Beryllium Machining Guide – Everything You Need to Know

Beryllium is a rare, light weight, highly stiff thermally conductive and corrosion resistant metal. Whether you deal with aerospace, defense, medical, or electronics, you have problems with warped materials, corrosion, or inefficient materials in terms of strength-to-weight. Beryllium addresses these challenges with unparalleled dimensional stability and is known to be reliable. This guide discusses its grades, machining processes, and safety precautions to enable you to choose the right material and process. Discover how you can take advantage of the strengths of beryllium in a secure manner and how to master accurate and efficient machining of your projects.

Table of Contents

ToggleWhy Use Beryllium in Machining?

You select beryllium because it is strong and light. It has a great strength-to-weight ratio and provides you with robust yet lightweight parts that remain stable in thermal and mechanical loads. You lose aerospace and satellites weight without losing integrity. The optical reflectivity of beryllium expands optical systems, providing you higher-resolution telescope and sensor images. These features enable your parts to be accurate, effective and dependable.

Admissible Feed Rate and Speed

Beryllium is a material that must be highly considered in terms of speeds and feed rates to ensure the best machining results with minimum wear and heat accumulation of the tool. Depending on the process, effective speeds are usually between 150-300 SFM with a feed rate of 0.1 to 0.3 mm/rev. The recommended parameters are:

| Process | Speed (SFM) | Feed Rate (mm/rev) |

| Turning | 200-300 SFM | 0.1 – 0.3 mm/rev |

| Cutting Off | 150 SFM | 0.08 mm/rev |

| Drilling | 150-200 SFM | 0.05 – 0.1 mm/rev (for 4.76 mm hole) |

| Reaming | ~150 SFM | 0.08 – 0.12 mm/rev (for 12.7 mm hole) |

| Tapping | ~150 SFM | Based on thread depth and diameter |

Admissible Beryllium Chemical and Mechanical Characteristics

Chemical Composition

| Category | Property | Value |

| Chemical Composition | Beryllium (Be) | Balance (~97-99%) |

| Aluminum (Al) | ~0.5% | |

| Silicon (Si) | ~0.06% | |

| Iron (Fe) | ~0.15% | |

| Copper (Cu) | ~0.25% | |

| Chromium (Cr) | ~0.20% | |

| Zinc (Zn) | ≤0.10% | |

| Titanium (Ti) | ≤0.15% | |

| Manganese (Mn) | ≤0.15% | |

| Other Elements | ≤0.05% each, ≤0.15% total |

Mechanical Properties

| Category | Property | Value |

| Mechanical Properties | Tensile Strength | 400 – 500 MPa (T6 temper) |

| Yield Strength | 300 MPa (T6 temper) | |

| Elongation | 5% (in 50mm) | |

| Hardness | 110 HB (Brinell) | |

| Density | 1.85 g/cm³ | |

| Thermal Conductivity | 200 W/m·K at 25°C |

Grades of Beryllium and Beryllium Alloys

High-Purity Beryllium (>99% Be)

When the maximum performance is required, you use high-purity beryllium. It provides high stiffness and very good thermal conductivity. You obtain components of high strength and low thermal expansion. The grade is suitable to aerospace optics, nuclear systems, and precision instruments.

S-200F

S-200F is the commercial grade material that you use in applications that require high strength and a good conductivity. It is nearly pure beryllium (98.5%) but has very little impurities. You enjoy confident optical and structural performance. The grade is economical in most aerospace and defense applications.

S-65 (HIPed Beryllium)

You use S-65 when you require superior density and uniformity. It is hot isostatically pressed to minimize internal defects. You are able to obtain enhanced fatigue resistance and high purity. This grade is suitable when it comes to satellite mirrors and nuclear parts.

(Vacuum Hot-Pressed)

I-220H is selected by you because of its high strength and fine grain structure. The microstructure is uniform by vacuum hot-pressing. You get an improved machinability over the less refined grades. The grade is applicable to missile guidance systems and precision optics.

PF-60 (Powder-Formed)

You choose PF-60 due to uniform properties and isotropic behavior. Powder metallurgy forms uniform performance in any direction. You achieve high purity with good stable dimensional control. This grade performs well in high precision parts and nuclear reactors.

Beryllium-Copper Alloys

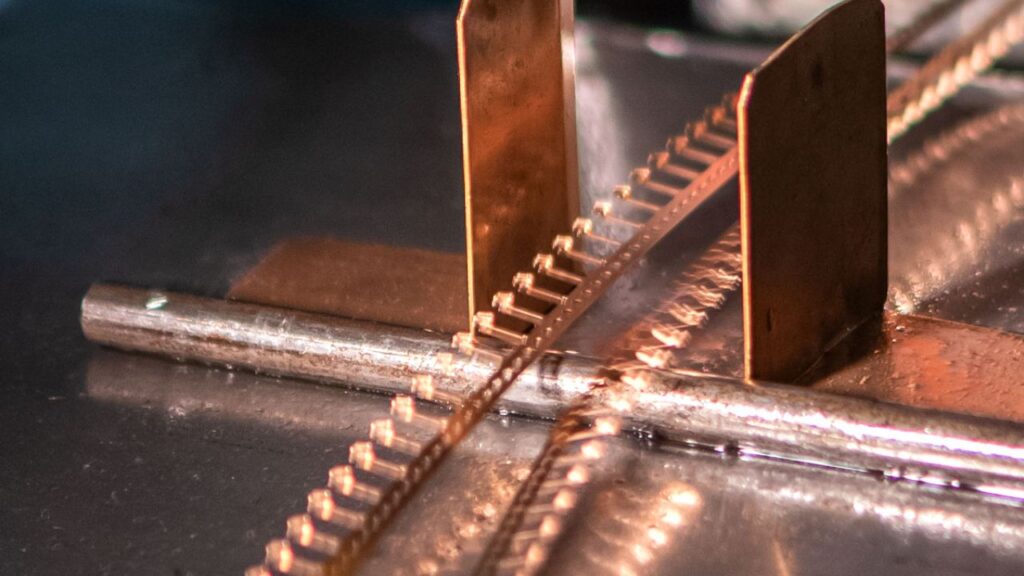

C17200 (Alloy 25)

C17200 is your choice when strength and high durability is important. Having 1.8-2% beryllium and copper balance, it has yield strength up to 1300 MPa. You are able to achieve superior fatigue, wear and corrosion resistance. It is effective in springs, aerospace bushings, and electric connectors. You can machining it with carbide or diamond tools but slow cutting speeds are required to provide precision.

C17300

You employ C17300 when machinability is a priority. Its minor addition of lead enhances chip breaking and tool life. You are maintained at high strength and can machine faster and have tighter tolerances. It fits screws, connectors and high-volume items.

C17500/C17510

You select these alloys because of mediocre strength and increased conductivity. They are able to take thermal loads with 0.5-0.7 percent of beryllium and cobalt or nickel. You have simpler machining, consistent mechanical performance, and predictable thermal efficiency of electrodes, heat sinks and contacts.

Beryllium-Nickel and Beryllium-Aluminum

Beryllium-Nickel

You select beryllium-nickel because it resists high temperature. It is tough in harsh aerospace and defense environments. You are also provided with high levels of corrosion resistance and perform better than many alloys based on copper when it comes to thermal stability.

Beryllium-Aluminum

You employ beryllium-aluminum in the low weight, high stiffness. It is much less dense than steel or copper alloys. You get good thermal stability on satellite and structural components. It is lighter, less brittle, and more machinable than copper alloys and has equally solid performance.

Comparison Table of Beryllium Grades and Alloys

| Grade/Alloy | Composition | Key Characteristics | Mechanical Properties | Machinability | Common Applications | Advantages | Limitations |

| High-Purity Beryllium (>99% Be) | >99% Beryllium | Lightweight, high stiffness, excellent thermal conductivity, X-ray transparency | Young’s modulus: ~287 GPa, Tensile strength: 370–520 MPa, Low ductility | Moderate; brittle, requires diamond/carbide tools, dust control critical | X-ray windows, aerospace mirrors, nuclear reflectors | Superior stiffness-to-weight ratio, thermal stability | High cost, toxicity risks, brittle |

| S-200F | 98.5% Be, <1% BeO | High strength, good thermal conductivity, commercial grade | Tensile strength: ~400 MPa, Elongation: <2% | Moderate; prone to cracking, needs careful handling | Optical components, satellite structures | Cost-effective for pure Be, reliable for optics | Limited ductility, stringent safety protocols |

| S-65 (HIPed) | >99% Be, hot isostatically pressed | Enhanced density, improved uniformity, high purity | Tensile strength: 430–550 MPa, Better fatigue resistance | Good; HIP process reduces defects, still brittle | Aerospace (e.g., James Webb Space Telescope mirrors), nuclear | High purity, excellent dimensional stability | Expensive, requires specialized machining setups |

| I-220H (Vacuum Hot-Pressed) | >98.5% Be, vacuum hot-pressed | High strength, fine grain structure, good thermal properties | Tensile strength: 380–500 MPa, Elongation: ~1–3% | Moderate; fine grains improve machinability slightly | Missile guidance systems, precision optics | Consistent microstructure, high strength | Toxicity, limited elongation, high cost |

| PF-60 (Powder-Formed) | >99% Be, powder metallurgy | Uniform properties, high purity, isotropic behavior | Tensile strength: 400–530 MPa, Elongation: ~2% | Good; isotropic nature aids machining | Nuclear reactors, high-precision components | Isotropic properties, high purity | Complex production, dust hazards |

| C17200 (Beryllium-Copper Alloy 25) | 1.8–2% Be, 0.2–0.6% Co, bal. Cu | High strength, excellent fatigue resistance, good conductivity | Yield strength: 1000–1300 MPa, Electrical conductivity: 22–28% IACS | Excellent; easier to machine than pure Be | Springs, connectors, aerospace bushings | High strength, good corrosion resistance | Moderate conductivity, Be toxicity concerns |

| C17300 (Beryllium-Copper) | 1.8–2% Be, 0.2–0.6% Pb, bal. Cu | High strength, improved machinability due to lead | Yield strength: 1000–1250 MPa, Electrical conductivity: 22–28% IACS | Excellent; lead enhances chip-breaking | Precision screws, connectors, molds | Enhanced machinability, high durability | Lead introduces additional toxicity risks |

| C17500/C17510 (Beryllium-Copper) | 0.5–0.7% Be, 1.8–2.5% Co/Ni, bal. Cu | Moderate strength, high electrical/thermal conductivity | Yield strength: 600–900 MPa, Electrical conductivity: 45–60% IACS | Very good; softer than C17200, easier to machine | Welding electrodes, electrical contacts | High conductivity, good formability | Lower strength than C17200, still toxic |

| Beryllium-Aluminum (e.g., AlBeMet) | 62% Be, 38% Al | Lightweight, high stiffness, moderate strength | Young’s modulus: ~193 GPa, Tensile strength: 290–350 MPa | Good; softer than pure Be, less brittle | Aerospace structures, satellite components | Lightweight, high stiffness-to-weight ratio | Lower strength than pure Be, costly |

| Beryllium-Nickel | 2–2.5% Be, bal. Ni | High temperature resistance, corrosion resistance | Tensile strength: 1200–1500 MPa, Good high-temp performance | Moderate; harder than Be-Cu, requires robust tools | High-temperature aerospace parts, electronic components | Excellent high-temp properties, durable | Difficult to machine, niche applications |

Selection Criteria for Grades

- Application Specific Requirements: You have to choose the beryllium grade that matches your application. To obtain aerospace optical stability and precision, select high-purity S-65. C17200 is suited to electronic connectors or oil and gas components; it is strong but has good conductivity. Grade matching provides maximum performance and life.

- Machinability Issues: You ought to consider grades that match your production process. C17300 is more readily machined with improved chip control and less tool wear. This is time-saving and maintains a high level of quality, particularly in large quantity production with close tolerances.

- Mechanical and Thermal Properties: Analyse working environment. You require high tensile strength, stiffness and good thermal conductivity in space, nuclear or heat sensitive applications. Select grades that are vibration resistant, stress resistant and temperature tolerant to be reliable.

- Purity vs. Cost Trade-Offs: The high-purity beryllium provides the best performance but is costly and must be handled with special care. Alloys offer a compromise between price, machinability, and performance, and so are well suited to cost-restrained projects.

- Health and Safety Regulations: You are required to observe safety regulations per grade. Undiluted beryllium requires the use of both dust control and PPE, whereas alloys are safer to work with. By choosing the right, compliant materials, you minimize risk and regulatory load.

Tooling and Equipment for Beryllium Machining

- Tool Materials: Carbide tools would be a good general-purpose choice in beryllium machining. They are durable and efficient in cutting. When the greatest possible precision is required and the wear is to be kept to a minimum, use PCD tools. These will last longer and deal with the abrasive nature of beryllium.

- Longevity Coatings: You can do the titanium nitride (TiN) or diamond-like coating to minimize friction and prolong tool life. Coated tools enhance wear resistance, heat control and assist in dimensional accuracy. This guarantees finishing with less effort and reducing the costs of replacements.

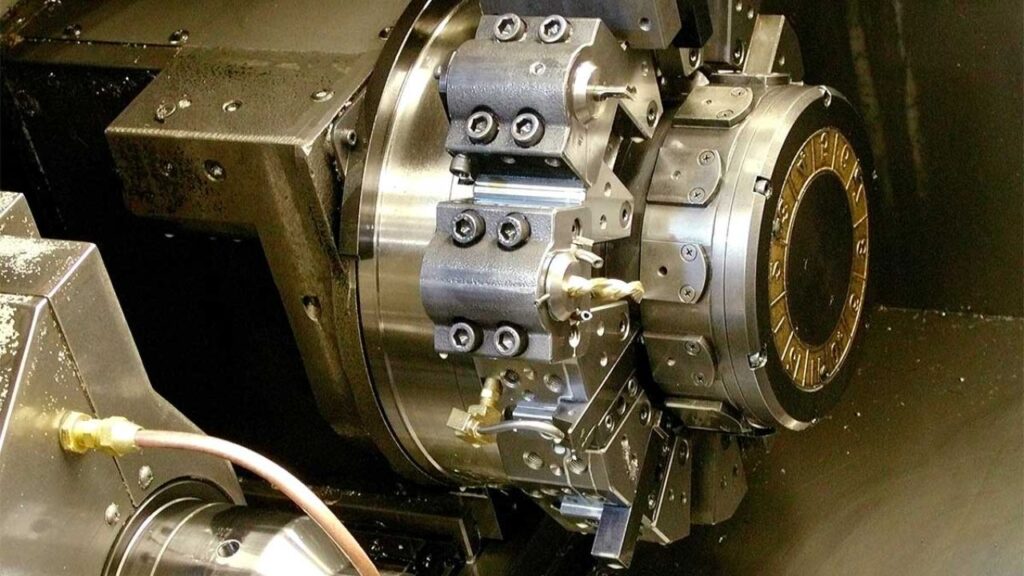

- Accuracy CNC Machinery: You require high-rigidity CNC systems to minimize vibration on brittle beryllium. Multi-axis configurations allow you to form complicated geometries with close tolerances. Frequent calibrations guarantee a consistent and accurate result.

- Coolant and Filtration Systems: In order to manage the heat and preserve the integrity of the surface, you have to employ the flood coolant. Harmful particles are trapped using HEPA filtration. Maintenance of clean systems will avoid contamination and extend tool life.

- Toolpath Optimization: You have access to software that calculates smooth and consistent paths of cutting. Toolpaths that have been optimized minimize cracking, increase tool life, and enable you to vary feeds and speeds according to geometry.

Challenges in Machining Beryllium

- Brittleness -Beryllium tends to crack under adverse cutting conditions. You have to have accurate speeds and feeds. High quality sharp tools minimize tension during machining. Do not be overly forceful as you might end up breaking the material.

- Toxicity:The dust and fumes of beryllium are highly toxic to the body. Chronic beryllium disease may occur by inhalation of particles. At all times, you should employ good dust extraction systems. Using approved respirators and strict safety measures should always be given.

- Expensive – Beryllium is very expensive to acquire and to process. You require special equipment and regulated work environments. This is further coupled with the cost of training skilled operators. Lack of proper planning may easily result in material and financial losses.

Beryllium Machining Methods

Machining beryllium requires you to select techniques that cannot jeopardize precision or safety. These are some of the main machining techniques you ought to think about:

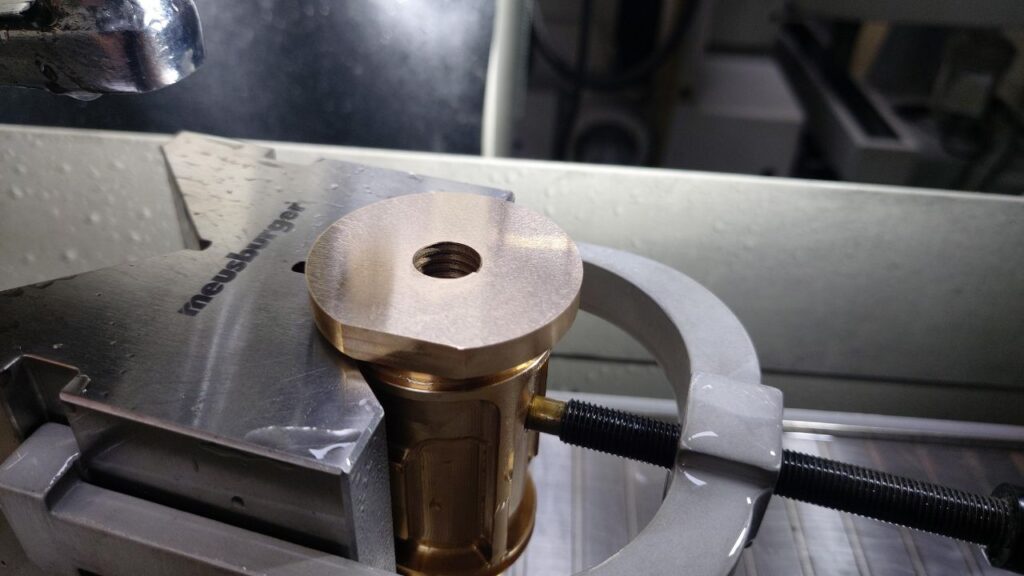

Turning

Achieve maximum precision with single-point diamond tools. Continue to maintain low cutting speeds in order to minimize heat accumulation. This assists in avoiding cracking and damage of material. Turning is effective in making cylinders with close tolerances.

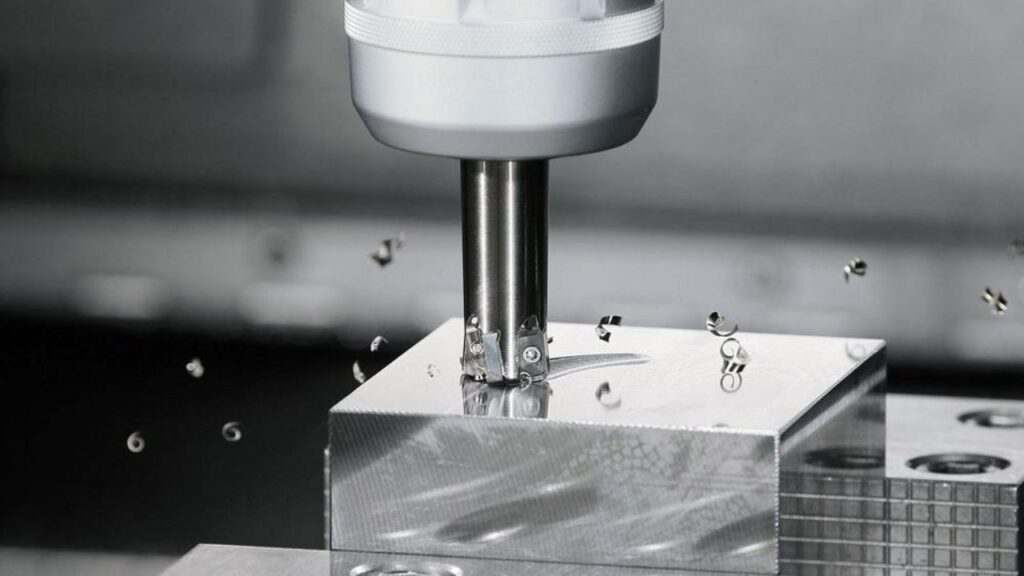

Milling

Use carbide or diamond coated tools to enhance durability and life of the tools. To manage dust and heat, use high-speed milling and coolant. With the correct application of coolants, thermal damage is avoided and the quality of surfaces is enhanced. Milling has the advantage of removing more material with retention of dimensions.

Grinding

Dust control requires wet grinding so that the work environment remains safe. It also enhances the surface finish and minimizes tool wear. Use diamond abrasives when high precision is required and when the material removal rates have to be high. Grinding is suitable in terms of finishing and tight tolerance.

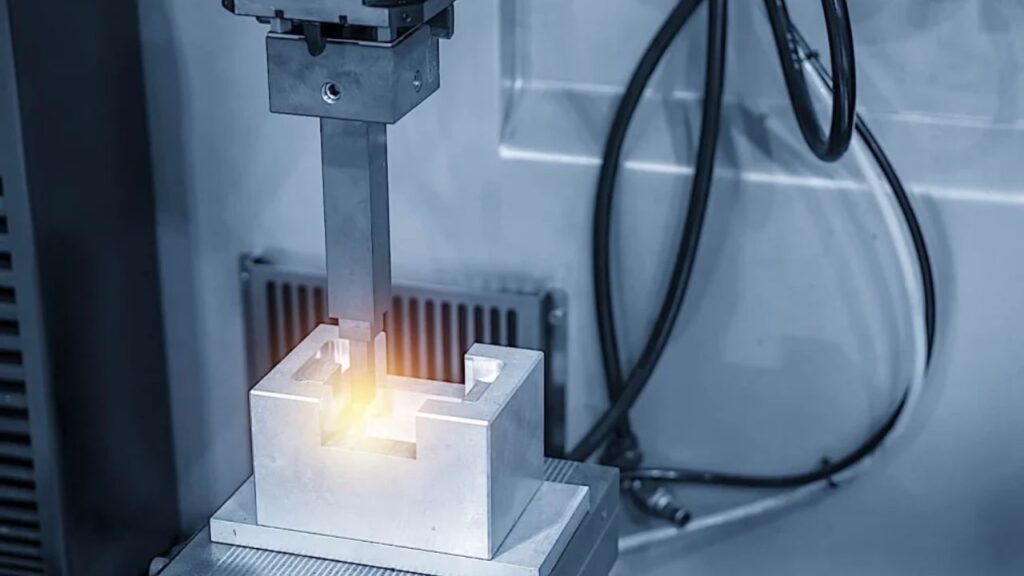

Electrical Discharge Machining (EDM)

EDM is applicable to intricate profiles and features that are difficult to machine. It reduces the mechanical stress, which is important to brittle beryllium alloys. Using EDM, you can effectively machine the alloys of beryllium-copper and still ensure that the dimensions are accurate. There should be good selection of electrodes to give best results.

Laser Cutting

Cut precisely and non-contact by laser cutting. Proper ventilation mechanisms should be installed to control toxic fumes. The laser makes quick and precise cuts, but precautions are needed so that operators are not injured. Thin sections must be low-power and avoided to melt.

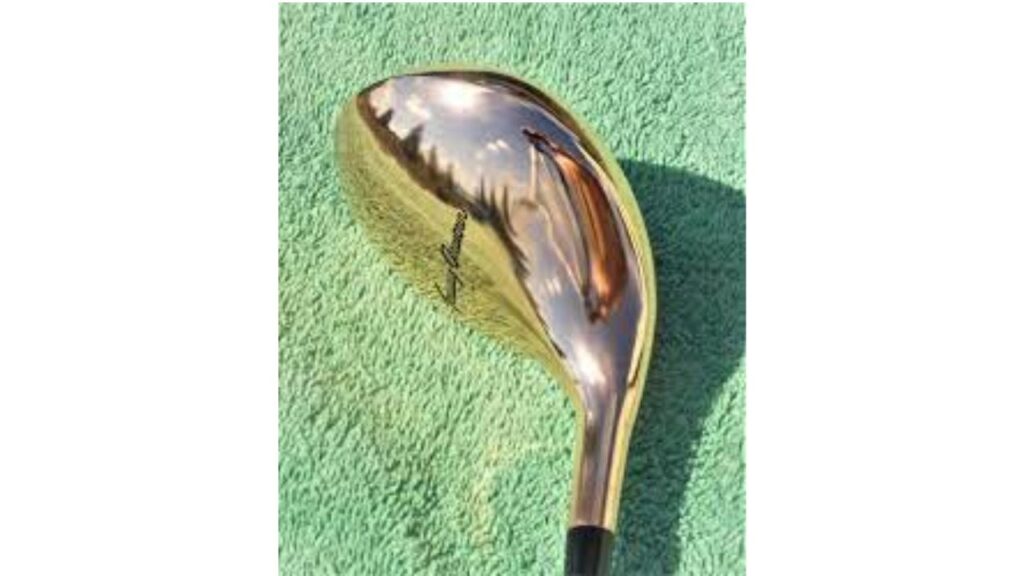

Polishing

Optical-quality surfaces such as telescope mirrors require polishing. To get a smooth reflective finish use cerium oxide or diamond pastes. Polishing improves the unusual reflectivity and dimensional stability of beryllium. Never work quickly so as not to overheat the surface.

Stamping

Stamping can be used to make repeated shapes in thin beryllium sheets. To prevent cracking, you are encouraged to employ sharp dies and controlled pressure. Lubrication also assists in minimizing friction and tool wear. It is optimal in high-volume parts where consistency is an issue.

CNC Mill and Turn

Multi-axis machining can be done accurately on CNC mill and turn machines. The complicated features can be made in a single setup to minimize handling errors. To work with the brittle material, use diamond-coated tools and stable feed rates. The technique is applicable to prototypes and low-volume production.

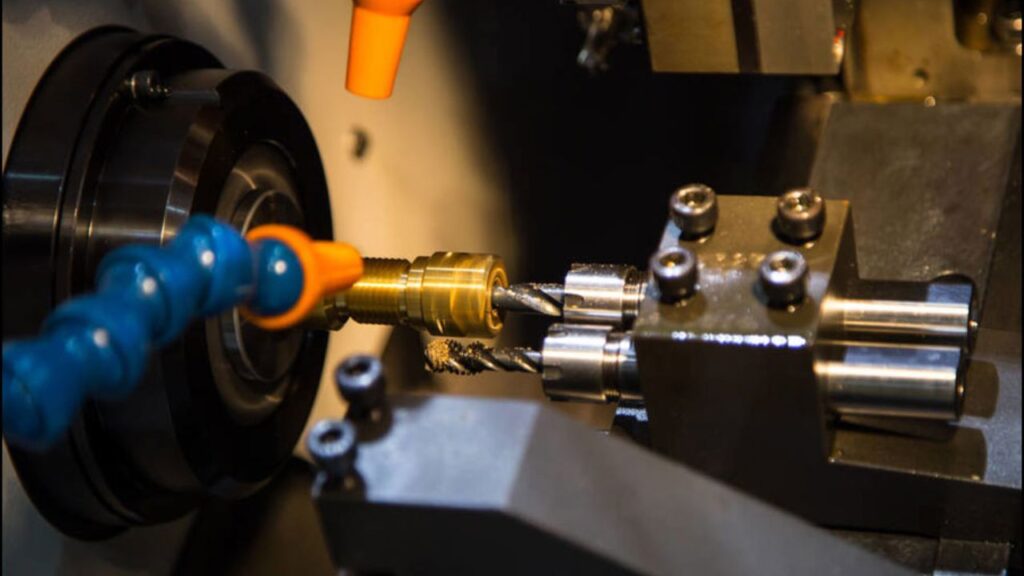

CNC Swiss Machining

CNC Swiss machining is a very precise process of manufacturing small and complex beryllium components. It is important to keep chip removal consistent to avoid heat buildup. Make use of appropriate lubrication to increase tool life. This is an outstanding technique with small parts and close tolerances.

Automatic Lathe Machining

Repeat cylindrical work is well suited to automatic lathes. It is possible to manufacture high-volume components of beryllium of consistent quality. Monitor wear on tools and coolant to alleviate the heat stress. The technique is used to produce very quickly and accurately with minimal human error.

Applications Driving Demand

Aerospace

You select beryllium in the aerospace industry because of its superior strength-to-weight ratio. It also allows you to create lighter frames without compromising strength. The dimensional stability guarantees accuracy in launch and orbit. Thermal stability makes its components dependable in extreme temperatures.

Defense

The hardness of Beryllium facilitates very precise missile guidance systems. Its low weight is of help to you in making portable radar units. It is not easily deformed under high acceleration and shock. Light armor is made durable without being bulky.

Medical

The reason why you use beryllium as X-ray windows is due to its ability to absorb little X-rays. This enhances image quality with less dosage needs. It is non-magnetic in nature which is beneficial to MRI systems. It is also corrosion resistant in sterilized conditions.

Nuclear

Beryllium is an efficient reflector of neutrons, thus useful in reactor cores. In research and power reactors, you achieve superior neutron economy. It resists radiation damage in long time. Assemblies with low density provide less structural stress.

Electronics

You choose beryllium in connectors since it offers conductivity and mechanical strength. It deforms with high current. Being a heat sink, it dissipates heat quickly and does not destroy delicate circuits. Its low expansion supports contact integrity.

Safety Considerations in Beryllium Machining

Chronic Health Risks

When you work with beryllium, you are in grave danger. Chronic Beryllium Disease (CBD) induces lung inflammation, scarring, and coughing and shortness of breath. Acute poisoning with chest pain, difficulty breathing, and fever may develop when one is exposed to high levels. Beryllium belongs to Group 1 carcinogens, therefore, you have to adhere to strict safety precautions. An awareness, prevention, and careful handling safeguard your health.

Regulatory Standards

You have to follow OSHA, NIOSH and EPA requirements. OSHA sets the limit of exposure to 0.2 micrograms per cubic meter within 8 hours. NIOSH suggests medical surveillance and air monitoring. Beryllium wastes must be disposed cautiously by the EPA to avoid contamination. The observance of these rules will keep you safe and will allow you to stay within the rules.

Ventilation and Containment

Airborne dust should be captured by using HEPA filtration. Machining systems are enclosed and sealed tools to a minimum. Controlled ventilation and confinement ensure a hygienic and safe working environment to you and your crew.

Personal Protective Equipment

You should use N95 or above respirators, gloves, and protective suits. Well-fitting and well-maintained PPE will keep hazardous particles out of contact with skin and out of the lungs. You remain safe when you wear the proper gear regularly.

Observation and Coaching

You require routine air sampling and surface wipe tests as well as BeLPT medical screening. Safe handling is reinforced through continuous upkeep of the workers. You mitigate the exposure risk and have a safe, compliant working environment.

Beryllium Machining Costs

- Expensive Material: You have to deal with high costs since beryllium is an expensive material, and it is also difficult to extract. The extraction of minerals such as beryl and bertrandite is restricted and the processing to purify them by chemical or electrolysis processes is complicated. Such aspects render it more expensive than ordinary metals.

- Special Tooling: You cannot use normal tooling because of the hardness and brittleness of beryllium. Common tools are to wear out soon. Tooling is the key to efficiency, as it makes the tools precise and it also minimizes replacements.

- Safety Costs: Beryllium dust is dangerous. You require HEPA filters, confined systems and protective clothing. Observing rigorous safety precautions safeguards the workers and complies with the regulations.

- Labor-Intensive: You need trained operators in safe handling. Tight procedures and oversights add labor costs, but experience guarantees quality and safety.

- Waste Handling: Beryllium waste is poisonous. Special disposal processes must be adhered to in order to prevent contamination and fines, increasing the total expenses.

- Cost Drivers: You manage the trade off between accuracy, small volumes, and performance needs. Being aware of these drivers, one is able to plan projects and budgets efficiently.

Conclusion

Beryllium machining provides great strength, low weight and high thermal stability of precise parts. You obtain materials that are lightweight and long-lasting to use in aerospace and electronics. Nevertheless, you should observe stringent safety measures since beryllium is toxic and brittle. Compliance and appropriate equipment helps to keep workers safe and quality. With the development of technology, beryllium machining will be important in the high-tech industries. You can depend on its distinctive characteristics to spur innovation and satisfy high performance requirements.