What is a Planetary Gear Set?

Wondering what is planetary gear set? An epicyclic system, also known as a planetary gear set, is a system with an orbiting gear around a central sun gear. These planet gears interlock with an internal ring gear. Motion changes are done by holding or driving various members. Load distribution is uniformly spread on several gear meshes. This is a design that conveys high torque. Planetary systems provide higher ratios within smaller areas when compared to parallel-shaft gears.

Top of the Line Planetary Gear Manufacturer

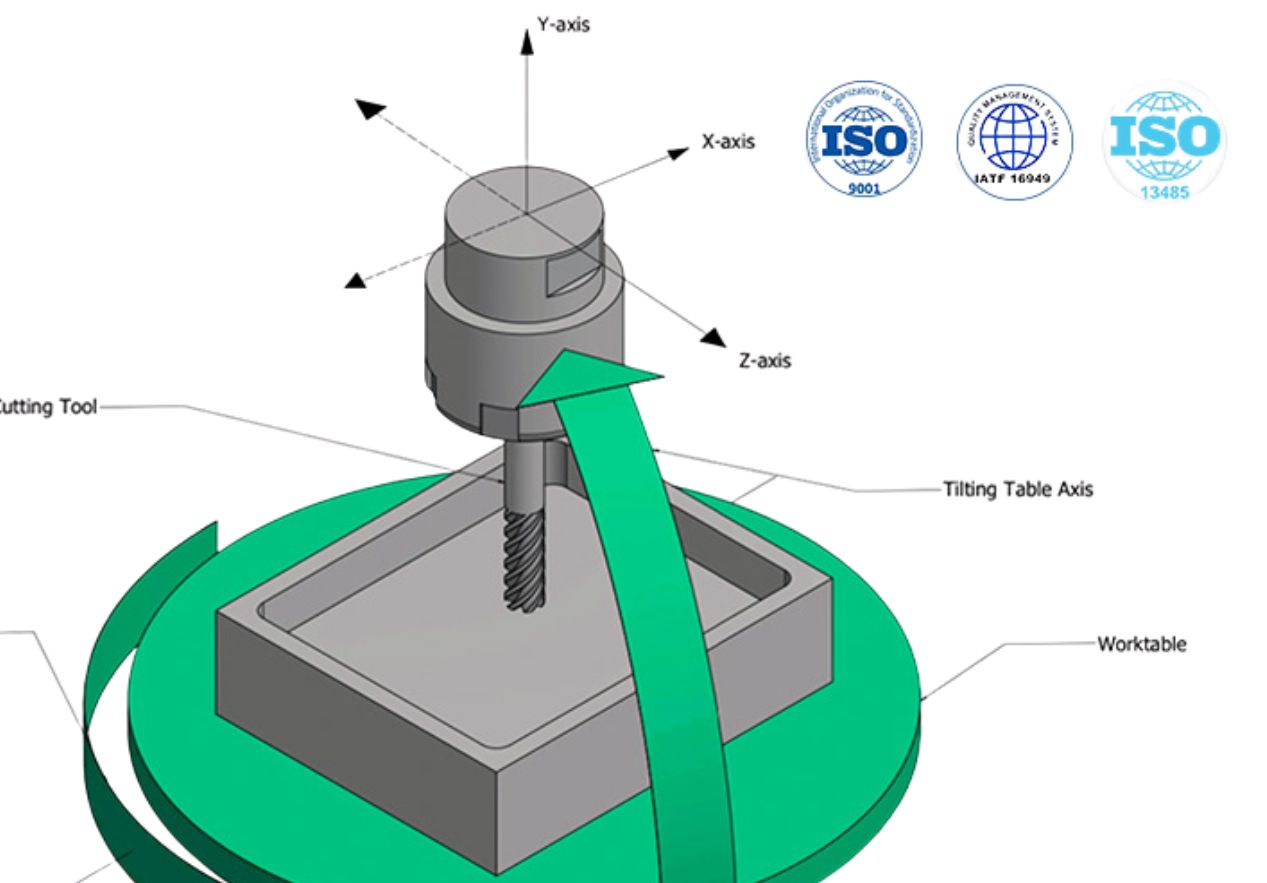

CNCSwissMasion is a reputable manufacturer of precision gear solutions and has more than 21 years of experience in planetary gear production, offering high-precision gear solutions to the worldwide market. With over 100 CNC turning and gear hobbing machines and 125 qualified technicians, we are capable of tight tolerances to DIN Grade 5 within the range of ±0.004 mm. We are certified by ISO 9001 and IATF 16949, which insures a high level of consistency, stability, and efficient transmission. We produce high-quality planetary gears that can be used in automotive, robotics, medical, and industrial applications since prototyping to high-volume production.

Materials

- Carburising steel (20CrMnTi,20CrMo/18Cr2Ni4WA/17CrNiMo6)

- Carbon steel (35CrMo 45#/40Cr/42CrMo)

- Nitriding steel (38CrMoAlA/31CrMoV9)

- Cast iron (HT250/QT600-3)

- Powder metallurgy (Fe-Cu-C/FC-0208/Fe-Ni-C/FN-0205

- Brass

- Copper

- Bronze (ZCuSn10P1/ZCuAl10Fe3)

- Stainless steel (316L,304,2Cr13 / 3Cr13,0Cr18Ni9)

- Aluminium (AISi10Mg,AiMgSi)

- PEEK

- Phenol-Formaldehyde

- POM

- PC

- PA66

Machines

- CNC Lathe

- CNC Machine

- Polishing machine

- External cylindrical grinding machine

- Surface grinding machine

- Centerless grinding machine

- Broaching Machine

- Slotting Machine

- Gear Hobbing Machine

Surface Finish

- Carburizing

- Induction Hardening

- Nitriding

- Diamond-Like Carbon

- Black Oxide

- Phosphating

- PVD coating

- Polishing

- Carbonitriding

- Quenching and tempering

- Anti-rust Oil Coating

Planetary Gears Explained – Key Types

Single-Stage Planetary Gear Set

The key components of this gear includes carrier, planet gears, sun gear, and a ring gear. This design provides dependable reduction of torque and speed in a small set up. It offers high torque density, smooth rotation and efficient transmission of power, which is suitable in industrial machinery, robotics and automotive applications where space is limited and performance is of concern.

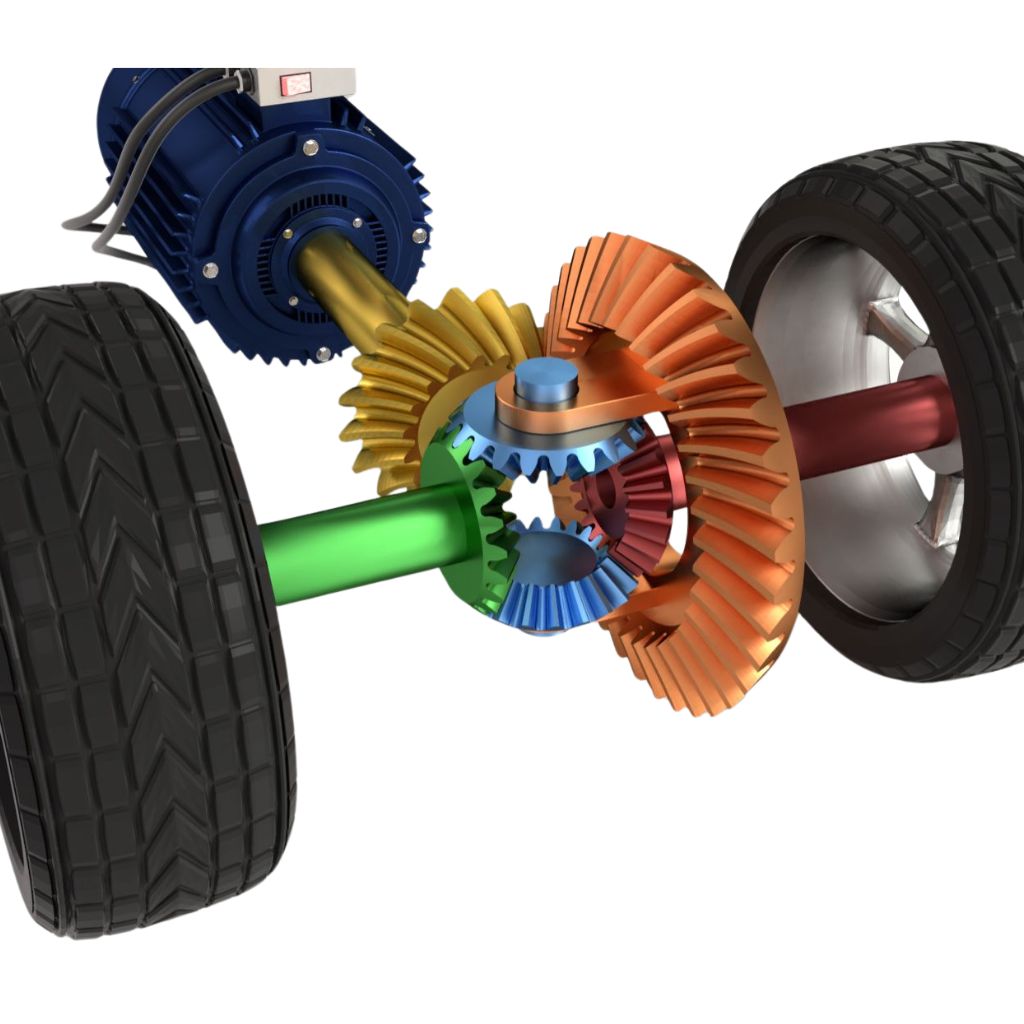

Differential Planetary Gear Set

Differential planetary gear sets divide torque between output shafts, but permit speed differentials. The input power is distributed equally by the sun, planet and ring gears. With this design, traction, stability, and safety during turns are enhanced. Differential gearboxes are common in automotive axles, off-road vehicles, and heavy machinery, as they offer stable torque, smooth rotation, and decent performance.

Harmonic Drive (Strain Wave Gear)

The harmonic drives incorporate a wave generator, flexspline and circular spline to provide high reduction ratios with near-zero backlash. The system flexspline bends, gripping teeth without any problem, and provides ultra-precise movement. Robotics, CNC machinery and aerospace actuators are best suited to harmonic drives. They offer high positional accuracy, repeatability, and small scale operation.

In-Line Planetary Gearing

The output and coaxial input shafts presents on the in-line geometry of this gear surrounds the central gear. The Planet gears play a key role in evenly distributing the load. The system caters to the high efficiency, lower backlash, as well as precision in torque transfer. The gearboxes find extensive applications in servo drives, industrial automation, and high-precision machinery that needs smooth rotation.

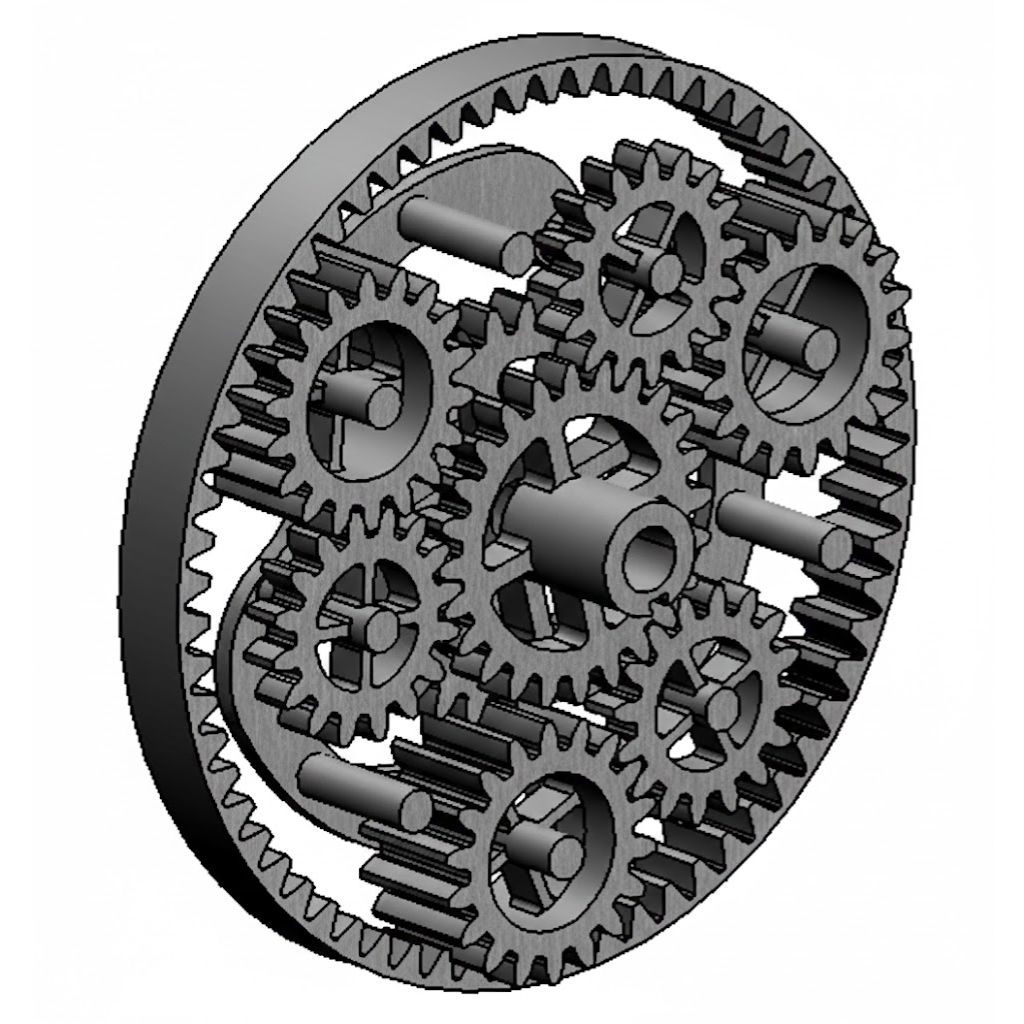

Multi-Stage Planetary Gear

Multi-stage planetary gear trains are planetary trains that stack two or more stages. This design is multi-ratio reduction and does not require a big size or fragility. It promotes high torque and various selections of speed in heavy-duty operations. Multi-stage gearboxes are often employed in wind turbines, conveyors, and high precision robotics, and provide strong performance, and smooth operation.

Offset Planetary Gear Set

Ravigneaux gear sets have two sun gears and a common carrier. This design enables a greater gear ratio with a smaller footprint, thereby fitting the multi-speed auto transmissions. It provides effective transmission of torque, high performance, and space savings in cars and high-performance use.

Ravigneaux Planetary Gear Set

The key components of this gear includes carrier, planet gears, sun gear, and a ring gear. This design provides dependable reduction of torque and speed in a small set up. It offers high torque density, smooth rotation and efficient transmission of power, which is suitable in industrial machinery, robotics and automotive applications where space is limited and performance is of concern.

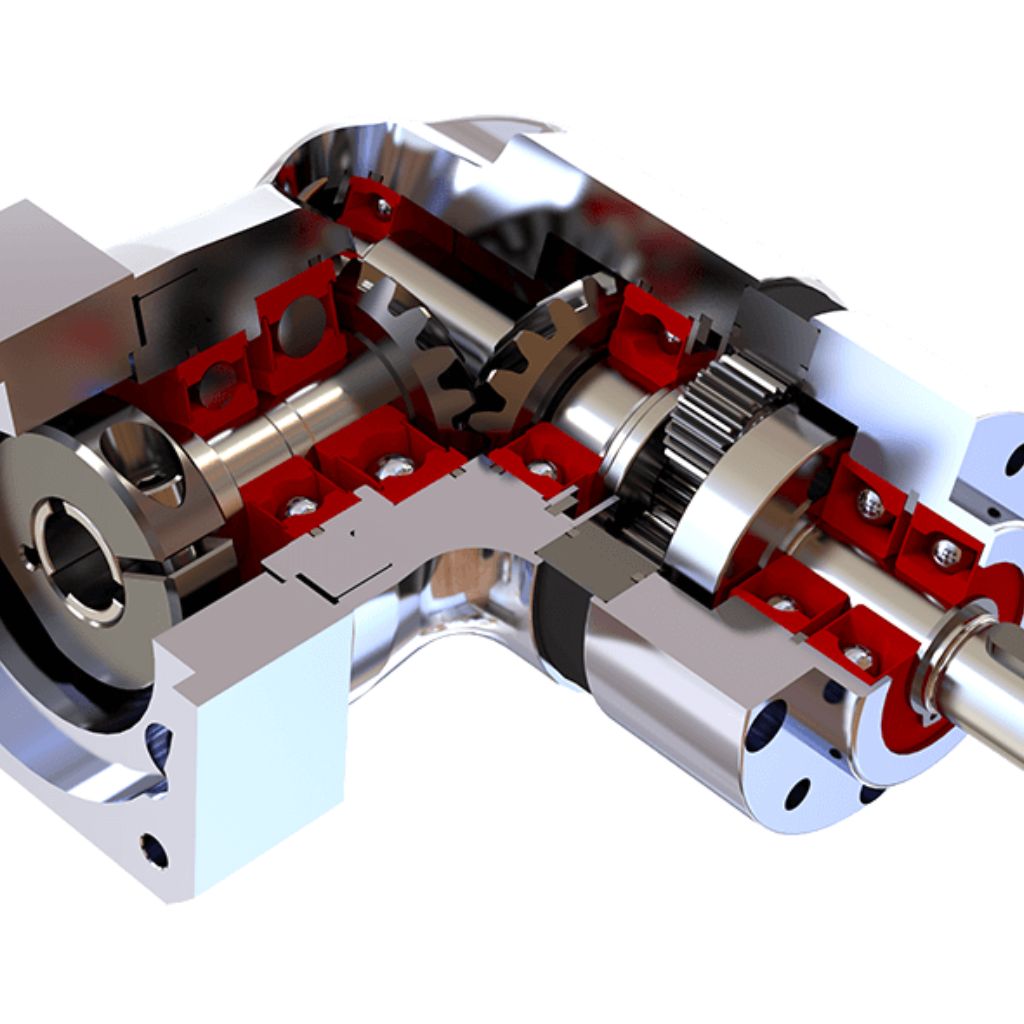

Right-Angle Planetary Transmission Gear

Planetary drives Right-angle planetary drives combine bevel or hypoid gears to deflect torque at right angles. The planetary stage is efficient and can be installed in narrow areas flexibly. These gearboxes offer smooth power transfer, high density of torque and compactness. They are applied in conveyors, machine tools, and automated vehicle applications that need high accuracy in rotary motion and flexible mounting options.

Simpson Planetary Gear Set

This gear system has a shared sun gear comprising of multiple planetary carriers that feature a connection within a sequence. In this compact design you can harness multiple forward speeds as well as reverse speed. Simpson gearboxes provide smooth gear changes, effective transmission of torque and good performance. They are widely applied in multi-speed automatics in motor vehicles.

Co-axial Planetary Gear System

Coaxial planetary gearboxes adopt concentric design with input and output shafts of equal axis. The design produces the highest possible torque density and mechanical stiffness in a small footprint. It provides easy rotation, high efficiency and is able to perform well under heavy loads. Coaxial gearboxes find applications in robotics, aerospace actuators, and industrial drives where size and high torque needed.

How Compound Planetary Gears Are Made?

The compound planetary gears are designed to cater to high torque and precise motion. The initial stage is the calculation of planetary gear ratios and kinematic analysis by designers taking into consideration load, torque, and efficiency. Alloy steel, hardened steel, aluminum, or cast iron are chosen and the material may be heat treated to improve strength and surface life. Gears are produced through hobbing, shaping or grinding, and may have spur or helical teeth. Sun, planet and ring gears are centrally aligned during the assembly, fusing carriers and shafts. Dimensional accuracy, tooth profiles and reliability are ensured by quality control with noise, vibration and durability testing.

Uses Of Planetary Gears – Which Industries Employ Planetary Gears?

Smooth change of speed in automatic transmissions is made possible by planetary gears. They spread the torque effectively and enhance the performance of the wheels drive. These gears deal with heavy loads and they conserve space in vehicles.

Automotive Industry

Planetary gears are used to operate conveyors, mixers, and heavy-duty reducers in industrial machines. They divide loads equally, and this enhances efficiency. Such gears enhance wear resistance and increase machinery life.

Industrial Machinery

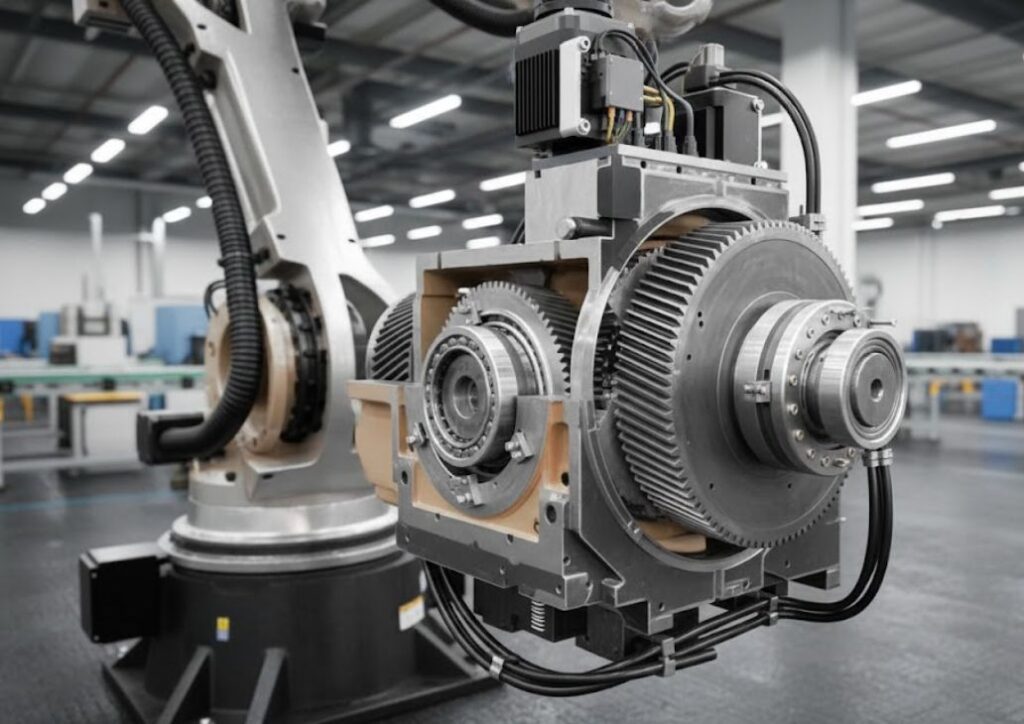

Planetary gears are used in robotics to provide accurate motion in servo drives. In compact areas these gears offer high torque. These gears provide precise operations in automated systems.

Robotics and Automation

Planetary gearboxes are employed to convert the low-speed rotations into high-speed generator input in wind turbines. They are more efficient in energy consumption and they manage variable loads. These gears assist in the long term, heavy-duty works of renewable energy systems.

Renewable Energy

Planetary gears are employed in the reduction systems of the compact motors in EVs. They are used in aerospace actuators as a means of control and flight. They provide credible torque in severe services.

Electric Vehicles and Aerospace

Planetary gears are used in imaging systems and surgical devices where high accuracy in movement is required. They offer small, stable performance. These gears make sensitive instruments safer and efficient.

Medical and Precision Equipment

Selecting the Right Planetary Gear System

Load and Torque Requirements

Calculate the load and torque requirements of the application. Planetary gears should deal with peak and continuous loads. Precise matching of the torque minimizes wear and enhances the reliability of the systems. Correct sizing will guarantee longer gear life and will avoid operational failure.

Speed Reduction Ratio

Choose a gear ratio to achieve required output speed. An increase in ratios increases torque and decreases the speed. Test trade-offs to enable a smooth acceleration and steady performance. You need to select ratios properly to improve productivity and the lifespan of the system.

Power Transmission and Efficiency

You need to assess energy losses and mechanical efficiency. This is because effective efficiency results in less heat generation and low energy waste. Proper lubrication and good alignment results in better power transmission. Efficient systems leads you to experience longer component life and cut off maintenance costs.

Size and Space Constraints

Take into account available space to install. Small planetary systems occupy space without compromising performance. Assess the mounting capabilities and ease of maintenance. Space conscious designs enhance integration of the systems.

Environmental and Operating Conditions

Consider temperature, lubrication, noise and duty cycle. Select materials and finishes that work in harsh environment. Environmental adaptation will provide dependable and long-term functioning.

Inspection and Quality Standards at CNCSwissMasion

Philosophy of Quality Assurance

CNCSwissMasion also guarantees that planetary gears are of high performance and accuracy. It has ISO and automotive gear standards. Continuous improvement is supported by full traceability and statistical quality control. Properive corrective actions are implemented as they are due and documented procedures give consistent repeatable results.

Material Certification and Traceability

Raw materials are tested in terms of composition, hardness and strength. Compliance is guaranteed through Mill certificates and batch traceability. The lot is checked against engineering specifications. Protocols ensure the material integrity, which ensures that gears are designed to the precise standards of performance.

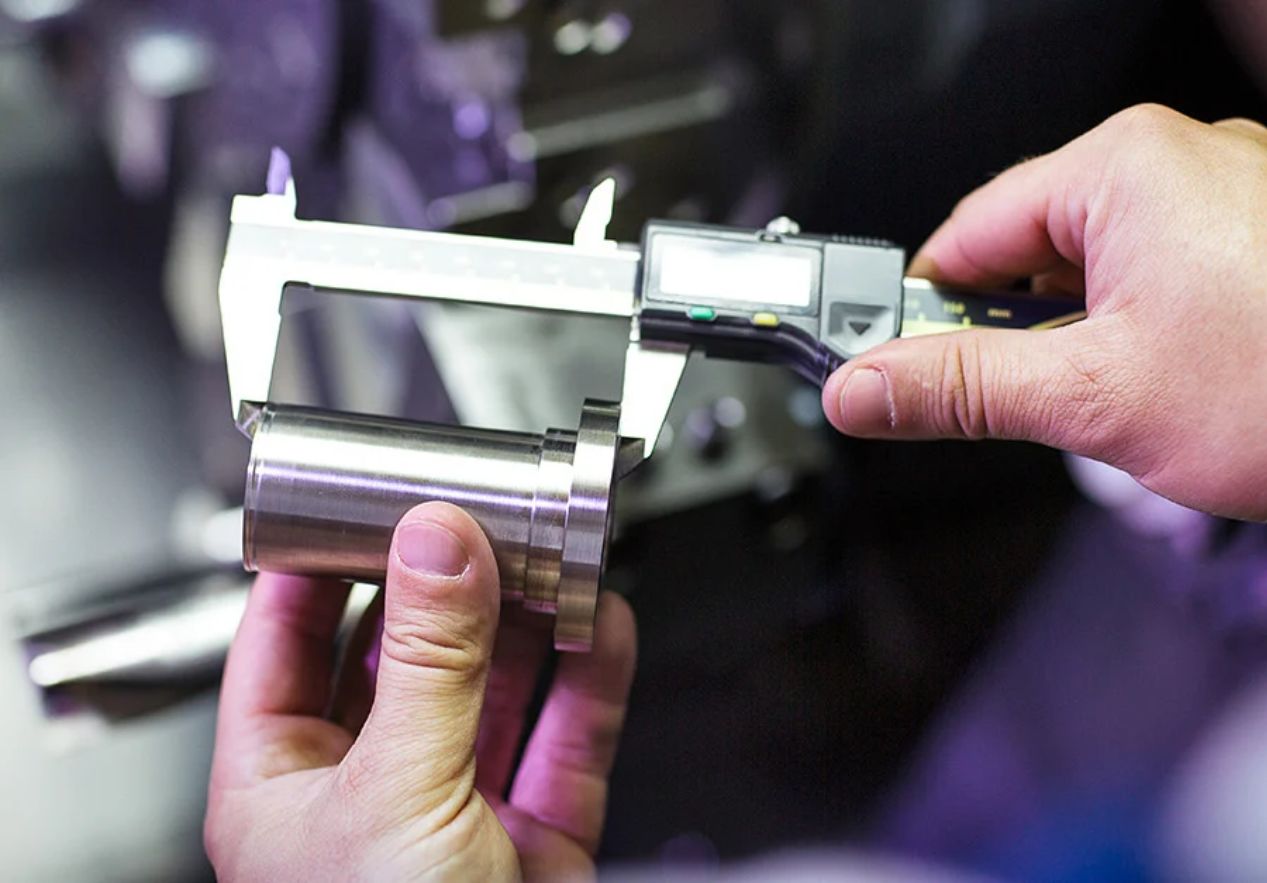

Processes of Precision Gear Inspection

Planetary gears are checked at various stages. Rolling tests, involute gauges and CMM testing are used to check tooth profiles. Precision is guaranteed by dimensional, surface and heat treatment checks. Vibration and noise performance is confirmed by dynamic testing. Bearings and assembly fits are also checked.

Quality Management Standards

CNCSwissMasion has an ISO 9001:2015 certified system and a system that is in compliance with ISO/TS 16949 and ISO/TS 22163. Quality is supported by calibration and documented procedures, and audits. Ongoing employee education would ensure the compliance with the most recent industry practices.

Explore Our Range of Products

What is a Planetary Gear Set - FAQs

How Does a Planetary Gear Work?

The central sun gear while on the carrier that rotates meshes with the orbiting planet gears. It works same as the miniature solar system. Yet, their dispensation may offer rapidity diminution, torque multiplication, or reverse rotation with effectiveness in a small format.

Are Planetary Gears Backdrivable?

Depending on the design and level of friction, planetary gears may be backdrivable. Other high-torque systems do not back-drive to avoid reverse motion. Nevertheless, the design of gears tooth and lubrication are selected by engineers to operate backdrivability safely and efficiently.

Do Manual Transmissions Use Planetary Gear Sets?

Planetary gear sets are hardly ever used in traditional manual transmissions. They use parallel gear pairs of shafts with synchronized shifting. Nevertheless, more advanced manual systems might use planetary gears to allow compactness or multi-speed systems.

Does a Semi-Automatic Transmission Have a Planetary Gear Set?

The majority of semi-autonomous transmissions operate planetary gear sets. Leveraging these allows the easy change of gears without a clutch pedal. These systems are however able to operate at higher torque and offer numerous gear ratios within a small package.

How Are Planetary Gear Ratios Calculated?

Calculations of the gear ratios are done by dividing the count of teeth on the sun, planet and the ring gears. This final ratio depends on the input, output and fixed components. Yet, very accurate calculations have to consider meshing conditions and the distribution of torque.

Does the factory have ISO 9001 and IATF 16949 (automotive industry) certifications?

CNCSwissMasion is based on the ISO 9001:2015 and IATF 16949 quality management systems. These certifications ensure that there is tight regulation of design, production and delivery processes. The IATF 16949 conformance guarantees automotive-level consistency, traceability, and risk-aversion. Consistency in audits, documented processes, and corrective measures promote the manufacture of stable planetary gears to global industries.

What production equipment does the factory have?

The plant has modern CNC lathes and CNC machining centers. Gear cutting machines allow cutting of external and internal gears in a precise manner. Surface and cylindrical finishing at high accuracy are assisted by grinding machines. Complex planetary gear structures are finished using broaching, slotting, and polishing machines.

What is the gear inspection process? Does the factory have a complete quality control system?

CNCSwissMasion has a total system of quality control that includes all production phases. The process begins with the inspection of the raw material and continues with machining and final assembly. Operators adhere to a set of inspection plans with established check points. In mass production, statistical process control is used to maintain uniformity and to forego deviation.

What are the testing methods and equipment for key gear parameters (such as tooth profile, tooth direction, and hardness)?

Tooth profile and tooth direction are measured using gear measuring centers and dimensional accuracy and concentricity is checked using coordinate measuring machines. Hardness during heat treatment is tested by Rockwell and Vickers procedures. The stability of operations and performance are checked by rolling, noise and vibration tests.

Does the factory support customized gear production? What is the lead time from drawing to sample?

CNCSwissMasion will help in designing everything in planetary gears manufacturing, based on customer drawings. The designs are evaluated by engineers with the aim of maximizing the manufacturability and performance. Approval normally takes 15-25 days to the production of samples. The lead times can be changed depending on the complexity of the material and design.

What is the gear precision grade?

The plant is capable of producing planetary gears to a DIN Grade 5 level of accuracy. Close tolerances to ±0.004 mm are achieved by controlled grinding. Accuracy is up to automotive, robotics, and medical industry standards. The batches contain reports on the inspection that verify the standards of accuracy achieved.

How Many Gears Are in a Planetary Gear System?

The simplest planetary system consists of three gears: sun, planet, and ring. Now you know facts on What is a planetary gear set. Complex systems can add sets of gears to obtain increased gear counts. Nonetheless, designers select settings to create the most efficient and maximum torque in every application.