Top 29 Types of Aluminum Screws – Features, Pros/Cons, and Uses

The reason aluminum screws are important is that they provide light strength, corrosion resistance, and efficiency over the contemporary engineering and constructing industries. It is important to know all of the types, because each design is meant to address a particular load, environment and assembly requirement. This paper discusses the best 29 aluminum screw types in 2026, their characteristics, advantages, disadvantages, alloys, and uses. You will have a clear understanding of selecting the correct aluminum screws that will perform, last long, and will be future ready.

Table of Contents

ToggleWhat Are Aluminum Screws?

Fasteners manufactured using aluminum or aluminum alloys through aluminum machining are called aluminum screws. They are characterized by a threaded shank and shaped head. You select them on the basis of lightweight assemblies and corrosion resistance. Pure aluminum screws are soft and conductive. Aluminum alloy screws incorporate other components such as magnesium or silicon. These alloys enhance strength, hardness and wear resistance. It provides you with enhanced load capacity and durability with low weight. They are applicable to electronics, marine products and decorative use.

Aluminum vs Steel vs Stainless Steel Screws

Weight is a significant difference when you compare aluminum, steel and stainless steel screws. The aluminum screws are not heavy and are convenient to work with. Steel screws are a bit stronger, with an increased weight. Stainless steel provides balance between weight and durability. Aluminum gives you the best strength to weight ratio. Stainless steel is preferable in corrosion resistance. Aluminum is self-resistant to corrosion. Steel needs coatings. You also have the advantage of better electrical and thermal conductivity of aluminum.

Common Aluminum Alloys Used in Screws

Aluminum Alloy | Typical Composition | Key Features | Perks for Screw Applications |

1100 | ≥99.0% Aluminum | Very soft, excellent corrosion resistance, high ductility | Easy to form and machine, ideal for light-duty and decorative screws |

2011 | Al + Copper (5–6%) + Bismuth/Lead | Free-machining alloy, good strength | Excellent machinability, produces clean threads, suited for precision screws |

2024 | Al + Copper (3.8–4.9%) + Magnesium | High strength, fatigue resistance | Strong screws for aerospace and structural applications |

3003 | Al + Manganese (1–1.5%) | Good formability, corrosion resistance | Cost-effective screws for general-purpose and sheet metal fastening |

5052 | Al + Magnesium (2.2–2.8%) | High corrosion resistance, good strength | Ideal for marine and outdoor screws exposed to moisture |

5083 | Al + Magnesium (4–4.9%) | Excellent strength, seawater resistance | Heavy-duty marine screws with long service life |

6061 | Al + Magnesium + Silicon | Balanced strength, corrosion resistance | Most popular alloy for screws, suitable for structural and industrial use |

6063 | Al + Magnesium + Silicon (lower strength than 6061) | Smooth finish, good corrosion resistance | Decorative and architectural screws with clean appearance |

6082 | Al + Magnesium + Silicon | Higher strength than 6061, good toughness | Load-bearing screws in construction and machinery |

7075 | Al + Zinc (5–6%) + Magnesium | Very high strength, low corrosion resistance | Aerospace-grade screws requiring extreme strength-to-weight ratio |

7050 | Al + Zinc + Magnesium + Copper | High strength, stress corrosion resistance | Critical aerospace fasteners with improved durability |

8011 | Al + Iron + Silicon | Moderate strength, good corrosion resistance | Lightweight screws for packaging and low-load assemblies |

Why Aluminum Screws Matter More Than Ever in 2026

- Aluminum Grades and Alloys

6061, 7075, 5052 are commonly found in screws. Alloy choices have a trade-off between strength, corrosion resistance and machinability. Grading selection also guarantees sound performance of your project requirements.

- Strength-to-Weight Ratio

Aluminum screws are very strong and light at the same time. It is possible to decrease the overall structure weight, without compromising stability or load-bearing capacity. They best suit automotive, aerospace and portable equipment.

- Corrosion Resistance and Anodizing Advantages

These screws are natural resistant to rust and chemical attack. Anodizing can also be used to increase durability, hardening of the surface and adding beauty to it.

- Thermal and Electrical Conductivity

Aluminum offers good heat dissipation and conductivity. These screws can be used in electronics, heat exchange, and energy efficient assemblies.

- Galling Surface Treatments and Risks

High friction may cause galling of aluminum threads. This can be reduced by coating, lubricating or the surface treatment and enhances reliability when installing.

- Environmental and Sustainability Benefits

Aluminum is recycled and environmentally friendly. One of the ways to contribute towards sustainable engineering is by selecting screws that minimize the environmental impact and energy consumption.

Top 29 Types of Aluminum Screws You Need to Know in 2026

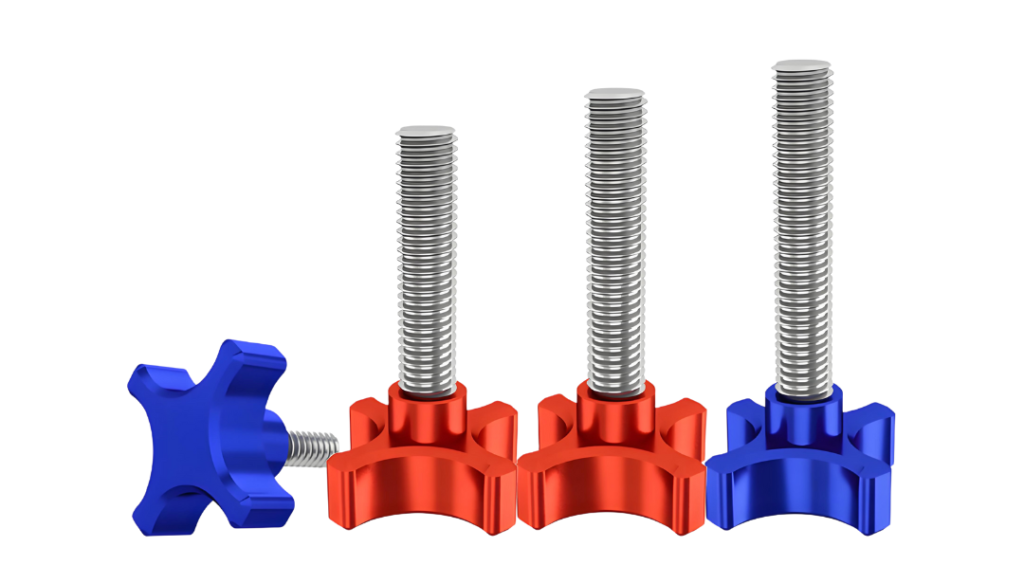

1) Aluminum Alloy Dome Head Hex Screws

Aluminum Alloy Dome Head Hex Screws have a dome shaped head and an outside hex drive. These screws are used to give a smooth finished look as high torque is applied. Their lightness of handling and resistance to corrosion is guaranteed by their aluminum alloy construction. The main characteristics are a polished head of the dome, robust aluminum body, and the accessibility of wrenches. The advantages are aesthetic finish, durability and ease of use. Nevertheless, the shape of the dome constrains flush mounting and tensile strength is weaker than steel. The best application would be architectural fixtures, ornamental panels, and outdoor enclosures where the aesthetic is important.

2) Aluminum Hex Socket Countersunk Head Flat Head Screw

It is an internal hex drive, which has a flat, countersunk head. You use it in situations where flush mounting is important, particularly in high accuracy assemblies. The hex socket of the socket and the countersunk geometry respectively provide controlled torque and even load distribution. Advantages are clean surface finish, less snagging and consistent application of torque. Cons include: the requirement of accurate countersinking and restriction of head-bearing surface. It is generally used in CNC-machined components, aerospace panels and electronics housings, where tight tolerance and a smooth finish are needed. It is pragmatic and up to the standard of professional aesthetics.

3) Aluminum Hex Socket Head with Serrated Flange and Captive Screw

This screw is designed with a captive and a serrated flange to avoid loosening. You use it to make joints more secure and prevent the loss of screws in the assembly. It has a serrated flange to resist vibration and captive retention that does not require washers. Its advantages include rapid assembly, better reliability, and less hardware requirements. Negatively, it is complicated to manufacture and has fewer reusability. Applications are in automotive assemblies and industrial equipment panels where high frequencies of vibration or movement would otherwise weaken the integrity of joints. It works very well in dynamic environments.

4) Aluminum Hex Socket Set Screw

Aluminum Hex Socket Set Screws are screws without heads and are internal hex screws that are used to hold components together. These screws are used when you require alignment without sticking out hardware. The characteristics are cup, cone, or flat points and internal hex socket drive to make accurate adjustments. They have small size, accurate placement and hidden fixation. In softer materials, maintaining the power is less, though. Common applications are shafts, pulleys, collars and adjustment systems where a safe, low profile interconnection is necessary. These screws provide limited positioning without disrupting the surrounding assemblies.

5) Aluminum Hexagonal Head Screw

Aluminum Hexagonal Head Screws offer a conventional six sided head to fasten with strongness. Using these screws, you choose screws that offer a high level of torque and have easy installation. Among them are wide bearing surfaces and a more traditional hex design. The advantages include easy compatibility of tools and dependable fastening during general use. The disadvantages are sticking noses and less pleasing appearance. Typical applications are structural assemblies, machine frames and utility equipment where appearance is less important than strength. These screws strike a balance between accessibility and usefulness in day-to-day mechanical operations.

6) Aluminum Hexagonal Torque Break Anti-Theft and Anti-Disassembly Screw

These screws have a breakaway hex head to ensure that they cannot be removed. You apply them on applications that need security and non-tampering. The main characteristics are that it has a torque-limited break-off head and a non-tamperable design. Advantages include high security and fixed-location. The disadvantages are that they are non-removable and require specific torque during installation. Common applications are in public infrastructure, signage and security enclosures where theft or tampering must be avoided. These screws make sure that after being installed, components cannot be disassembled non-authoritatively.

7) Aluminum Low-Profile Large Flat Head Screw

Low Profile Large Flat Head Screws have wide thin heads to distribute loads. You use them when you desire a smooth finish but do not want to lose contact with the surface. Major characteristics are a big bearing surface and a lowered head height. Advantages include limited surface damage, esthetic look, and stability. Disadvantages consist of the fact that it requires precise countersinking and reduced torque strength. Common applications are lightweight assemblies, electronics casings, and thin panels. These screws allow you to keep your finish flat and unobstructed and moderate loads without sticking out hardware.

8) Aluminum Phillips Countersunk Head Screw

These screws are used with a combination of Phillips drive and a tapered and flat countersunk head. You apply them to flush mounting in softer materials, including sheet metal or light assemblies. It has a Phillips recess to align and a standard countersunk angle to distribute the loads. Advantages are that they are widely available, installed easily and aligned easily. Disadvantages include risks of cam-out and reduced torque control. Common uses are in light structural assemblies, sheet metal work and cabinetry. This kind of screw is convenient, simple to install and has moderate holding force in general purpose applications.

9) Aluminum Phillips Countersunk Self-Tapping Screw

It is also a self-tapping type, which enables you to make threads on thin materials without prior thread-tapping. You apply it in quick assembling aluminum sheets, plastics or lightweight enclosures. The major characteristics are cutting threads, Phillips drive and tapered countersunk head. The benefits are rapid installation and lack of pilot holes. Cons include poor reuse and low thread retention in comparison with machine screws. Common uses are light enclosures, aluminum panels and plastic housings. These screws are time-saving in production and assembly processes and they have the same finish as a flush.

10) Aluminum Phillips Flat Head Screw

Aluminum Phillips Flat Head Screws are flat on the underside and cross-slot Phillips. You use them when you have to touch the surface without complete countersinking. The major characteristics are a flat head and standard cross-slot drive to make it easy to install. Advantages are ease of installation, low cost, and easy accessibility. Disadvantages include the screw failing to offer a fully smooth finish. Common applications are brackets, panels and light-duty assemblies. Such screws give you the opportunity to have low-profile fixing where aesthetics flush mounting is not as important as fastening.

11) Aluminum Phillips Round Head Screw

The Aluminum Phillips Round Head Screw has a domed head with a centrally placed Phillips drive. You can apply it to places where functionality and looks are important. Its rounded head gives it a decorative finish as well as simple fastening. This screw can be fitted using normal Phillips screwdrivers and is convenient to use in daily applications. The screw sticks out slightly beyond surfaces and this may restrict flush fitting. Nonetheless, it is effective in consumer goods, ornamental fittings and in light assembly works. Its attractive design makes it fit well in the projects where projects require aesthetics to supplement functionality.

12) Aluminum Ping Pong Paddle Screw

The Aluminum Ping pong Paddle Screw is a lightweight corrosion resistant screw that is used in sports equipment. It can be trusted to attach rubber sheets to paddle blades without compromising balance. It has low mass that keeps it under player control as well as corrosion resistance prevents its exposure to sweat and humidity. It is a very specialized product but offers a high degree of reliability in fastening solutions in the production of table tennis paddles. You should only apply it to intended equipment because its use beyond paddles is restricted. Its special design makes it durable, lightweight and accurate in sports usage.

13) Aluminum Sex Bolt

The Aluminum Sex Bolt is a two-part connector that is made up of a male and a female barrel. Thin materials can be clamped strongly and the surface cleaned and smooth. Its internal threading is used to evenly spread the load and to give it secure fastening, making it ideal in furniture, signage, and architectural panels. During installation, you must have access to both sides and this restricts certain applications. Nevertheless, it provides a smooth finish and a good level of strength, which is professional in appearance. It can be applied to any project where beauty and structural integrity are of equal concern.

14) Aluminum Slot Thumb Screw

The Aluminum Slot Thumb Screw has a slotted head and knurled grip that can be hand-tightened without any tools. The parts can be adjusted or fixed easily and it is ideal in tool-free applications. Its ergonomic structure makes it easy to fasten and remove and the slotted top permits standard screwdrivers where necessary. The screw is not able to sustain high torque and this restricts its usage to heavy load applications. You can count on it to provide adjustable fixtures, equipment covers, and electronics panels. The fact that it is user-friendly and has a simple design makes it convenient in cases where settings need to be adjusted frequently.

15) Aluminum Slotted Set Screw

The Aluminum Slotted Set Screw is a straight slot drive, headless fastener. Components can be locked in place discreetly creating a flush or hidden installation. Its design is simple and can be removed easily hence making it easy to maintain and make adjustments. A possible disadvantage is slot damage, particularly when tightened excessively or not lined up. You may employ it to fix shafts, mechanical parts and fine-tuning. Its low-profile design is appropriate in situations where the looks and size matter. It can be trusted to keep your items safe and functional without sticking out hardware.

16) Aluminum Socket Head Cap Screw

The Aluminum Socket Head Cap Screw is a threaded screw with an internal hex head. You are able to use increased torque than a Philips screw without losing a small head design. Its deep socket drive and precision threads allow it to be firmly fastened in tight areas. Installation requires a hex key, and this can be done with additional tools. Nonetheless, it is superior in machinery, robotics and automation systems where reliability and strength are premount. You may rely on it to have high accuracy with tight tolerance applications and high load performance.

17) Aluminum Spot Welding Screw

The Aluminum Spot Welding Screw is applicable in alignment prior to spot welding. Components can be placed temporarily or permanently without the need to place more fixtures. Its head design is such that it allows the welding processes to be carried out with good precision. It is restricted to welding, and cannot be a general fastener. It can be used in automobile body panels, fabrication shops and metal assemblies that need to be welded precisely. Although it has a specialized application, it simplifies production, increases accuracy, and decreases setup time. You enjoy efficiency and a regular fit in welding-heavy set ups.

18) Aluminum T Types Screw

The T-slots T-shaped head of the Aluminum T Types Screw. Slide and position it, allowing flexibility in the fastening of aluminum extrusions. T-head profile provides a safe grip in slot systems, thus eliminating rotation under load. Slot specific is limited to general applications beyond T-slot structures. It can be used in workstations, machine frames, and modular assemblies where adjustability is critical. Although it is not very versatile, it is convenient when it comes to adjustable structures. It will give you the accuracy of alignment and stability in modular aluminum structures.

19) Aluminum Thumb Screw

The Aluminum Thumb Screw has a textured hand-operable head, which provides tool-free installation. Components can be attached and detached repeatedly, and time spent on the assembly and modifications can be saved. It has a comfortable, ergonomic design, often knurled or wing-shaped. Poor torque limitation limits its application in high load applications. It may be used in electronics panels, camera mounts, and adjustable equipment, where it is necessary to access it frequently. It provides convenience and control although limited by torque. You can rely on it when you want to have ease of operation and fast adjustments.

20) Aluminum Torx Drive Screw

The Aluminum Torx Drive Screw has six-point star recess to transfer the torque. You may decrease cam-out, guard the drive and attain extended tool life. Its design is efficient in its ability to handle more torque than the Phillips or slotted drives. Installation needs special Torx drivers, and this can be a problem. It can be used in electronics, automotive interiors, and precision assemblies where reliability and strength are important. Although it will need a special tool, it guarantees uniform performance and minimizes wear. You have the advantage of safe fastening and long life drive in high-torque applications.

21) Aluminum Torx Handle Screw

The Aluminum Torx Handle Screw has a Torx-driven screw with an inbuilt handle, which gives it an excellent manual control. It is perfect when you need to do a lot of tightening with increased leverage, which makes it accurate. Its Torx interface is star-shaped and provides comfort and less slip during work through its ergonomic handle. You gain fast, precise fastening and the larger design can hamper narrow places. Its screw is a good fit in inspection panels, modular equipment, and other cases where you require both torque control and easy hand-use that merge both functionality and easy design.

22) Aluminum Torx Screw

The Aluminum Torx Screw is a conventional screw with a Torx recess, which is developed to be fixed with moderate loads. The star-shaped drive will guarantee the steady application of torque, minimizing the chance of stripping and giving clean engagement. You are accustomed to good fastening in consumer electronics and appliances where precision is essential. Although the design will need a matching Torx tool, it will provide better performance than the conventional slotted or Phillips screws. It is a reliable screw that has great control, consistent torque, and life and is a good selection on assembly lines and maintenance operations where consistency in quality is essential.

23) Custom Aluminum Screws

Custom Aluminum Screws are produced to suit the needs of a particular client, offering a specialized solution to a special application. You have the option of choosing precise dimensions, materials and head styles that will maximize performance in your project. Such screws may have a special geometry or proprietary alloys, which guarantee a good fit and maximum reliability. They will be more expensive and require longer lead times, but you will have unmatched flexibility. They have extensive use in OEM, specialty machinery and custom assemblies where standard fasteners are ineffective. By selecting custom screws you can achieve precise mechanical, aesthetic, and functional needs in an efficient way.

24) Custom Aluminum Special-Shaped Screws

Custom Aluminum Special-Shaped Screws are irregular in design in proprietary systems or special assembly requirements. You are able to provide safe fastening in designs that cannot be screwed using standard screws. Their non-standard profiles and dedicated drive systems gives exclusivity in design without sacrificing the functionality. The scarcity and increased complexity in production might present a challenge to you in sourcing. Such screws are suitable in medical equipment, specialized equipment or where tamper-resistant fixing is needed. With special-shaped screws, you can provide proprietary component security, alignment of assemblies, and compatibility with complex mechanical systems without interfering with the design or performance.

25) DIN 84 Round Slot Aluminum Screw

The DIN 84 Round Slot Aluminum Screw is a conventional, standardized screw with a round head and a straight slot. It will be dependable in both restoration and contemporary fastening. Its uniform sizes allow interchangeability, which guarantees easy substitute. Although slotted drives can be susceptible to cam-out, it can be controlled by proper tool placement. These screws are commonly used in light machinery, restoration of antiques, and electrical equipment. They provide a well-known, old-fashioned design enabling you to assemble or assemble parts using reliable, old-fashioned fastening techniques.

26) DIN 912 Aluminum Socket Head Cap Screw

The DIN 912 Aluminum Socket Head Cap Screw is a metric standard screw joint, intended to be used in precision engineering. It has standardized dimensions and alignment characteristics that allow you to attain very high accuracy in fastening. The hexagonal socket head of it enables the predictable application of torque that minimizes assembly errors. Though you need a hex key or driver, the screw guarantees compatibility worldwide and similar functionality. It is widely used in industrial equipment, automation and robotics. With this screw, you have a reliable degree of precision, mechanical reliability, and ease of incorporation in engineered assemblies where consistency of performance is important.

27) Double-Ended Aluminum Screw

The Double-Ended Aluminum Screw is a threaded screw that has no head and is threaded at both ends, allowing the components to be joined secretly. You are able to make smooth assemblies where a visible head is not required. Its two threadings enable internal fastening that is secure and at the same time has a clean look. Installation can be more complicated and it needs exact alignment but you have versatile connectivity. Such screws are typically applied in furniture, structural connectors and modular structures. Using the double-ended screws you have a streamlined design, stable joining, and useful integrity in applications where appearance and concealed fastening is at least as significant as strength.

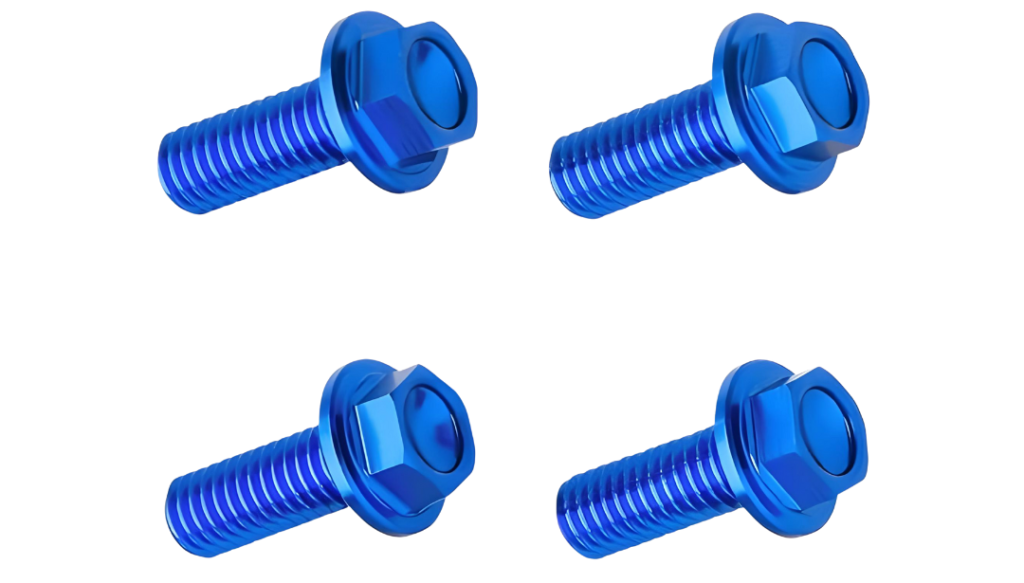

28) Hex Flange Head Anodized Aluminum Screw

Hex Flange Head Anodized Aluminum Screw is a screw that has a hexagonal head along with a washer flange and anodized finish. You can be able to gain better load distribution and at the same time improve corrosion resistance without having to install separate washers. It has an anodized surface that enhances its durability and longevity hence suitable to use in outdoors or marine conditions. Although this is more expensive than plain finishes, the benefits gained are worth the expense. Such screws find extensive application in outdoor structures, marine fittings and structural elements that are subjected to severe environments. This integrated design gives you strength, reliability, and maintenance free performance.

29) Square Head Aluminum Screw

The Square Head Aluminum Screw has a four-sided head that has good grip and can be controlled manually. Torque may be applied using a wrench or spanner without slipping. Its vintage look is slip-resistant and is able to be used in a restoration project or high-duty fixtures. The tooling can be less compatible in modern tooling which restricts some applications. Antique furniture, heritage equipment, or where there are strong engagement requirements use these screws. The choice of square head screws gives you traditional appearance and practical strength, and you have the ability to maintain accurate fastening and still retain the traditional design integrity of both manual and mechanical assemblies.

How to Choose the Right Aluminum Screw in 2026

When selecting the appropriate aluminum screw in 2026 several factors need to be taken into account. The second step is to determine the load and torque parameters to make sure that the screw is able to withstand the stresses of operation. Then there is the case of environmental exposure that includes moisture, chemicals, or extreme temperatures that influence the corrosion resistance and material life. Test head type and accessibility to get it installed in narrow places. Choose a type of drive that is most efficient and corresponds to available tools. Lastly, balance standards compared with tailored solutions to address performance and regulatory requirements appropriately.

Future Trends in Aluminum Screws for 2026 and Beyond

The future of aluminum screws in 2026 and other years will be intriguing. You will witness more application of EVs and lightweight transport, where minimization of weight is very important in efficiency. The development in anodizing and surface engineering will enhance corrosion resistance, durability and appearance. Application-specific and custom fasteners will increase and they will provide you with a specific fit to unique designs. Recycled aluminum screws will be produced by sustainability and easier to the environment. Precision CNC methods and smart manufacturing will guarantee increased quality, consistency and quick production of your projects.

Conclusion

It is important to know the broad range of aluminum screws to get strength, durability, and efficiency in contemporary projects. By reading about the best 29 types, you learn about features, alloys, applications, and limitations, to make informed decisions. The choice of the fastener guarantees the maximum performance, resistance to corrosion, and reliability. With fastener technology changing in 2026 and beyond, keep up with innovations and use them to your advantage, such as the ability to design custom designs, use advanced coating, and environmentally friendly materials to make your projects future-proof and highly efficient.