Types of Pins: Features, Uses, and Advantages Explained

The role of pins are undeniable when it comes to facilitating alignment, and securing components across broad industries. You can find these pins everywhere from automottive sector to construction jobs. They improve funtionality and stability. Extensive knowledge on different types of pins assist you in selecting the right one as per your needs.

This blog aims at guiding you through the common pin types, features, uses, and more. Sounds exciting? Let’s dive right in!

Understanding Pins

Table of Contents

ToggleIn general, the pins are nothing but fasteners that you can use to align, secure, or join different components. They are a key in various industries like automotive, manufacturing, and even in construction. There are two main pin categories including quick release and semi-permanent. You can use semi-permanent pins to ensure fastenning for longer term. On the other hand the quick release pins serve convenient release or re-installation. Multiple types including cotter pins, clevis pins, dowel pins assist in ensuring stronger and stable connection. Uncover more about such and other pins right in the following section.

Different Types of Pins: A Comprehensive Guide

Getting familiar with the importance of the of pins, now is the time to understand different types of pins, their materials, and uses.

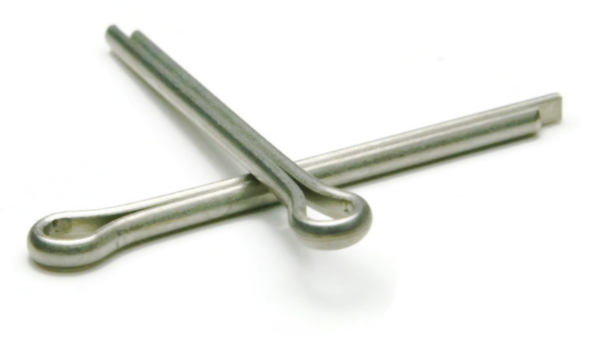

Cotter Pins

The cotter pins feature two prongs which bend up after insertion to keep components secure. These pins are utilized as a safety measure to prevent loosening of other fasteners.

You can apply cotter pins in automotive sector as well as in machine assemblies. You can perfectly secure shafts, wheels, or other machine parts with cotter pins.

Brass, steel or stainless steel goes into the manufacturing of these pins. These materials resist corrosion and offers durability.

There multiple types of cotter pins exists including locking or plain type. You can choose anyone depending on the target application. Key things influencing the type of the cotter pin includes material, size, and bending style.

Dowel Pins

These pins feature a cylinderical shape and cater to percise holding and perfect alignment. The sole purpose of dowel pins is alignment maintenance.

The areas which mostly use these pins includes machinery, furniture, machinery, and automobile sector. You can harness lasting performance using these pins.

Notable materials which goes into the manufacturing of these pins are carbon steel, hardened steel as well as stainless steel. You can use these pins in heavy duty applications without any worries.

When it comes to types there are spring as well as solid pins, for permanent alignment prefer using solid dowel pins while for cushioning or impact receiving areas use spring dowel pins.

Lynch Pins

Lynch pins refer to pins featuring locks which functions through self-lock rings. Ideal for situations where you want to secure components besides facilitating convenient removal.

These are perfect to use in farming as well as in heavy duty machinery. You can found them in farm trailers, and equipments.

Key materials contributing to the manufacturing of these pins includes stainless steel and carbon steel. These materials feature higher strength and resists wearing.

Concerning category, the lynch pins comes under lock pin types as they feature self locking mechanism. These types are perfect where frequent replacement needs to be carried out.

Spring Pins

As the name suggest these pins equipped with the springs that assist in locking. Spring pins feature a cylindrical shape. During installation you need to compress the spring and later it expands for secure components holding.

You can found the usage of these pins in industrial setting, auto sector, and various kinds of machinery.

For higher strength and flexibility features fulfillment, these pins are made up of rolled steel as well as stainless steel. For types of these pins you can get them in coil, slotted, or in tension form. Your selection depends on your alignment needs.

Wire Lock Pins

Locking pins are pins with steel wire loops on them, used to ensure that the pin is in place. The benefit of these pins is that it’s an easy and quick way to assemble and disassemble components.

In automotive and construction industries where fast assembly and disassembly are needed, these pins are often used.

The usual materials for wire lock pins are steel and stainless steel, which are durable and corrosion resistant.

It is categorized into the Pin Fastener types that provide both functionality and convenience in assembling or disassembling parts.

Taper Pins

Narrow taper pin ends for precise alignment. It is tapered which makes it easier to insert and remove, though, once fully inserted, it provides a very tight fit.

In machine assembly and automotive tools, taper pins are commonly used to align parts for accurate and secure assembly.

Taper pins are typically made from hardened steel or brass for their strength and resistance to wear.

The types of pin hardware used, which include taper pins, are considered part of the pin hardware used in high precision applications where alignment is critical..

L-Handle Pins

L-handle pins have L shaped handle used to lock and secure components. It makes easy pin insertion or removal without tools through the handle.

Generally we use these pins in industrial machinery and agricultural equipment. It has a quick and easy to adjust and assemble design.

The reasons stainless steel and aluminum are preferred for Lhandle pins are their strength, corrosion resistance and light weight.

The L-handle pins are a subset of the locking pins since they offer a secure fastening and at the same time easy removal if needed.

Clevis Pins

Pins with a head and hole for a cotter pin are known as clevis pins. Secondly, these pins are used to secure two parts together, with the ability to pivot between the two.

In construction, automotive and marine applications where part need to be held firmly but have the ability to rotate, clevis pins are often used.

Usually clevis pins are of stainless steel or brass by nature for strength and corrosion resistance.

The different clevis pins have different head shapes or those intended for higher load capacities to ensure versatility in different industries.

Spring Plungers

The spring plungers refers to the pins that feature springs. You can use it for indexing as well as positionning. The role of the spring is to ensure that the pin stay in place unti you manually displace it.

Widely applied in the areas of machining setups as well as in mechanical fixtures. Common materials in which you can get these pins are zinc plated as well as steel. The reason behind usage of these materials is the associated longevity and performance.

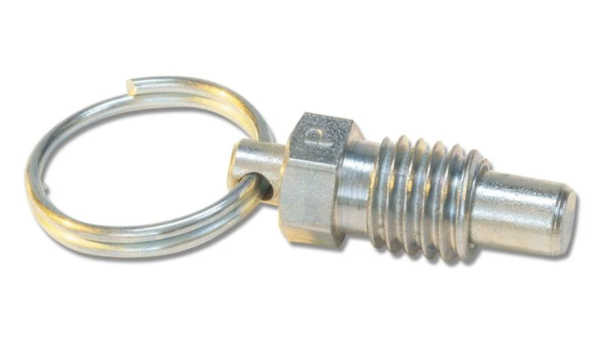

Detent Pins

These pins are the pins which feature pull rings in construction. These rings allow the convenient positioning or repositioning of these pins. You don’t need additional tools to handle these pins.

Main areas of application for these pins includes construction as well as auto repairs. Manufacturing materials of these pins includes stainless steel as well as lower carbon steel. These materials further add up durability and strength to these pins.

Among various types of pins the detent pins are crucial in dynamic sectors. You cannot deny the roles of these pins.

Retractable Spring Latch Pins

As the name indicates these pins are retractable because of the embeded spring within them. These spring latch pins stay secure in place until you manually retract these pins.

For industrial fixtures as well as high stress bearing machinery the value of these pins is truly undeniable. Specially scenarios where quick locking and adjustment is paramount.

You can buy these pins with materials including zinc steel as well as pins featuring polypropylene handle. This you can harness durability as well as convenience.

What is the process behind fasteners manufacturing?

There are several manufacturing processes for making pin fasteners, each of which has its own advantages.

With CNC Machining, precision cutting is done so pins are as detailed as possible with exact dimensions. This is the best option for specific designs and small batches.

For mass production of larger pins, stamping is used. It is particularly efficient for high volume manufacturing because it shapes pins from sheets of metal.

For heavy duty applications, pins are produced by forging to create strong and durable pins. It works by enhancing the strength and wear resistance of the pin by shaping it under high pressure.

Cold Heading is a cost effective process where metal is shaped at room temperature. It allows for fast production with maximum cancellation of material loss, making it suitable for high volume runs.

Creating complex pin shapes is perfect casting. Molds are filled with molten metal, so the design is relatively flexible, and pins are strong and durable.

Different pin types including dowel pins, cotter pins, clevis pins, and locking pins can be made with these processes, which are useful for hardware and assembly applications.

Common Materials for Pins

There are many factors to be considered when choosing the right material for your pins, especially if your pins will be used in a specific manner. Here are some common materials you might encounter:

- Strength and durability are two reasons why steel is a popular option. They can bear heavy loads, and therefore is suitable for high stress applications. Hence they are ideal for various usage such as the assembly pin or pin fastener types.

- Aluminum is corrosion resistant and lightweight, and works well for pins used in outdoor or marine environments. It is common in light weight pins, such as backpacks, etc.

- Brass has an attractive appearance and excellent corrosion resistance, thus it is employed in decorative pins and hardware, where appearances are important.

- Due to its high strength and heat resistance, titanium is suitable for demanding applications where extreme conditions are required, for example, in locking pins and cotter pins.

Whichever applications you need, whether electrical pins, clevis pins, or lock pin types, choose the right material.

Advantages of Using Pin Fasteners

There are many advantages for Pin fasteners and they’re quite a widely used solution for many industries. Here’s why you should consider using them:

Durability: Pin fasteners are made to last. These are comprises of strong materials made for long lasting performance in a wide range of applications. These pins are capable of withstanding wear and tear and can be used with all types of machinery, vehicles etc.

Universality: They are applicable across a number of sectors including construction and electronics. Types of pins provide an array of functions to depend on including securing components and attaching parts together in various projects.

Ease of Installation: Pin fasteners are fast to install. You can save yourself some time and effort. It makes the job easier whether you are working with types of dowel pins or types of clevis pins.

Cost-Efficiency: The different pin types are affordable for scalable production. They are cheap particularly when designed as lock pin types or assembly pin type.

Safety and Adjustability: Pin fasteners prevent accidents and facilitate easy adjustments. Types of locking pins provide a way to ensure security while making reconfigurations without hassle.

Factors to Consider When Selecting Pins

Material: The importance of the pin material cannot be overstated. It must be appropriate for the environment where it will be used. For instance, stainless steel or alloy pins suit well in a harsh or outdoor environment because they’re strong and long-lasting.

Size and Shape: The pins vary in size and shape and are for application. It is important to choose the appropriate size and shape for the intended use. For instance, if you are employing types of dowel pins in a really specific assembly, they should be accurately sized in order to enter the holes they will secure.

Load Capacity: Depending on your application, you will need to pick pins with sufficient load capacity to resist stress and bending.

Corrosion Resistance: Corrosion resistance is a key factor if you are working in outdoor or marine environments. There might be various coating and rust resistant type of pins that you might require to have for the pins to have lasting performance..

Applications of Pins in Various Industries

The versatility of pins makes them popular across all the industries.

Automotive: Pins are needed in automobile industry to fix the wheels, brake assemblies and the shock absorbers. Clevis pins and assembly pins are common types used for fast assembly and disassembly of parts.

Medical: Surgical tools, retractors, and forceps involved in medical instruments all rely on pins to provide precise operation. In surgical instruments, lock pin types are frequently used to secure parts.

Construction: For instance, pins secure frameworks and scaffolding in construction to keep it safe. They are usually strong enough to carry heavy loads.

Aerospace: Precision is necessary in aerospace applications. In aircraft assembly and maintenance, pins of different kinds used to provide tight and secure fittings.

Machinery and Manufacturing: In machining and manufacturing, pins are also frequently used to hold machine parts in place or affix tooling fixtures. Depending on the application you use types of locking pins or types of metal pins for durability and security.

Partner with CNC Masion for Custom Pins

When you are working with Masion rest assured that you are going to recieve custom designed qualitative components. For cnc swiss machining projects the need for a reliable and well reputed manufacturer featuring modern and latest technology is paramount. At Masion you can get different types of custom pins including types of dowel pins, types of clevis pins, types of cotter pins, and more.

Option exist to select the types of pins hardware or types of locking pins from the pre-made parts. Apart you can customize your selection in different finishes, materials, and even dimensions. Choosing Masion will make you harness efficiency, quality, strength, durability, high end perfromance to name a few. Boost up your projects practicality with consistent, precise, personalized pins by choosing Masion

Conclusion

The importance of selecting the right pin from different types of pins available is crucial for the success of your project. Each pin type offer different features, specs, and role. Apart each pin type serve purpose in a specific sector or area. As discussed in the above article you need to make a wise selection for pin regarding finishing, features, materials gone into that specific pin during manufacturing. The right choice enable you to benefit from security, efficacy, as well as assembly. You can put your trust on Masion for unmatchable results.

FAQs

What types of pins used in construction projects?

The widely used pin types in the construction projects includes cotter pins, clevis pins, and even dowel pins. These pins are popular for offering high end stability as well as security.

How to select the right pin for automobile sector?

For automobile sector you can choose locking pins as well as cotter pins. It depends on the connetion type you want or need. Before choosing take into account material features including size, strength, and resistivity.

Do stainless steel pins offer rust resistivity?

Yes, the stainless steel pins offer excellent resistivity to rust formation. Please they are not 100% rust resistive. When you expose these pins to harsh conditions like exposure to saltwater they may rust. You need to choose the steel grade carefully to avoid such rusting.

What industrial sectors depend heavily on types of dowel pins?

Multiple industrial sectors including automobile, construction, as well as manufacturing sector take advantage of the types of dowel pins. These pins are crucial in applications requiring unmatchable precision.

Can you tweak these pins for speciality applications?

Yes, if you are choosing Masion then you can expect customization in different types of pins. You can order pins in your desing, material, size, custom features, etc.