CNC Fixture Selection: A Step-by-Step Guide for Manufacturers

The thing which raises issues for manufacturers are unstable work pieces during cnc machining. It eventually leads you to face lower efficiency in operations, delayed productions and higher expenses. You cannot contribute to repeatability or accuracy in operations without the right CNC fixture.

The aim of this article is to guide you through various kinds of CNC fixtures, their usage, and design considerations. You will also unveil insights on the selection process of CNC fixtures. In the end you will be able to get benefit from higher productivity lower costs, standards compliance operations. Sounds exciting? Keep reading to uncover facts!

Understanding CNC Fixture

Table of Contents

ToggleIt is nothing but a fixture which you can use in CNC machining operations. CNC fixture holds, position, or stabilize work pieces in different operations at hand. These operations includes turning, milling, drilling, etc. The CNC fixture keeps the workpiece stationary and secure against the moving tool. You can buy or order these fixture as per your preferences to accomplish specific custom tasks.

Major Characteristics of CNC Fixtures

- The CNC fixture make sure solid clamping of the workpieces, it prevent the workpieces from moving or vibrations

- With CNC fixtures you can contribute to extremely tight tolerances by maintaining the correct positioning of the workpiece through entire process

- These fixture are completely able to withstand the higher stress because of composition of aluminum or steel

- You can use one fixture for broad range of workpieces, shapes, sizes, etc.

- The CNC fixtures are repeatable, it means you can conduct multiple production cycles using a single fixture

Importance of CNC Fixtures in Machining

There are multiple factors which indicates the importance of the CNC fixtures such as:

- They contribute to high end precision and accuracy by preventing the workpiece from misalignment. Hence contributing to smooth finishing

- You can expect a boost in production efficiency through elimination of the frequent or time consuming alignment and setup of the fixtures

- CNC fixtures keeps workpieces stable, without these fixture you cannot expect even, fine, uniform, and accurate end results

- Incorporating auto compatible fixture prevent you from periodic manual alignment. It eventually reduces human error

- You can improve or double up security of the workplace and eliminates chances of accidents by emmploying CNC fixtures.

Applications of CNC Fixtures

The applications of the CNC fixtures are not confined. You can apply these fixtures to broad range of operations including:

- You can use these fixtures in CNC milling where they stabilize workpieces during complicated shaping and cutting process

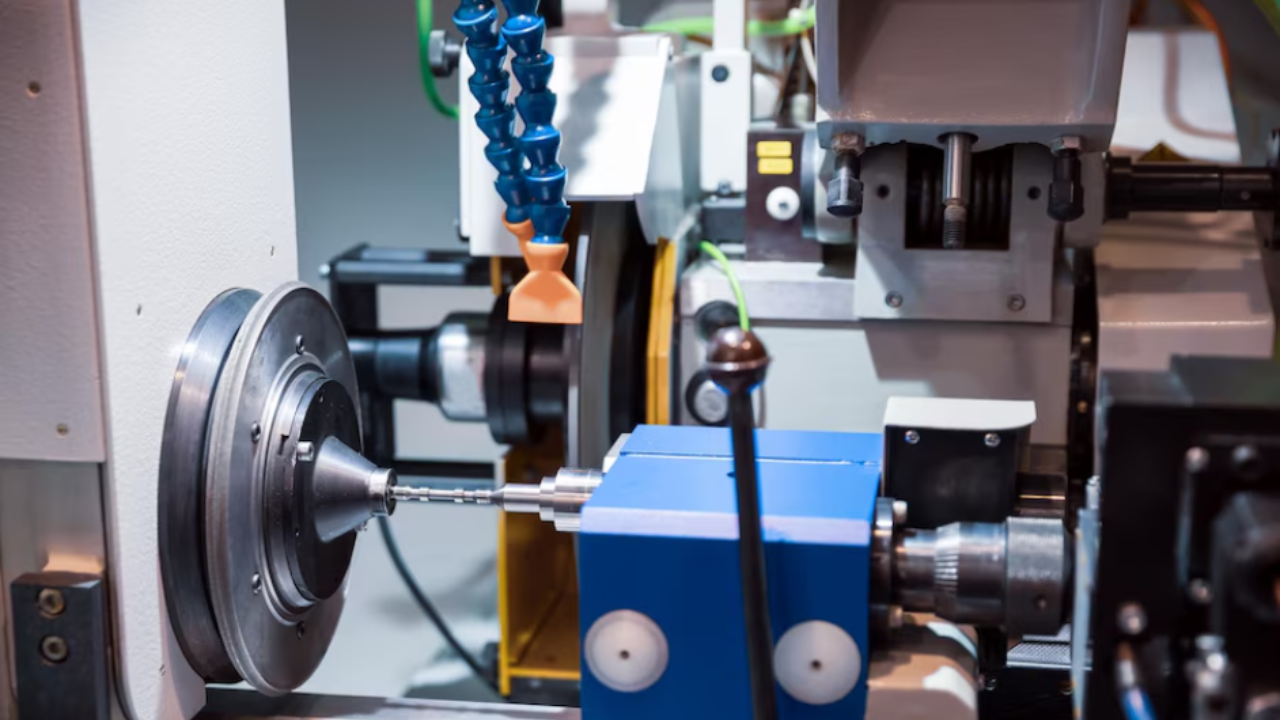

- In CNC turning you can clamp out cylindrical workpieces for smoother internal as well as external rotations

- CNC grinding makes use of fixtures to ensure accurate surface finishing and tight tolerances

- The CNC fixture role in CNC drilling is undeniable. It maintains workpiece steadiness, hence contributing to accurate drilling. This also prevent tool deflection.

- In CNC boring operations the CNC fixture maintain the exact and accurate positioning of the workpiece for deeper and precise bores.

Types of CNC Fixtures

Based on CNC Machining Operations

Multiple fixture types exist depending on the machining operations. Some of the key types for your consideration are:

Milling Fixtures

The milling fixtures are those fixtures which hold workpiece securely as the tool cuts. Main types are:

- Rotary Tables – Enable precise rotation for multi-axis machining.

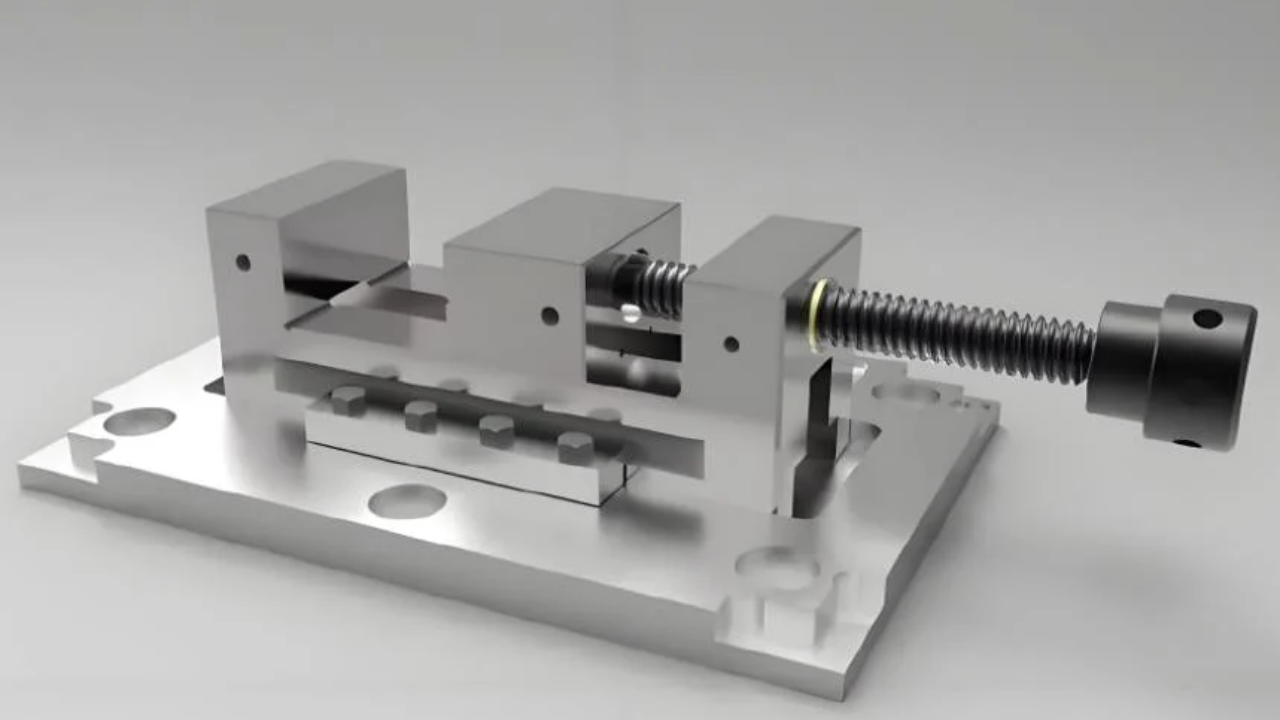

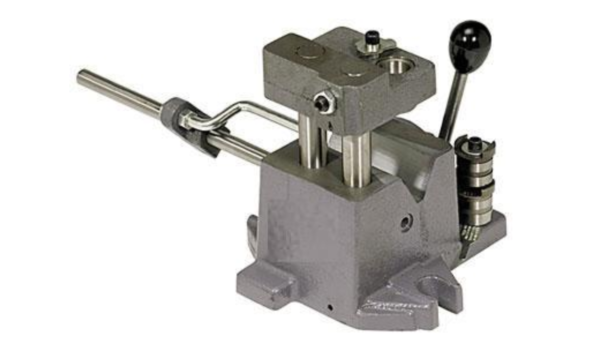

- Vise Fixtures – You can use it for basic milling, it ensures optimum firmnessHold

- Fixture Plates – Features a flat surface to mount your workpieces

- T-slot Fixtures – This fixture features t-slots for firm clamping and added flexibility

Turning Fixtures

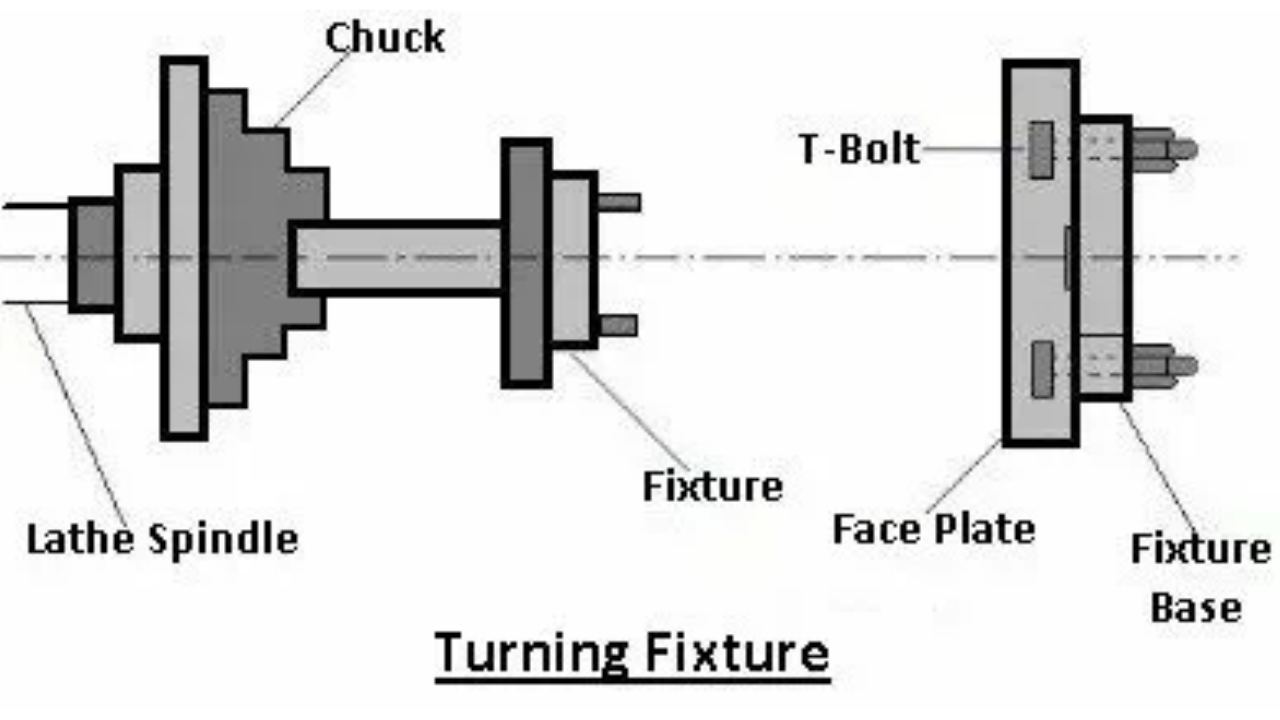

Turning fixtures stabilize parts while rotating in a lathe. Popular types are:

- Faceplates – Attach irregularly shaped workpieces for turning.

- Collet Fixtures – Harness unmatchable precision through tight gripping using collets.

- Chuck Fixtures – Use chucks with jaws to clamp cylindrical objects securely.

Grinding Fixtures

Grinding fixtures ensure accuracy and stability during precision grinding. Examples include:

- Centerless Fixtures – It supports workpiece without holding it from center

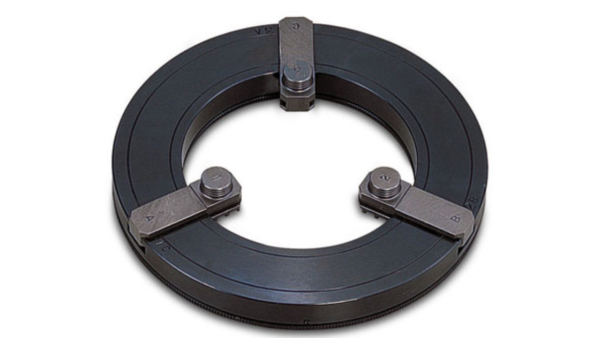

- Magnetic Chuck Fixtures – Make use of magnetic forces to keep ferrous workpieces in place

- Sine Bar Fixtures – You can precisely deal with angular adjustments during grinding

Drilling Fixtures

Key notable types for the drilling fixtures are:

- Drill Jigs – Position and guide drill bits for consistent hole placement.

- Radial Drill Fixtures – Holds workpieces featuring larger holes and sizes statically

- Multi-Spindle Drill Fixtures – Using this fixture you can create multiple holes in one piece simultaneously

Boring Fixtures

Using the boring fixture you can bore with any workpiece at hand:

- Boring Bars – These bars facilitates precise centering of workpieces for deep boring

- Boring Heads – Adjust tool position to create accurate hole sizes.

Based on Uses:

There are muliple types of the fixture when it comes to the applications. The key ones are:

- CNC Vise Fixtures: The vise fixtures contribute to higher clamping force and fine level positioning. For the projects requiring tight tolerances you need to use these fixtures. With these fixtures you can expect repeatability and fulfill larger production cycles.

- Angle Fixtures: When you need to secure the workpiece at an angle against the tool then the angle fixtures play a key role. You can achieve seamless anglura cuts or machining with greater ease.

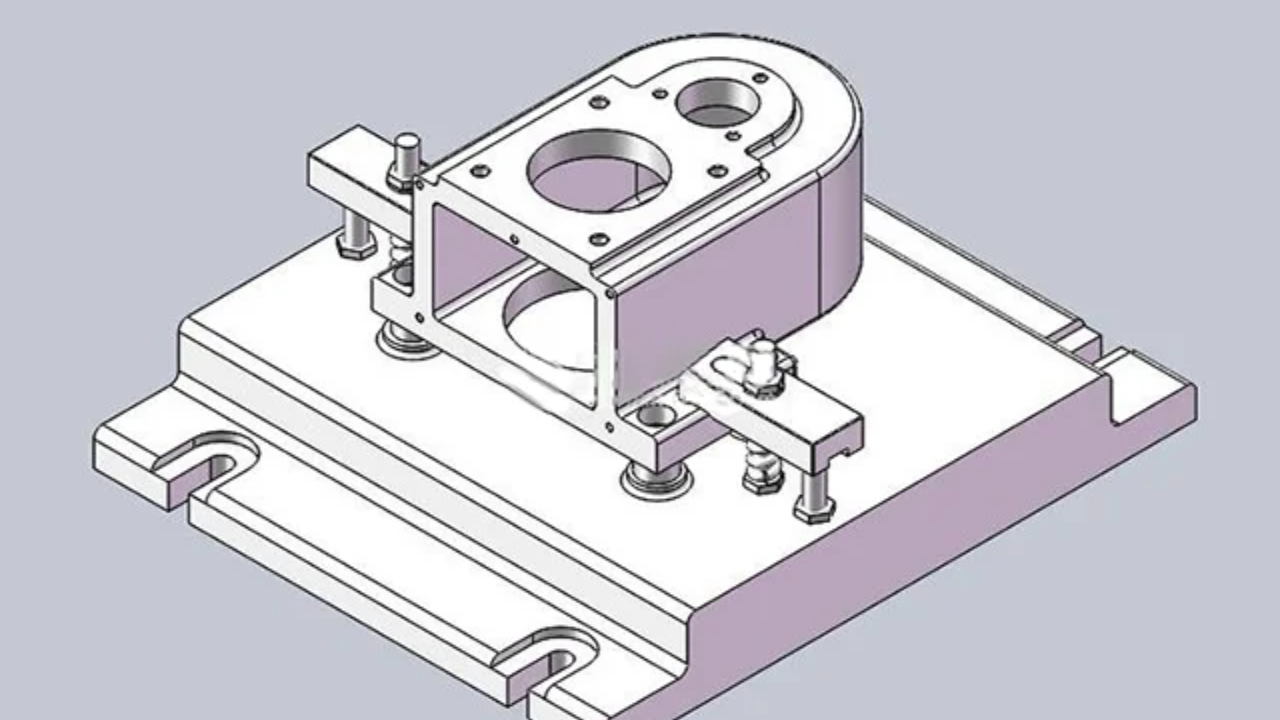

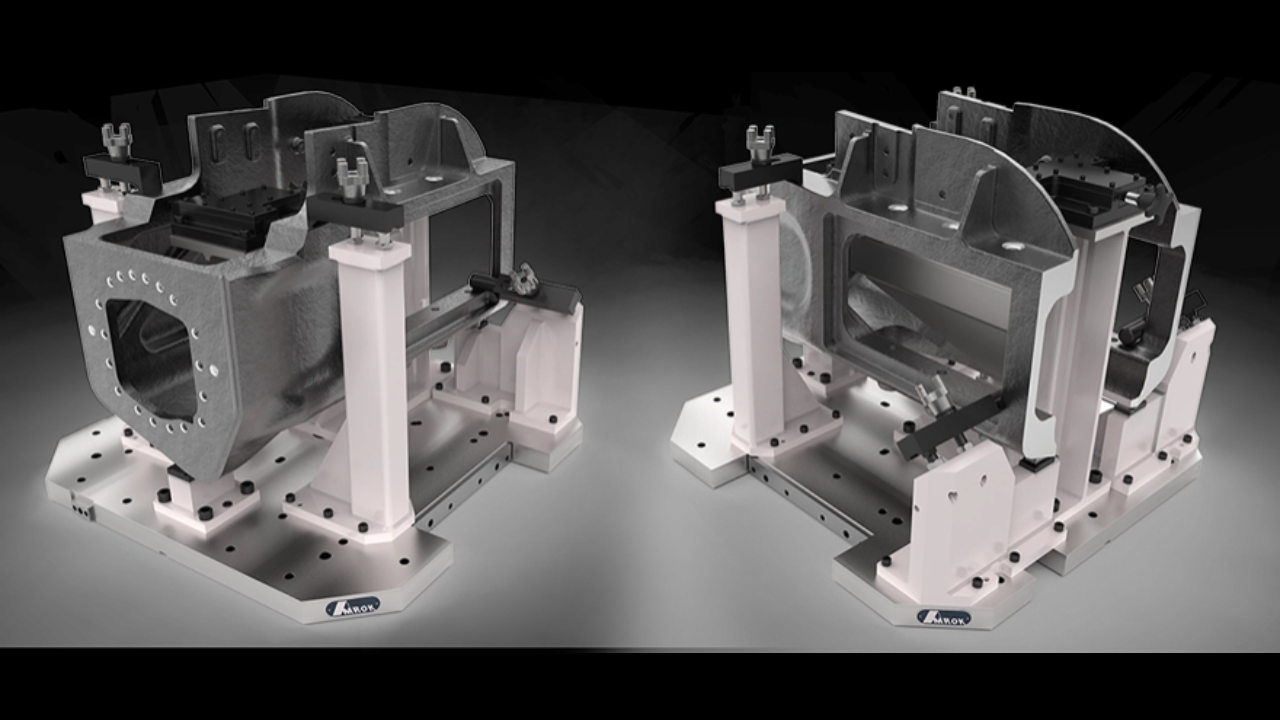

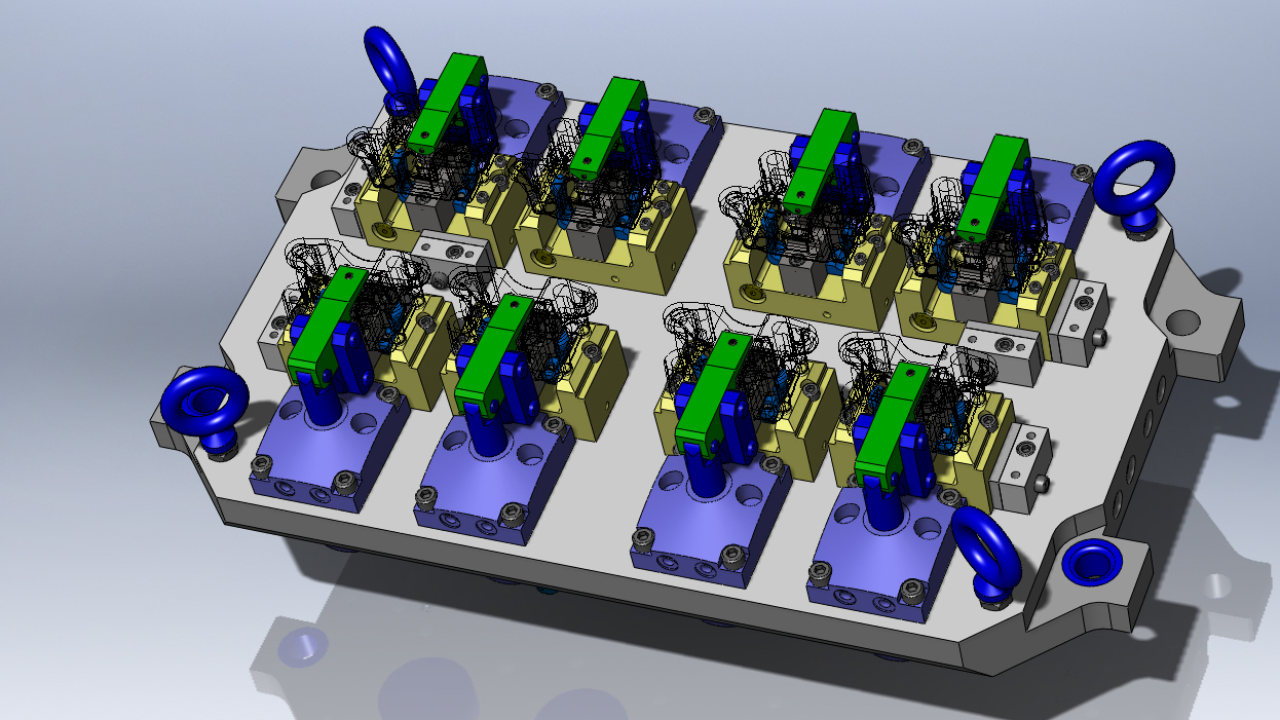

- Modular Fixtures: With these fixtures, you can configure it to align with several application requirements. There are no hard rules to follow regarding the placement, size, and shape of your components—these can all be tweaked. This will eventually lend you versatility with respect to the efficiency of the products.

- Jig Fixtures: Jigs fixtures are used to guide CNC drilling operations. They are able to regulate the movement of the cutting tool to ensure the accuracy and decrease the errors in the drilling processes.

- Clamp Fixtures: In these fixtures, mechanical clamping by screws or springs is generally used to hold parts in place during machining. They are very easy to set up and are commonly used to secure smaller or lighter workpieces at lower cost.

- Universal Fixtures: The universal fixtures are adjustable to be used for various different work pieces sizes. These fixtures are machinable and used where there are multiple part types or the production has to run like a series of parts with slight variation.

Based on Power Source:

Focusing on the source of power, project needs, and level of precision needed, there are options to choose various fixture types including:

Manual Fixtures

As the name suggests these fixture features manual setup. Using the screws, bolts, you can set them in place. They are not goof for higher volume production and demnds sufficient time for setup.

Electrical Fixtures

Using these fixturesa you incorporate automation in your operations. They set themselves auotmatically and with high end precision. For complex and technical operations these fixtures are the ideal solution.

Pneumatic Fixtures

The workpiece is locked up in place using compressing air, and these fixtures are used. At this fixture the air activates the clmaps. They have high speed, precision, accuracy and automation. With this fixture, you can produce higher volume.

Magnetic Fixtures

Magnetic fixtures can use magnetic force to ‘clamp’ metal workpieces. They are very efficient and easy to set up. Particularly well suited to flat ferrous materials, magnetic fixtures offer consistent hold power and reduce setup error.

Hydraulic Fixtures

For these fixtures, the workpiece is secured using clamps under pressure from hydraulics. As they have good holding force with little setup time, they are excellent fixtures for heavy duty applications. Used commonly in industries that require high precision and power.

Vacuum Fixtures

Suction secures nonferrous or delicate workpieces in vacuum fixtures. These tongues are gentle on materials, and apply a uniform clamping force. They are used widely in industries that require delicate handling, such as electronics or aerospace.

CNC Fixture Design Considerations

Define Design Requirements

What’s required for your design is the first step. Think about precision, production goals and cost. Make sure that your fixture is capable of meeting the required tolerance and functionality at a reasonable cost.

Gather CNC Shop Information

Learn about the basic information of the CNC shop. Understand the type of machine, material and actual machining sequence. This will allow you to bring whatever equipment you can work with once you get this fixture.

Create Draft Designs

Scrub fixture design options. It allows you to experiment with other options. Break down the design in factors like the ease of use, material compatibility, and fixture time setup.

Choose the Right Design

Therefore, look at each option and decide if there are advantages or disadvantages. Keep in mind: minimum cost of production, speed, and accuracy in production. Look for design that fits your production requirements and budget.

Optimize and Implement

Once you have nailed down the design, you have to optimize it for production. Fine tune details until everything fits together perfectly. Design, implement the design, minimize costs and production requirements, so as to implement and have success.

Advantages of CNC Fixtures

Improved Machining Accuracy

This allows for the workpiece to be kept securely in CNC fixtures and moved during machining without movement. It guarantees precision cuts for results that will be accurate as may be. This tighter tolerance results in more stable positioning and is responsible for producing high quality parts.

Reduced Production Time

Fixtures help greatly with setup, as they decrease machine loading and unloading times. If you’re running machines more efficiently then less time is required to produce the whole unit.

Enhanced Workpiece Stability

By holding the workpiece firmly and preventing vibration and movement, this fixture doubles as a clamp. The result is finished products with consistent machining results.

Versatility and Customization

CNC fixtures can be modified for specific parts and designs. You can create fixtures if you want them of a custom shape and size so that the fixtures of each project are always different.

Cost-Effective Manufacturing

CNC fixture eliminates errors as well as parts that require rework, and reduces material costs. They also reduce machine downtime, maximize productivity, and are cost effective for high volume production.

CNC Fixture Design Challenges

While designing CNC fixtures, there will always be challenges. Nevertheless, these fixtures are quite critical in holding and positioning workpieces during machining and thus must be carefully planned and effectively executed.

Complex Design Requirements

Precision and functionality requirements are inherent in CNC fixtures with complex design requirements. However, factors such as work piece geometry, specie of material to be machined and method of machining must be taken into account. These needs should also be accommodated in fixture design to minimize errors during production. Usually this is a big fight to see how much rigidity and how much flexibility it should be.

Material Selection

One challenge in selecting a material to use with CNC fixtures is the choice of material. Find out what material you will pick, and make sure that it is durable, that it provides such a great wear and tear resistance, and that it can withstand stress. This can be steel, aluminum, or even specialized composites. Each material has its advantages and limitations, depending on the application.

Manufacturing Tolerances

CNC fixtures must take into account the manufacturing tolerances. For small deviations, errors can occur even during machining. To allow for high precision operations, the fixture itself must be manufactured to extremely tight tolerances. It requires advanced quality control and advanced machining.

High Initial Cost

Custom designed CNC fixtures can be expensive. Developing fixtures can take a lot of time and resources. However, the investment later proves worthwhile.

CNC Fixture Maintenance Tips

Maintenance of CNC fixtures can help ensure longevity and extensive use. Machining care can prevent downtime and improve machining accuracy.

Regular Inspection

Regularly inspect your CNC fixtures so you can catch signs of wear or damage early. Check for deformations, cracks or wear on key components, such as clamping elements. This prevents costly repairs and makes sure your fixture always performs at its best.

Cleaning and Lubrication

CNC fixtures need to be cleaned and lubed to last a long time. Dust, metal shavings can also harm the performance of the fixture. Regularly clean the fixture to prevent build up and use the appropriate lubricant to minimize friction and wear on moving parts.

Key is Timely Repairs and Replacements.

Timely maintenance and repairs of worn out fixtures should be employed by you. Remove the components that have zero level functionality and replace with components. This may disrupt the machining process otherwise. Eventually, it will help you keep your fixture in a better operational condition.

Storage Best Practices

When not in use, store your CNC fixtures out of the way and away from damage. Store them in a dedicated area to storage and with minimal environmental exposure to aspects of humidity and temperature fluctuations. This also helps your fixtures last longer and stay in top form.

Custom CNC Fixtures: When to Use Them

Standard fixtures might not satisfy your needs in your machine process sometimes. In situations like these, custom CNC fixtures might be the answer.

Standard Fixtures Are Insufficient.

Standard fixtures are often specified for common applications. However, for complex parts they may not offer the precision or flexibility needed. If you often work with custom or irregularly shaped workpieces, custom fixtures can improve your accuracy and they can help reduce setup time.

Irregular and Complex Workpieces

There are workpieces with unique geometry and complex features requiring their own custom fixtures. They provide the much needed stability and support to allow for efficient and accurate machining operations.

High Precision Machining.

When the machining depends on high precision, custom fixtures are the best choice. They can be made with tight tolerances and low errors so that every part will fit the needed specs.

Prototype / Low Volume Production

For prototype and low volume production runs, custom CNC fixtures are generally used. They are designed to produce high quality products without the need for mass production equiptments yet meet the needs of small batches.

Case Study Example: CNC fixture application

A Company who was producing high precision aerospace components encountered problems using standard CNC fixtures. However, due to the complexity and irregular shape of the workpieces, it was difficult to reach the necessary precision. For their part, the company implemented custom CNC fixtures to tackle these challenges.

A description of a Real World Application.

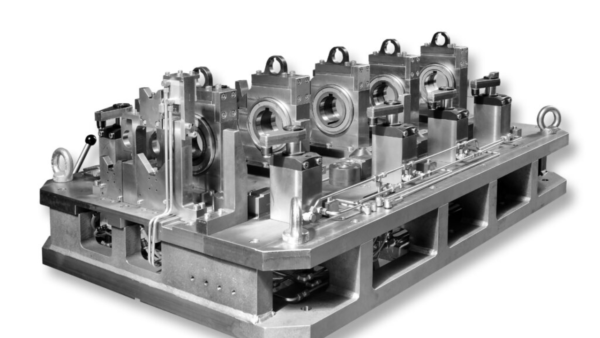

The company designed and built custom fixtures for the purpose to securely hold the aerospace components while machining. The fixtures had been made from high strength steel, with precise clamping means to prevent any movement during machining.

Challenges and Solutions Implemented

The complexity of the component was one of the most difficult things to machine. More than one staging was required. For each stage of the machining process, the custom fixture was designed with adjustable clamping features to allow component repositioning. It increased flexibility by reducing setup times and increasing accuracy.

Results Achieved

The company therefore notes that they experienced big improvements in the efficiency of production processes and product quality. The custom fixtures allowed for tight tolerances with lower setup time, contributing to a competitive edge in the marketplace.

Future Trends in CNC Fixtures

Technoloigical advancements are what driving the future of the CNC fixtures. Some of these are:

Smart and Automated Fixtures

The incorporation of the sensors as well as feedback systems offers you with real time insights on the performance of the fixture as well as positioning of the workpiece. With this you can achieve high end performance and quicker adjustements.

CNC Machine Sensors Integration

With these fixtures you can keep an eye on the process of machining. Using these sensors you can boost performance, enable the operators to make informed choices and harness incredible accuracy levels.

Fixture AI Design

Using AI technology in fixture designing eliminate the chances of errors and offer you with what exactly you need. It assists in optimizing or aligning the parameters of the fixtures, and overall lead you to experience faster production.

Feature Rich Materials Incorporation

By utilising the latest compositions of materials you can harness from the technical features. You can increase strength, durability, and in the end avoid accidents, deviation from desired dimensions, etc. This will help you get fixtures featuring longer service lifes.

Conclusion

Choosing the right CNC fixture is paramount in order to ensure the machining operations success. Before choosing a specific fixture make sure to select the material, know design challenges, maintenance measures, etc. When you are unable to find the standard options fitting right to your application then you can move to design your custom CNC fixture. They are perfect fit for the high end accuracy, lower volume, and latest materials. Please not if you employ in your CNC fixtures the feature loaded materials, auto compatibility, then you can stay ahead in CNC machining era.

FAQs

How would you differentiate a Jig and a CNC fixture?

The role of the CNC fixture as you know is to keep the workpiece secure and static against the tool. While the role of the jig is to guide the tool for accurate positioning.

What types of the CNC fixtures exists?

There are many types including clamps, vises, personalized fixtures etc. to name a few.

How do you choose a CNC fixture?

There are many thing which you need to pay attention to including workpiece shape, size, machining operation you are employing etc. You need to make sure the fixture offer accurate stability, ease, and precision.

Which materials contribute to the best in class CNC fixture?

There are multiple materials including aluminum, steel, and other special compositions. These fixutres can resist wearing and tearing, and offer you with incredible strength.

Can You personalize the CNC fixture?

Yes, anyone can personalize or tweak the composition, desired features of the CNC fixture. Option exist to tweak their shape, form, size, materials, etc.