Multitasking Machining – Explore Every Single Insight

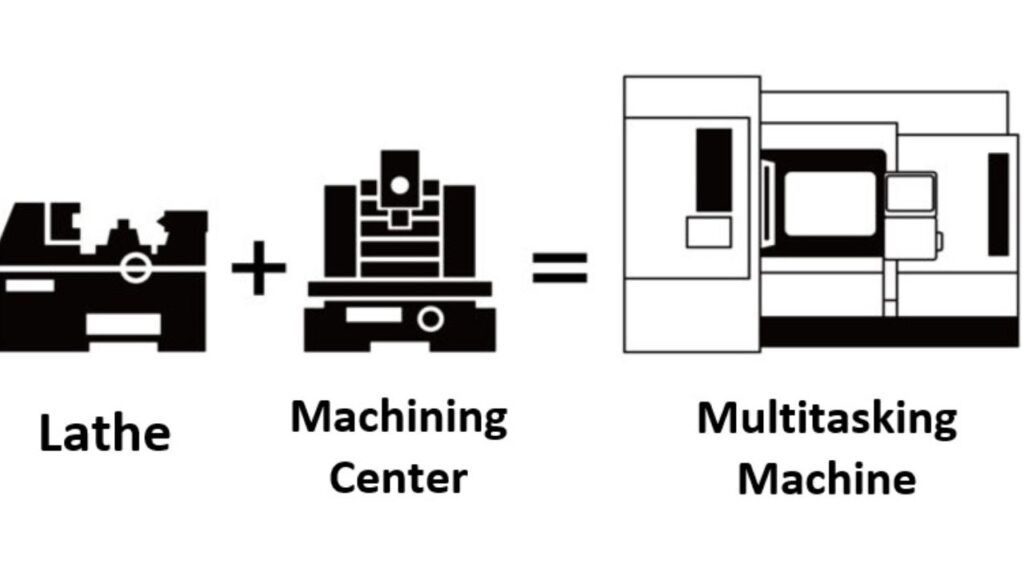

Multitasking machining is making a huge difference in modern manufacturing. It brings together different processes in one machine, saving you effort, space and money. That means you must learn everything you can about multitasking machining to make the best choices. This article looks at everything from the way it works to the kinds of machines and software involved. You’ll also find out about the advantages, barriers, primary uses and Guidelines for selecting the right CNC for your shop.

Table of Contents

ToggleWhat is Multitasking Machining?

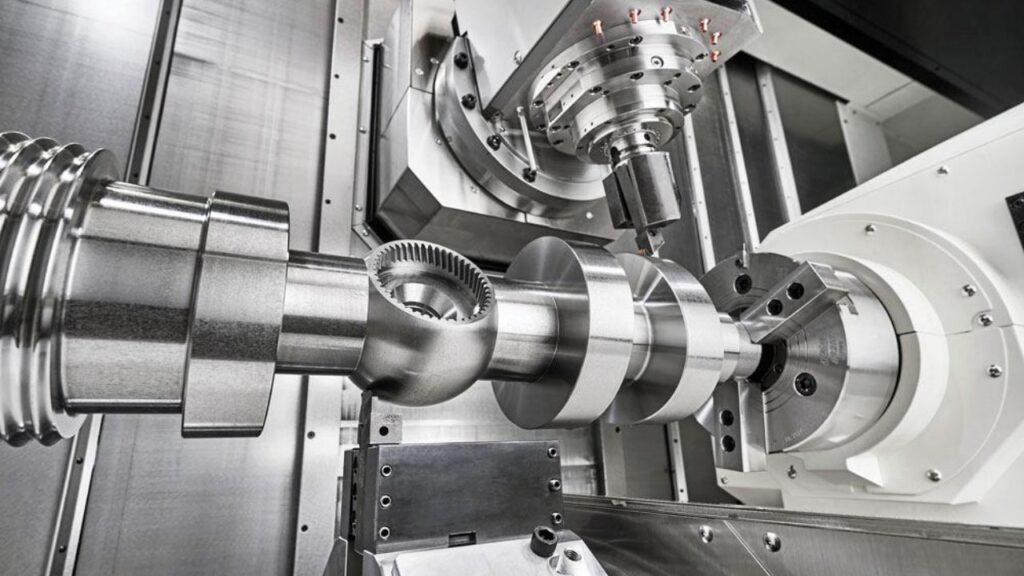

The process of multitasking machining means a machine is designed to turn, mill and drill in one setup. Being able to use only one machine reduces setup time and increases accuracy. Traditional CNC machines can only work on one task at a time, but multitasking machines make it possible to finish multiple steps in one operation. They include spindles, turrets and advanced control systems to run smoothly. You can picture this machine by imagining a main spindle, tool magazine and control unit.

| Feature | Traditional CNC | Multi-Axis CNC | Multitasking Machine |

| Number of Processes | 1 per machine | 1-2 | Multiple |

| Setup Time | High | Medium | Low |

| Footprint | Multiple machines | Medium | Compact |

| Accuracy | Moderate | High | Very High |

| Automation Capability | Limited | Medium | High |

Core Components of Multitasking Machines

Main Spindle and Sub-Spindle

Cutting actions are mainly handled by the main spindle. It supports and spins your workpiece during different operations. With a sub-spindle, it’s possible to carry out secondary processes without moving the workpiece by hand. Reducing the number of setups saves your time and makes your results more reliable.

Turret & Tool Magazine

Multiple tools are in the turret, rotated and placed where they are needed. When you combine a tool magazine, you can use multiple tools in just one cycle. It lets you continue your work on complex parts without any breaks.

Y-Axis and B-Axis Capabilities

Changes you make to the Y-axis let you machine objects that are not centered on the Z-axis. Multi-axis cutting is possible along the B-axis, enabling machine tools to use intricate angles and designs. They allow you to manage complicated parts with less effort.

Automatic Tool Changer (ATC)

An ATC changes tools on its own during different operations. You don’t have to stop the machine for tool changes and you save time when working on many small batches.

Bar Feeders and Parts Catchers

Bar feeders keep giving raw material and catchers ensure that completed pieces are properly picked up. Both the robot and the system make lights-out machining possible and decrease the need for operator involvement.

Integrated Probing Systems

They measure both tool offsets and the alignment of workpieces as the machine operates. They allow you to achieve higher quality and reduce scrap when accuracy matters.

Types of Multitasking Machining

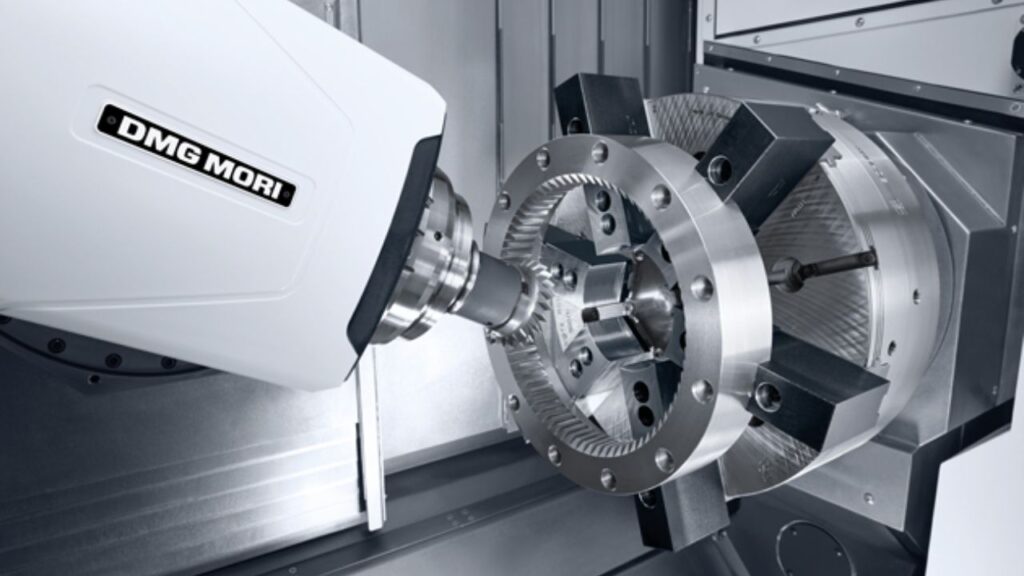

Mill-Turn Machines

A mill-turn machine allow you to mill and turn a workpiece in a single pass. You’ll notice that a spindle spins the workpiece and a milling head carries out the actual cutting of the material. It features Y-axis travel and allows live tooling, so several functions can be accomplished in only one cycle. Cylindrical parts with complex shapes are best made using these machines. You’ll spend less time setting up, achieve more accurate results and be more efficient.

Turn-Mill Machines

These machines are close to the previous type but mainly serve to complete turning tasks. The principal difference is found in how the spindle is positioned and controlled. You would use them most often when working on shaft-type parts where you make many turns but sometimes also need to mill. When you want to create exact slots, holes or flat surfaces on turned pieces, these machines are most helpful. It is easier to take care of many small steps in the process without needing to move instrument parts between machines.

5-Axis Multitasking Machines

On a 5-axis multitasking machine, you can control three linear axes as well as two rotational axes. Because of this, you can design complicated geometries all in one go. Aerospace or mold components are no challenge for these machines because they work well with undercuts, contoured areas and deep holes. Both your part quality and setup number can be improved.

Hybrid Machines

Hybrid multitasking machines are able to perform traditional machining and additive manufacturing. You can use them to make objects by stacking layers one after another. 3D printers are useful for making prototypes, fixing things and producing elaborate parts. Recent models are equipped to handle several materials simultaneously and allow you to check progress as you go.

| Machine Type | Primary Operations | Axes | Best Use Case | Typical Industries |

| Mill-Turn | Milling + Turning | 3-5 | Cylindrical components | Aerospace, Automotive |

| Turn-Mill | Turning + Milling | 3-5 | Shaft parts with slots | Energy, Medical |

| 5-Axis Multitasking | All + Complex Cuts | 5+ | Aerospace, molds | Aerospace, Die & Mold |

| Hybrid | CNC + Additive | 3-5+ | Prototyping, repairs | R&D, Medical, Aerospace |

Key Features of Multitasking Machines

Multiple Spindles and Turrets

The main and sub-spindles, together with several turrets, are typical features on these machines. You don’t need to move the part between machines for turning, milling or drilling. With this system, handling is reduced and results become more accurate.

Live Tooling

With live tooling in place, you don’t have to pause the spindle to carry out drilling or milling operations. You can do these actions with the part in motion, cutting down on the time it takes and making setup simpler.

Sub-Spindles

The sub-spindle makes it possible to perform work on both ends of your part at the same time. This helps you save time because you don’t have to move parts by hand and you also get better alignment for more complex parts.

Tool Changers and Automatic Tool Indexing

With such systems, you can easily change tools and keep working automatically. You keep your work moving and reduce the time needed for changing tools.

Integrated Metrology Systems

On-machine probing ensures you can measure and fix any issues in dimensions quickly. You are able to use all your materials and keep parts consistent in quality.

Thermal Compensation and Stability

High temperatures can modify the parts of an aircraft. Thanks to thermal compensation, the machine can handle temperature changes by itself. Whether you are carrying out operations at pace or not, your results are always accurate.

Benefits of Multitasking Machining

Reduced Setup Time

Multitasking machining greatly reduces the time needed to set up a machine. Multi-functionality means you can avoid wasting a lot of time by switching between machines. Using just a single load, the machine does every step required for the process. It saves you effort and improves the overall pace of your tasks.

Lower Handling Errors

Reducing the number of parts transferred from parent boards cuts down on mistakes. With multitasking machines, you can perform several operations without changing positions. As a result, you can maintain the structural integrity and achieve closer tolerances. Handling things manually is minimized, resulting in more consistent and exact results.

Smaller Floor Footprint

Rather than using many separate machines, you can use a multitasking system. It leads to having extra floor space in your shop. This setup works well for those whose space is limited, as it takes up little room. Your building costs and utility expenses are also reduced.

Higher Productivity

Working quickly, these machines do tasks like turning, milling and drilling simultaneously. You finish tasks before the deadline and raise your daily productivity. For those handling a variety of jobs or large quantities, you can expect much better productivity.

Better Surface Finish

With less movement and clamping, these machines achieve polished surfaces. You can form detailed and complex curves and forms in one go. It enables you to get advanced shapes with less cleaning up afterward.

Fewer Fixtures Needed

Avoiding special fixtures is easy due to multitasking. You do more work using less equipment. It leads to lower production expenses and makes the manufacturing process more swift.

Advantages of Lean Manufacturing

When operations are combined, you cut down the time needed for production and minimize the number of unfinished goods. You work toward an efficient and flexible way of producing goods. It allows you to meet the needs of the market more quickly.

Challenges and Limitations

High Initial Investment

If you choose multitasking machines, expect costs to be high right from the start. Because these machines can do more than one thing, they are more expensive. You must calculate your production amount to decide whether it justifies the cost. If you do not plan well, your investment results may take longer to show.

Skilled Labor Requirements

If you’re not an experienced worker, operating multitasking machines is not recommended. You should look for highly skilled people for both operation and programming. If your team does not have much experience, you’ll have to budget for training. It makes you work for a while, spending money, before you are fully efficient.

Complex Programming Needs

You will manage complicated CAM software and make sure all channels are synchronized. As a result, programming for a CAM-controlled machine is more difficult than with a traditional CNC. If your code lacks precision, your machine’s tools could crash into each other and your parts might not turn out right.

Downtime and Maintenance Cost

These machines must be looked after regularly. A lack of upkeep can increase the chance of downtime in your operation. Keeping the machine in good condition will cost you more because it is so complex.

Tool Access and Collision Risks

Having many tools operating at the same time creates a crowded environment. You have to map out tool movements well to make sure no accidents happen. Mistakes in setting up equipment can lead to harm and make the site more dangerous.

Software and Control in Multitasking Machining

Use Advanced CNC Controllers

For multitasking machines to work well, you should use top-of-the-line CNC controllers. FANUC, Siemens and Mazak systems provide strong processing, control over several channels and very precise synchronization. They assist you in handling many spindles and turrets all at the same time, increasing accuracy and shortening your work cycle.

Choose Compatible CAM Software

You should use CAM software that can handle several tasks simultaneously. With Mastercam, ESPRIT and Siemens NX CAM, setting up mill-turn, hybrid and 5-axis operations is quick and simple. With these tools, you can automatically plan routes, manage tool switches and carefully manage several movements at the same time.

Simulate to Avoid Collisions

Simulation software plays an important role in multitasking machining. You can count on them to confirm the path of tools, detect overlap and stop crashes. Because of this, you prevent expensive outages and unnecessary waste of materials. CAM software frequently has 3D machine simulation to help with planning and enhance safety.

Use Digital Twin Technology

Your physical machine is replicated in real-time by digital twin technology. You can check new ideas, check their effects and plan actions for real equipment using a simulator. This reminds you that you have what it takes to succeed from the beginning.

Monitor for Predictive Maintenance

With modern control systems, you have access to live information about your machine. You can recognize when tools need replacing, expect failures and arrange necessary maintenance in advance. As a result, everything runs smoothly and you have fewer unexpected breaks in your operation.

| Sr. No. | Software | Features | Compatibility |

| 1 | Siemens NX CAM | Multi-axis, simulation, digital twin | Turn-mill, Swiss-type |

| 2 | Mastercam Mill-Turn | Modular multitasking, verification | Mill-turn centers |

| 3 | GibbsCAM | Sync manager, multiple channels, automation | Swiss-type, hybrid machines |

| 4 | ESPRIT | AI toolpath generation, 5-axis, additive-ready | All multitasking machines |

Applications of Multitasking Machining

Aerospace

Critical parts for aerospace such as turbine blades, housings and structural pieces, are made using multitasking machining. It is very important to be precise, considering how quickly small mistakes can influence safety and performance. Multitasking equipment allows you to meet exact standards and make the most of your materials which lowers waste and reduces your expenses.

Medical Devices

Precision in small batches is very important when making orthopedic implants and surgical tools. Because of multitasking machining, each part that comes out can be made to meet the strict requirements in the medical industry. Your need for constant quality in small batches is supported by this technology.

Automotive

To get the best automotive parts, you require both fast delivery and regular consistency. You can set up a variety of operations together using multitasking machines which helps you produce more while maintaining accuracy. As a result, you can handle a lot of products more efficiently.

Energy Sector

Tough materials are used for both oil and gas valves and for turbine components. Thanks to multitasking machining, it is possible to work with unusual and tough metals, making equipment more durable and accurate in tough surroundings.

Tool and Die

Using 5-axis contouring on your molds and dies, multitasking machines help you polish and finish them much less. As a result, your work is more efficient and gives you excellent finishes.

Machine Selection Criteria

- Type of Material and Part Geometry: You need to assess the materials you will be using, no matter if they are hard metals, plastics or composites. The machine must be able to handle the details of your part’s shape and size. If your work requires parts with finely detailed features or exact dimensions, choose machines with high multi-axis abilities.

- Production Batch Size and Volume: Determine the number of parts you want to make. A machine that can be set up fast and works well with small batches is the better choice for prototypes. If you are doing high-volume work, pick machinery that is efficient and automated.

- Complexity of Parts: If your parts need several operations such as milling, turning, drilling or grinding, a machine that does all of them together lowers handling and helps achieve high accuracy.

- Budget Constraints: Your budget should not exceed what you can realistically earn from your investments. While expensive, modern multitasking machines help businesses save money and operate more efficiently.

- Compatibility with Your Software: Confirm that the machine’s programming features are supported by the CAM software already in use. Training your machine operators can ensure your machine is used to its highest ability.

Maintenance and Best Practices

- Regular tool calibration and probing: You should often use calibration methods and probes to make sure all your tools are in proper condition and function. Doing this ensures there are no mistakes while machining and keeps accuracy high in the factory.

- Coolant system management: Coolant levels and condition should be looked after regularly. Always pay attention to your coolant’s concentration and change or filter it as necessary to stop overheating and possible damage to your tools.

- Software updates and backup: Updating your CNC controllers and CAM software is important. New updates usually have essential bug fixes as well as new features. In addition, regularly save copies of your programs and settings on a separate device to ensure you don’t lose anything important.

- Training operators in new skills and practices: Your operators should keep learning about new features and programming techniques. When you simulate jobs using software, you can avoid many mistakes and practice complicated tasks in safety.

Conclusion

Manufacturing is revolutionized by multitasking machining, as it combines several operations in a machine which saves effort and ensures greater accuracy. With advanced components, FDM printers help produce complex parts efficiently in the aerospace and medical device sectors. Though the costs and skill level needed are high, the better setup speed, greater precision and increased production make it necessary for tomorrow’s manufacturing. Multitasking machining in your shop can increase both efficiency and your place in today’s competitive market.

FAQs

Is multitasking machining suitable for small shops?

Multitasking machining can help small shops by decreasing setup time and requiring fewer pieces of equipment. Since the initial investment is greater, it’s important to measure your production and budget carefully. When you have to work with different items that call for several operations, multitasking machines can make you work faster and use less room.

What materials can multitasking machines handle?

Many types of materials such as steel, aluminum, titanium and exotic alloys, are used by multitasking machines. You can also machining plastics and composites. Good results depend on selecting the correct machine settings and tools to work with the material you are using.

Do all multitasking machines support 5-axis machining?

It’s important to note that multitasking machines don’t all have 5-axis capacities. A number of machines are made to work with only 3 or 4 axes due to their setup. If you plan to make complex components, consider using 5-axis multitasking machines to do the job.