is important for part alignment. We are able to position within 0.002mm tolerance for micro precision machining.

Other Critical Tolerances

We have to have the cilndricity of 0.002 mm, flatness of 0.002 mm, symmetry of 0.002 mm and circular runout of 0.002 mm. By our high quality miniature machines the overall performance of micromachined components depends on these tolerances.

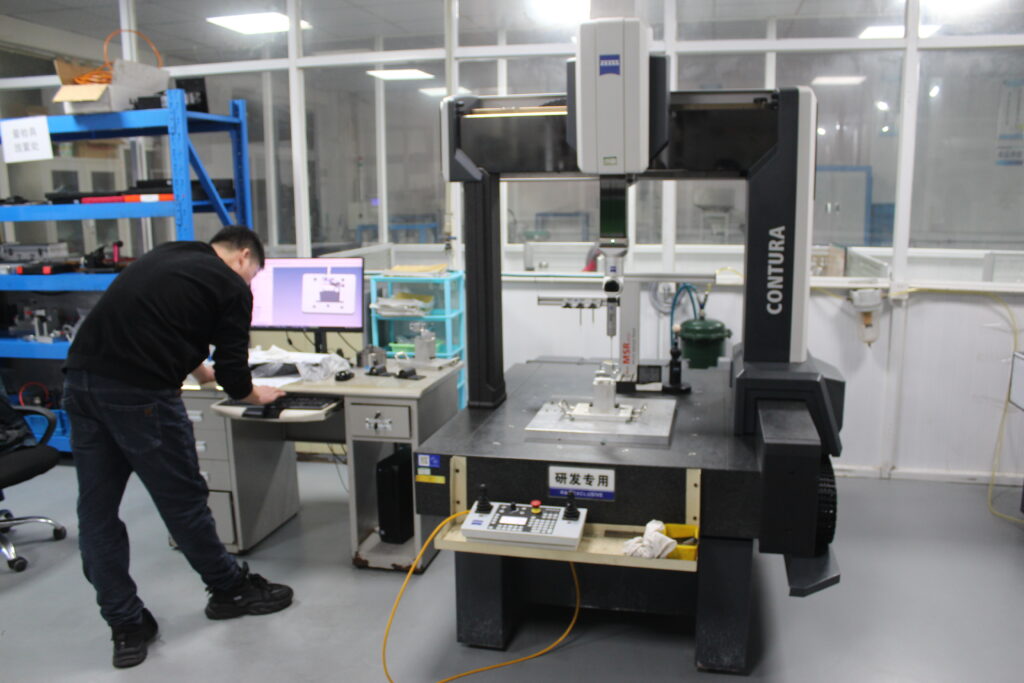

CNC Micromachining Quality Control

All stages of miniature machining process at Masion are quality controlled for precision and reliability. The techniques we work with are advanced, and deliver high quality micro parts for your needs.

24 Hours Full Automatic Detection

To ensure quality, we have 24 hours fully automatic detection. All are being monitored constantly through our system, and discrepancies are caught in real time. This prevents errors and guarantees that every miniature part will meet your exact specifications.

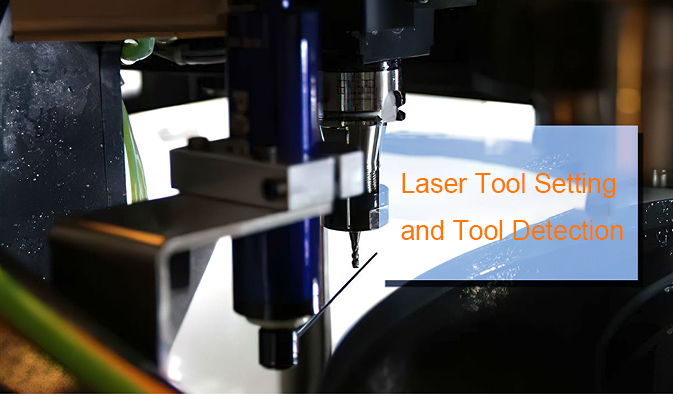

Tool setting and tool detection by using the laser

Laser tool setting and detection are among the key services of micro machining that support micro machine shop operations, enabling precise alignment to machine micro-precision components with high accuracy.

In Machine Auto Measurement

We use in machine online automatic measurement to monitor the status of precision of each part in production. This process will help you to prevent the defects and allows your machine or other miniature parts to attain the exact tolerances for micromachining.

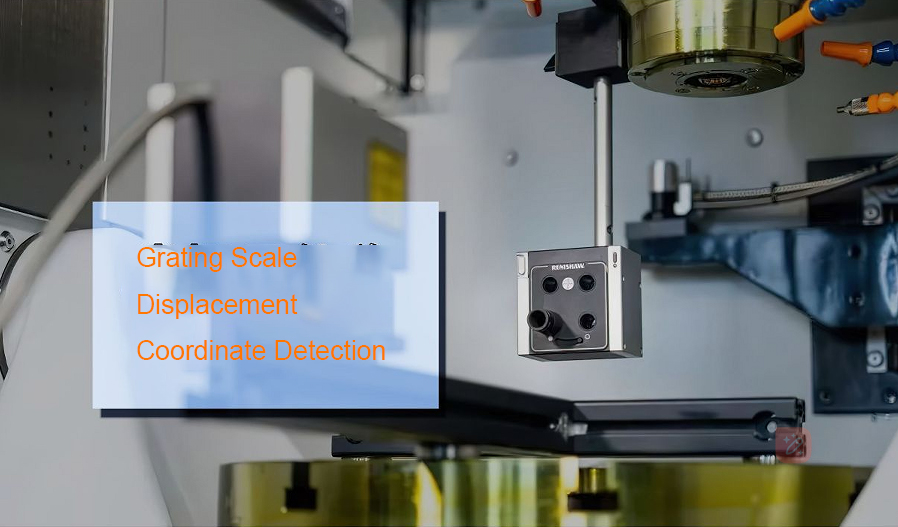

Grating scale displacement coordinate detection

Grating scale displacement coordinate detection can improve the accuracy of parts machining. It ensures that every part is designed with utmost precision necessary for micro precision machining.

Raw Material Feed Control

We keep tight control over the supply of raw materials and only high quality materials are used to make it. The product quality as well as the environmental standards are ensured by REACH and RoHS reports of all the materials used in the product.

Process control of Finished Product

It is rigorously inspected in production. So that it is designed to those specifications, with complete and documented records and analysis for traceability and quality assurance.

Product Traceability

From raw materials to delivery, we track every step of the manufacturing process. It can guarantee traceability of any part, including precision CNC machining parts, so you know it’s up to your standards.

Factory Quality Assurance

Timely delivery thanks to random reinspections, dotted verification and signature confirmations ensure guaranteed quality. Masion is glad to offer inspection reports whenever you wish to support in proving the quality you expect from a first rate micro cnc machining manufacturer.

Our Certificates

Masion is the best of the best when it comes to micro machining. Our over 21 years of experience in the industry have earned us the certifications that we hold, which are dedicated to precision and customer satisfaction. These certifications prove that we keep up with the standards followed by leading precision machining companies, so our products are always at the highest possible standard.

To drive excellence and precision through the entire micro machining process, we have a robust quality management system. The certifications showcase our ongoing focus to continue improvement and commitment to delivering products that meet industry standards.

- ISO 9001: Quality Management System

- ISO 14001: Environmental Management System (EMS) Certification

- IATF 16949: Automotive Quality Management Systems

- RoHS Compliant: Restricted Hazardous Substances available on request

- SGS Certified: Product testing to ensure compliance with international standards

- CE Marking: Conformity to European regulations and standards

Explore Our Miniature Precision Components Gallery

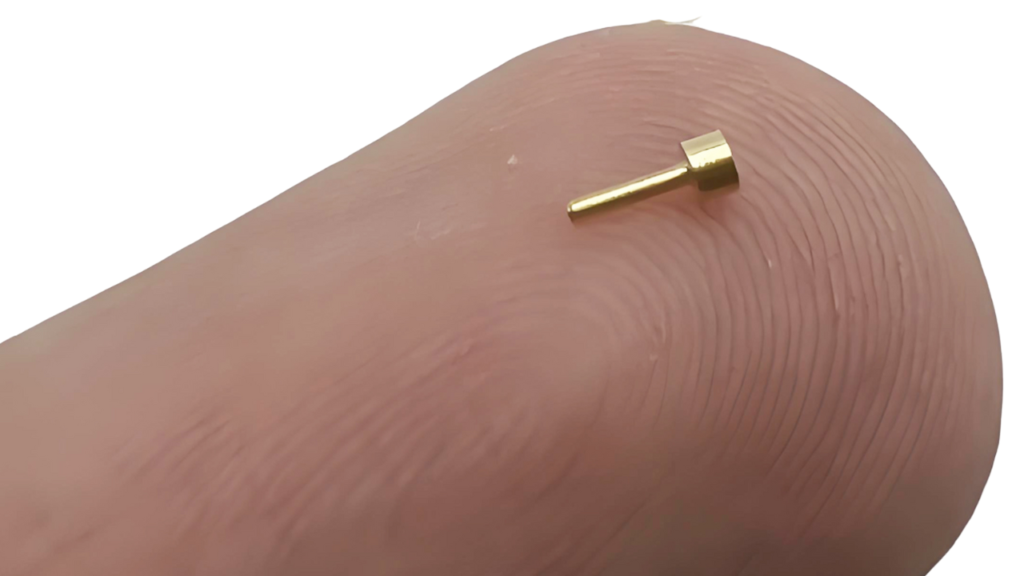

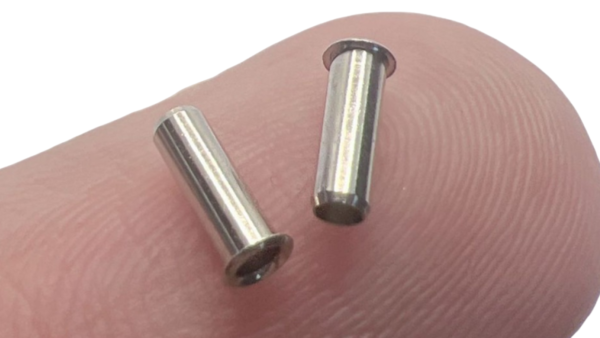

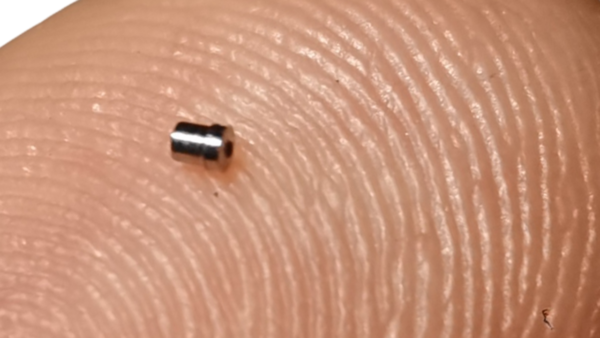

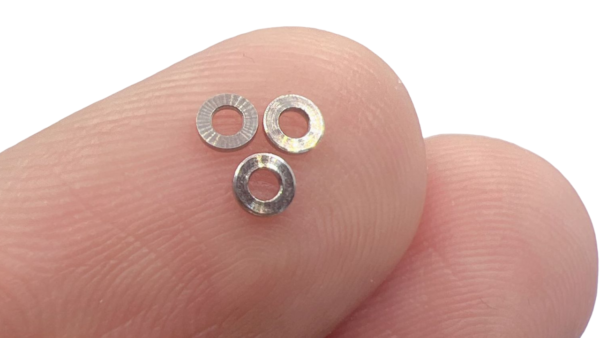

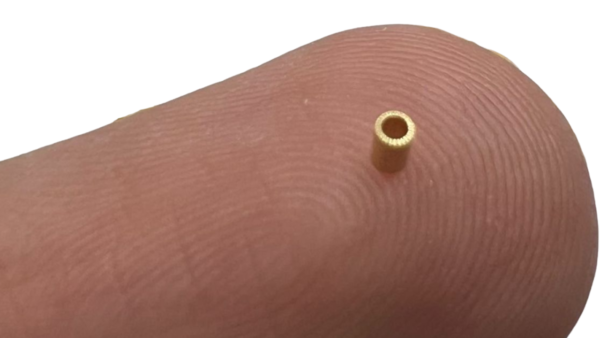

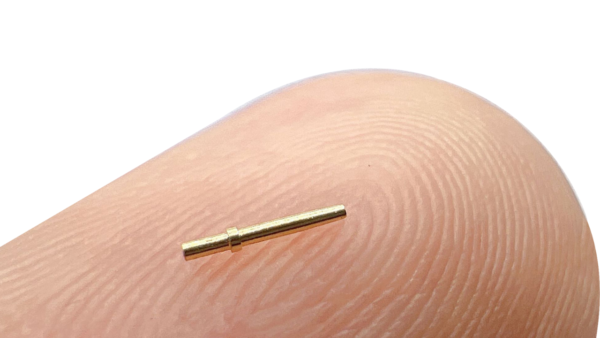

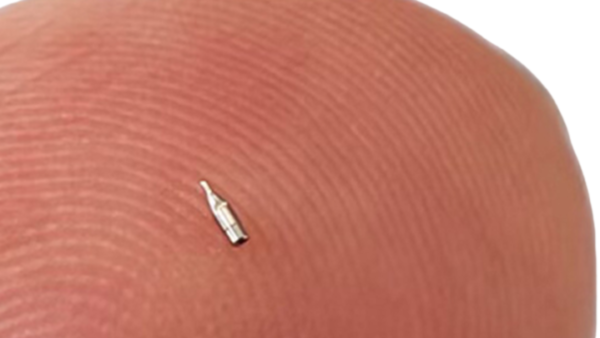

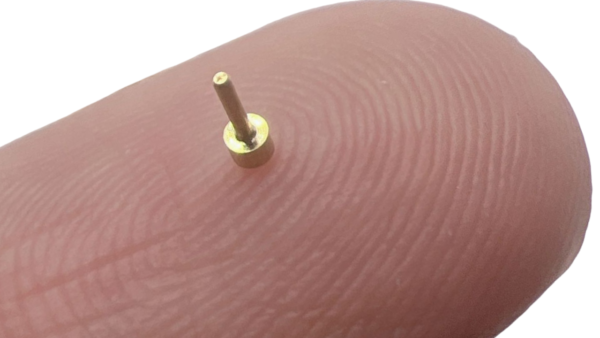

Small Stud

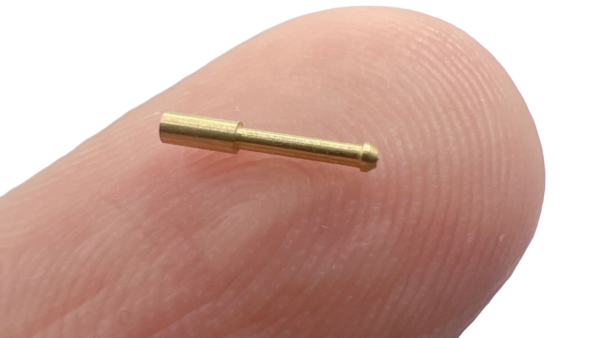

Small Probes

Small Cylinder

Miniature Parts Machining

Mini Spacer

Mini Sleeve

Mini Probes

Micro Surgical Knife

Micro Stud

Micro Sting

Micro Machining Industries

In particular, the micro machining industries are crucial to providing high precision components. These industries serve many different market sectors requiring ultra accurate, miniature parts produced through advanced micromachining services. Swiss machining is ideal for micro machining services where tight tolerances are needed. Here’s a quick breakdown of industries relying on Swiss micro machining:

- Medical Industry: Creating micro precision components for implants, medical devices and diagnostics.

- Electronics Industry: Manufacturing of miniature parts, micro probes, and electronics components.

- Automotive Industry: Micro parts manufacturing and precision machining for engine components.

- Watchmaking Industry: Performing micromachining of tiny, intricate components that demand high precision.

- Telecommunications Industry: It is used in making precision micro machined parts through CNC micro-machining for telecommunication equipment.

- Robotics and Automation: Manufacturing small parts for robotic systems and automated machinery.

- Hardware and Industrial Parts Industry Utilized in precision micro CNC machining for both specialized shops and industrial applications.

FAQs

How does Masion achieve precision in manufacturing micro parts?

With advanced CNC machines combined with mini probes and talented technicians, Masion guarantees accuracy. It ensures quality and precise micro parts.

Is micro machining a viable means of production for low quantities?

For small scale production, micro machining is a cheap process. Masion lowers labor costs through efficient processes and produces high quality precision parts for small runs.

What does Masion do to ensure small parts are delivered on time?

Masion optimize their production schedules and use high performance micro CNC machines to ensure your precision parts are out on time.

As for the micro machining, how to assure the material quality?

So during machining stage, high quality parts are manufactured from Premium materials and strict quality control is applied to ensure that the micro parts are perfect.

Can bead blasting be used for micro machining?

By bead blasting, surface finish is improved and stress is reduced, thus making micro parts more durable and visually appealing, as well as producing better results.

Why is the accuracy of threading important in micro machining processes?

Masion’s micromachining is indispensable to produce a perfect fit and function in micro parts.

Can you explain why surface finish Ra 0.1µm is important for micro parts?

It is important in high performance micro parts because of its Ra 0.1µm surface finish, smoothness, reduced friction, and durability.

What sets Masion apart from others that provide micro machining services?

Masion has services that are scalable on large projects, with automated processes and strict quality control to deliver your project on time.