Invar Machining Explained: Tools, Parameters, Grades and Techniques

The machining of Invar is of vital concern in those industries where even thermal movement that is microscopic can affect precision and performance. Due to the radically different behavior of Invar compared to traditional steels, the machinability, work-hardening behavior, and thermal behavior of Invar need to be understood to prevent expensive mistakes. This article is a full technical reference to Invar machining, defining alloy grades, tooling options, cutting data, CNC methods, and best practices to guide manufacturers in obtaining consistent dimensions, high quality surfaces, and consistent precision outcomes.

Table of Contents

ToggleWhat Is Invar?

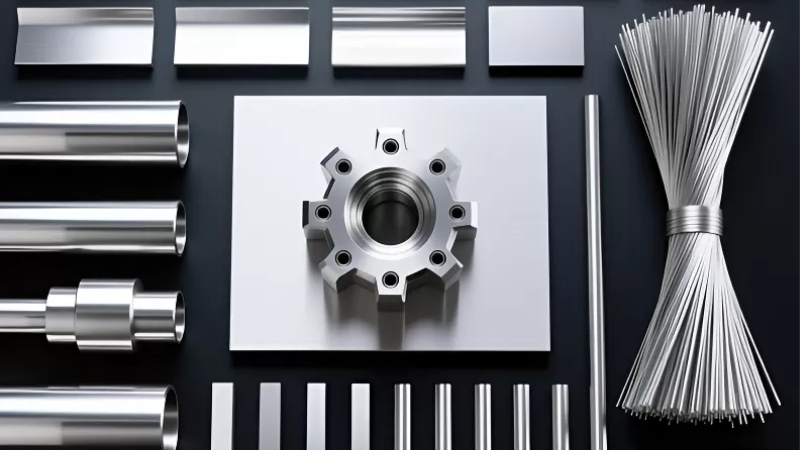

Invar (UNS K93600) is a 36 percent nickel-iron alloy that is distinguished by its special characteristics. It is characterized by a very low coefficient of thermal expansion (CTE 1.2 ppm/° C ), so it hardly contracts or expands with changes in temperature. Invar can be trusted when it comes to applications that demand superior dimensional stability. This thermal stability allows accurate manufacturing in aerospace, electronics, optics, and scientific instruments, where components are accurate with changes in temperature.

Why Invar Is Important for Modern Manufacturing

Invar plays a vital role in modern-day production due to its outstanding stability in temperature. You also use Invar in optical instruments, electronic, aerospace and precision measuring equipment. Its low thermal expansion guarantees uniform performance even in the conditions of variations in temperature. Since industries require greater precision, you gain the trust of Invar in preserving the dimensional integrity. Its industrial significance is emphasized by the growing application of low-expansion materials. When you use Invar you guarantee accuracy, durability and efficiency in high-performance procedures in various industries.

The Challenge and Opportunity in Machining Invar

- Softness and Ductility

Invar is soft and highly ductile, and thus it becomes easy to bend or deform when cutting. Unless it is taken care of, its material structure can result in uneven surface finishes. Tools are to be engaged carefully to ensure dimensional accuracy and eliminate chatter.

- High Tendency to work hardening

Invar hardens rapidly during the mechanical load and makes it harder at the cut. Tools can be sharpened quickly through continuous machining without alteration. You can schedule light passes and change feeds to prevent the build-up of stress and keep the tool life.

- Chip Control Challenges

The alloy contains stringy and gummy chips that have the potential of wrapping the tools or blocking the work zone. This may cause the breakage of tools and surface damage. Optimized tool geometry and controlled feeds can be used to enhance chip evacuation.

- Tooling and Parameter Selection

Combining a tool with its parameters is a tooling process that involves the whole-design of the tool and the channels through which the information is to be transmitted to the instrumenters of the tool.

- Comparison to Austenitic Stainless Steel

Invar machining is often more difficult than machining 304 or 316 stainless steel because it is ductile and hardens its own. You need to use reduced feeds and optimized tool angles to develop similar surface quality.

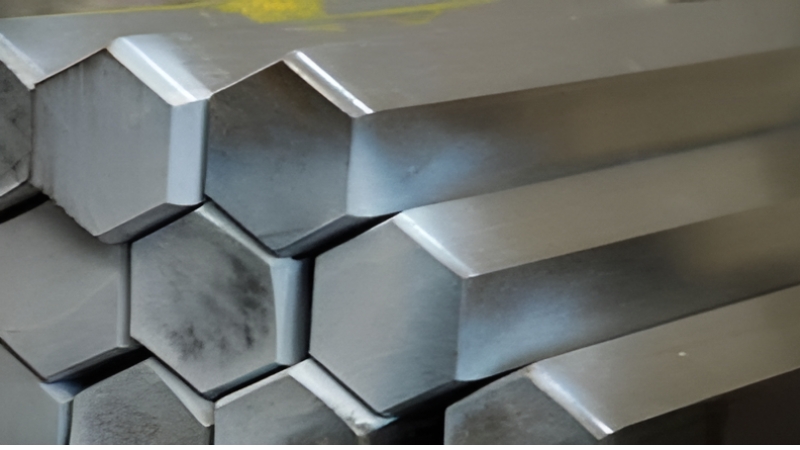

Types of Invar Alloys for Machining

Standard Invar 36

The Standard Invar 36 is a nickel-iron alloy whose composition is about 36 percent nickel content, and the rest is iron. When low thermal expansion is paramount, you depend on it. It has a special composition whereby it maintains its dimensions as temperatures vary. It has extensive applications in satellite components, optical benches, and metrology structures with high precision. By using Invar 36, you get precision, minimized error due to thermal effects and long term reliability in high precision applications.

Free-Cut Invar 36 (UNS K93050, ASTM F1684)

Free-Cut Invar 36 (UNS K93050, ASTM F1684) has been made selenium-based to enhance its machinability. It gives you a better result of removability of the material and a smoother cutting effect that is best suited to high-volume CNC machining. Its moderately larger CTE is insignificant with most applications. There are small trade-offs that you should be aware of such as a small decrease in corrosion resistance and transverse toughness. It is the preference of many manufacturers, as it has the ability to enhance productivity by up to 250 per cent and save costs as well as time without reducing performance.

Composition Comparison Table

Nominal Analyses | |||||||

| C | Mn | Si | Ni | Co | Se | Fe |

Carpenter Invar “36” Alloy | 0.02 | 0.35 | 0.29 | 36 |

|

| bal |

Free-Cut Invar “36” Alloy | 0.05 | 0.9 | 0.35 | 36 | 0.2 | 0.2 | bal |

Super-Invar and Specialty Grades (Brief Overview)

A NiFeCo alloy called super-Invar has ultra-low thermal expansion in precision applications. You use it where the dimensional stability with changes in temperature is a major factor. Such special grades have special properties but cannot be machined very fast because of poor machinability. In dealing with Super-Invar, you will need to pay much attention to accurate cuts and stable configurations in order to keep accuracy and avoid distortion of the material.

Material Properties Affecting Machining Behavior

- Thermal Expansion Coefficient

The high coefficient of Inconel leads to dimensional deviations during heating during machining. You have to consider thermal growth to achieve narrow tolerances. Sudden growth may cause erroneous cuts, and platform variances. Good fixturing and coolants can be used to regulate thermal effects.

- Density

This alloy is on the heavier side that enhances the cutting forces when machining. Feed and speed must be adjusted to increase material loads. Bollocky work pieces demand strong tool gripping and firm machine shank installation. Controlling density is important to obtain dimensional correctness and minimise vibration during cutting.

- Tensile Strength

High tensile strength does not allow deformation but it raises the pressure on a tool. To counter this resistance, you need to choose sharp and hardy tools. Work hardening at the cutting zone is avoided by keeping the feed rates constant. Optimal machining of strong alloys requires cutting techniques to prevent early tool obsolescence.

- Low Thermal Conductivity

Inconel concentrates the heat at the cutting edge leading to rapid wear of the tool. High pressure coolant or emulsion fluids should be used to cool. In temperature monitoring, the tool geometry and surface finish are preserved.

- High Ductility

The alloy is in the form of long, continuous chips that may plug tools or interfere with the cut. It is recommended to control the chips flow using chip breakers or optimized rake angles. Effective evacuation of chips helps in maintaining good machining with no interruption.

- Ferromagnetic Behavior

The magnetic characteristics of Inconel may interfere with a few measuring instruments and machining sensors. You should be aware of magnetic interference to tool placement and tool inspection. Shielding or non-magnetic fixtures are used properly.

Comparing Machinability: Standard vs Free-Cut Invar

In comparison of machinability, Free-Cut Invar forms brittle chips that are easy to break, and this decreases the problem of handling chips. Standard grade Invar is long and stringy coiling chips that require aggressive chip breakers to avoid entanglement. You are required to vary cutting plans, depending on the grade, and use appropriate tooling and feeds. Knowing these variations assists you to keep efficiency, surface quality and tool life under control in machining.

General Machining Guidelines for Invar

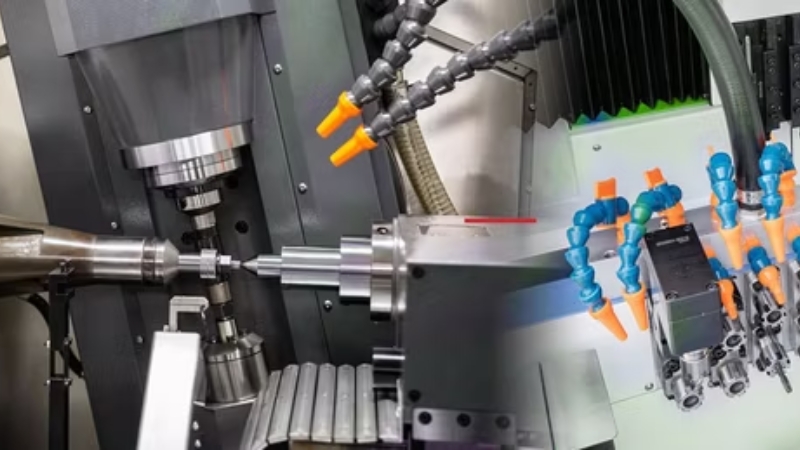

Tooling Requirements

Hard, high-pressure tooling is a necessity in clean cuts and low vibration. High-mass items are heat sinks, minimizing localized heating. Best durability and consistent performance is achieved when using high-speed steel (HSS), carbide, or carbide-tipped tools.

Cutting Fluid Requirements

Smear oils are sulfochlorinated to offer good lubricity in smooth cutting. Emulsifiable fluids are used where machining is secondary to cooling. Ensure that recirculated coolant systems are maintained at high levels of cleanliness to avoid sliver contamination and surface flaws.

Workpiece Handling

Do not write deep marks, which cause localized hardening of work and deformation of the surface. Sharp three-corner punches are used to make accurate and clean markings. Interrupted cuts should be avoided as much as possible to minimize vibration and tool chatter.

Preventing Ordinary Machining Problems

Work hardening and glazing may be experienced when the feed rates are uneven; keep the feed constant and do not rub. The emergence of chatter and chatter marks is the result of tool instability; correct tool geometry and rigid setups. Overheat can cause deformation of the workpiece; apply the appropriate mass of tool and choose fluids to conduct thermal energy away effectively.

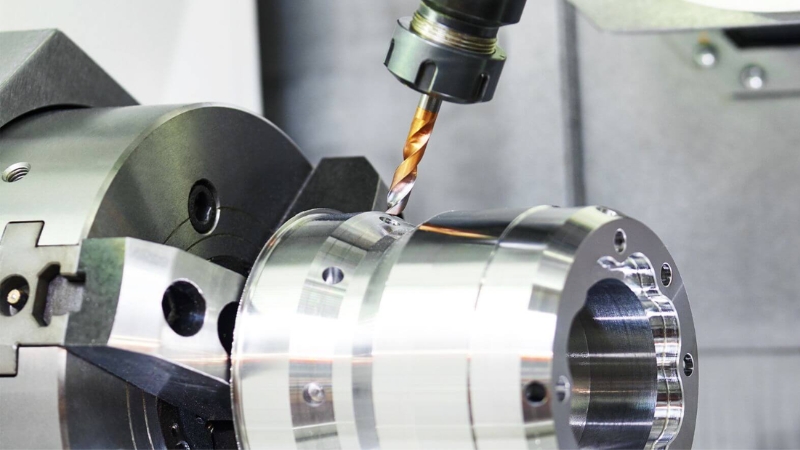

CNC Machining Invar

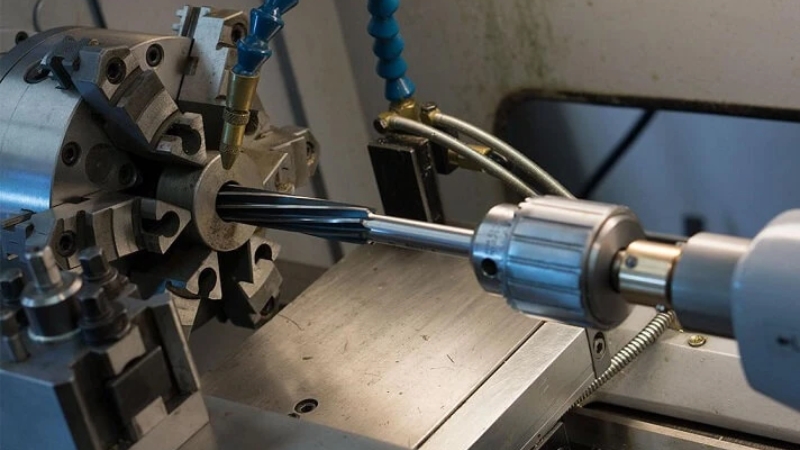

CNC Turning

CNC turning must have a constant feed to provide a smooth surface finish and dimensional accuracy. Feed rates should be carefully monitored, since changes can result in chatter or rough cuts. During turning, there is heat buildup and this influences dimensional stability causing expansion and possible tolerance problems. The choice of the tool material is important: carbide is the best in high rigidity and deep cuts, whereas HSS is applicable in light cuts using flexible setups. You should also have plans on how to handle long chips like chip breakers or effective flow of coolant to avoid entanglement and damage of tools.

CNC Drilling

CNC drilling involves high accuracy, uniform flow of coolant, and rigid workholding to achieve accuracy and eliminate tool deflection. You are expected to pull back the drill regularly depending on its diameter to eject chips and eliminate heat accumulation. It should not be allowed to stay at the drill point because it may lead to glazing and poor surface finish. A chip relief groove enhances the evacuation of chips and minimizes cutting forces, which prolongs the life of the tool. These practices allow you to keep the dimensional accuracy, preserve cutting tool and get efficient and high-quality drilling results.

CNC Tapping

CNC tapping is used to provide accurate threads on a wide range of materials such as work-hardening alloys. Through holes should be used with spiral-point taps, which eject chips in a forward manner. In blind holes, the chips are pushed out of the hole using spiral-flute taps, avoiding clogging and tool breakage. Evacuation of the chip properly is essential to ensure the quality of the thread and prevent the surface damage. In the case of hard, work-hardening alloys, thread integrity is guaranteed by regulating feed, speed, and tool contact. Knowing how to select tap and how to machine, you can get precise and long-lasting threads every time and minimize tool life.

CNC Milling

In CNC milling, you are able to get accurate material removal by choosing the appropriate cutting tools. Helical or spiral cutters have smooth cutting and good chip evacuation, and they are suitable in most milling jobs. In heavy milling, a 45-degree left-hand spiral cutter can be used to assist in lowering cutting forces and also to enhance surface finish. The cutters to be used should be coarse-tooth cutters to remove material quickly and fine-tooth cutters to finish the work in detail. Feed rate, speed, and tool geometry are essential considerations when milling carbide insert to ensure a tool does not wear out and retain the same accuracy.

CNC Broaching

CNC broaching is superior in that it has an embedded stepped geometry, which removes material in one pass. The sequential tooth design allows you to attain accurate shapes and steady sizes. In order to secure a tool and workpiece, cutting fluids such as sulfochlorinated oils that are diluted with paraffin are recommended. Broaching is usually conducted in phases, with roughing taken as the rapid stage where bulk material is removed, semi-finishing as the profiling phase, and finishing as the phase to guarantee finish accuracy and smoothness. These steps assure tool life, get better surface quality, and ensure repeatability in complex machining operations.

CNC Reaming

CNC reaming provides a finish of the holes and correct diameters. Many chip evacuation and low cutting forces You should employ spiral-fluted reamers to a helix of about 7o. Left-hand spiral with a right-hand cut tool is suggested to achieve the maximum of the tool life and finish. It is important to ensure cleanliness of cutting fluids because dirt contamination may lead to tool wear and substandard surfaces. Carbide-tipped reamers may also be a consideration of great hardness, heat resistant and stable functioning during high speed or intensive operations.

EDM Machining of Invar

Invar is best EDM machined when it comes to hard-to-cut profiles or fine exclinations. You will be able to produce the complex shapes that would have been difficult with traditional cutting tools. You can achieve tight tolerances with a high level of accuracy using wire EDM. As EDM does not impose mechanical cutting forces, you do not get work hardening and material deformation. This guarantees both dimensional integrity and surface finish thus EDM is an ideal option in precision Invar parts.

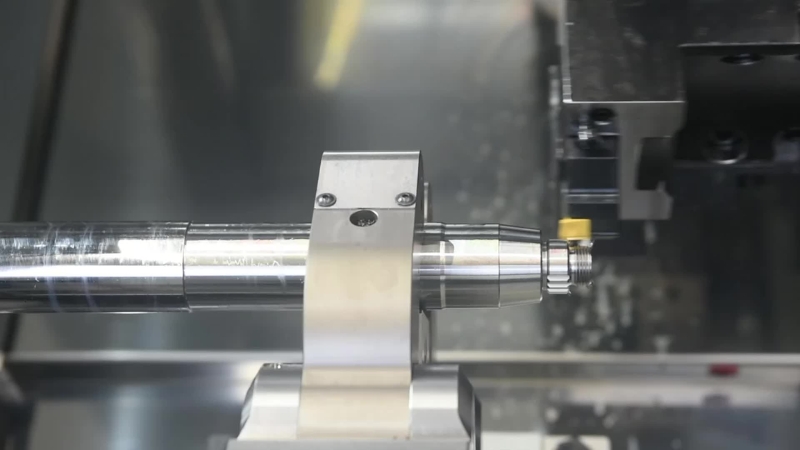

Swiss Machining of Invar

Swiss machine Invar works well in creating room-rods of small diameter. You get the advantage of the guide bushing, which puts the material into place when cutting. Such a method guarantees a close tolerance and uniformity of surface finish. It is especially beneficial to telecom components, optical mounts, and minute aerospace parts where there is a need of precision. The technique reduces both deflection and vibration and enables high-quality and reliable results even on difficult, miniature geometries.

Tool Geometry Recommendations (Critical Section)

Turning Tool Geometry

To turn, keep the top rake angle at 5-10 degrees, higher is better to cut effectively. Secure front clearance of 7 -10o and side clearance to avoid rubbing. Large nose radii and tool holders should be used to minimize vibration and enhance surface finish. The correct geometry will assist you in keeping things straight and protract life of tools.

Cutoff Tool Geometry

Adjust the upper rake to 7 – 10o and front clearance to 7 -10o to enable efficient chip removal. Keep a minimum side clearance of 3o and use circular cut off tools where possible with rigidity. Proper geometry will enable you to minimize deflection and you will have a consistent cut when separating parts.

Form Tool Geometry

Front rake should be 5-10 degrees, relief angle should be 1-5 degrees, depending on depth of forms. Roughing is best done with larger rake angles and finishing is best done with smaller ones. Add corner rounding of deep forms. This geometry assists you in getting good profiles with minimum work hardening and tool wear.

Drill Point Geometry

Choose the suitable point angle, lip relief, and web thickness to drill Inconel. Maintain the drill very sharp so that it does not harden and to have a smooth penetration. Proper geometry enables you to cut with less force and generate a stable dimensional accuracy.

Cutting Parameters (Speeds, Feeds, Depths)

Turning Parameters

Cutting speeds should also be varied depending on alloy and tool material. Engagement is influenced by depth of cut, such as 0.150 in or 0.025 in. High-speed steel and carbide tools react in different ways and cutoff or form tools must have the correct speeds and feeds to ensure accuracy and prevent tool wear when turning.

Drilling Parameters

Due to the hardness differences, you need to learn to use various speeds on each alloy. Alloys with selenium additions have an impact on the penetration of drills and the shape of chips, which necessitates close attention to the speed change. Adequate control will result in smooth holes and will minimize tools wear.

Tapping Parameters

Feed needs to be adjusted depending on the type of tap and tool material. Inappropriate feeds may lead to chip packing, thread damage or breakage, which influences the quality of parts and tool life. Proper methods provide proper threads and easy machining of Inconel and other hard alloys.

Milling Parameters

You need to maximize feed/tooth by cutter diameter and depth. Misaligned feed may lead to uneven removal of material, deflection, or stress of the tool. The right selection guarantees uniform loading of the chips, fine surface finishing and extended cutter life when performing milling.

Broaching Parameters

You have to regulate tooth-to-tooth feed progression during broaching. Irregular feeding may overwork individual teeth, break the tool or create non uniform profiles. Proper feed control guarantees a smooth material removal and part geometry.

Reaming Parameters

During reaming, you need to keep the correct coolant flow and flushing. Poor cooling can result in heat accumulation, adhesion of chips or low surface finish. A correct technique guarantees close tolerances and finishes on the reamed holes.

Stress Relief & Heat Treatment

The importance of Stress Relief to Invar

You have to do stress relief since machining causes internal stresses which distort properties of Invar. These stresses may influence the thermal expansion behavior, lowering dimensional stability. Invar is created to have low thermal expansion, so anything that causes distortion due to stress weakens its functionality. Proper stress relief makes sure that the material maintains its desired behavior to enable accurate use in precision tools and aerospace as well as tools.

Temperature Ranges of Stress Relief Recommended

To achieve full anneal, warm Invar to 760980C (1400-1800oF) to de-stress deep. To relieve light stress, apply 315- 425o C (600-800o F) to minimize small residual stresses. Never leave the atmosphere uncontrolled to prevent oxidation that will lead to loss of surface integrity and material overall performance. Effective stress relief can be achieved by proper temperature control without harming the alloy.

Cleaning & Passivation

Once machined, clean up, particularly selenium compounds in Free-Cut Invar. Passivation enhances the stability of the surface and prevents corrosion or chemical assault. Surface quality should be under controlled procedures, and this guarantees the functional reliability and dimension consistency of Invar to sensitive engineering use.

Surface Finishing Options

As-Machined

Surface Finishing As-machined surface is finished with the original cutting or milling finish. You can save time and cost. This alternative maintains the dimensional integrity but can present tool marks or slight scratches. It is applicable in internal parts or components where the cosmetic appearance is not vital.

Grinding

Grinding finishes and levels the surface to fine tolerances. You have better surface finish and improved flatness. It also makes parts smooth and ready to proceed with processing. It can be used in high precisional work where dimensions need to be precise.

Electropolishing

Electropolishing is a chemical removal of a thin layer of metal that increases the resistance to corrosion. You have a clear, smooth finish with no mechanical scratching. It fills micro-crevices, lowers surface stress, and enhances hygiene. The technique is applicable in medical, food, and chemical use.

Mechanical Polishing

Manual and Automatic polishing Mechanical polishing employs abrasive instruments to smooth out surfaces. You will be able to remove scratches and enhance beauty. It gives a mirror polish, improves corrosion resistance and lays components ready to be coated or finished.

Bead Blasting

Bead blasting is used to blast minute beads on the surface to create uniformity. You get a matte or satin finish and eliminate debris. It enhances the coating adhesion and minimizing surface defects. The technique is good in both functional and ornamental use.

Applications of CNC-Machined Invar

Aerospace

You use aerospace components made by CNC-machining Invar that require a small thermal expansion. It preserves dimensions stability of engines, sensors, and structural components in high-temperature conditions with high precision and a constant ability to operate in flight functions.

Electronics and semiconductor fittings

Invar fixtures use delicate electronic and semiconductor components with small heat drifts. Keeping clean alignment and avoiding warping at the production or testing stage of the manufacturing process helps to promote credible yields and accurate microelectronic assembly operations.

Optical Systems

Invar is used in optical mountings and optical supporting structures where accuracy of lens and mirror positioning is depended on by thermal stability. It maintains concentration and focus of telescopes, cameras, and high-precision imaging devices.

Medical Devices

Medical equipment such as CNC-machined Invar components provide high precision and stability of components. The use is advantageous because it does not expand due to thermal changes in surgical tools and diagnostic equipment that are favored to remain reliable under delicate circumstances.

Instrumentation & Metrology

Invar plays a crucial role in metrology equipments because it ensures precise measurements. Instruments, gauges and measuring systems can be relied on to maintain accuracy even when subjected to fluctuations in temperature.

Bimetallic Thermostats and Precision Regulators

Bimetallic thermostats are best suited to invar due to its possessing low expansion properties. You can also apply it in precision regulators to ensure that there is consistent control of temperature sensitive systems.

Troubleshooting Guide for Machining Invar

Machining Invar is usually inefficient when using the standard alloys and thus to enhance efficiency, Free-Cut Invar should be used. Hardened or glazed surfaces need you to feed the machine more slowly to achieve a smooth cut and a uniform removal of material. When you experience chattering or a lack of control over the chips, then you need to adjust tool geometry to stabilize cutting and improve chip evacuation. Overheating of tools may cause damage to both the tool and the workpiece, thus change cutting fluids or add tool mass to control temperature.

CNC Machining Invar: Best Practices (From Machinist Perspective)

Use Consistency Feed and Do Not Dwell on Tool

Use a constant feed rate to avoid local work hardening in cuts. Do not stop and sit on a single point to guard the tool. The steady movement is to guarantee a smooth cutting and minimization of surface glazing. With this process, you maintain dimensional accuracy and increase tool life.

Choose sharp tools that are well supported

Use sharp cutting tools as much as possible to reduce rubbing and heat. Make sure that tools are well supported in hard holders to avoid chatter. High pressure minimizes vibration and enhances surface finish. You obtain regular cuts and safeguard the tool and the workpiece.

Opt for Carbide When Rigidity Is High

Apply carbide tools when rigidity of setups is high in machining Invar. Carbide retards edge damages and cutting performance at stress. It offers extended tool life and predictable operation during extended operations. You make accurate and dependable cuts and enhance machining performance.

Always Have Generous Coolant

Use a lot of coolant to cool heat and lower the cutting forces. Coolant/material softening Cools the material and removes the chips efficiently. It preserves surface finish and minimizes the wear of tools in operation. You enhance the quality of machining and last a long time.

Do not Repeat a Drill on a Glazed Surface

Do not resume hardened or glazed Invar surface drills. Re-engaging may lead to poor surface quality and breakage of tools. This avoids any damages to the workpiece and provides clean holes. You ensure the regular quality and prevent the expensive failures of tools.

Avoid Shallow and Repeated Cuts

Superficial repeated movements enhance hardening of work and rapid wearing of the tool. When possible use deeper continuous cuts to minimize machining stress. The strategy enhances efficiency and integrity of tools in the long run. You get cleaner cuts and you save time on every cut.

Working With a Manufacturing Partner

You would select a dealer who has experience with Invar to work with it accurately. You have the advantage of high quality with high-level metrology equipment and controlled heated environments. With respect to an example, the machining abilities of DEK mean that, they have high accuracy parts with minimal tolerances. Collaboration with professionals guarantees stability, productivity, and maximum outcomes of your projects.

Conclusion

Invar requires skill in machining because it exhibits unusual low thermal expansion and work-hardening properties. With the knowledge of the right tooling, cutting parameters and CNC methods you are able to produce accurate, stable and high quality components. The reliance on appropriate Invar grade, the hard and fixed systems and on seasoned manufacturing partners guarantee reliability. Best practice is also used to give maximum efficiency and minimize tool wear and produce better outcomes in aerospace, optics, medical equipment, and high precision industries where dimensional control is vital.

FAQs

Is Invar Difficult to Machine?

Yes, the low thermal expansion and high toughness are also obstructing to machine Invar. To prevent work hardening and distortion of surfaces, you need to work with sharp, rigid tools and slow cutting speeds. Cooling and steady configurations aid in accuracy. You will be able to get a smooth finish and dimensional accuracy by using the right approach.

What is the Difference Between Inconel and Invar?

Inconel is a nickel-chromium type of superalloy characterized by heat and corrosion resistant properties whereas Invar is an iron-nickel type of alloy with extremely low thermal expansion. You use Inconel when you need it to be high temperature and chemically resistant, and Invar when it needs to be accurate and high precision is at stake. The alloys are both subject to special machining procedures, but their use and the characteristics of their behavior vary widely.

What Grade of Invar is Most Common for CNC Machining?

CNC machining with Invar 36 is the most prevalent due to the predictable low thermal expansion and machinability. You can count on its consistent qualities to provide precise parts like measuring instruments, optics, and aircraft parts. Invar 36 eliminates chances of distortion in cutting and after machining, which guarantees high precision and uniform dimensions behavior in numerous applications.