What is Reaming? – Concept, Tools, Process, Perks and More

Drilled holes create irregular dimensional problems because of their imprecise diameter. The technique leads to assembly problems and weak connections that affect essential industries such as aerospace and automotive manufacturing. When machining parts without refinement they do not fit properly which raises friction and lowers operational efficiency.

By refining holes into specific tolerances reaming achieves better alignment and smoother surfaces. You can make strong machined parts at exact dimensions when you use appropriate tools with proper production methods.

This article examines everything about reaming including its production steps, equipment types, and implementation areas to help you choose the right machining solution.

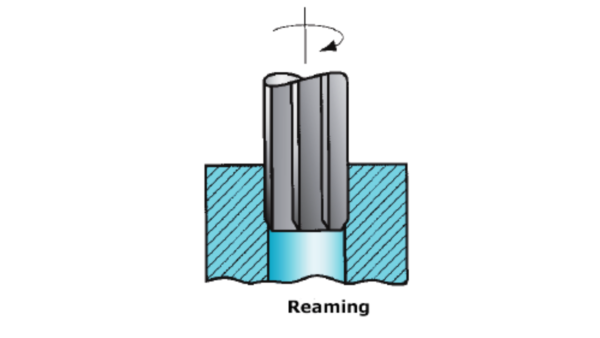

What is Reaming?

Table of Contents

ToggleReaming uses cutting tools to widen or perfect drilled holes. This operation takes away minor material amounts to create better precision and smoother surfaces. The rotating reamer tool cuts accurately to produce round smooth holes meeting exact specifications. You mostly rely on reaming to work with precise metal parts. The selection of proper drill sizes when reaming protects against over-removal of material. When precise sizing matters the adjustable reamers offer their benefits. Practicing with a reamer assists you in creating identical and precise holes.

Types of Reaming

Straight Reaming

Straight reaming serves as the leading method used regularly. The tool enlarges your hole while smoothing its surface without altering its form. The technique produces a perfectly smooth metal hole that you require for specific applications.

Tapered Reaming

When you use a tapered reamer the hole gets a cone shape that aligns easily with matching parts. What does a reamer achieve when you need secure connections between parts? One purpose of taper reamers is to create the necessary hole geometry.

Flute Reaming

Flute reamers enable better metal processing while decreasing cutting forces and enhancing chip evacuation. The tools stay stronger and produce better surface quality while you work. Select the appropriate drill size for reaming operations to obtain precise results.

Spiral Reaming

A spiral reamer directs chips better during cutting to boost performance. This tool produces precise metal reaming at fast speeds to generate better results.

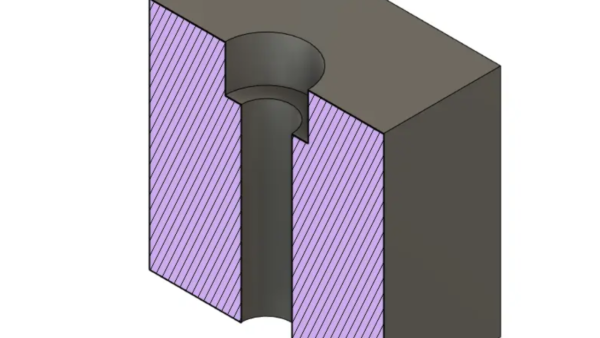

Counterbore Reaming

The counterbore reaming operation produces a flat-bottomed hole with a wider opening. An adjustable reamer helps you achieve specific hole size requirements.

Reaming Tools and Equipment

Reamers exist in different forms built to handle one particular job. Learning about these choices will help you decide which metal reaming tool works best.

Hand Reamer

You can create highly exact product sizes with hand reamers because they work without electricity.

- Includes rose or fluted reamers with a slight taper at the cutting end for smooth entry.

- The reamer exists in solid and adjustable forms to help users expand a drilled opening at controlled rates.

- The blades have unusual spacing to stop vibrations and provide constant material removal.

Floating Reamers

When used correctly the floating reamer ensures alignment between the drilled area and the reaming tool during the cutting process.

- During operation this tool automatically adjusts to keep precise results.

- It features two replaceable cutting edges that move radially within a slots for adjustment.

- Best for rotary workpieces in turret lathes.

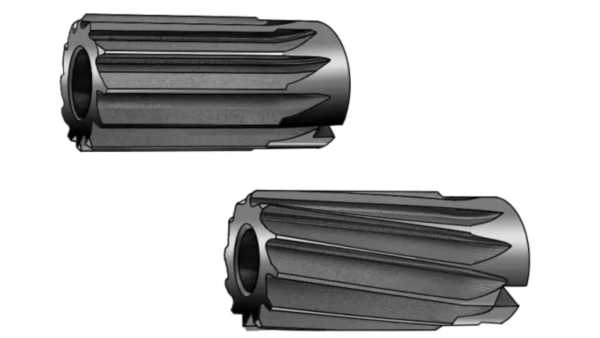

Shell Reamers

The tool holder attachment of a shell reamer helps produce precise hole dimensions.

- Shell reamers produce very precise enlarged holes consistently.

- This tool type handles free-cutting materials and makes perfectly sized reamed holes.

Carbide Reamers

These reamers handle materials that resist high abrasion.

- Made from carbide for durability and wear resistance.

- It delivers robust tool durability plus excellent surface quality while reaming a hole.

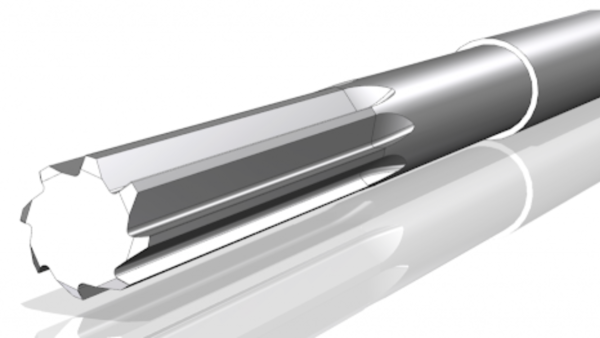

Tool Design and Features

The shape and construction elements of a reamer influence how well it works. The effectiveness of a reamer to expand a hole depends on a set of important elements including:

- The tool’s sharp edges help reaming tasks go faster while ensuring the hole stays intact.

- Rotating flutes help move chips out and stop blockages during operation.

- Advanced layers of TiN and TiAlN help tools survive longer and run smoothly.

How to Ream a Hole: A Stepwise Guide

Preparation for Reaming

Validate that the hole contains sufficient material before beginning the reaming process. The reamer will rub against the metal when there is not enough material in the hole. On the other hand when excessive material exists you can experience incorrect size hole. Setting up the hole properly helps reaming tools achieve precise dimensions in metal.

Step 1: Secure the Workpiece

Use clamps to hold the workpiece steady during the process. Match your reamer size selection with the drilled hole, making it 1.5 times wider. You can use an adjustable reamer when specific measurements are required for the project.

Step 2: Spot-Drill the Hole

Insert a spot drill with a taper that is a bit wider than the existing drill bit. This technique ensures the reamer moves in the right direction. A center drill damages tool accuracy.

Step 3: Determine the Correct Drill Size

When reaming you need to choose a drill bit that is smaller than the reamer by a small amount. Change the reamer size by 2% for hard metals and 4% for soft metals when preparing the tool. This prevents over-sizing.

Step 4: Apply Correct Feed and Speed

Change the drill’s operating speed and material feed rate to optimize results. Apply cutting oil or liquid coolant as it helps tools cut through metal better and produces smoother results. Adequate lubrication helps the reamer stay useful for longer.

Step 5: Control Feed and Speed of the Reamer

Adjust the drill speed to run between 50% and 66% of its normal rotation during drilling operations. Shift from drilling speed to reaming speed by doubling the speed. The specified tool settings maintain a perfectly shaped hole while protecting the reamer from excessive wear.

Step 6: File Hole Top

For round hole edges utilize countersink tool at an angel of 90º/82º. The filing process stops the reamer from creating sharp points on the drilled hole surface.

Step 7: Use Appropriate Lubrication

Light oil or coolant application is needed for this step. Stay away from heavy lubricants since they create unwanted buildup that lessens accuracy. Reamer movement at this point creates an optimal hole surface.

Step 8: Proper Reaming Technique

Keep reaming without interrupting or touching the workpiece. Allow the reamer to travel freely through the hole without stopping or breaking the motion. End reaming operations by halting the spindle before taking out the reamer. Continuous motion with the reamer helps stop both parts from breaking.

Applications of Reaming

Aerospace Industry

Turbine blades require precision reaming along with structural parts and fuel nozzle manufacturing. Keeping both safety and performance working requires precise hole dimensions. Aerospace manufacturers use metal reaming to achieve precision components by creating smooth surfaces with tight technical requirements.

Automotive Industry

Reaming technology makes sure that engine block parts and transmission components match their precise engineering limits. Properly reamed holes deliver better results and last longer. An adjustable reamer tool helps you adjust precision bores in important parts.

Medical Equipment

Equipment for surgery and medical implants must have perfectly drilled holes. The way the hole fits together creates mechanical system strength. You need to select the correct drill size for reaming to produce the best outcome.

Tool and Die Making

Tool and die production depends on correct reaming practices. The process delivers tight part fitments that boost durability. Exploring reamer usage will help you achieve better results when you are not sure.

Construction and Heavy Equipment

Structures with large size holes need reaming to create a strong bonding connection. You need to pick a reamer that will support strong and stable construction.

Oil and Gas Industry

Metal reaming tools boost oil and gas downhole equipment performance by moving fluids better at high pressure. One learns which reaming process fits best by knowing reaming’s purpose.

Advantages of Reaming

Precision and Accuracy

Reaming a hole makes it more precise and gets it to specific dimensions. The reaming process supplies dimensional accuracy not available with other methods. The hole connections are created with a precise reaming process and they work better.

Improved Surface Finish

Reaming leaves a smooth inside surface of the drilled hole. It produces smooth surfaces that extend part life expectancy. Such reaming operations produce a high quality metal finish that will prolong the life of products.

Enhanced Performance

Sufficiently sized precision reamed holes assure parts will assemble as intended. This technique makes holes that give better performance and longer service life. The reamer can be fine tuned to pick the right hole dimension.

Cost Efficiency

Reaming offers hole quality improvements without material consumption. This method makes manufacturing operations more efficient since it requires fewer expensive processing tools. Working faster on a production run requires manufacturers to choose the right drill sizes.

Consistency and Repeatability

The use of reaming tools produces consistent manufacturing results that remain consistent from order to order. By using a reamer correctly, you will make uniform holes in each project. Knowing reaming’s principles will bring you to better project outcomes.

Challenges and Limitations of Reaming

Reaming however, comes with technical challenges at the same time, their accuracy.

Tool Wear and Durability

Tools that ream experience strong working pressures. The end of your reaming tool is worn out and needs to be constantly replaced. It prevents the reamed hole from developing uneven dimensions.

Material Limitations

But you need unique reaming tools for difficult engineering materials such as hardened steel and titanium. The type of material you are working with determines what you should do reaming wise.

Precision Control

Maintaining consistent precision is tricky. If your machine settings and tool wear are not managed, no production tolerance standards will be met.

Cost Considerations

Exchange of advanced reamers increases the production cost above what is normally incurred with normal drilling equipments or other procedures. Drill sizes change requires more but produces better final work.

Revealing Main Differences – Reaming vs Drilling

Know both drilling and reaming techniques to handle your materials correctly. Each stage is different but equally important in the final result.

Purpose

Reming improves the basic holes that are created by drilling for exact dimensions and form. They drill holes with a drill and then use reaming tools to finish off product dimensions.

Cutting Process

As they spin the drilling tools move the material away from them. A rotating tool with multiple sharp edges cuts around the hole to make it match your specifications.

Tolerances

During production work, drill bits make quick rough holes. Finished holes are given precise dimensional accuracy through a reaming operation.

Surface Finish

The reaming tools tend to produce a smoother hole than the basic drilling procedure. The reaming method makes polished smooth openings while drilling result in imperfect ones.

Applications

Holes are drilled quickly enough to fulfill all needs. Reaming operations offer the measurement of exact size and smooth surface for the metal components.

How to Select the Right Reaming Method

The type of reaming tool will depend on the materials you process. The selection of your reamer depends on material hardness and workability. For hard material surfaces you need more powerful reamers.

Hole Size and Tolerance

Pick up the reamer which best suits your desired hole specifications and precision standards. The precise hole specifications can be achieved by the reamer of your drill dimensions. This method gives a reamed hole with smooth ends.

Surface Finish Requirements

Select reaming techniques so that they produce the required surface finish. For your application precision reamers will produce a smooth polished finish you desire.

Machine Type and Capability

Make sure that your machine can handle the reamer you want to use. When you have sufficient cooling resources, test your machine’s feed rate and running speed. Right tools lead to good outcomes for metal reaming applications.

Tool Life and Durability

When you are choosing multiple reaming tools, study the tool life data. Special designs are needed for reamer tools to cope with tough manufacturing tasks. The life of the tool is extended by regular maintenance.

CNC and Automated Systems Use Reaming Methods

CNC Reaming

The reaming using CNC machines are accurate and gives holes with precise dimensions. All your projects will have accurate reaming results with the automatic system.

Automation and Speed

The automation of the system allows it to operate faster and carry out multiple parts without direct human touch in cutting operations. It has the technology to produce more parts with higher quality at a faster rate than processing time.

Software Integration

However, the system can work by programming software to achieve the best results. Tool path settings are calculated by the software to overcome error prone reaming processes. The outcome of reaming operations is precise when it is performed with software.

Advantages of CNC Reaming

Reduced preparation work produced by the CNC reaming system provides high quality results faster. CNC system automation reduces the number of necessary manual changes, which improves your reaming results.

Conclusion

You now know “What is Reaming?”. Reaming technology is required for precision machining to produce precise holes used in aerospace, automotive and medical manufacturing sectors. The right reaming tools especially an adjustable reamer produce precise and smooth outcomes for better component durability. As reaming becomes more important for automated production systems, new manufacturing technology will further push reaming into becoming a more important operation. Know reaming tools and their applications and deliver top results from better performance.